Transcription

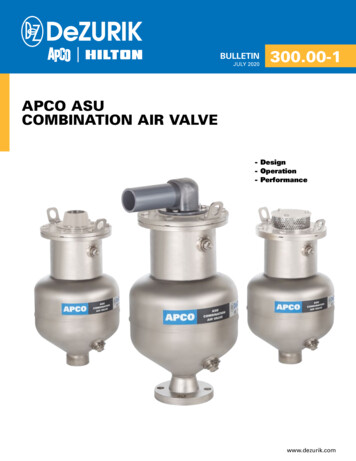

BULLETIN 10.00-10MAY 2012APCO INDUSTRIAL CHECK VALVESDouble DoorCheck ValveWafer - Silent Check ValveGlobe - Silent Check ValveSwing Check ValveSlanting Disc Check ValveRubber Flapper Check Valve

APCO Double DoorCheck ValvesAPCO Wafer –Silent Check ValvesDesign and ConstructionDouble Doors are spring loaded for fast non-slamshut–off against the elastomer body seat. APCODouble Door check valves are available with luggedor wafer bodies in sizes 2–60" (50mm–1500mm).Very short length, results in lowest purchaseand installation costs.Materials of ConstructionAPCO Double Door check valves are regularlysupplied in Ductile Iron, Bronze, Carbon Steel, 316Stainless Steel, 410 Stainless Steel or Monel Bodyand Door Materials. Spring and Hinge Pin are 316Stainless Steel or Inconel. Resilient Seat materialsinclude CR, EPDM, FKM, NBR, or SiliconeIndustry StandardsAPI 594 – C lass 125, 150, 250, 300 &400 Valve DesignDesigned to open at approximately 0.25 to 0.5 psi(2–3 kpa) for complete closure upon pumpshut down – before flow can reverse itself.APCO Wafer – Silent Check Valves are availablein sizes 1–10" (25–250mm). Stops reverse flow,a major cause of water hammer, before it starts.Materials of ConstructionAPCO Wafer – Silent Check Valves are regularlysupplied with Ductile Iron, Carbon Steel, 304 or 316Stainless Steel Body Materials. Ductile Iron, 304,316, or Bronze Plug Materials. 313 Stainless SteelSpring Material. Metal, NBR, FKM or EPDMSeat Materials.API 598 – Valve Pressure Testing and InspectionIndustry StandardsAPI 6D/ISO 14313 – Pipeline Valve Pressure ClassesMSS SP-125 – G ray Iron and Ductile Iron In-Line,Spring-Loaded, Center-GuidedCheck ValvesASME B16.10 – Face-to-FaceASME B16.34 – Pressure/Temperature RatingsASME B16.5 & B16.47 – V alves with integratedflanges. All Valves aredesigned to acceptmating flangesApplicationsRecommended for Clean Liquids and Gasses inRefineries, Petro-Chemical Plants and for HVACapplications.2Design and Construction 2012 DeZURIK, Inc.MSS SP-126 – S teel In-Line Spring-Assisted CenterGuided Check ValvesApplicationsRecommended for Commercial and IndustrialHVAC applications such as heating systems andcondensate return lines.

