Transcription

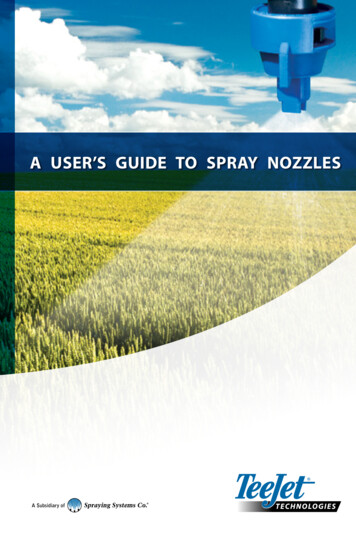

A USER’S GUIDE TO SPRAY NOZZLES

HOW A USER’S GUIDETO SPRAY NOZZLES ISDIFFERENTA User’s Guide to Spray Nozzles iseducational and informative. It providesfacts, not opinions.This guide provides you with cutting edgereference material that will help make youa more knowledgeable buyer and user ofspray nozzles. We hope this guide enablesyou to better evaluate performance claimspublished by all nozzle manufacturers.Spray nozzles are highly engineered,precision components. Full considerationshould be given to the manufacturer and themanufacturer’s capabilities.

A USER’S GUIDE TOSPRAY NOZZLESIntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2SECTION ONEThe Costly Consequences OfSpraying Too Much or Too Little. . . . . . . . . . . . . . . . . . . 4SECTION TWOSpray Nozzle Fundamentals. . . . . . . . . . . . . . . . . . . . . . . 6SECTION THREEKnow Your Nozzle Types . . . . . . . . . . . . . . . . . . . . . . . . 16SECTION FOURSelecting The Right Spray Nozzle. . . . . . . . . . . . . . . . 24SECTION FIVEConsult The Experts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40SECTION SIXMaking Maintenance A Priority. . . . . . . . . . . . . . . . . . 42SECTION SEVENSprayer CalibrationEnsures Optimal Performance. . . . . . . . . . . . . . . . . . . . 4 6SECTION EIGHTFuture Trends inSpraying and Nozzle Technology. . . . . . . . . . . . . . . . 52A User’s Guide to Spray Nozzles1

INTRODUCTIONApoor choice inspray nozzles,or use of under-performing nozzles,can lead to re-spraying and reducedperformance – two problems no usershould face.2

Your successin any spraying season is dependent onmany individual factors. Some of these factors, like the equipment you chooseto use, are controlled by you; others, like the weather, are not. The purpose ofthis guide is to assist you in an area where you have total control: spray nozzleselection and use.Even though spray nozzles are a physically small component in your overalloperation, they are vitally important. Improper application of plant protectionproducts can be extremely costly if re-spraying is required, performance isreduced or legal issues arise as a result of chemical drift. However, many usersperceive spray nozzles as fairly simple components, when in fact it is quite theopposite. There are dozens of nozzle types from various manufacturers thatoffer very different performance.This guide will help you: Learn more about the technical aspects of spray nozzles elect the spray nozzles best suited to your specific applicationSrequirements Maintain your spray nozzles for optimal performanceA User’s Guide to Spray Nozzles3

SECTIONONETHECOSTLYCONSEQUENCESOFSPR AYING TOO MUCH OR TOO LIT TLEMaking sure you have the proper spray nozzles for your applica-tion and that they are performing properly are two things that every user shouldpractice to maximize performance and profitability. The spray nozzles youselect will determine: The amount of chemical applied to an area The uniformity of the application The coverage of the chemical on the target surface The amount of potential driftUsing the wrong spray nozzle or a spray nozzle that isn’t performing properlycan result in over or under application. Over application can be wasteful andcostly; under application can result in a reduction in performance or the need forre-application.The use of a rate controller can certainly help ensure the proper amount issprayed. You can also make minor adjustments to sprayer pressure or speed toapply the correct amount of chemical. However, the proper application volumedoesn’t necessarily mean maximum effectiveness.EVEN A SPRAY NOZZLEWITH ONLY 10% WEARMAY NOT GIVE YOU THE COVERAGEAND PERFORMANCE YOU EXPECT4

