Transcription

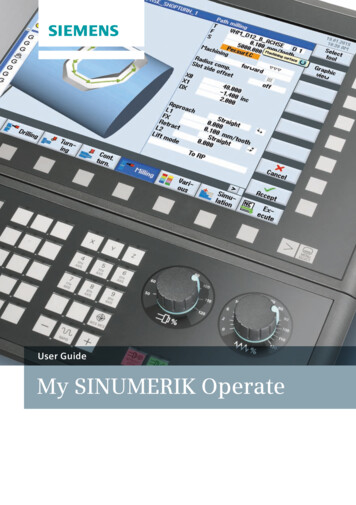

PrefaceFundamental h operation withSINUMERIK Operate3SINUMERIK 840D slMillingSetting up the machine4Execution in manual mode5Machining the workpiece6Simulating machining7Generating a G code program8Creating a ShopMill program9Operating ManualValid for:SINUMERIK 840D sl / 840DE slSoftwareversionCNC system software for 840D sl / 840DE sl V4.92SINUMERIK Operate for PCU/PCV4.92Programming technologicalfunctions (cycles)10Multi-channel view11Collision avoidance12Tool management13Managing programs14Alarm, error, and systemmessages15Working with ManualMachine16Teaching in a program17HT 8 (840D sl only)18Ctrl-Energy19Easy Extend20Appendix06/2019A5E44903512B ABA

Legal informationWarning notice systemThis manual contains notices you have to observe in order to ensure your personal safety, as well as to preventdamage to property. The notices referring to your personal safety are highlighted in the manual by a safety alertsymbol, notices referring only to property damage have no safety alert symbol. These notices shown below aregraded according to the degree of danger.DANGERindicates that death or severe personal injury will result if proper precautions are not taken.WARNINGindicates that death or severe personal injury may result if proper precautions are not taken.CAUTIONindicates that minor personal injury can result if proper precautions are not taken.NOTICEindicates that property damage can result if proper precautions are not taken.If more than one degree of danger is present, the warning notice representing the highest degree of danger will beused. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to propertydamage.Qualified PersonnelThe product/system described in this documentation may be operated only by personnel qualified for the specifictask in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualifiedpersonnel are those who, based on their training and experience, are capable of identifying risks and avoidingpotential hazards when working with these products/systems.Proper use of Siemens productsNote the following:WARNINGSiemens products may only be used for the applications described in the catalog and in the relevant technicaldocumentation. If products and components from other manufacturers are used, these must be recommended orapproved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation andmaintenance are required to ensure that the products operate safely and without any problems. The permissibleambient conditions must be complied with. The information in the relevant documentation must be observed.TrademarksAll names identified by are registered trademarks of Siemens AG. The remaining trademarks in this publicationmay be trademarks whose use by third parties for their own purposes could violate the rights of the owner.Disclaimer of LiabilityWe have reviewed the contents of this publication to ensure consistency with the hardware and software described.Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in thispublication is reviewed regularly and any necessary corrections are included in subsequent editions.Siemens AGDigital IndustriesPostfach 48 4890026 NÜRNBERGGERMANYDocument order number: A5E44903512B AB 06/2019 Subject to changeCopyright Siemens AG 2008 - 2019.All rights reserved

PrefaceSINUMERIK documentationThe SINUMERIK documentation is organized into the following categories: General documentation/catalogs User documentation Manufacturer/service documentationAdditional informationYou can find information on the following topics at the following address w/108464614): Ordering documentation/overview of documentation Additional links to download documents Using documentation online (find and search in manuals/information)If you have any questions regarding the technical documentation (e.g. suggestions,corrections), please send an e-mail to the following upport/DocumentationAt the following address umentation),you can find information on how to create your own individual documentation based onSiemens' content, and adapt it for your own machine documentation.TrainingAt the following address (http://www.siemens.com/sitrain), you can find information aboutSITRAIN (Siemens training on products, systems and solutions for automation and drives).FAQsYou can find Frequently Asked Questions in the Service&Support pages under ProductSupport faq).SINUMERIKYou can find information about SINUMERIK at the following address g Manual, 06/2019, A5E44903512B AB3

