Transcription

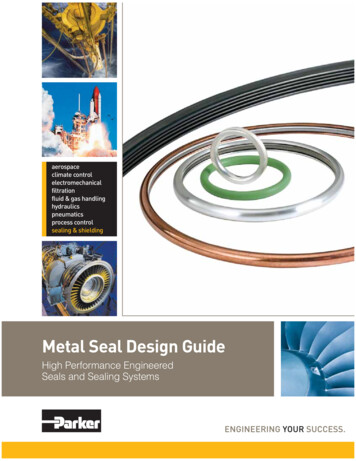

aerospaceclimate controlelectromechanicalfiltrationfluid & gas handlinghydraulicspneumaticsprocess controlsealing & shieldingMetal Seal Design GuideHigh Performance EngineeredSeals and Sealing Systems

!WARNING – USER RESPONSIBILITYFAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONALINJURY AND PROPERTY DAMAGE.This document and other information from Parker-Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigationby users having technical expertise.The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance,maintenance, safety and warning requirements of the application are met. The user must analyze all aspects of the application, follow applicable industry standards, andfollow the information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors.To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user, the useris responsible for determining that such data and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the components or systems.OFFER OF SALEThe items described in this document are hereby offered for sale by Parker-Hannifin Corporation, its subsidiaries or its authorized distributors. This offer and its acceptanceare governed by the provisions stated in the detailed “Offer of Sale” elsewhere in this document or available at www.parker.com/salesterms/.

Metal Seal Design Guide Table of ContentsIntroduction. 4Section A – General Metal Seal InformationAdvantages of Metal Seals .A-8How to Use the Metal Seal Design Guide .A-9Market Applications .A-10Section B – Metal Seal Type SelectionSelecting the Metal Seal Type for Your Application .B-11Seal Selection at a Glance.B-14Section C – Metal Seal Size SelectionFace SealsECI Metal C-Ring, Internal Pressure Face Seal . C-16ECE Metal C-Ring, External Pressure Face Seal . C-18ESI Spring Energized Metal C-Ring,Internal Pressure Face Seal . C-20ESE Spring Energized Metal C-Ring,External Pressure Face Seal . C-22EEI Metal E-Ring, Internal Pressure Face Seal . C-24EEE Metal E-Ring, External Pressure Face Seal . C-26EOI Metal O-Ring, I.D. Vented, Internal Pressure Face Seal. C-28EON Metal O-Ring, Plain, Internal Pressure Face Seal . C-28EOP Metal O-Ring, Pressure Filled,Internal Pressure Face Seal . C-28EOE Metal O-Ring, O.D. Vented,External Pressure Face Seal . C-30EOM Metal O-Ring, Plain, External Pressure Face Seal. C-30EOR Metal O-Ring, Pressure Filled,External Pressure Face Seal . C-30EUI Metal U-Ring, Internal Pressure Face Seal . C-32EUE Metal U-Ring, External Pressure Face Seal . C-34EWI Metal Wire Ring, Internal Pressure Face Seal. C-36EWE Metal Wire Ring, External Pressure Face Seal . C-38Axial SealsECA Metal C-Ring, Axial Seal . C-40Seals for Standard ApplicationsBoss Seal for MS-33649 Fluid Connection Bossand MS-33514/33656 Fitting Ends. C-42Metal E-Ring for AS1895 Flanges . C-44Metal O-Ring for Aerospace Standards. C-45Section D – Material Selection ProcessSelecting the Metal Seal MaterialMaterial Codes for Non-Spring Energized Seals . D-52Material Codes for Spring Energized Seals . D-53Temperature Capabilities – Stainless Steel. D-53Temperature Capabilities – Nickel Alloys . D-54Temperature Capabilities – Cobalt Alloys. D-55Temperature Capabilities – Other Materials. D-55Aerospace Material Specification (AMS) Reference. D-56Yield Strength, Relaxation & Springback . D-56Metal Seal, Platings, Coatings and FinishesTemper Codes . D-58Finish Codes. D-59Finish Thickness Selecting Guidelines. D-60Silver-Indium Plating . D-61TriCom Plating . D-62TriCom-HT Plating . D-64Section E – Technical Information Performance DataLoad, Deflection and Springback / Terminology . E-68Metal C-Ring Performance. E-70Metal E-Ring Performance . E-72Metal U-Ring Performance. E-73Metal O-Ring Performance .E-74Metal Energized C-Ring Performance .E-76Metal Wire Ring Performance . E-77Leak Rate Information . E-78Fatigue and Stress Relaxation. E-79Installation GuidelinesSurface Roughness . E-80Surface Flatness . E-80Surface Hardness. E-81Compression Limiters. E-81Bolt Load and Tightening Torque Guidelines . E-82Seal Shaping Requirements for Non-Circular Seals. E-84Metal Seal Manufacturing SpecificationsMetal Seal Roundness and Flatness . E-85Metal Seal Surface Finish . E-85Metal O-Ring Weld Finish . E-85Preferred C-Ring and Spring Energized C-Ring Sizes. E-86Tolerance Reference Table . E-92Conversion Tables . E-93Section F – Additional Metal Seal StylesFormed Seals.F-96Precision Machined Seals .F-96Beaded Gaskets .F-97Additional E-Ring Styles .F-98Frequently Asked Questions.F-99Application Data SheetsFace Seal .F-103Axial Seal .F-104Parker Hannifin Corporation Composite Sealing Systems DivisionAdvanced Products Business Unit 33 Defco Park Road, North Haven, CT 06473Phone: 203 239 3341 Fax: 203 239 4409www.parker.com3