For example, if you are using the wrong nozzle or if the nozzle is worn by aslittle as 10%, the spray pattern may not be uniform across the boom and youwill not get the spray coverage you expect. Coverage may be streaky and someareas may receive more or less chemical than intended, resulting in the need tore-apply the product.No matter the root cause, over and under application both have high pricetags – thousands of dollars, and in some cases, tens of thousands of dollars.The full cost of these losses will likewise depend on your operation and the plantprotection products you use. See the example below.Problems like this can be avoided by making sure you’ve selected the properspray nozzles for your application and that they are in good working order. If youthink there is a nozzle that may better meet your needs, or you suspect that yournozzles are worn, do not hesitate to replace them. The cost of replacing nozzlesis minor compared to the effects of poor spraying. In fact, you’ll recoup the costof the nozzles almost immediately by applying the proper amount of chemical injust a few acres.Cost calculator for under or over application:Under application of chemical causing re-spray* (U.S. dollars): 27/acre x 100 acres 27/acre x 1000 acres 27/acre x 2000 acres 2,700 27,000 54,000*Does not include time/labor, fuel or machinery expense.Over application of chemical by 10% (U.S. dollars):( 27/acre x 10%) x 100 acres( 27/acre x 10%) x 1000 acres( 27/acre x 10%) x 2000 acres 270 2,700 5,400A User’s Guide to Spray Nozzles5

SECTIONTWOS P R AY N O Z Z L E F U N D A M E N TA L SSpray PatternsThere are many types of nozzles and spray patterns available; your best choicewill depend on the application. Three of the most common types are: Flat fan Cone spray Streaming nozzlesFlat FanThe flat fan spray nozzle forms a narrow, elliptical, inverted “V” pattern commonlyreferred to as a tapered spray (FIGURE 1). Deposition is heaviest at the centerof the pattern and dissipates toward the outer edge. A uniform distributionpattern across the boom is achieved when the boom height and nozzle spacingare optimized for proper spray pattern overlap of adjacent nozzles. Variations ofthe flat fan include:6 xtended range flat fan for broadcast spraying; designed to operateEwith a wider range of spray pressures (FIGURE 1). ymmetric or asymmetric twin flat fan for broadcast spraying; flowSis divided between two orifices pointed forward and backward; canprovide improved coverage and canopy penetration (FIGURE 2). looding for broadcast spraying; wide angle flat pattern using largerFdroplets (FIGURE 3). ven spray for band spraying; non-tapered spray patterns provideEeven coverage without overlapping (FIGURE 4). dditionally, all of the above nozzle types may be offered in aAtraditional single orifice design, pre-orifice design or air inductiondesign. More to come on this in the next section.

HigherPressureLowerPressureAT 15 PSI / 1 barPRESSUREFIGURE 1:Extended range flat fanspray patternFIGURE 3:Wide angle flat fanspray patternOverlap broadcast patternAT 60 PSI / 4 barPRESSUREFIGURE 2:Symmetric twin flat fan spray patternFIGURE 4:Even spray patternBand spray applicationA User’s Guide to Spray Nozzles7

Spray Nozzle FundamentalsCone SpraysCone sprays come in two basic variations - hollow cone and full cone. Thehollow cone spray nozzle forms a ring-shaped pattern, finely atomized sprayand can be operated at high pressures. These unique characteristics makehollow cone nozzles well suited for air blast applications as well as specialtyand directed spray applications. Hollow cone nozzles may be offered in a singlepiece tip design or a two-piece disc and core design. Air induction hollow conenozzles are a recent development that produces a spray pattern like a traditionalcone spray, but with much coarser droplets to reduce drift. (FIGURE 5 & 6).The full cone spray nozzle creates a full, circular spray pattern. Full conestypically produce coarser droplets and are offered in larger capacities thanhollow cone nozzles. These nozzles are typically used for directed spraying andother specialty applications. Full cone nozzles may be offered in a single-piecetip design or a two-piece disc and core design (FIGURE 7).FIGURE 5:Hollow Cone Spray PatternFIGURE 6:Air Induction Hollow ConeSpray PatternFIGURE 7:Full Cone Spray PatternStreaming NozzlesSolid stream or broadcast streaming nozzles are offered in a variety ofconfigurations and are commonly used for liquid fertilizer application. Thesolid stream spray pattern reduces foliar coverage to minimize leaf burn whileprojecting the liquid more directly to the soil surface where it can be absorbed bythe root system. More to come on these nozzles in the next sectionSpray Tip Geometry8The charts to the right provide information on the theoretical spray coverage ofthe included spray angle at various spray heights. These values are based on theassumption that the spray angle remains the same throughout the entire spraydistance. In actual practice, this does not happen due to the effects of gravity(FIGURE 8).

