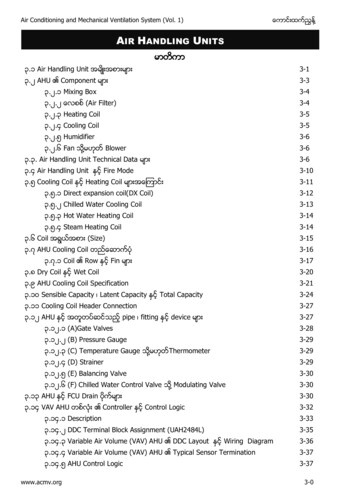

Transcription

MOV93585 EPCE04-25BFan coil unitsCyan Magenta Yellow Black

MOV93585 EPCE04-25B2PictogrammesManual cool/heat changeoverAutomatic cool/heat changeover based on water temperatureAutomatic cool/heat changeover based on air temperatureControl of the 3-way/4-port ON/OFF valve. The water valve shut-off once the desiredtemperature is reached.The controller controls the electric heater as integration or replacement of the hot waterheating system. When the operating mode selector witch is turned on “electric heater” and theelectric heater is turned on, the fan runs continuously at medium speed.3The fan speed can be set at one of the 3 speeds (low, medium or maximun) by turning theoperation mode selector.The fan speed is switched automatically based on the difference between the temperature seton the thermostat and the room temperature.Optimised comfort cooling. When the fan coil has reached the desired setpoint, the fan willoperate at medium speed and at regular intervals to ensure constant room temperature andlower sound.The controller prevents the fan coil unit from operating in one mode, if the required watertemperature is not achieved to operate in the selected mode.The dead zone is a temperature interval close to the set temperature. When the air iswarmer/cooler than the top/lower limit of the neutral zone, the cooling/ heating mode is selected.Cyan Magenta Yellow Black

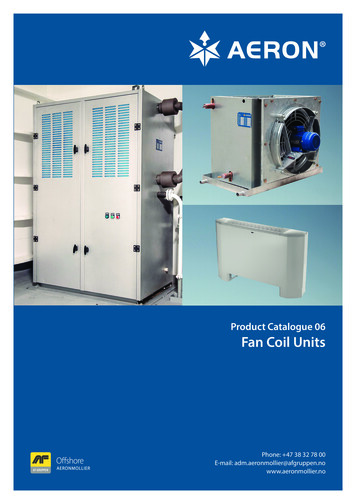

MOV93585 EPCE04-25B3Product portfolioDaikin fan coil units deliver quiet, reliable, controllablecomfort of air conditioning without all the noise of othercentral systems.The new range of fan coil units offers 5 models, of which3 in flexible application. A wide range of accessories isavailable.Fan coil units are a highly efficient means of turning awater chiller or hot water boiler into an efficient, quietair conditioning system.For the ultimate in quiet, controllable air conditioningwith all the comfort but none of the bulk or noise, theclear choice is Daikin.The units are super quiet because the only moving part isthe fan; making them ideal for use in offices, hotels andthe home.Fan CoilFWVReference012345678910 11 peFWLFWMFan CoilFWB4-pipeReference2-pipe4-pipeFan CoilFWDReference2-pipe4-pipeCoolingHeatingCyan Magenta Yellow Black

MOV93585 EPCE04-25B4FWV, FWL, FWMEasy to installFast and easy field set up, ready for use!KEY HOLE SYSTEM / LEVELLINGÔÔÔÔÔÔ Quick fixing system for wall/ceiling mountingAdvantage : No need to unscrew the nut Units just need to be perfectly leveledAdvantage : No need to calculate the condensate drainageWATER CONNECTIONÔÔÔ Pre-assembled 3-way/4-port ON/OFF valves are availableValve packages are insulated, no extra drain pan requiredValve packages contain balancing valves and sensor pocketValve packages can be factory-mounted and are leak testedSame valve package can be installed vertically and horizontally, on theright or on the left side of the unit without changeAdvantage : Easy to connect even when space is limitedCONDENSATE DRAINAGEÔÔÔÔÔÔ Condensate drain pan features slopes to reduce water accumulation Supplied with flexible rubber hose pipe for easy connectionAdvantage : Eliminates the need to align drain pan outlet withcustomer pipingAdvantage : No need for collar if pipe diameter is compatibleQUICK ELECTRICAL CONNECTIONSÔÔÔCyan Magenta Yellow Black Fast-on connections for electrical options : no tools needed Controls are already factory-wired and testedAdvantage : Control panel no longer needs to be opened(external customer connections) Wiring diagram on the cover of the electrical box