APCO Globe –Silent Check ValvesAPCO SwingCheck ValvesDesign and ConstructionDesign and ConstructionDesigned to open at approximately 0.25 to 0.5 psi(2–3 kpa) for complete closure upon pumpshut down – before flow can reverse itself.APCO Globe – Silent Check Valves are availablein sizes 3–42" (80–1100mm). Stops reverse flow,a major cause of water hammer, before it starts.Heavily constructed with full unobstructed flow.Available with Air Cushion (fast closing) or OilControl (slow closing). APCO Swing Check Valvesare available in sizes 2–72" (50–1800mm).Cushions/controls reduce pressure surges, slamand water hammer.Materials of ConstructionMaterials of ConstructionAPCO Globe Silent Check Valves are regularlysupplied with Ductile Iron, Carbon Steel, 304 or 316Stainless Steel Body Materials. Ductile Iron, 304,316, or Bronze Plug Materials. 313 Stainless SteelSpring Material. Metal, NBR, FKM or EPDMSeat Materials.APCO Swing Check Valves are regularly suppliedwith Ductile Iron or Cast Iron Body Materials withCast Iron, Ductile Iron, Aluminum Bronze, 304 or 316Body Seat Materials. Ductile Iron Disc with Bronzeor 316 Stainless Steel Metal Disc Seat Materials,NBR, FKM or EPDM Resilient Disc Seat Materials.303, 304 or 17-4PH Stainless Steel Shaft Materials.Industry StandardsMSS SP-125 – G ray Iron and Ductile Iron In-Line,Spring-Loaded, Center-GuidedCheck ValvesMSS SP-126 – S teel In-Line Spring-Assisted CenterGuided Check ValvesApplicationsRecommended for Commercial and IndustrialHVAC applications such as heating systems andcondensate return lines.Industry StandardsMSS SP-71 – Testing Gray Iron Swing Check ValvesMSS SP-136 – T esting Ductile Iron SwingCheck ValvesASME B16.1 – G ray Iron Pipe Flanges andFlanged FittingsASME B16.5 – Conforms to Bolt Pattern and DrillingApplicationsRecommended for clean and dirty applications suchas Industrial Water or Raw Waste Water Service.3

APCO Slanting DiscCheck ValvesAPCO Rubber FlapperCheck ValvesDesign and ConstructionRugged yet uniquely simple design with only threemajor parts. APCO Rubber Flapper Swing CheckValves are available in sizes 2–48" (50-1200mm).Durable and requires virtually no maintenance.Materials of ConstructionDesign and ConstructionSplit body design with slant disc position producessuperior flow characteristics creating very low headloss. APCO Slanting Disc Check Valves are availablein sizes 2–72" (50–1800mm). Most reliable andefficient check valve available.Materials of ConstructionAPCO Slanting Disc Check Valves are regularlysupplied with Ductile Iron, Cast Iron Carbon Steelor 316 Stainless Steel Body Materials. Bronze,Ductile Iron, Carbon Steel or 316 Stainless SteelDisc Materials. Bronze or 316 Stainless Steel SeatMaterials. 303 Stainless Steel Pivot Pin Material.Industry StandardsASME B16.34 – P ressure/Temperature Ratings,Class 150 through 20", Class 300through 14"ASME B16.1 – G ray Iron Pipe Flanges andFlanged FittingsASME B16.5 – Conforms to Bolt Pattern and DrillingMIL-V-18436F – Conforms to Slanting Disc CheckValves with Bottom Buffer with CastIron or Carbon Steel Body Materialswith the exception of face-to-facedimensionsApplicationsRecommended for clean Industrial Water and otherIndustrial Applications.4APCO Rubber Flapper Swing Check Valves areregularly supplied with Ductile Iron, Cast Ironor Bronze Body Materials. Bodies are availableUnlined or Lined with Chloroprene (CR), NaturalRubber, NBR or EPDM Elastomers. NBR,Chloroprene (CR), FKM or EPDM Flapper Materials.Industry StandardsMIL-V-18436 F – C onforms to Material Requirementsof Group A, Type III, Trim 1, BronzeSwing Check ValvesApplicationsRecommended for a variety of Industrial Liquids,Waste Water or Slurry Applications.

Other DeZURIK APCO Willamette Industrial ProductsIsolation ValvesButterfly ValvesKnife Gate ValvesPorted Gate ValvesSpecialty Service ValvesDeZURIKControl Valves100% Eccentric Plug ValvesHigh Performance ButterflyV-Port Ball ValvesRotary Control ValvesCoal BurnerIsolation ValvesSevere Service ValvesHigh PerformanceGate Valves3 & 4 Way ValvesPulp and PaperUrethane LinedGate ValvesResilient LinedEccentric Plug ValvesConsistency TransmittersOtherAPCOAir ValvesBasis Weight Control ValvesAir Release ValvesAir/Vacuum ValvesCombination Air ValvesPump Priming SystemsWillamettePlus many others:Pump Check ValvesBalancing ValvesBi-Directional Knife Gate ValvesDust Collector Gate ValvesSquare/Rectangular Knife Gate ValvesSledge Hammer ValvesBonneted Knife Gate ValvesPump Priming ValvesPump Protector ValvesAnd more, see our website at www.dezurik.com or contact yourDeZURIK Representative for additional informationMetal Seated Cone Valves5

