Transcription

ECHO WIRELESSVIBRATIONMONITORINGpcb.com/echo 1 800 959 4464

PERFORMANCEWhy use valuable manpower to collect vibration data onhealthy machines? Why settle for measurements once amonth when you can have them multiple times daily? Whyhave people venture into unsafe areas to collect routinemeasurements? Echo Wireless Vibration Sensors cansafely “look” at the machine’s health several times per dayand provide immediate notification when warning or criticallevels are reached. This frees up technical experts, likecertified vibration analysts, for higher value tasks such asfault analysis.The Echo Wireless Vibration Sensor and the EchoPlus Wireless Junction Box make the set of overall vibrationmeasurements, listed below, that provide early warningof most common machine faults. In addition to thesemeasurements, Echo provides accurate battery status.Using a user-programmable vibration threshold, Echo can detect if the machine is not running and if not, skip ameasurement to conserve battery power.2HIGHLIGHTS Easily integrates with legacy vibration and plantmonitoring systems via Modbus Transmits long distances, eliminatingexpensive cable runs Runs standalone or with junction box Stores data in ODBC format Requires no repeaters, gateways, or mesh

SIX PRIMARYMEASUREMENTS RMS Velocity: RMS Velocity is the average of all velocityvalues captured within the sampling window and identifieslow frequency faults such as unbalance and misalignment.Peak Velocity: Peak Velocity is RMS Velocity multipliedby 1.414 and identifies low frequency faults such asunbalance and misalignment.RMS Acceleration: RMS Acceleration is the average of allacceleration values captured within the sampling windowand identifies high frequency faults such as broken rotorbars in electric motors.Peak Acceleration: Peak Acceleration is RMS Accelerationmultiplied by 1.414 and identifies high frequency faultssuch as broken rotor bars in electric motors.True Peak Acceleration: True Peak Acceleration is thehighest acceleration value captured within the samplingwindow and identifies high-frequency, impulsive faultssuch as rolling element bearing defects and some geardefects.Crest Factor: Crest Factor is the ratio of True Peak to RMSAcceleration and is used as an indicator of fault severitywith caution.3

SYSTEM COMPONENTSWIRELESS VIBRATION SENSORMODELS 670A01 & CS670A01 (916 MHz)MODEL 670A02 (868 MHz)MODELS 672A01 & CS672A01 (916 MHz)MODEL 672A02 (868 MHz) Transmits long distances Instantly converts existing sensors to wireless Eliminates expensive cable runs Runs independently or with existing junction box Installs easily Uses 24 VDC or battery powerThe Echo Wireless Vibration Sensor is a stand-alone,battery powered industrial vibration sensor. Echo has anLED that provides visual feedback on the status of the sensor,including: on, off, measuring, transmitting or changingstates. The sensor has an embedded magnetic switch andcan be activated or deactivated by holding a strong magnetnext to the sensor. Upon activation, the sensor makes andtransmits a set of measurements.The Echo Wireless Vibration Sensor is also offered in ahazardous area certified variation (CSA approval of 916 MHzversion only.) Model CS670A01 can be used in hazardousarea requiring Class 1, Division 2 certification. The modelcan be used in hazardous applications, such as oil wellheads,for remote wireless vibration monitoring on these machines.4WIRELESS JUNCTION BOXThe EchoPlus Wireless Junction Box is an 8-channeljunction box that instantly converts installed industrialsensors to wireless operation. This incredibly economicaldevice periodically powers each sensor, makes the sameset of overall measurements and transmits them wirelessly.The default transmission interval is 8 hours, but it is userprogrammable. Additionally, it operates as a standardjunction box allowing full data collection with a portable datacollector at the box. It can be powered using either standard24 VDC or any battery between 6 and 13 VDC. The unit can beused by itself or in conjunction with an existing junction boxby simply jumping wires between them.The EchoPlus Wireless Junction Box is also offered in ahazardous area certified variation (CSA approval of 916MHz version only). Model CS672A01 can be paired withhazardous certified ICP accelerometers for wirelessvibration transmission in hazardous areas requiringClass I, Division 2 certification. When combined with anappropriate intrinsic safety barrier, the EchoPlus canbe used in applications such as refinery pumps, fans,motors and gas compressors to trend and alarm machinevibration levels.