Spray Nozzle FundamentalsAlways keep in mind that spray coverage will vary based on operating pressure,spray height and nozzle spacing. Follow the manufacturer’s recommendations toachieve uniform coverage.Optimum spray heights can be found in the table on the next page (FIGURE 9).These heights are based on laboratory testing and provide the overlap requiredto obtain uniform distribution. In many cases, typical height adjustments arebased on 1:1 nozzle spacing to height ratio. For example, 110 flat spray nozzlesspaced 20″/50 cm apart are commonly set 20″/50 cm above the target.Theoretical Coverage at Various Spray Heights (in)Included SprayAngle8"10"12"15"18"24"30"36"15 20 25 30 35 40 45 50 55 60 65 73 80 85 90 95 100 110 120 130 140 150 66.472.078.685.9103Included SprayAngle20 cm30 cm40 cm50 cm60 cm70 cm80 cm90 56.865.574.683.993.710411513315116518019621525715 20 25 30 35 40 45 50 55 60 65 73 80 85 90 95 100 110 120 130 140 150 Disc CoreTheoretical Coverage at Various Spray Heights (cm)FIGURE 8:Theoretical CoverageA User’s Guide to Spray Nozzles9

Spray Nozzle FundamentalsThe most commonly used spray angle for various nozzle types are listed below. Tapered flat fan nozzles are most often available with 80º or 110 spray angles ven flat fan nozzles are commonly available with 40 , 65 , 80 , or 95 Espray angles Flooding (wide angle) nozzles typically produce a 120 spray angle Hollow cone nozzles are commonly available with 65 or 80 spray anglesThe trend in broadcast flat fan spray tip design is toward wider sprayangles. This is why you will see most new generation tips offered in 110ºor wider spray angles only. The advantages of wider spray angles includeincreased overlap for better spray distribution and the ability to run boomscloser to the target surface to reduce drift potential.Spray PressureNozzle flow rate varies with spraying pressure. In general, the relationshipbetween flow rate in gallons per minute (GPM) or liters per minute (l/min) andpressure in PSI or bar is shown at the right (FIGURE 10).Key facts about pressure:10 Increasing the pressure by four times doubles the flow rate Higher pressure decreases droplet size and increases drift potential Higher pressure increases orifice wear ressure impacts the spray angle and coverage; operate your sprayPnozzles within the proper pressure range erformance data is typically provided in spray nozzle catalogs forPspraying water. Liquids more dense, or heavier, than water, like 28%liquid nitrogen, form smaller spray angles. Liquids less dense, orlighter, than water form wider spray angles.

Spray Nozzle Fundamentals(in)20"30"40"30"NR*NR*110 20”30"NR*120o24"30"39"80 (cm)50 cm75 cm100 cm80 75cmNR*NR*110 50cm75cmNR*120o60cm75cm100cmFIGURE 9:Optimum spray heights*Not recommendedGPM1GPM2l/min1l/min2 PSI1PSI2bar1bar2FIGURE 10:Relationship between flow rate (GPM or l/min) and pressure (PSI or bar)A User’s Guide to Spray Nozzles11

Spray Nozzle FundamentalsDroplet Size BasicsA nozzle’s spray pattern is made up of many droplets of varying sizes. Dropletsize is the diameter of an individual spray droplet and measured in microns(micrometers) often notated with the symbol µ. One micron equals 0.001 mm(0.0000394″); there are 25,400 microns in one inch. For example, the diameterof a human hair is about 100 microns.Most nozzles have a wide array of droplet sizes. These droplet sizesare commonly summarized by statistical analysis based on testing fromsophisticated droplet size measuring equipment such as laser and imagingsystems. Droplets are then classified as shown to the right (Figure 11). Theseclassification categories enable comparisons to be made between nozzles.The most reliable droplet size data will conform to the British Crop ProtectionCouncil (BCPC) standard in accordance with the American Society ofAgricultural and Biological Engineers (ASABE) standard S572.1. This standardprovides strict conditions for spray droplet measurement and is preferredbecause it uses reference nozzle sets to normalize data. This eliminatesinterpretation differences when comparing statistical data among differenttypes of laser measuring equipment (Figure 12). Generally speaking, withoutthese classification categories, you can never accurately compare droplet sizenumbers between nozzles or nozzle types.Droplet size is a key factor in nozzle selection: hen coverage is critical, such as in post-emergence contactWapplications, nozzles with finer droplets are used because of theexcellent coverage on leaf surfaces. ozzles producing mid-range droplets are most commonly usedNfor application of contact and systemic herbicides, insecticides andfungicides. ozzles producing coarser droplets are typically used for systemicNherbicides and pre-emergence soil applied herbicides whileminimizing drift.Remember, droplet size can vary based on pressure. The same nozzle canproduce medium droplets at low pressures and fine droplets at higher pressures.12