MOV93585 EPCE04-25B5FWV, FWL, FWMEasy to maintainLow maintenance and high effeciencyQUICK REMOVAL OF WASHABLE FILTER No tools needed Same system on vertical and horizontal unitsAdvantage : very fast filter removalELECTRIC HEATER RESETTING No relay up to 2kW capacityAdvantage : even quieter operation Manual reset easily accessible Equipped with two overheat cut-out thermostats(manual & automatic reset)Advantage : anticipates the upcoming standardsFAN MOTOR/CONTROL PANEL ACCESSIBILITY 4 screws to access to the fan motorFan board is removable without bringing the unit downMotor is life-lubricated and has a life span of 40,000 hoursControl panel removable by a single screwCan be unfolded for a better component accessRemovable grillesEasy access to control valvesCyan Magenta Yellow Black

MOV93585 EPCE04-25B6FWBSTRUCTURE Modular concept Height of the units only 240mm for all the sizes Cooling coil and fan module is made of:- galvanised sheet steel- internally insulated (with 3mm close-cell polyurethane) Key-hole system for fast mounting Rubber anti-vibration damper to isolate the unit from supporting structure Straight duct connector is mounted to both suction and discharge side (width 30mm) A template is available in the carton box for easy connection to the ceilingHEAT EXCHANGER 3, 4 or 6 stage row cooling coil Standard left handed water connections air-purge(water connections can easily be turned) Drain pan can to collect the condensate from:- Heat exchanger- Regulating valvesFAN MOTOR ASSEMBLY 1, 2 or 3 centrifugal fans with forward profile blades, dynamically andstatically balanced 7-speed electrical motors (with thermal protection on windings) All 7 speeds pre-wired in the factory in the terminal block of the switch box To reduce the requested installation space is the terminal block located onthe same side as the water connectionsAIR FILTER Located in the air inlet Removable from the bottom Made of acrylic fiber, filter class EU2Cyan Magenta Yellow Black

MOV93585 EPCE04-25B7FWDSTRUCTURE Possibility of installation both in horizontal and vertical position Reduced height 280mm up to model 10 The unit is made of:- galvanised sheet steel- insulated with noise-proof/anti-condensing material(self-extinguishing in Class 1, with a thickness of 10mm) Key-hole system for fast mounting Straight duct connector is mounted to discharge side(width 30mm)HEAT EXCHANGER 1 or 2 stage row cooling coil Standard left handed water connections air-purge System for collecting and discharging condensate setup either for ceiling or wallmounting.FAN MOTOR ASSEMBLY Dual intake centrifugal fans made of aluminum, dynamically and statically balanced 3-speed electric motor, installed on vibration damping supports(with thermal protection on windings)AIR FILTER Air-intake module Filter is standard delivered with each unit Removable filter from the bottom Made of acrylic fiber, filter class EU2Cyan Magenta Yellow Black

MOV93585 EPCE04-25B8Easy to control !The new fan coil units can be operated by 3 differentcontrollers: electronic control built-in (ECFWEB6) electronic control remote (ECFWER6) electromechanical control built-in (ECFWMB6)The electronic control consists of: Operating mode selector, to turn the fan coil on and off,to choose the type of operating mode (automatic or atfixed speed) and to control the electric heating. Cooling / Heating selector Operational LEDs that indicates the current operationmode Thermostat to control the room temperature Free contacts for external enabling signal that may switchon or off the unit. Free contacts for centralized cool/heat changeover Water temperature probe Air temperature probePower interface / master slave interfaceAn additional interface is required for units with acurrent greater than 1,12A.Master slave interface (EPIMSA6: 4x3A)For remote control of up to 4 fan coil units, an optionalmaster/slave interface can be installed. Up to 3 EPIMSA6can be connected in parallel (-- max. 12 fan coils).Power interface (EPIA6: 1x16A)This is absolutely required for connection of ECFWER6 toFWD12 to18. It can be used as an alternative for EPIMSA6for all other fan coils.vSeveral configurations are possible by changing dip switches.01FWV/L/MvFWBs/usMaster slave interface is only needed in case of remotecontrol of multiple fan coil unitsObigation to use master slave interface or power interfaceObligation to use power vu/svu/svu/sBasic controlfunctionsOptions121618sssControl features2-pipe3 4-pipe3 The electromechanical controller includes a fan speedselector (3 speeds stop) and manual cool/heatchangeover. In case of the on/off valves, control can also bedone through this controller.ECFWMB6Cyan Magenta Yellow Black