The Global Leader in Sealing TechnologyParker Hannifin specializes in high performance engineered seals and sealing systems.The Advanced Products Business Unit was founded in 1954 and is headquartered inNorth Haven, Connecticut where a 60,000 square foot facility is home to a state-of-the-artmetal seal plant, with fully integrated engineering analysis, design, production, assemblyand test.In addition to its diversified line of sealingcomponents, Parker Hannifin offers fullyengineered sealing systems for specialtyapplications over a wide range of challenging environments. Parker Hannifin’s highlyrespected jet engine seals are widely usedin commercial and aerospace engines andinclude E-rings, C-rings, O-rings andAS1895 seals. Parker also suppliescryogenic and high temperature metallicseals for the space shuttle main engineand other major rocket programs.Parker Hannifin holds ISO 9001, AS9100,FAA approvals and various NADCAPapprovals for special processes.Your True Partner fororSealing SolutionsWe focus on serving the fluid containmentntneeds of high-technology industries demandingmandingabsolute integrity and reliability. With ourur extensive and integrated line of seals and sealingsystems we are able to design, test, analyzeand produce the total fluid containmentent andsealing needs for extreme environments.We have a reputation for innovative designs,high quality products, responsive supportand a long history of producing customizedsolutions for unique extreme environments.You will find our company a vigorous partnerin both development and production of yoursealing system.Parker Hannifin Corporation Composite Sealing Systems Division4Advanced Products Business Unit 33 Defco Park Road, North Haven, CT 06473Phone: 203 239 3341 Fax: 203 239 4409www.parker.com

Serving the Needsof High-TechnologyIndustriesDependable SealingSystems for Safety-Criticaland Extreme EnvironmentsMaking dependable sealing systems forsafety-critical and extreme applicationsgoes beyond excellence in design andmanufacturing. It also means a deepcommitment to quality as a way of life.Our company's diversification includesa wide variety of industries such asaerospace, semiconductor, oil and gas,power generation, military, transportationand automotive.CompleteSealing SystemsHigh PerformanceEngineered Seals andSealing SystemsA sealing system consists of the mainsealing elements such as our metal andpolymer seals. These are mated withother system components such asflanges, clamps, connectors, valve bodies,to create a complete sealing system.We are your partner for the entire sealingsystems process from concept, designand development, through qualificationand production. We provide expertise incomplete project management, engineering, production, assembly and test inorder to provide you a turnkey solution.Contract R&DWe offer our services in the researchand development of materials and sealingtechnology. Our team of experienced engineersand scientists are able to develop and test newproducts and materials, perform extensiveresearch and create new technology.Parker Hannifin Corporation Composite Sealing Systems DivisionAdvanced Products Business Unit 33 Defco Park Road, North Haven, CT 06473Phone: 203 239 3341 Fax: 203 239 4409www.parker.com5

