Transcription

/ Aquatower Steel Cooling Tower /

Aquatower Steel Cooling Tower / Features and Benefits Proven Performance. CTI Certified. Plus SPX standsby its responsibility for reliable thermal performance. Wedesigned it. We rate it. We guarantee it! Induced-Draft Design. Save on fan power. The fan willoperate in a warm atmosphere even in winter, so you’llnever have to work on frozen mechanical equipment. Crossflow Design. Save on pump power becauseyou only pay to move the water to the top of the tower.Gravity does the rest. The mechanical equipment andwater distribution system are out where you can easilymaintain them. All-Season Reliability. Aquatowers perform as specifiedin the heat of summer. They respond well to energymanagement techniques in the spring and fall andwith appropriate fan controls, they can operate virtuallyice-free in the dead of winter. Plus they offer simplemaintenance all year long. Proven Corrosion Protection. Thousands of usersover more than 60 years confirm the value of heavygalvanizing. And Marley’s G-235 is the most effectivegalvanizing used in the industry.2 P VC Film Fill with Integral Drift Eliminators andLouvers. If you’ve ever had to replace deterioratedeliminators or louvers, you’ll appreciate this advantage.Integral honeycomb louvers keep the circulating waterinside your tower. S elect Your Aquatower on Our Website. The MarleyUPDATE web-based selection software—available atspxcooling.com/update—provides Aquatower modelrecommendations based on your specific designrequirements S imple, Flexible Installation. Just mount the motor,belts and belt guard, install the outlet connection thatsuits your needs—both side suction and bottom outletare provided, complete with screens—and adjust the floatvalve and your Aquatower is ready for operation.

Aquatower Steel Cooling Tower / Features and Benefits3You’ll enjoy single source responsibility and reliabilitybecause we design and manufacture virtually all majorcooling tower components.All Marley components are designed and selected tobe a part of an integrated system. For example, the spraypattern from nozzles and the pressure drop through drifteliminators both affect a fill’s heat transfer capacity. So, weinclude that impact in our thermal analysis. Drift eliminatorsmust be effective at the air velocities where fill is mostefficient. So, we’ve carefully designed both components towork together efficiently.How many other cooling tower companies can offeryou this assurance? They may use one brand of nozzle withbrand of fill and another manufacturer's drift eliminators.When they all come together, the whole may be less thanthe sum of the parts.Today’s Aquatower may be the most space/energyefficient cooling tower available. Your needs havedictated constant technological improvement. Thousandsof Aquatower users enjoy the benefits of eight majorredesigns and dozens of minor improvements in the past60 years. For example, PVC film-fill enables the Aquatowerto reject more heat per unit size. We also put the air inletlouvers and drift eliminators right on the fill sheets. Thisnew arrangement saves you fan horsepower by improvingairflow through the tower.The Aquatower is a maintenance delight! You’llappreciate the way the Aquatower simplifies maintenance.No hidden spray systems, tiny nozzles, or enclosed basinshere! You can easily replace and align V-belts from outsidethe tower.All primary components of the Aquatower are opento view. You can easily remove any debris from the upperbasin or nozzles while the tower is in operation.Heavy mill galvanizing on all steel components preventsbase metal corrosion. You won’t have to worry about paintchips clogging your strainers and nozzles, because there isno paint to flake off. Heavy galvanizing also protects muchbetter than paint.Our total system approach assures that all theparts work together to provide you the greatest totalperformance. And because we design specifically forcooling towers, all our components will provide many yearsof service with minimal maintenance.Every Aquatower cooling tower carries a full one-yearwarranty. The Aquatower you buy from us will work on yourjob or we’ll make it right. Your warranty includes thermalperformance and every component of the tower. TheSPX Cooling Technologies warranty is your assurance ofperformance—for a full year.Above all, the Aquatower is readily available. You won’thave to wait around—or accept second best—when youneed a cooling tower. We maintain an impressive stock ofcompleted towers at our own plants. A growing number oflocal distributors can draw from that stock.The Aquatower has inspired many imitators. OnlySPX Cooling Technologies can offer you the original.Contact your local distributor or Marley representative.They’ll be glad to help you choose the proper model foryour needs. They can also help you with your layout andpiping.