MOV93585 EPCE04-25BTotal capacity (H)Sensible capacity (H)Water flowPressure dropHeating capacity (H)Water flowPressure dropHHEATINGPower inputCoil water volumeAir flowSound power levelWeight4-pipe ( ** FN)COOLINGHEATINGPower inputAir flowSound power levelWeightWater connectionsMax. absorbed currentDimensionsPower MkgFWLkgTotal capacity (H)kWSensible capacity (H)kWWater flowl/hPressure dropkPaCooling coil water volume lHeating capacity (H)kWWater flowl/hPressure dropkPaHeating coil water volume WMmmV/ /HzOption descriptionAdditional single row heat exchanger*Electric heater**2-pipe ON-OFF 3-way motor driven valvewith complete mounting kit*4-pipe ON-OFF 3-way motor driven valvewith complete mounting kit*(**)Fan stop thermostat**(only for ECFWMB6)Air intake & discharge grille front filter fixing kit for concealed modelsSupporting feet( supporting brackets covers)Supporting feet grilleManual fresh air intake louverRear panel for vertically installed unitsController - electromechanical built-in**Controller - electronic built-in water probe**Controller - electronic remote water probePower interface for connection of up to 4 FCUto a single control panelVertical drain panHorizontal drain PVA6xxxEDPHA6-xxMeasuring conditions (at nominal air flow and ESP) COOLING Air temperature entering the unit: 27 C/19 C Water temperature entering the unit 7 C Water temperature rise 5 KHEATING Room air temperature 20 C For 2 pipe units : Water inlet temperature 50 C - Water flow rate same as for the cooling test For 4 pipe units : - Water inlet temperature 70 C - Water temperature decrease 10 KCyan Magenta Yellow Black** TN (2-pipe, without valves), TV (2-pipe, with valves), FN (4-pipe, without valves)2-pipe ( ** TN or TV)COOLING01* Can be ordered factory mounted** factory mounted on requestFWV/FWL/FWM01-10C**

MOV93585 EPCE04-25B10FWB02FWB02-10AT2-pipe/4-pipe Add. Heat exchanger2-pipeAir flow rateAvailable static pressureCOOLINGHEATINGMachine weightDimensions (HxWxD)HEATINGTotal capacity (H)Sensible capacity (H)Water flowPressure dropHeating capacity (H)Water flowPressure dropHeating capacity (H)Water flowPressure dropWeightDimensionsPower input (H)Running curent (H)Sound power level (H)Power 659239x1,138x2431920.9460230V/1 .28691010.346.91,7742618.781,6471848Measuring conditionsCOOLING 2-pipe: air: 27 CDB/19 CWB - entering water 7 C - leaving water 12 CHEATING 2-pipe: air: 20 CDB - entering water 70 C - leaving water 60 CSound power level according to ISO3741 - sound pressure calculated at 1.5m distance - Q 2Option descriptionAdditional heat exchanger0203EAH04A6EAH07A63-way valve std h/e3-way valve add. h/eE2MV307A6factory mounted on requestE2MV207A6Controller electronic - remote(*) In combination with ECFWER6, EPIMSA6 or EPIA6 must be installed for FWB08-10Cyan Magenta Yellow BlackE2MV210A6factory mounted on requestFan stop thermostatMaster slave interface (*)EAH10A6E2MV310A6Electric heaterPower interface (*)09factory mounted on request2-way valve std h/e2-way valve add. h/e06YFSTA6-EPIA6EPIMSA6ECFWER610