The Global Leader in Sealing TechnologyState-of-the-Art EngineeringDependable Sealing Systems for Safety-Criticaland Extreme EnvironmentsOur technical strength comes from a broad based R&D and engineering staff withspecialties across many scientific disciplines and engineering fields. Our engineeringcapabilities include: Fatigue and stress relaxation analysis Complete sealing system design, development and qualification testing in accordancewith various industry design codes, including, American Petroleum Institute API 6A andAPI 17D, American Society of Mechanical Engineers ASME B31.3, ASME Section III,ASME Section VIII, Society of Automotive Engineers and Aerospace Standards Classical stress analysis Non-linear finite element analysis (FEA), 2-D and 3-D 3-D solid modeling and design of sealing systems components Modeling of loads, pressure effects and system dynamics for determining deflectionand pressure induced stressesMaterials ResearchComprehensive research, analysis and testing of metals, polymers, thermoplastics andcomposites enables us to develop and utilize materials that are best suited for yourapplication. Factors such as strength, hardness, corrosion, temperature, fatigue, wear,friction, lubricity, elongation and extrusion are considered. Mindful of commercial issues,our material evaluation process also takes into consideration issues such as cost,availability and sourcing.MetallurgyOur ongoing research program is focused onincreasing the working temperature limits forseals. Exploring both metal and metal compositetechnologies that are less prone to stress relaxationat high temperatures, we are developing seals fortomorrow’s gas turbine and rotary engines.TribologyStudying the interaction of sliding surfaces, weemploy multiple disciplines including the physicsof friction, material science of wear and chemistryof lubrication. Testing diverse combinations ofmaterials, heat treatments,surface treatments andcoatings ensures oursealing systems willendure the dynamicrequirements of theapplication and meetyour requirements forperformance and integrity.Parker Hannifin Corporation Composite Sealing Systems Division6Advanced Products Business Unit 33 Defco Park Road, North Haven, CT 06473Phone: 203 239 3341 Fax: 203 239 4409www.parker.com

Manufacturing TechnologiesOur core manufacturing technologies include metal roll and die forming, various fusionweld methods, CNC machining of metals, polymers and thermoplastics, vacuum heattreatment and electroplating. Production engineering skills include CAE development ofroll and die forming tools, as well as the design and development of specialized formingmachines and proprietary welding processes.Test CapabilitiesAn important part of the development processof a sealing system is the rigorous testing ofthe new design. We perform comprehensivequalification testing of the sealing systems aswell as 100% functional testing of productionunits prior to delivery if desired.Our extensive testing capabilities include: Pressure testing: 10-5 torr to 20,000 psi (140 MPa) Helium mass spectroscopy leakage testing: 10-11 mbar liter/sec Temperature range: Cryogenic to 1800 F (982 C) High cycle fatigue testing Dynamic wear, friction and torque testing Extrusion testing Load versus deflection seal testing and measurementWe are also able to design elaborate test fixtures and equipment to meet the testing andfunctional requirements of your unique sealing system. When necessary, we collaboratewith outside test facilities, universities, and our customer’s own engineering departmentsand laboratories for specialized performance and qualification testing.Total Project Management –Budgeting, Scheduling & PlanningThe Key to Successful ProjectsEvery Parker sealing system is treated with a complete project management approach toensure all aspects of the program run smoothly, efficiently and in strict adherence to yourschedule requirements. The project manager is your single point contact; however, youalso have access to our engineering staff throughout the program.Our project manager develops a comprehensive program schedule identifying all projectmilestones and the “critical path”. The project manager then coordinates the responsibilities of all functional teams including engineering, manufacturing, purchasing and qualitycontrol ensuring all tasks are performed on time. We believe the philosophy of adedicated project manager is key to the success of the program.Parker Hannifin Corporation Composite Sealing Systems DivisionAdvanced Products Business Unit 33 Defco Park Road, North Haven, CT 06473Phone: 203 239 3341 Fax: 203 239 4409www.parker.com7