Spray Nozzle GURE 11:Droplet Size ClassificationLaser AnalyzerA User’s Guide to Spray Nozzles13

Spray Nozzle FundamentalsDefining Spray DriftSpray drift is defined as the movement and deposition of spray particles throughthe air to non-target locations. The two forms of spray drift are: particle driftwhich results from droplets physically moving to non-target locations via aircurrents; and vapor drift which results from the evaporation of and later redeposition of spray particles in non-target areas. Droplets most prone to driftare those less than 150 microns in diameter.Factors that determine drift: Wind velocity and direction has the greatest impact on spray drift. he greater the distance between the spray tip and the target area,Tthe greater impact wind velocity can have on drift. A temperature inversion layer, a situation where the air temperatureis cooler near the earth’s surface than in the air immediately above it,can lead to increased lateral movement of spray particles leading tospray drift. I ncreased operating speeds can cause the wind to be diverted backinto upward wind currents and vortices behind the sprayer that trapsmall droplets and can contribute to drift. hen temperatures are over 77 F (25 C) with low relative humidity, smallWdroplets are more prone to drift because of the effects of evaporation. L ow application rates usually requires the use of small nozzle sizes,increasing the risk of drift. he smaller the nozzle size and the greater the spray pressure, theTsmaller the droplet size and the greater proportion of driftable droplets.Various agencies conduct rigorous distribution and drift testing. Whenevaluating drift data, always inquire about the source of the data. The best datawill come from independent testing agencies, such as Food and EnvironmentResearch Agency (FERA) in the United Kingdom, the Julius Kühn Institute(JKI) in Germany and the Centre for Pesticide Application and Safety (CPAS)in Australia.14Certain agencies also conduct assessment testing on spray applicationsystems. Some of these agencies have rating systems and accreditationprograms. Ask to see these such ratings when evaluating drift potential. Themost popular rating system is the Local Environment Risk Assessment forPesticides (LERAP).

Spray Nozzle FundamentalsFor more information, please contact:ASABE (http://www.asabe.org)FERA (http://www.fera.defra.gov.uk)JKI (http://www.jki.bund.de/en)Pesticides Safety Directorate (PSD) (http://www.pesticides.gov.uk/)CPAS (http://www.uq.edu.au/agriculture)LERAP ps)Helpful Drift Control Tips: educe operating pressure to increase droplet size. Flow rate willRbe reduced so it may be necessary to go to a larger nozzle size tostay within the labeled application rate. se nozzles that produce larger droplets such as drift reducingUnozzles or nozzles of larger capacity. L ower boom height to reduce drift but maintain proper overlap forspray coverage. Pay close attention to weather conditions throughout the day andadjust your application methods accordingly.A User’s Guide to Spray Nozzles15

SECTION THREEKNOWYOURNOZZLETYPESVenturi Air Induction NozzlesAir induction (AI) nozzles feature two orifices. The first orifice, known as thepre-orifice, meters the liquid flow. The second orifice, known as the exit orifice, islarger than the pre-orifice and forms the spray pattern. A venturi or air aspiratorsits between the two orifices. This air venturi draws air into the body of thenozzle where it is mixed with water. This mixing creates an air-entrained spraypattern at a lower pressure. The spray pattern is comprised of large, air-filled,coarse droplets with very few drift-susceptible droplets.Using AI nozzles:16 I deal for drift reduction while maintaining good coverage; when usedwith the proper chemicals/additives, air bubbles are formed in the dropletcausing the droplets to shatter on impact, providing improved coverage. e sure to use the proper operating pressures to achieve the properBdroplet size. Some AI nozzles require an operating pressure of30 to 100 PSI (2 to 7 bar) to maximize performance. Many newer AInozzles have been designed to operate effectively at pressures as lowas 15 PSI (1 bar). Most AI nozzles produce a wide angle flat fan or twin flat fan pattern. nozzles are typically used for broadcast spraying of post-emergenceAIsystemic herbicides, fungicides and insecticides. In banded anddirected spraying, AI nozzles provide excellent performance inapplication of pre-emergence herbicides, post-emergence systemicherbicides, fungicides and insecticides. symmetric twin spray nozzles are a more recent development thatAfeatures one spray pattern projected downward for canopy penetrationand one pattern projected horizontally for coverage at the top of thecrop canopy/seed head. These nozzles have proven to be particularlyeffective for fungicide application and disease control in small grains.