APCO Check Valve Selection Guide FeatureFeatureCushionSwingCheckValveDoubleDoor Globe)AutomaticControlCheckValveLowest Initial CostShortest Laying LengthHighest Head LossLowest Head LossResilient Seat (Standard)Resilient Seat (Optional)Metal Seat (Optional)Can be Rubber LinedWaste Water and Raw SewageClean WaterBuried ServiceVertical Installation (Flow Up or Down)Vertical Installation (Flow Up Only)Free Open - Free CloseSilent Closing CharacteristicsCushion ClosingControl Open and Close (Standard)Control Close (Optional)Remote ControlShut Off ValveThrottling ValveReverse Flow (For Draining)Electric Motor OperatedDisc Position Indicator125/300# ClassOutside Lever AvailableUp to 250/300# ClassUp to 600# ClassUp to 1500# ClassVelocities to 10 FPSVelocities to 15 FPSVelocities in Excess of 15 FPSNote: This valve selection chart is designed to provide you with a quick reference on valve style capabilities. The chart considers both cost andperformance factors for a specific application when determining whether a valve style is rated Typical, May Be Used, or Limited Application.For more information, contact DeZURIK, Inc. or your local representative with your specific application requirements.6

DeZURIK Valve Selection Chart1 Typical Application2 May Be Used3 Limited rtPerformance Eccentric Eccentric4 Not UsedGate Valves3-Way&4-WayKnifeGatePortedGateRotary sion3334414444Media:Liquids (Clean)1111111311Liquids (Dirty)2231111111Liquids (Viscous)2121111111Liquids (Corrosive)4211112111Slurries (Sludge)2231111111Liquids & Slurries(Scaling)4442244123Slurries (Abrasive)4322221113Slurries (Fibrous)4222211141High Pressure Steam( 150lbs.)4414444413Low Pressure Steam4413434311Gasses (Clean)1111112211Gasses (Dirty)2231112211Gasses (Corrosive)4211112211Dry Materials4242241144Valve Characteristics:High Flow Capacity1112111111Low Head Loss(Wide Open)11121111N/A1Low Torque/Thrust2212212221High Temp., 800 F (425 C )4433441434Cryogenic44344444244321131113Cavitation (Kc) @ 60% OpenErosion Resistance.35.35.35.59.59N/AN/AN/A.60.49Recovery FactorFL2 @ 60% Open.40.40.43.70.70N/AN/AN/A.70.61Shutoff ClassAWWAC504ANSI VIor betterANSI IV, V,VI or betterANSI IV,VI orbetterANSI VIorbetterN/ATAPPIClass VIor BetterANSIIV-VIANSI II,IV, VI ORBETTERPressure RatingAWWA25, 75,150 &250200/250 psiCWPANSI150 & 300125450 psiCWP150175 psiCWP125 psiCWPANSI150 &300100/150ANSIpsi CWP 150-300ANSI150 &300Note: This valve selection chart is designed to provide you with a quick reference on valve style capabilities. The chart considers both cost andperformance factors for a specific application when determining whether a valve style is rated Typical, May Be Used, or Limited Application.For more information, contact DeZURIK, Inc. or your local representative with your specific application requirements.7

Sales and ServiceFor information about our worldwide locations, approvals, certifications and local representative:Web Site: www.dezurik.com E-Mail: info@dezurik.com250 Riverside Ave. N. Sartell, Minnesota 56377 Phone: 320-259-2000 Fax: 320-259-2227DeZURIK, Inc. reserves the right to incorporate our latest design and material changes without notice or obligation.Design features, materials of construction and dimensional data, as described in this bulletin, are provided for your information onlyand should not be relied upon unless confirmed in writing by DeZURIK, Inc. Certified drawings are available upon request.Printed in the U.S.A.

Isolation Valves Air Valves 5 Other DeZURIK APCO Willamette Industrial Products APCO Willamette Metal Seated Cone Valves Plus many others: Pump Check Valves Balancing Valves Bi-Directional Knife Gate Valves Dust Collector Gate Valves Square/Rectangular Knife Gate Valves Sledge Hammer Valves Bonneted Knife Gate Valves Pump Priming Valves Pump Protector Valves And more, see our