The Parker Metal SealThe most extreme environments demand metal seal sealingsolutions. Resilient metal seals meet the challenges of hightemperatures or cryogenics, high pressures or hard vacuum,corrosive chemicals and even intense levels of radiationperforming dependably year after year.Advantages of Metal Seals Independent Optimization of Functional Componentsmeans each discrete function including load, springback andouter sealing layer ductility/hardness can be optimized to ensurehighest seal performance in every situation. Directly Bonded Electroplating onto the load bearingsubstrate eliminates unnecessary parts and failure modes. Pressure Energization uses internal hydrostatic pressuresbeneficially to supplement the self-energization forces from thetubing, jacket or spring. This becomes particularly helpful at highpressures over 3,000 psi (21 MPa) enabling metal seals to sealat 25,000 psi (170 MPa) and beyond, without risk of blow-byduring proof or burst testing. Total Metal Seal Service covers custom and standard sizedseals from 0.250" to 300" (6 mm to 7,60 m), including circularand non-circular shapes. We also offer the complete range ofMS metal O-ring sizes, all AS1895 E-ring sizes, and the fastestdelivery of C-rings from our preferred size list (see page E-86). Rapid Response and JIT (just-in-time) deliveries are assureddue to design, testing and all manufacturing processes (includingroll and die-forming, machining, welding, heat-treatment,electroplating) being performed within our own facilities.Metal Seals are the Preferred Solution in many jet engine andspace applications as well as oil, gas, and chemical equipment,plastic molding, diesel engines and a growing variety of industrialequipment. With ever more stringent pollution and leakagelegislation, plus the demand for greater efficiency and lifetimereliability, metal seals provide the highest integrity sealingsolutions for today’s world and tomorrow’s.Parker Hannifin Corporation Composite Sealing Systems Division8Advanced Products Business Unit 33 Defco Park Road, North Haven, CT 06473Phone: 203 239 3341 Fax: 203 239 4409www.parker.com

How To Use the Metal Seal Design GuideThe Advanced Products Business Unit’s line of resilient metal seals are offered in avariety of sizes, shapes, cross sections and materials to satisfy the sealing needs ofyour extreme environments.Section AGeneral Metal Seal InformationSection A – General Metal Seal InformationThe metal seal part number defines all of the key design elements as indicated onthe following page.XXX - 000000 - 00 - 00 - 0 - XXXMetal Seal Type(Section B)Seal Diameter(Section C)(inches specified to three decimalplaces or millimeters specified to twodecimal places)Seal Cross Section(Section C)Material(Section D)Temper(Section D)Plating, Coating or Finish(Section D)This design guide provides a rapid, unambiguous, self-selection process with all the features,applications and limitations of each product clearly stated. The guide is organized into sections whicheasily allows you to determine the part number of the metal seal that is right for your application.Section Bhelps you to determine which metal seal type is most appropriate foryour application.Section Cis organized by metal seal type. Having selected the best metal seal typefrom Section B, simply turn to the page in Section C for the seal selectedand you will find all the groove and metal seal dimensions you need.Section Dlists the many available metal seal materials and assists you indetermining which combination of materials is most appropriate foryour sealing environment.Section Eprovides supporting technical information and recommendations.Section Fshows a number of other metal seal designs which are availablefor unique applications when only a special seal will do. In thesecases, please contact one of our applications engineers at any of ourworldwide offices and we will be happy to assist you. Please send us yourapplication data sheet (Page F-103 & F-104) for a fast, complete response.Parker Hannifin Corporation Composite Sealing Systems DivisionAdvanced Products Business Unit 33 Defco Park Road, North Haven, CT 06473Phone: 203 239 3341 Fax: 203 239 4409www.parker.comA-9