arry a few spares. Even though cleaning these nozzles shouldn’tCrequire tools, in-field cleaning isn’t recommended because of thenumber of small pieces. If in-field cleaning is necessary, keep a smallcan of compressed air on board the sprayer.Twin Spray VenturiAir Induction NozzleAsymmetric Twin SprayVenturi Air Induction NozzleVenturi Air Induction NozzleVenturi Air Induction NozzleA User’s Guide to Spray Nozzles17

Know Your Nozzle TypesExtended Range Flat Fan NozzlesExtended range flat fan nozzles provide excellent spray distribution over a rangeof pressures. When operated at lower pressures drift can be reduced while athigher pressures coverage can be improved.Using extended range flat fan nozzles: ommonly used for contact products (herbicides, insecticides &Cfungicides) where thorough leaf coverage is needed for effective control. L ower pressures and higher flow rates will produce droplets moreresistant to drift. Pressures above 30 to 40 PSI (2 to 3 bar) producefiner droplets more prone to drift. ozzles should be placed so patterns overlap a minimum of 30%Non each spray pattern edge.Extended Range Flat Fan Nozzle18

Know Your Nozzle TypesPre-Orifice Flat Fan NozzlesPre-orifice flat fan nozzles reduce the operating pressure internally and producea larger droplet than conventional flat fan nozzles. The nozzle’s pre-orificerestricts the amount of liquid entering the nozzle and creates a pressure dropthrough the tip. Fewer droplets prone to drift are produced creating excellentspray pattern uniformity. Pre-orifice nozzles are available in flat fan and plugresistant flooding versions.Using pre-orifice nozzles: lat fan versions operate at pressures from 15 to 90 PSI (1 to 6 bar),Frequire a minimum of 30% overlap on the edge of each spray patternand should be mounted so the preset spray angle is directed awayfrom the direction of travel. lat fan versions are widely used for the application ofFpost-emergence products. ompared to extended range flat fan nozzles, drift can be reducedCby as much as 50%. arry a few spares. The pre-orifice is more difficult to clean thanCconventional nozzles and not practical for in-field cleaning. If in-fieldcleaning is necessary, keep a small can of compressed air on boardthe sprayer.Pre-Orifice Flat Fan NozzleA User’s Guide to Spray Nozzles19

Know Your Nozzle TypesFlooding Type NozzlesFlooding type nozzles produce a wide angle flat fan pattern. Pressure changesaffect the width of the spray pattern more than with extended range flat fan nozzles.Using flooding type nozzles: est distribution is achieved with nozzles mounted for 100% (or double)Boverlap, meaning the edge of one spray pattern extends to the centerof the adjacent nozzle, at the lowest possible operating pressure. ozzles can be mounted to spray in any direction but the mountingNposition will impact the distribution. If spraying downward, rotating thenozzles 30 to 45 up from horizontal will help uniformity at operatingpressures in the 10 to 30 PSI (0.7 to 2 bar) range. t low pressures, flooding type nozzles produce large droplets; at highApressures, smaller droplets are produced – even smaller than flat fannozzles with an equivalent flow rate. ompared to extended range flat fan nozzles, drift can be reduced byCas much as 50%. re-orifice style flooding versions operate at pressures fromP10 to 40 PSI (0.7 to 2.8 bar), require a minimum of 30% overlap onthe edge of each spray pattern and can be mounted in a variety ofpositions for spraying in any direction. looding versions are well-suited for soil applications especially whenFapplying a mix of fertilizers and herbicides.Flooding Type Nozzle20

Know Your Nozzle TypesNozzles for Specialty ApplicationsThere are many variations to the basic nozzle types and many other specialtynozzles available as well. Your choice will, of course, depend on yourapplication requirements. Variation of standard nozzles includes, wide angle and extra wideangle sprays, double-outlet flat spray and even flat spray. oomless nozzles are designed for spraying areas not easily accessedBwith a boom sprayer. Flat spray and extra wide flat spray patterns aretypically used to provide a wide swath. ollow cone nozzles are available in disc and core types for sprayingHpesticides at higher pressures and flow rates. Standard hollow conenozzles produce a finely atomized spray and are commonly usedfor spraying post-emergence contact herbicides, fungicides andinsecticides. Wide angle versions are also available. ull cone nozzles provide a coarse spray pattern and are available inFstandard and wide angle spray patterns. These nozzles can be used inbroadcast spraying and in some banded applications.Boomless Type NozzleA User’s Guide to Spray Nozzles21