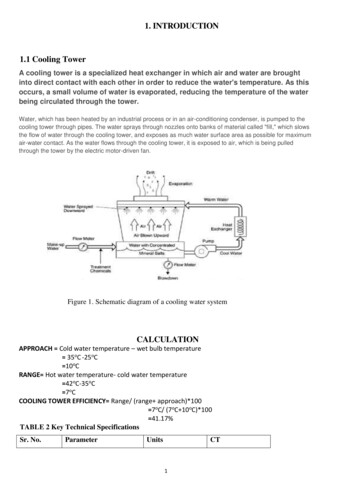

Aquatower Steel Cooling Tower / Engineering Data: Schematic4DLWTOWER CL INLETHVERTICALDISCHARGE(OPTION-NOTE 3)MOTORAINLET PIPING(BY OTHERS)CSCL SIDE OUTLETUSE FORSTATIC LIFTTOWER COLLECTIONBASINBTOWER CL OUTLETECL BOTTOM OUTLETAIR INLET ELEVATIONSIDE ELEVATIONDimensionsTowerModelNominal Tonsnote1LWHABC note 2490A82'-111 2"4'-2 7 8"5'-33 8"1'-313 16"67 8"2'-0"490D102'-111 2"4'-2 7 8"5'-33 8"1'-313 16"67 8"2'-0"492D223'-111 2"5'-0 3 4"7'-41 2"1'-5"91 2"4'-0"492G283'-111 2"5'-0 3 4"7'-41 2"1'-5"91 2"4'-0"493G365'-111 2"5'-1"7'-41 2"1'-5"91 2"5'-0"493H425'-111 2"5'-1"7'-41 2"1'-5"91 2"5'-0"494G515'-111 2"6'-55 8"9'-0"1'-1115 16"111 2"6'-0"Dnote 3note 3note 310'-8"Enote 68"SMotorhpPipingConnectionInletOutlet note 64'-4"1 32"2" F4'-4"12"2" F6'-5"14"4" M8"6'-5"24"4" M8"6'-5"24"4" M8"6'-5"34"4" M91 4"7'-101 2"26"6" MC494H575'-111 2"6'-55 8"9'-0"1'-1115 16"111 2"6'-0"10'-8"91 4"7'-101 2"36"6" MC494K685'-111 2"6'-55 8"9'-0"1'-1115 16"111 2"6'-0"10'-8"91 4"7'-101 2"56"6" MC495K807'-111 2"6'-53 4"9'-0"1'-1115 16"111 2"7'-0"10'-8"91 4"7'-101 2"56"6" MC495M917'-111 2"6'-53 4"9'-0"1'-1115 16"111 2"7'-0"10'-8"91 4"7'-101 2"71 26"6" MC496K1119'-111 2"6'-61 8"9'-81 4"1'-113 16"111 2"9'-0"10'-1111 16"91 4"8'-7"56"6" MC496M1269'-111 2"6'-61 8"9'-81 4"1'-113 16"111 2"9'-0"10'-1111 16"91 4"8'-7"71 26"6" MC1. Nominal tons are based upon 95 F HW, 85 F CW, 78 F WB, and3 GPM/Ton. The Marley UPDATE web-based selection softwareprovides Aquatower model recommendations based on specificdesign requirements.2. Minimum clearance for adequate air supply. Consult your Marley salesrepresentative or your local distributor if this clearance is impracticalfor your job.3. Vertical discharge hood is for applications in restrictive enclosuresor other locations where horizontal discharge is not desirable. CTICertification does not apply when this option is selected. Availableonly on models 494 and larger.4. Motors less than 1 hp are 115/230 volt, single-phase TEFC. 1 hpthrough 7.5 hp motors are 230/460 volt, 3-phase TEFC.5. Motor, belt and belt guard ship uninstalled. Installation by others.6. Outlet sizes shown are side outlets. All models except 490A and490D have connections for both side and bottom outlet. Install thedesired connection and seal the unused opening with the coverplateprovided. Pump suction should use side outlet. See page 9 for sizeand flow capacities of bottom outlets.7. Overflow is a 2" F connecton located in side of collection basin.8. Drain is a 2" F connection located in collection basin floor.9. Makeup valve connection is 3 4" M located in tower side.