LOW COST ICP ACCELEROMETERSFOR ECHOPLUS JUNCTION BOXMODELS (EX)602M138, (EX)603M170, (EX)607M140RECEIVERMODEL 673B01 (916 MHz)MODEL 673B02 (868 MHz) Requires no repeaters, gateways, or mesh Outputs to Ethernet Installs easilyThe Echo Receiver is a stand-alone unit that communicatespoint-to-point with Echo Wireless Vibration Sensors andEchoPlus Wireless Junction Boxes. Using an ultra-narrowbandwidth filter with Extended Range RF (ERRF) technology,it has unprecedented -145 dBm sensitivity and can detect anddecode RF signals as low as about a millionth of a billionth ofa milliwatt. This results in very long distance point-to-pointcommunications in plants, eliminating the need for repeatersor complicated mesh networks. Actual tests in a typical powerplant achieved successful signal transmission distances ofover 1200 ft (365 m) and even through buildings. Outdoortests have achieved transmission distances measured inmiles and transmissions are at only 0.75 mW ERP using verylittle battery power.6 dBi ANTENNA (868 & 916 MHz)MODEL 070A908 dBi ANTENNA (916 MHz ONLY)MODEL 070A915

ON DEMAND AND MOBILE APPLICATIONSECHO ON DEMAND Wirelessly capture overall vibration data on demandwith EchoPlus Remote Trigger (with or withoutWireless Remote) Monitor non-continuously running rotating assets Eliminate difficult data collection within dangerous locationsAPPLICATIONSECHO MOBILEThe Echo Wireless Vibration Monitoring System is simpleand compact with few components, so it can be easilytransported for use in the most difficult/remote applications.An Echo Receiver paired with a laptop (running Echo Monitoring Software) creates a receiving station that caneasily fit into a rugged case and be used in a vehicle formobile wireless data collection.APPLICATIONS Overhead cranes Tailings ponds Pumps in tailings ponds Remote crusher spreads Intermittent machines Long conveyor belts/runs Machines in restricted areas Other remote hazardous areas Equipment in hard-to-reach areasWIRELESS REMOTEMODEL 070A00 (916 MHz ONLY)ECHOPLUS REMOTE TRIGGERMODEL 070B97 (868 OR 916 MHz)(PICTURED WITH ECHOPLUS WIRELESS JUNCTION BOX)6

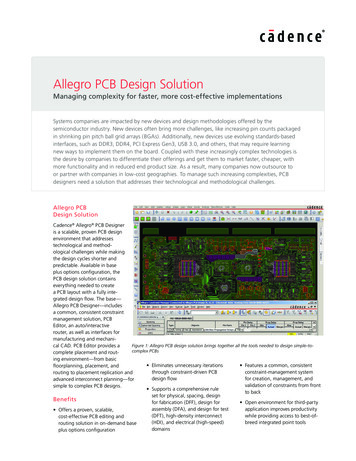

CONFIGURATION SCHEMATICTYPICAL CONFIGURATION 1Optional high gain antennaEchoPlus Wireless Junction BoxProcess 24 VDC power or 6-13 VDC battery powerEcho ReceiverMonitored MachineryTraditional,Wired SensorTYPICAL CONFIGURATION 2Echo Wireless Vibration Sensors100-240 VAC to12 VDC UniversalPower SupplyIncludedantennaTCP/IPEcho ReceiverTraditional, Wired SensorConnected to EchoPlus Wireless Junction BoxVIBRATION ANALYSIS USING DATA COLLECTOREchoPlus Wireless Junction BoxData collector connects directly to:nEchoPlus Wireless Junction Boxvia standard BNC connectorWireless transmission stops while analogacceleration output is acquired via BNC. Afterhandheld data collection, device returns toregular transmission schedule.Transmissionstemporarily pausedduring handhelddata collection7

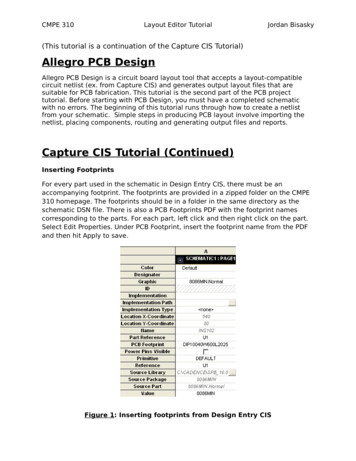

The Echo Wireless Vibration Monitoring System is simplein design, easy to install, cost-effective and flexible inconfiguration. With over 400 points per receiver, the systemcan monitor over 3,500 points even within the same RFcoverage area. Outside the same coverage area, the numberis even higher. Stand-alone Echo Sensors and EchoPlus Junction Boxes can be mixed and matched as desired.EchoPlus provides a raw vibration output via cable to adata collector for detailed fault analysis. Echo MonitoringSoftware provides standard monitoring features, such as:machine status, reports, trend plots and email alerts. It canbe run single or multi-user at no additional charge per user.Echo DataClient ServiceCollects transmissionFormats dataStores in databaseGenerates alarm emailWith optional integratedModbus TCP/IP Server interfacennnnnEcho DataPresentation SWTrend plotsStatusAlarmsReportsEcho sensorconfiguration utilitiesnnnnnEcho Sensor DataMS SQLEthernetTCP/IPServer 2005All monitor stations, either through LAN orremote access, have all the same functionalityas server system, but do not store data.Echo DataPresentation SWEcho DataPresentation SWAccess to SQL Databasethrough internet with LANAccess to SQL Databasethrough internet with VPNnnn8Trend plotsStatusAlarmsnnReportsSensor configurationnnnTrend plotsStatusAlarmsnnReportsSensor configuration