PrefaceTarget groupThis documentation is intended for users of milling machines running the SINUMERIK Operatesoftware.BenefitsThe operating manual helps users familiarize themselves with the control elements andcommands. Guided by the manual, users are capable of responding to problems and takingcorrective action.Standard scopeThis documentation describes the functionality of the standard scope. Extensions or changesmade by the machine manufacturer are documented by the machine manufacturer.Other functions not described in this documentation might be executable in the control.However, no claim can be made regarding the availability of these functions when theequipment is first supplied or in the event of servicing.Furthermore, for the sake of clarity, this documentation does not contain all detailed informationabout all types of the product and cannot cover every conceivable case of installation, operationor maintenance.TermsThe meanings of some basic terms used in this documentation are given below.ProgramA program is a sequence of instructions to the CNC which combine to produce a specificworkpiece on the machine.ContourThe term contour refers generally to the outline of a workpiece. More specifically, it refers to thesection of the program that defines the outline of a workpiece comprising individual elements.CycleA cycle, e.g. milling a rectangular pocket, is a subprogram defined in SINUMERIK Operate forexecuting a frequently repeated machining operation.Note regarding the General Data Protection RegulationSiemens observes standard data protection principles, in particular the principle of privacy bydesign. That means thatthis product does not process / store any personal data, only technical functional data (e.g. timestamps). If a user links this data with other data (e.g. a shift schedule) or stores personal dataon the same storage medium (e.g. hard drive) and thus establishes a link to a person orpersons, then the user is responsible for ensuring compliance with the relevant data protectionregulations.4MillingOperating Manual, 06/2019, A5E44903512B AB

PrefaceTechnical SupportCountry-specific telephone numbers for technical support are provided in the Internet at thefollowing address 2090) in the "Contact"area.MillingOperating Manual, 06/2019, A5E44903512B AB5

Preface6MillingOperating Manual, 06/2019, A5E44903512B AB

Table of contentsPreface .3123Fundamental safety instructions.211.1General safety instructions.211.2Warranty and liability for application examples .221.3Industrial security .23Introduction.252.1Product overview.252.22.2.12.2.2Operator panel fronts .26Overview .26Keys of the operator panel .282.32.3.12.3.2Machine control panels .36Overview .36Controls on the machine control 4.132.4.142.4.152.4.162.4.17User interface.40Screen layout .40Status display.41Actual value window.43T,F,S window .45Current block display.46Operation via softkeys and buttons.48Entering or selecting parameters .49Pocket calculator.51Pocket calculator functions .52Context menu.54Changing the user interface language .55Entering Chinese characters.55Function - input editor .55Entering Asian characters .57Editing the dictionary.58Entering Korean characters .60Protection levels.62Cleaning mode .64Display live image from a camera .64Online help in SINUMERIK Operate .65Multitouch operation with SINUMERIK Operate.693.1Multitouch panels .693.2Touch-sensitive user interface .703.3Finger gestures .713.4Multitouch user interface .74MillingOperating Manual, 06/2019, A5E44903512B AB7

Table of contents483.4.13.4.23.4.33.4.43.4.5Screen layout .74Function key block .74Further operator touch controls.75Virtual keyboard .76Special "tilde" character 93.5.103.5.113.5.123.5.133.5.143.5.15Expansion with side screen.77Overview .77Sidescreen with standard windows .77Standard widgets .79"Actual value" widget.79"Zero point" widget .80"Alarms" widget .80"NC/PLC variables" widget.80"Axle load" widget .81"Tool" widget .81"Service life" widget.82"Program runtime" widget .82Widget "Camera 1" and "Camera 2" .82Sidescreen with pages for the ABC keyboard and/or machine control panel .83Example 1: ABC keyboard in the sidescreen.84Example 2: Machine control panel in the sidescreen.853.63.6.13.6.23.6.3SINUMERIK Operate Display Manager (840D sl only) .86Overview .86Screen layout .87Operator controls .87Setting up the machine.914.1Switching on and switching off .914.24.2.14.2.2Approaching a reference point .92Referencing axes .92User agreement .934.34.3.14.3.24.3.3Operating modes.95General .95Modes groups and channels .97Channel switchover.974.44.4.14.4.24.4.3Settings for the machine .99Switching over the coordinate system (MCS/WCS).99Switching the unit of measurement .99Setting the zero offset .9Measure tool .103Overview .103Manually measuring drilling and milling tools.103Measuring drilling and milling tools with the workpiece reference point.104Measuring drilling and milling tools with fixed reference point .105Measuring radius or diameter .106Fixed point calibration .107Measuring the drilling and milling tool length with electrical tool probe.107Calibrating the electrical tool probe.110Manually measuring a turning tool (for milling/turning machine).111MillingOperating Manual, 06/2019, A5E44903512B AB