Aquatower Steel Cooling Tower / Engineering Data: Support Options1"LFCL ANCHORHANCHOR CLBOLT1"HANCHOR CLBOLTW GTOWERCOLLECTIONBASIN5/8" DIAMETER HOLESBBOLTBOLTAIR INLET FACEHTOWERCOLLECTION BASINCL ANCHORCL ANCHORTOWERCOLLECTION BASINAIR INLET FACEHTOWERCOLLECTIONBASIN1"MIN. BEARING WIDTHAT EACH ANCHOR BOLT2"NORMALGAUGENORMALGAUGESUPPORT(BY OTHERS)SUPPORT(BY OTHERS)SECTION ATowerModel1"ANCHOR CLBOLTBOLTGA W5/8" DIAMETER HOLESLFCL ANCHORANCHOR CLBOLTBOLT1"5DimensionsShipping WeightHlbMaximumOperatinglbVIEW BMaximunOperating Loadat AnchorWind Load lbMax. VerticalMax. HorizontalReaction at Anchor Reaction at AnchorLWFG4902'-111 2"3'-41 8"2'-91 2"3'-0"21 16"4377561851801154923'-111 2"4'-15 8"3'-91 2"3'-6"313 16"7421396349355210lb4935'-111 2"4'-15 8"5'-91 2"3'-6"313 16"98219954995252854945'-111 2"5'-61 8"5'-91 2"5'-0"31 16"139829487375553554957'-111 2"5'-61 8"7'-91 2"5'-0"31 16"175838539637454704969'-111 2"5'-61 8"9'-91 2"5'-0"31 16"20964751118810956404945'-111 2"5'-61 8"5'-91 2"5'-0"31 16"179833488377005154957'-111 2"5'-61 8"7'-91 2"5'-0"31 16"2133423310587455154969'-111 2"5'-61 8"9'-91 2"5'-0"31 16"2596525113131095640Models with Vertical Discharge Hood Option1. Use this bulletin for preliminary layouts only. Obtain current drawingsfrom your Marley sales representative or your local distributor.2. Purchaser to provide tower supports complete with holes and bolts foranchorage. All supports must be framed flush and level at top. Maximumdeflection to be 1/360th of span, not to exceed 1 2".3. Maximum weight occurs with basin full to overflow level at shutdown.Actual operating weight varies with GPM and piping scheme.4. Wind loads are based on 30 psf and are additive to operating loads.Reactions due to wind loads exceed those resulting from seismic loadsbased on the 1997 UBC code, Zone 4 and an Importance Factor of1.00 per Section 1634—Towers Not on a Building.Use this data for preliminary layouts only.Obtain current drawing from your Marley salesrepresentative.UPDATE web-based selection software available atspxcooling.com/update provides Aquatower modelrecommendations based on customer's specificdesign requirements.

Aquatower Steel Cooling Tower / Construction and Components6 Water Distribution System Fill/Louvers/Drift EliminatorsWarm water flows through external piping (notincluded with the tower) into a splash box at the top of theAquatower. This splash box prevents the incoming waterfrom spilling out of the basin and helps provide uniformwater distribution. Water then flows by gravity from thebasin through nozzles to the fill. Hot water distribution basincovers are provided as standard equipment to keep thedistribution basin free from airborne debris and to reducethe likelihood of biological growth.Marley MX Fill features integral louvers and drifteliminators, designed to minimize resistance to airflow. Thispatented arrangement prevents water from escaping thefill, assuring proper heat transfer throughout wide variationsin airflow. Users find MX fill operates ice-free even inextremely cold weather.The thermoformed 15 mil (.015″) thick PVC fill sheetswithstand hot water temperatures as high as 125 F. Fillsheets are immune to biological and corrosive decay andtheir flame spread rating is less than 25 per ASTM E-84.Galvanized structural tubes support and stabilize the fill.They also hold the bottom of the fill sheets above the coldwater basin floor to simplify basin cleaning. Removable1" x 1" mesh galvanized air inlet screens keep largerairborne trash out of the collection basin and fill area.Eliminator air-seal removed showing distribution area above fillAll Aquatowers use Marley “Spiral Target” nozzles.These inert polypropylene nozzles are evenly spacedthroughout the distribution basin to assure uniform waterdistribution over all portions of the fill. Their large openingsresist clogging. Nozzles are easy to remove and replace ifyou ever want to change the design water flow rate.MX Fill Cold Water Collection BasinThe Aquatower’s collection basin reduces operatingweight, simplifies basin cleaning, and assures properoutflow. Water flows from the elevated area under the fillinto the basin’s rear depressed section, where side suctionpiping connects. A bottom outlet is also available for gravityflow applications.Marley Spiral Target distribution nozzleStandard equipment on each tower basin includes:a screened suction connection; a threaded overflowconnection, a threaded and plugged drain connection anda float-operated make-up valve. Models 492 through 496also include a bottom outlet conforming to 125# flangespecification. A blank cover plate is provided to seal theoutlet opening if not used.