ECHO MONITORINGSOFTWAREEcho sensor data is collected and stored by the Echo Data Client Service software in a Microsoft SQL database. The databasestructure is available from IMI so it can be accessed by users directly using any ODBC-compliant application. The Echo DataClient Service can also be configured as a Modbus TCP/IP Server to service Modbus requests from an existing Modbus Client application.Echo data can also be exported from the Echo Data Presentation Software to a tab delimited spreadsheet file that is suitablefor use with Excel or other data viewing applications for post processing.ECHO DATA CLIENT SERVICE Installs locally or on a serverECHO DATA PRESENTATION SOFTWARE (It is highly recommended that the service is installed on a dedicatedPC or Server running 24/7)This software application is used to characterize anddisplay data collected by the system. It runs in singleor multi-user environments and provides: Runs continuously whether a user is logged on or not System level status & alerts SQL Database interface and/or Modbus TCP/IP Sensor history and trend plots Provides email alerts if SQL interface is enabled Sensor level status and alarms Service Status application runs from notification trayto view service / receiver statusSENSOR VIBRATION ALARM PANEL& VIBRATION TREND PLOT SCREENSHOT System, database, and senor configurationutilities with administrative accessECHO MONITORING SYSTEMOVERVIEW SCREENSHOTMICROSOFT IS A REGISTERED TRADEMARK OF MICROSOFT CORPORATIONEXCEL IS A REGISTERED TRADEMARK OF MICROSOFT CORPORATION9

SPECIFICATIONSSystem InformationModel NumberEcho Receiver673B01673B02Data Received Per TransmissionDateMM/DD/YYYYTimeHH:MM:SSVibrationRMS VelocityArithmetic Average of Velocity Value SamplesPeak Velocity1.414 x RMS VelocityRMS AccelerationArithmetic Average of Acceleration Value SamplesPeak Acceleration1.414 x RMS AccelerationTrue Peak Acceleration3.7 sec sample @ 61.4 kHzCrest FactorTrue Peak/ RMS AccelerationSensorSensor IDFactory Set Unique NumberBattery Status1 to 4 (4 best, 1 worst)Signal Status1 to 4 (4 best, 1 worst)Average PowerAverage Transmission Power (dBm)Noise PowerBackground Noise Level (dBm)Average SNRDifference between Average Power and Noise (dB)Radio SpecificationsRadio StandardProprietary Extended Range RFModulationNarrowband FSKLine-of-Sight tested up to 1 mileTransmission Range1200 ft (365 m) in typical industrial environmentsTransmission IntervalProgrammable, 1 min to 24 hrs (Default of 8 Hours)CertificationsFCC, IC, ANATELCERadio Sensitivity-145 dBmFrequency Band902 - 928 MHz868.0 - 868.8 MHzNumber of Independent129RF BandsMaximum Power (ERP)0.75 mWRF Data Rate20 bps10Model Number673B01673B02PerformanceMAC AddressIP Address (Programmable)Sensors per receiverUnique and Factory SetDynamic or Static400 at 3 Transmissions/Day,1% miss1200 at 1 Transmission/Day,1% missElectricalPower12 VDCEnvironmentalEnclosure RatingTemperature RangeIP67NEMA 1, 2, 4, 4X,12,13-6 to 138 ºF-21 to 59 ºCPhysicalEnclosure MaterialDie Cast AluminumPower ConnectorBayonet Multi-Pin MILProgramming ConnectorBayonet Multi-Pin MILEthernet ConnectorRJ-45Antenna ConnectorN-female7.87 x 6.65 x 1.97 in199.9 x 168.9 x 50.0 mm2.37 lb1.08 kgDimensionsWeight