Section A – General Metal Seal InformationMarket Mil StdBoss Seal EngineeredE-SealO-RingMil StdBoss Seal EngineeredE-SealO-RingMil StdBoss Seal EngineeredE-SealO-RingMil StdBoss Seal EngineeredMil StdBoss Seal EngineeredAccessoriesGas Turbine Bleed AirGas Turbine Compressor SectionsGas Turbine Cooling AirGas Turbine Fuel NozzlesGas Turbine Fuel SystemsGas Turbine, Turbine SectionsHydraulic SystemsMS 33649 Fluid Connection BossMS StandardsProbe and SensorsRocket Fuel SystemsV-Band CouplingOil & Gas, Power GenerationApplicationC-SealGas Turbine CasingGas Turbine CombustorGas Turbine Compressor SectionsGas Turbine Cooling AirGas Turbine Fuel NozzlesGas Turbine Fuel SystemsGas Turbine, Turbine SectionsGas Turbine Vane SealHeat ExchangersMS 33649 Fluid Connection BossNuclear Waste Container CasksOil Field Control SystemsPiping and FlangesSteam Turbine Casing SealsValve SeatsValvesMilitaryApplicationC-SealAerospace StandardsImaging DevicesMissilesMS 33649 Fluid Connection BossSatellite SystemsVehicle Engine Exhaust SystemsWeaponsSemiconductorApplicationC-SealGas Delivery SystemsHeavy Duty Mobile, Transportation rsEngine Exhaust SystemsParker Hannifin Corporation Composite Sealing Systems DivisionA-10Advanced Products Business Unit 33 Defco Park Road, North Haven, CT 06473Phone: 203 239 3341 Fax: 203 239 4409www.parker.com

Section B – Metal Seal Type SelectionMetal seals are produced in a number of standard designs which are appropriatefor use in a broad spectrum of the most commonly encountered applications.The Metal Seal Type is designated in the part number as shown below.EXX - 000000 - 00 - 00 - 0 - XXXMetal Seal Type(The first letter, E, indicates that the sealdimensions are specified in English units (inches))Seal Diameter(inches specified to three decimal places; 000.000)Section BMetal Seal Type SelectionSelecting the Metal Seal Type for Your ApplicationSeal Cross Section (Section C)Material (Section D)Temper (Section D)Plating, Coating or Finish (Section D)The flow diagrams on the following pages are designed to provide guidance to the appropriate metalseal type for your application. There are two basic types of applications:Face Seal ApplicationsCLHigh LoadGenerally, the highload seals providegreater leak tightnessand are preferredwhen there is sufficientseating load (the loadrequired to compressthe seal) and littleflange movement dueto thermal excursions,vibrations, etc.CLSee page B-12.High ElasticityLower load seals arefrequently used whenresiliency or springbackis needed to maintaineffective sealing duringflange separation orrotation. Additionally, lowload seals are suitable forapplications where seatingload is limited or there isconcern about yielding ordamaging the matinghardware surfaces.See page B-13.Axial Seal ApplicationsCLECA, Axial C-Ringcan be used as either a static seal or insemi-dynamic applications such as aquarter-turn valve stem seal.See page C-41.Parker Hannifin Corporation Composite Sealing Systems DivisionAdvanced Products Business Unit 33 Defco Park Road, North Haven, CT 06473Phone: 203 239 3341 Fax: 203 239 4409www.parker.comB-11

Section B – Metal Seal Type SelectionFace Seals for Higher Seating Loads& Lowest Leakage RatesESI(Greater than 100 lb/inch circumference)InternalPRESSUREDIRECTION63μ inch Raor rougherExternalESESURFACEROUGHNESS32 μ inch dium(30%)STARTECESPRINGBACKEOI, EON or EOPLow( BACKEOE, EOM or EOREWILimited nalEWEParker Hannifin Corporation Composite Sealing Systems DivisionB-12Advanced Products Business Unit 33 Defco Park Road, North Haven, CT 06473Phone: 203 239 3341 Fax: 203 239 4409www.parker.com

Metal Seal Type SelectionIFace Seals for Lower Seating Loads & Higher SpringbackFace Seals for Lower Seating Loads& Higher SpringbackSection BMetal Seal Type Selection(Less than 100 lb/inch EEESTARTHighestSpringback(95%)High Springback (60%)Higher pressurerating, arker Hannifin Corporation Composite Sealing Systems DivisionAdvanced Products Business Unit 33 Defco Park Road, North Haven, CT 06473Phone: 203 239 3341 Fax: 203 239 4409www.parker.comB-13