Aquatower Steel Cooling Tower / Construction and Components7 Mechanical EquipmentBelt-drive propeller fans ensure design airflow atminimum horsepower. Fans are supported by a stainlesssteel fan shaft in a cast iron oil-lubricated tapered rollerbearing assembly with remote oil reservoir.For ease of maintenance all drive components areaccessible from outside the tower.Fan drive motor showing adjustable base and belt guard Hoisting and HandlingHoisting instructions on each tower explains how to usea spreader-bar and slings beneath the cold water basin floorto hoist the Aquatower. The tower’s design also allows easyhandling with a forklift. SafetyFan and fan guard. Guard is easily removed for access to fanand drive beltsFan drive motors are TEFC designed specifically forcooling tower use. Standard motor horsepower appear inthe table on page 4. Other types of motors are available.Typical options appear under Optional Accessories onpage 10.CAUTIONThe cooling tower must be located at such distanceand direction to avoid the possibility of contaminateddischarge air being drawn into building fresh air intakeducts. The purchaser should obtain the services of aLicensed professional Engineer or Registered Architectto certify that the location of the cooling tower is incompliance with applicable air pollution, fire and cleanair codes.Standard Aquatower safety features include fan guardsand belt guards. Fan guards consist of welded heavy gaugesteel wire hoops and spokes, hot dip galvanized afterfabrication. The galvanized steel belt guard encloses bothbelts and pulleys. Guards are easily removed for servicing. Construction and FinishAquatowers offer the corrosion protection of G-235galvanized—providing a zinc thickness of 2.35 oz/ft perASTM A-653—providing long term protection for the steel.Assembly hardware is also galvanized.2

Aquatower Steel Cooling Tower / Engineering Data: Freeze PreventionWhen the ambient air temperature falls below 32 F, thewater in a cooling tower can freeze. Marley Technical Report#H-003 “Operating Cooling Towers in Freezing Weather”describes how to prevent freezing during operation. Askyour Marley sales representative for a copy or downloadfrom our website.Water collects in the cold water basin during shutdowns,and may freeze solid. You can prevent freezing by addingheat to the water left in the tower. Or, you can drain thetower and all exposed piping at shutdown. Electric Basin HeatersChoose from two types of automatic basin heatersystems, based on your site conditions and preferences.You may choose a heater system consisting of thesecomponents (shipped separately for installation by others): Stainless steel electric immersion heater element(s).Threaded couplings are provided for installation.NEMA 4 enclosure containing these components:–Magnetic contactor to energize heater.–Transformer to convert power supply to 24 volts forcontrol circuit.– Solid state circuit board for heater control and low-watercutoff.Enclosure may be mounted on the side of the tower.Control probe to monitor water temperature and waterlevel. Threaded couplings are provided for installation.Or you may prefer a pre-assembled submersible tanktype heater which requires no tower modification and canplug into a standard grounded 3-prong 120V outlet.The Incoloy heater element was chosen for its long lifein submerged environments. A built-in thermostat senseswater temperature and controls the supply of electricity tomaintain proper water temperature. A built-in safety switchcuts off power whenever the element is exposed to air.The element mounts in the tower basin on a stainless steelplate.Any exposed piping that is still filled with water atshutdown—including the makeup water line—should beelectrically traced and insulated (by others).8 Indoor Tank MethodWith this system, water flows from an indoor tank,through the load system, and back to the tower, where it iscooled. The cooled water flows by gravity from the towerto the tank located in a heated space. At shutdown, allexposed water drains into the tank, where it is safe fromfreezing.The table on page 9 lists typical drain-down capacitiesfor all Aquatower models. Although we do not producetanks, many of our representatives offer tanks supplied byreputable manufacturers.The amount of water needed to successfully operatethe system depends on the tower size, GPM and thevolume of water contained in the piping system to and fromthe tower. You must select a tank large enough to containthose combined volumes—plus a level sufficient to maintaina flooded suction on your pump. Control makeup wateraccording to the level where the tank stabilizes duringoperation.You should always use a bottom outlet for this type ofpiping system. The table on page 9 lists the flow capacitiesfor bottom outlets.Basin Heater SelectionTowerModel 10 F Ambient-10 F AmbientTank HeaterComponentHeaterTank HeaterComponentHeater4901.5 kW3 kW1.5 kW3 kW4921.5 kW3 kW1.5 kW3 kW4931.5 kW3 kW2 @ 1.5 kW3 kW4942 @ 1.5 kW3 kW2 @ 1.5 kW3 kW4952 @ 1.5 kW3 kW3 @ 1.5 kW4.5 kW4963 @ 1.5 kW4.5 kW4 @ 1.5 kW6 kW1. Required kW is the amount of heat needed to maintain 40 F basinwater temperature at the indicated ambient air temperature.2. Tank heaters shown are 120 volts, single-phase.3. C omponent heaters shown are 480 volts, three-phase. Options or special heater selections may add several weeks todelivery.4. Heaters do not operate continuously. Heaters cycle on and off automatically as basin water temperature dictates.5. Contact your Marley sales representative for selections appropriatefor other ambient conditions than those shown here.