Know Your Nozzle TypesFertilizer NozzlesSolid stream nozzles are offered in a variety of sizes offering anywhere from1 to 7 or more individual streams. By utilizing individual liquid streams insteadof a fan spray, liquid fertilizer can be applied more directly to the soil surfacewhere it is needed. This minimizes foliar coverage in standing crop reducingthe chances of leaf burn and makes the likelihood spray drift extremely low.Fertilizer streaming tips are not recommended for pesticide application.Using fertilizer nozzles:22 treaming nozzles typically utilize a removable pre-orifice to meter theSflow. The ability to remove this pre-orifice for cleaning is a good feature. hen selecting a liquid fertilizer tip, always remember to apply theWliquid density correction factor when calculating your application rateand selecting the tip size/operating pressure (see Section Four formore details). ingle stream tips are often used in conjunction with a coulter or knifeSwhich creates a trench in the soil surface and allows the liquid fertilizerto penetrate into the root zone where it is most accessible to the plant. 3 -stream (or similar) tips produce a narrower coverage area andproject liquid more directly to the soil surface. These are morecommonly used in directed spray applications. The fewer streamsand narrower spray pattern generally require a lower, more consistentboom height and may be more suitable for lower-speed applicationscommon with pull-type machines. 7 -stream (or similar) tips produce a wider coverage area making themideal for broadcast application in both standing crop and bare soil.Due to the greater number of streams and wider spray pattern thesetips are most ideal for higher boom heights as well as higher groundspeeds commonly encountered with self-propelled machines.

Know Your Nozzle Types ue to the more 3-dimensional nature of some streaming nozzles, be sureDto verify that the spray pattern formed by the tip is compatible with yourspray boom. Some manufacturers offer simple adapters that can be utilizedto adjust the orientation/position of the tip for optimum performance.Fertilizer Nozzle Spray PatternsA User’s Guide to Spray Nozzles23

SECTION FOURSELEC TING THE RIGHT SPR AY NOZZLETo find the right spray nozzle,ask yourself these questions:1. What are you spraying?2. How are you spraying?3. What is your tolerance to drift?4. What is the weight of the spray solution?5. What is the pressure range of the sprayer?6. What is the nozzle spacing on the boom?7. What is the boom height?8. Which nozzle material is best?9. Who is the nozzle manufacturer and why does it matter?24

There is a reason why there are dozens of different nozzletypes available in hundreds of different sizes, capacities and materials. Eachnozzle is designed to yield very specific performance based on what you’respraying, when you’re spraying and how you’re spraying.It may be tempting to overlook the role spray nozzles can have in the overallsuccess of your spraying season simply because they are a small, relatively lowcost component. However, a poor choice in spray nozzles or the use of underperforming nozzles, can lead to re-spraying or reduced performance – twoproblems no user should face.Giving serious consideration to your spraying objectives and studying your optionsshouldn’t be shortchanged. It’s a small time investment that will help maximizeyour success. Start by reviewing your spraying requirements and be prepared tohave multiple nozzle sets on hand to meet your varying needs.1. What are you spraying?Herbicides, fungicides or insecticides — for soil incorporated, pre-emergenceor post-emergence? If post-emergence, contact or systemic? Is it a wettablepowder, emulsifiable concentrate or flowable? Will two or more chemicals beused in combination?A User’s Guide to Spray Nozzles25

Selecting The Right Spray Nozzle2. How are you spraying? Broadcast? Banded? Directed? Mechanical air assisted?The answers to these basic questions will get you started. Consult the charts atthe end of Section Four for recommended nozzle types. Another good sourceof information on nozzle type is the pesticide label. In addition to informationon recommended nozzle types, many chemical labels include information ongallons per acre (GPA) or liters per hectare (l/ha), nozzle spacing and dropletsize recommendations.3. What is your tolerance to drift?If you answer yes to any of the following questions, you may want to considerlow drift nozzles.26 Will you be applying near any residential areas? Do you spray in an area with different, adjacent crops or ornamentals? o the adjacent crops have different herbicide tolerant genetics and/orDwill spray drift result in crop damage? Are you concerned about the impact your spraying may have onthe environment? Have you had a drift complaint in the past? Do time cons

A User's Guide to Spray Nozzles 5 For example, if you are using the wrong nozzle or if the nozzle is worn by as little as 10%, the spray pattern may not be uniform across the boom and you