Transcription

MASTERCAM FOR EDUCATION MastercamMILLLATHE StudentsMILL-TURNWIREJobsROUTERMASTERCAM forSOLIDWORKS DESIGN

YOUR STUDENTS WILLSHAPE THE FUTURE OF MANUFACTURINGEducation’s #1 CAMwith more installationsthan any other package*Dedicated to educationwith 30 years of directservice to educatorsTeach what gets jobs –Mastercam is also #1 inindustrial CAM installationsTechnological leaderexposing students to what’sused in today’s best shopsOne-stop solutionoffering CAD, milling,turning, wire EDM,and moreWith a huge machine toollibrary, Mastercam will runyour machine, or 3D printerEasy to teachand easy to learnOpen platform lets youdesign in Mastercam or openany other CAD formatMastercam skills are in higher demand than for any other NC software.Endow your students with the cutting-edge skills that will give them theadvantage in the job market. Your students deserve the best. Teach themindustry’s software of choice. Mastercam skills launch careers.*CIMData 2017

EDUCATIONAL SUITEThe Mastercam Educational Suite puts the world’s#1 CAM software* at your students’ fingertips.MILLINGMastercam MillROUTERMastercam RouterStreamlined milling for2½- to 5-axis machining,powered by our exclusiveDynamic Motion technology.Complete 2- to 5-axis routerprogramming with blockdrilling, aggregate headsupport, and more.TURNINGMastercam LatheINTEGRATED SOLUTIONSMastercam forSOLIDWORKS Fully associative CAD/CAMfor turning, with solids-basedtoolpath verification andDynamic Motion strategies.MULTI-TASKINGMastercam Mill-TurnCombining Mill and Lathefor efficient multi-taskingmachining.WIRE EDMMastercam WireYour favorite MastercamMilling, Turning, and Routerstrategies directly integratedin SOLIDWORKS. Availablewith the Educational Suiteor as a standalone.MODELINGMastercam Design3D solids and surface modelingCAD software aimed at gettingparts of the machine quicker.2- to 4-axis CAD/CAM forwire EDM programming,from basic to advanced.For more information, visit Mastercam.com

ADDITIONAL MASTERCAM PRODUCTSEvery classroom and program is different. These additional products allow youto customize your Mastercam experience to your unique needs.QuickPart (Standalone)ProDrillA step-by-step approach thatguides students through theCAD/CAM/CNC process. Learningapplicable terminology, principles,and processes while using industryleading software and create andcut parts from day one. Can also beused in conjunction with 3D printers.Automatically detect, group, and applydrill strategies to large amounts of holes,and automatically create tooldefinitions from existing geometry.Port ExpertFile TranslatorsSpecialty data translators for UG/NX, Pro/E(read only), and CATIA ensure you canread and use the files you need.Creates engine cylinder headporting toolpaths on surface orsolid data, while minimizingunnecessary motion.Mastercam Productivity Blade ExpertArtToolpaths for multi-bladed parts,delivering superior blades, splitters,floors, and fillets.TMBrings Renishaw in-process probing andinspection to your Mastercam programs.Quickly bring your 2D sketches, clip art,photos, and CAD files to life by craftingthem on-screen and cutting them witheasy, specialized toolpaths.For more information,visit Mastercam.com

MASTERCAM'S LATEST INNOVATIONSFROM START TO FINISHINGDYNAMIC MOTIONTM TECHNOLOGYDynamic Motion toolpaths maximize safe engagement and can reduce cycletimes by 25 to 75%. Dynamic Motion uses a proprietary set of rules to analyzematerial removal, constantly changing the cut motion based on the stock at thatmoment. The results are radically shorter cycle times, as well as longer tool andmachine life, benefiting your shop and your students’ future shops.ACCELERATED FINISHINGTM TECHNOLOGYMastercam's Accelerated Finishing technology is the next leap forward inaddressing today's innovative profile tools and processes aimed at greaterefficiency and higher machining productivity.Innovations designed for productivity.Mastercam's Dynamic Motion toolpaths cut roughing times byup to 75%. And now with our exclusive Accelerated Finishingtechnology, total cycle times are again being dramatically reduced.Maximum machining effectiveness is achieved at the intersectionof optimal machine capability, maximum cutting tool performance,coupled with optimized toolpath strategies. Mastercam's DynamicMotion and Accelerated Finishing technologies provide thetoolpath performance needed to reach this goal.Cutting ToolPerformanceOptimumFeed RateSavings andPerformanceSweet SpotMachineCapabilitiesMastercam is designed to help users consistentlyhit the savings sweet spot of faster run times andless wear on machines and tools.