Table of contents54.5.104.5.11Manually measuring a turning tool using a tool probe (for milling/turning machine) .112Logging tool measurement results .94.6.104.6.114.6.124.6.12.14.6.12.2Measuring the workpiece zero .116Overview .116Sequence of operations .120Examples with manual swivel .121Setting the edge .122Edge measurement.123Measuring a corner .126Measuring a pocket and hole .129Measuring a spigot.132Aligning the plane.137Defining the measurement function selection .140Logging measurement results for the workpiece zero .141Calibrating the electronic workpiece probe .142Calibration of length and radius or diameter .142Calibrate on sphere.1444.7Settings for the measurement result log .1464.84.8.14.8.24.8.34.8.44.8.54.8.64.8.7Zero offsets .148Display active zero offset .149Displaying the zero offset "overview" .149Displaying and editing base zero offset .151Displaying and editing settable zero offset.152Displaying and editing details of the zero offsets .152Deleting a zero offset .154Measuring the workpiece zero .1554.94.9.14.9.2Monitoring axis and spindle data.156Specify working area limitations.156Editing spindle data.1564.10Displaying setting data lists.1584.11Handwheel assignment.1594.124.12.14.12.24.12.34.12.4MDA .161Loading an MDA program from the Program Manager.161Saving an MDA program.162Editing/executing a MDI program.163Deleting an MDA program.164Execution in manual mode .1655.1General .1655.25.2.15.2.25.2.35.2.4Selecting a tool and spindle .166T, S, M windows.166Selecting a tool.168Starting and stopping a spindle manually .168Position spindle .1695.35.3.15.3.2Traversing axes.171Traverse axes by a defined increment .171Traversing axes by a variable increment .172MillingOperating Manual, 06/2019, A5E44903512B AB9

Table of contents6105.4Positioning axes .1735.5Swiveling .1745.6Manual retraction .1795.7Simple face milling of the workpiece .1815.85.8.15.8.2Simple workpiece machining operations with milling/turning machines.184Simple workpiece face milling (milling/turning machine).184Simple stock removal of workpiece (for milling/turning machine) .1865.9Default settings for manual mode .190Machining the workpiece .1916.1Starting and stopping machining.1916.2Selecting a program .1936.3Testing a program .1946.46.4.16.4.26.4.3Displaying the current program block.196Current block display.196Displaying a basic block .197Display program level.1986.5Correcting a program .2006.6Repositioning 8Starting machining at a specific point.202Use block search.202Continuing program from search target .204Simple search target definition.204Defining an interruption point as search target .205Entering the search target via search pointer .205Parameters for block search in the search pointer.206Block search mode.207Block search for position pattern.2096.86.8.16.8.2Controlling the program run .211Program control.211Skip blocks .2126.9Overstore Editing a program.216Searching in programs .216Replacing program text .218Copying/pasting/deleting a program block .

Programming technological functions (cycles) 10 Multi-channel view 11 Collision avoidance 12 Tool management 13 Managing programs 14 Alarm, error, and system messages 15 Working with Manual Machine 16 Teaching in a program 17 HT 8 (840D sl only) 18 Ctrl-Energy 19 Easy Extend 20 Appendix A. P