Section B – Metal Seal Type SelectionSeal Selection at a GlanceIn addition to the metal seal selection flow diagrams on the precedingpages, the following rating table provides simple guidelines which canbe used to confirm the appropriate metal seal selection. Refer to thetable below for a comparison of metal seal types.Ratings:ExcellentVery GoodGoodFairNot RecommendedSealing RequirementsSeal TypeHigh SpringbackLow LoadHigh LoadLow Leak RatePressureCapabilityLow CostMetal C-RingMetal E-RingMetal O-RingMetal U-RingMetal Wire RingSpring Energized C-RingStandard Metal Seals for Specificand Standard ApplicationsThe metal seal type for these applications are listed below.Seal DescriptionMetal SealTypeBoss Seal for MS-33649 Fluid ConnectionBoss and MS-33514/33656 Fitting Ends . ECIMetal E-Ring for AS1895 Flanges . EEIMetal O-Ring for Aerospace Standards . EONParker Hannifin Corporation Composite Sealing Systems DivisionB-14Advanced Products Business Unit 33 Defco Park Road, North Haven, CT 06473Phone: 203 239 3341 Fax: 203 239 4409www.parker.com

Section C – Metal Seal Size SelectionSelecting the Metal Seal Size for Your ApplicationMetal seals are available in any diameter from 0.250 inch to 300 inches and avariety of free heights to fit the various cavity sizes you may have.The metal seal size is designated in the part number as shown below.EXX - 000000 - 00 - 00 - 0 - XXXMetal Seal Type(The first letter, E, indicates that the sealdimensions are specified in English units (inches))Seal Diameter prior to plating(inches specified to three decimal places; 000.000)Material (Section D)Temper (Section D)Plating, Coating or Finish (Section D)Refer to the page of the metal seal type selected for your application to determine the appropriateseal diameter, cross section and cavity dimensions. Cavity, seal dimensions and seal performancedata for the standard metal seals can be found on the following pages:Seal TypeSeal DescriptionSection CMetal Seal Size SelectionCross Section CodePageFace EWEMetal C-Ring, Internal Pressure Face Seal .C-16Metal C-Ring, External Pressure Face Seal.C-18Spring Energized Metal C-Ring, Internal Pressure Face Seal .C-20Spring Energized Metal C-Ring, External Pressure Face Seal .C-22Metal E-Ring, Internal Pressure Face Seal .C-24Metal E-Ring, External Pressure Face Seal .C-26Metal O-Ring, I.D. Vented, Internal Pressure Face Seal.C-28Metal O-Ring, Plain, Internal Pressure Face Seal.C-28Metal O-Ring, Pressure Filled, Internal Pressure Face Seal .C-28Metal O-Ring, O.D. Vented, External Pressure Face Seal.C-30Metal O-Ring, Plain, External Pressure Face Seal .C-30Metal O-Ring, Pressure Filled, External Pressure Face Seal .C-30Metal U-Ring, Internal Pressure Face Seal .C-32Metal U-Ring, External Pressure Face Seal.C-34Metal Wire Ring, Internal Pressure Face Seal.C-36Metal Wire Ring, External Pressure Face Seal .C-38Axial SealsECAMetal C-Ring, Axial Seal .C-40Seals for Standard ApplicationsBoss Sealfor MS-33649 Fluid Connection Boss and MS-33514/33656 Fitting Ends.C-42Metal E-Ring for AS1895 Flanges .C-44Metal O-Ring for Aerospace Standards .C-45Parker Hannifin Corporation Composite Sealing Systems DivisionAdvanced Products Business Unit 33 Defco Park Road, North Haven, CT 06473Phone: 203 239 3341 Fax: 203 239 4409www.parker.comC-15

Section C – Metal Seal Size SelectionECI Metal C-RingInternal Pressure Face SealApplications:Z2A Excellent internally pressurized static face seal for valveassemblies, pressure vessels, jet engines, fuel injectors,separable fittings, etc. Moderate load permits the use of lighter flangesand fewer bolts.F Good springback properties to accommodate thermalcycles and joint separation.R Temperature range from cryogenics to 1600 F.GG Pressure range from vacuum to 76,000 psi and above.Features: Wide range of 10 standard free heights from 1/32" to 1/2".RCLDCOUNTERBOREMODEGROOVEMODE Available in any diameter

EUI Metal U-Ring, Internal Pressure Face Seal .C-32 EUE Metal U-Ring, External Pressure Face Seal .C-34 EWI Metal Wire Ring, Internal Pressure Face Seal .C-36 EWE Metal Wire Ring, External Pressure Face Seal .C-38 Axial Seals ECA Metal C-Ring, Axial Seal .C-40 Seals for Standard Applications Boss Seal for MS-33649 Fluid .