Aquatower Steel Cooling Tower / Engineering Data: Field Assembly Field AssemblyDrain-Down CapacityTower Model490492493494Range of Tower Design GPMMaximum Drain-Downgallons15 - 262827 - 513052 - 853386 - 1533621 - 534954 - 925493 - 15160152 - 2116533 - 837784 - 14484The following table shows the sizes and weightsof the largest Aquatower components for each model.You can use this information to plan your rigging andtransportation needs.Unassembled tower shipment may add 3 to 5 weeksto normal lead times. Your Marley sales representative willbe glad to help you plan for your unique needs.94239 - 32810160 - 141134ComponentSize inchesWeight lb142 - 227145Collection Basin End12 x 13 x 3615228 - 376162Collection Basin Floor3 x 30 x 3223377 - 563178Front Panel2 x 36 x 4421Casing Panel2 x 40 x 5243Distribution Basin8 x 16 x 3218Collection Basin End14 x 16 x 4824Collection Basin Floor3 x 36 x 4437Front Panel2 x 48 x 6852Component Sizes and WeightsTower Model490A490B182193 - 270496If you choose to assemble your Aquatower at the jobsite, your Aquatower will be shipped unassembled withcomplete assembly instructions.145 - 23882 - 192495192271 - 513219514 - 763241104 - 196228197 - 286243287 - 497271498 - 963320492493Volumes shown are maximums for the GPM ranges indicated. Actualvolumes will usually be less. Contact your local Marley sales representative for more specific information.Bottom Outlet Maximum GPM24Collection Basin End14 x 16 x 7237Collection Basin Floor3 x 36 x 6856Front Panel2 x 37 x 7235Casing2 x 26 x 633437Distribution8 x 16 x 68Collection Basin End18 x 18 x 7247Collection Basin Floor4 x 34 x 6856412 x 40 x 766310"Distribution Basin8 x 28 x 6852225naOptional Discharge Side2 x 41 x 7737270350naOptional Discharge Floor9 x 45 x 6846310350625638"492120225493120494140140342 x 44 x 726"4962 x 26 x 638 x 16 x 44Front Panel4"140Casing PanelDistribution BasinCasing PanelOutlet DiameterTowerModel49593103103503504948508504951. Maximum GPM applies to both pump and gravity flow piping systems.The outlet piping on gravity flow systems must have sufficient verticaldrop to overcome all other head losses in the system.2. Bottom outlet is not available on 490 model

Aquatower Steel Cooling Tower / Features and Benefits 3 Today’s Aquatower may be the most space/energy- efficient cooling tower available. Your needs have dictated constant technological improvement. Thousands of Aquatower users enjoy the benefits of eight major redesig