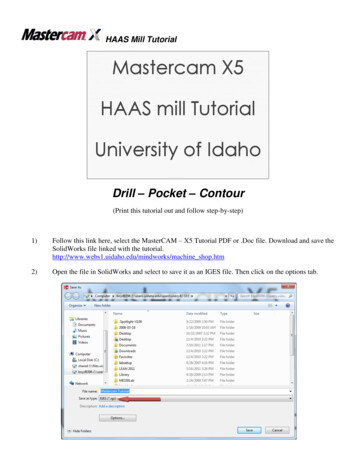

HOW MASTERCAM SHAPES THECurriculumOne of the benefits of choosing the most widely-taught CAD/CAM software is the abundance of availablecurriculum for nearly every level of instruction. With the widely varied curriculum packages produced bothby CNC Software and by outside sources, there is sure to be a package that fits the needs of you and yourprogram. There is no need for you to spend precious time creating materials from scratch when you can useour resources to get your class up and running quickly and effortlessly.UNIVERSITYMastercam UniversityOnline, video-based training that is developedexclusively by CNC Software, Inc. Sharpenyour skills on your own schedule, use it tobolster your resume, and get started on thepath to Mastercam Certification with thesame training used by corporate staffersand Resellers.mastercamu.comMastercam CertificationStudents and teachers looking to set themselves apart asskilled Mastercam programmers in the increasingly competitivejob market can turn to Mastercam Certification. BecomingMastercam Certified immediately gives recognition to the skillsyou’ve acquired and bolsters your resume. Our MastercamAssociate Level Certification is acquired by achieving scores of80% or above in select Mastercam U courses, and our MastercamProfessional Level Certification is a proctored test administeredby a Certified Mastercam Instructor. Teachers also have theopportunity to become Certified Mastercam Instructors.

FUTURE OF MANUFACTURINGCompetitionsAt Mastercam, we’re dedicated to future generations of machinists. We are strong supporters of a numberof motivational competitions for students.Our Wildest Parts Competition challenges students to design andmachine something that is different from anything we have everseen before. Students can create something new or simply sendin parts they already made for class over the course of the schoolyear. Each entrant receives a Mastercam shirt and has the chanceto win a cash prize of up to 1,000.For more information, visit www.mastercam.com/WildestParts.In addition to our Mastercam-sponsored competitions, we aredeeply involved in numerous local, national, and worldwidecompetitions, where many schools compete using Mastercam.Participation in these competitions engage students’competitive spirit, and gets them excited about their projects.These competitions ensure your students engagement andinterest in manufacturing.Contact us at TeacherInfo@mastercam.com to help you findthe best competition for your needs.It’s Our Responsibility to Help Shape the Future of ManufacturingInstructor TrainingTo ensure instructors are preparedwith the latest Mastercam offers, wehost Summer Teacher Training allaround North America. Find out moreat www.mastercam.com/STT.Teachers and students can rely onMastercam for the focused supportthey need. And when students areready for the job market, Mastercambacks them up with the largestnetwork of industrial CAM supportorganizations in the world.

The WORLDWIDE LEADER in EducationAs the world’s most widely-used CAM software, Mastercam knowledge is key toyour students’ success in the job market. Choosing Mastercam for your programwill ensure that you have the most competitive students around.100125,400120Educational installed seats (in thousands)125,400 seats installed*80604020ESPRITINVENTORHSM lyFeatureCAMGibbsCAM*CIMData 2017PartnershipsThe choice to invest in Mastercam is clear for the future of manufacturing. But with Mastercam, you have a wholeworld of collaborative opportunities opened to you through our partnerships. Here are a few examples of the top tierpartners you’ll have access to by choosing Mastercam.CNC Software, Inc.671 Old Post RoadTolland, CT 06084www.mastercam.comMastercam is a registered trademark of CNC Software, Inc. Copyright 1983-2017. All rights reserved.SOLIDWORKS is a registered trademark of Dassault Systèmes Solidworks Corp. All other trademarks are property of their respective owners.Be Dynamic.

Dynamic Motion technology. MILLING Complete 2- to 5-axis router programming with block drilling, aggregate head support, and more. Mastercam Router ROUTER Mastercam for SOLIDWORKS Your favorite Mastercam Milling, Turning, and Router strategies directly integrated in SOLIDWORKS. Available with the Educational Suite or as a standalone. INTEGRATED SOLUTIONS Fully associative