ECHO Wireless Vibration SensorModel NumberECHOPLUS Wireless Junction Box(CS)670A01670A02PerformanceVelocity RangeModel Number(CS)672A01672A02Performance0 - 4 ips rmsVelocity RangeVelocity Linearity (0 - 1 ips rms) 1%Velocity Linearity (0-1 ips rms)Velocity Linearity (1 - 4 ips rms) 8.5%Velocity Linearity (1-4 ips rms)Velocity Frequency Range ( 3 db)4 to 2300 Hz0 - 4 ips 1% 7%Velocity Frequency Range ( 3 dB)4 to 2300 HzVelocity HP Filter2 Hz, 1-pole RCVelocity HP Filter2 Hz, 1-pole RCVelocity LP Filter2.4 kHz, 3-pole ChebyshevVelocity LP Filter2.4 kHz, 3-pole ChebyshevVelocity Resolution0.001 ips rmsVelocity Resolution0.001 ips rmsAcceleration Range0 - 20 g pkAcceleration Range0 - 40 g pkAcceleration LinearityAcceleration Frequency Range( 3 db) 1%Acceleration LinearityAcceleration HP Filter2 kHz, 4-pole ChebyshevAcceleration LP Filter15 kHz, 3-pole Chebyshev 1-pole RCAcceleration Resolution0.007 g pkTransverse SensitivityTemperature Range 7%Hazardous Area Approval1000 gBattery Operating TemperatureBattery Life (Room Temperature)Electrical Isolation (Case)7.2 V Lithium Battery Pack, Replaceable-76 to 185 ºF-60 to 85 ºC1 year @ 3 measurements/dayPhysicalSensing ElementSensing GeometryShearStainless SteelCap MaterialPolycarbonate1/4-28 FemaleMounting Torque2 to 5 ft-lb1.66 x 4.40 in42 x 112 mm1-3/8” HexDimensions (Diameter x Height)Base SizeWeight15.9 oz450 g-6 to 158 ºF-21 to 70 ºCIP66, NEMA 4XCSA (CS only)N/A23 to 25 VDCPower (Battery)6 to 13 VDCCurrent ConsumptionSensor Power SuppliedChannel Gain 150 mA24 VDC @ 2.2 mAconstant currentProgrammable, Defaultfor 100 mV/gPhysicalEnclosure MaterialFiberglassPolyester (CS only)FiberglassCord GripsTen PGME07Ten M16 (CS only)Ten PGME07Raw Vibration ConnectorUrethaneMounting0.005 g pkPower (External)CeramicHousing and Base MaterialMechanical Isolator MaterialAcceleration ResolutionElectricalN/A 108 ohmAcceleration LP FilterHazardous Area ApprovalElectricalPower2 kHz, 4-pole Chebyshev15 kHz, 3-pole Chebyshev 1-pole RCEnclosure RatingIP66CSA (CS only)Acceleration HP FilterTemperature Range-6 to 158 ºF-21 to 70 ºCEnclosure Rating2.3 to 15 kHzEnvironmentalEnvironmentalShock Limit (through base) 1%Acceleration Frequency Range ( 3 dB)2.3 to 15 kHzDimensionsWeightBNC Jack, Internal8 x 6 x 4 in203 x 152 x 102 mm10.24 x 3.54 x 6.30 in(CS only)261 x 90 x 160 mm(CS only)2.88 lb1.3 kg5.2 lb (CS only)2.4 kg (CS only)8 x 6 x 4 in203 x 152 x 102 mm2.88 lb1.3 kg11

3425 Walden Avenue, Depew, NY 14043-2495 USAToll-Free in the USA: 1 800 959 4464Phone: 1 716 684 0003 Email: imi@pcb.comIMI Sensors, a division of PCB Piezotronics, Inc. manufactures industrial vibration monitoringinstrumentation, such as accelerometers, vibration transmitters and switches that feature ruggedstainless steel housings and survive in harsh environments like paper and steel mills, mines, gasturbines, water treatment facilities and power plants. Integrating with portable analyzers andPLC’s, IMI instrumentation helps maintenance departments reduce downtime and protect criticalmachinery. Visit IMI Sensors at www.pcb.com. PCB Piezotronics, Inc. is a wholly owned subsidiaryof MTS Systems Corporation. Additional information on MTS can be found at www.mts.com. 2020 PCB Piezotronics, Inc. In the interest of constant product improvement, specifications are subject to change without notice. PCB , ICP , Swiveler , Modally Tuned , and IMI with associated logo are registered trademarks of PCBPiezotronics, Inc. in the United States. ICP is a registered trademark of PCB Piezotronics Europe GmbH in Germany and other countries. UHT-12 TM is a trademark of PCB Piezotronics, Inc. SensorLine SM is a service mark of PCB Piezotronics. Inc.SWIFT is a registered trademark of MTS Systems Corporation in the United States.IMI-VIB-Echo-042012MTS Sensors, a division of MTS Systems Corporation (NASDAQ: MTSC), vastly expanded its range of products and solutions after MTS acquiredPCB Piezotronics, Inc. in July, 2016. PCB Piezotronics, Inc. is a wholly owned subsidiary of MTS Systems Corp.; IMI Sensors and Larson Davis aredivisions of PCB Piezotronics, Inc.; Accumetrics, Inc. and The Modal Shop, Inc. are subsidiaries of PCB Piezotronics, Inc.

Wireless Vibration Sensor is a stand-alone, battery powered industrial vibration sensor. Echo has an LED that provides visual feedback on the status of the sensor, including: on, off, measuring, transmitting or changing states. The sensor has an embedded magnetic switch and can be activated or deactivated by holding a strong magnet