MOV93585 EPCE04-25B11FWDFWD04-18A*2-pipe ( * T)COOLINGTotal capacitySensible capacityWater flow (H)Pressure drop (H)Heating capacityWater flow (H)Pressure drop (H)HEATING2- pipe / 4-pipe4-pipe ( * F)Available static pressureWeightCOOLINGHEATINGAvailable static pressureWeightAir flow ratePower inputWater connectionsMax. absorbed currentDimensionsSound power levelPower supplyTotal capacitySensible capacityWater flow (H)Pressure drop (H)Heating capacityWater flow (H)Pressure drop Pakgm3/hWinchAmmdBAV/ 352x1,384x7187878Measuring conditions (at nominal air flow and ESP) COOLING Air temperature entering the unit: 27 C/19 C Water temperature entering the unit 7 C Water temperature rise 5 KHEATING Room air temperature 20 C For 2 pipe units : Water inlet temperature 50 C - Water flow rate same as for the cooling test For 4 pipe units : - Water inlet temperature 70 C - Water temperature decrease 10 KOption descriptionElectric heater: small (2)Electric heater: big (2)2-pipe 3-way valve (1)4-pipe 3-way valve D2MV12A6ED2MV18A6ED4MV04A6ED4MV10A62 x ED2MV12A62 x ED2MV18A6EDDPV10A6EDDPV18A6EDDPH10A6EDDPH18A6Fan stop thermostatYFSTA6EDMFA04A6Controller - electronic remote water probe (3)Master / Slave Interface SA6-EPIA6Notes:1. The valves for FWD12-16-18 do not contain piping nor drain pan.2. Requires electronic control.3. Neglecting the absolute requirement to install an additional interface (EPIA6 or EPIMSA6) to FWD06 -- 18 may cause fire or other damage to the equipment.4. In combination with ECFWER6, EPIMSA6 or EPIA6 must be installed for FWD06-10.5. In combination with ECFWER6, EPIA6 must be installed for FWD12-18.Cyan Magenta Yellow Black18ED2MV10A6Horizontal drain panPower interface (5)16ED2MV04A6Vertical drain panFresh air intake louvers (motorised)12--

MOV93585 EPCE04-25BDaikin Europe N.V. is approved by LRQA for its QualityManagement System in accordance with the ISO9001standard. ISO9001 pertains to quality assuranceregarding design, development, manufacturing aswell as to services related to the product.ISO14001 assures an effective environmentalmanagement system in order to help protecthuman health and the environment from thepotential impact of our activities, products andservices and to assist in maintaining and improvingthe quality of the environment.Daikin units comply with the European regulationsthat guarantee the safety of the product.Zandvoordestraat 300B-8400 Oostende, Belgiumwww.daikineurope.comCyan Magenta Yellow BlackDaikin Europe NV participates in the EuroventCertification Programme for Air Conditioners (AC),Liquid Chilling Packages (LCP) and Fan Coil Units(FC); the certified data of certified models are listedin the Eurovent Directory.The present publication is drawn up by way of information onlyand does not constitute an offer binding upon Daikin EuropeN.V. Daikin Europe N.V. has compiled the content of thispublication to the best of its knowledge. No express or impliedwarranty is given for the completeness, accuracy, reliability orfitness for particular purpose of its content and the productsand services presented therein. Specifications are subject tochange without prior notice. Daikin Europe N.V. explicitly rejectsany liability for any direct or indirect damage, in the broadestsense, arising from or related to the use and/or interpretation ofthis publication. All content is copyrighted by Daikin Europe N.V.Daikin products are distributed by:EPCE04-25B / CD / 04/06 La MovidaPrinted on non-chlorinated paper / Printed in BelgiumDaikin’s unique position as a manufacturer ofair conditioning equipment, compressors andrefrigerants has led to its close involvement inenvironmental issues. For several years Daikinhas had the intention to become a leader inthe provision of environmental friendlyproducts. This challenge demands the ecodesign and development of a wide range ofproducts and an energy managementsystem; which involves energy conservationand reduction of waste.

Fan coil units are a highly efficient means of turning a water chiller or hot water boiler into an efficient, quiet air conditioning system. The units are super quiet because the only moving par t is the fan; making them ideal for use in offices, hotels and the home. The new range of fan coil units offers 5 models, of which 3 in flexible .