Transcription

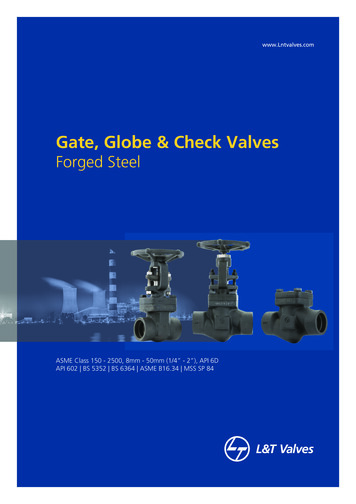

Gate, Globe & Check ValvesForged SteelASME Class 150 - 2500, 8mm - 50mm (1/4” - 2”), API 6DAPI 602 BS 5352 BS 6364 ASME B16.34 MSS SP 84

L&T Valves Limited is a wholly owned subsidiary of Larsen & Toubro. Backed by an fif ty-year track-record of excellence andworld-leading innovation, the company provides engineered flow-control solutions for key sectors of the economy.L&T Valves Limited is synonymous with world-class manufacturing and quality assurance systems. Our plants have the agilityand flexibility to deliver a wide variety of valves against time constraints and dynamic market demands. International safety,health and environment standards govern every phase of the manufacturing process.ASMEClass800Gate Valvesscrewed/sock.wldsock.wldBS 5352flangedscrewed/sock.wldGlobe & CheckValvesflangedBS API5352 602Bellows-SealedGate Valves screwed/Bellows-Sealed sock.wldGlobe Valvesscrewed/sock.wldCryogenicGate & GlobeflangedValvesASME B16.34/MSS SP 84Y-patternscrewed/Globe Valvessock.wld/Y-patternCheck Valves 015002500150025001/4” 3/8” 1/2” 3/4” 1” 11/4” 11/2” RBFBRBFBRBFBFBFBFBFB RB - Reduced Bore - bore conforms to BS 5352 Reduced Bore and API 602 Standard PortFB - Full Bore - bore conforms to BS 5352 Standard BoreSP - Standard Port - bore conforms to API 602 Standard Port02L&T Manufacturing ProgrammeEndConn.API 602 / BS 5352ValveTypeBS 6364DESIGN STANDARDIntroductionL&T Forged Steel Gate, Globe and Check Valves have established themselves the world over for their quality, reliabilityand long service. Rugged and compact in design, these valves are manufactured to the latest international designs usingadvanced manufacturing techniques and stringent quality control checks. The valves are regularly supplied to major Indianand international clients including oil refining companies and EPC contractors. They are available in a range of sizes startingfrom 1/4” to 2” (in reduced-bore design) and from 3/8” to 11/2” (in full-bore design).

ValveTypeH Y D R O S T A T I CSeat ClosureBack 2112200155800B’SealedGlobe- for other materials30002112200155High Pressure Low Pressurepsikg/cm2 5163011541029220015555039-2200--155Working Pressure (in psi)A I R---* Test pressure values are for ASTM A105 and LF2 materials of construction.For other materials, substitute corresponding figures from the table alongside. Forcheck valves, low pressure hydrostatic closure test is carried out at 25% of the highpressure closure pliance StandardsValve TypeValve DesignFace-to-facedimensionGate ValvesAPI 602*BS 5352L&T StandardEnd Connection(screwed/socket-weld/butt-weld)Globe andCheck Valves BS 5352*ASME B1.20.1 (NPT) BS 21 / ISO 7(screwed - taper)BS 2779 / ISO 228 BS 21 / ISO 7(screwed - parallel)ASME B16.11ASME B16.10BS 2080Cryo Gate &BS 6364Globe Valves(socket-weld)(flanged)Y-Globe and ASME B16.34Check Valves MSS SP 84ASME B16.5 RF 125-250 Ra(flanged)see page 10L&T StandardPressure / Temp.rating**Valve inspectionand testingAPI 602ASME B16.34API 598BS 5352BS 5352ASME B16.34Technical InformationPressure testing as per API 598 - for ASTM A105 and LF2*API 598BS 5352BS 6364API 598 BS 5352BS 6364ASME 16.34API 598For Class 150 valves, the flange drilling dimensions will be as per Class 150 and all other dimensions as per Class 300.End flanges are welded onto the body.Bellows-Sealed Gate and Globe valves conform to BS 5352.Socket-weld Class 800 Reduced Bore valves conform to Class 3000 (or Sch.80/Sch.XS) fit tings of ASME B16.11.Socket-weld Class 800 Full Bore valves conform to Class 6000 (or Sch.160) fit tings of ASME B16.11.Socket-weld Class 1500 Standard Port valves conform to Class 9000 (or Sch.X XS) fit tings of ASME B16.11.*Full Bore design also conforms to ASME B16.34 ** API 602/BS 5352 for Class 800 and ASME B16.34 for Class 150/300/600/1500/2500.Ordering Information - Straight-pattern ��2”Valve TypePressure Class2 - Gate5 - Globe8 - Check13568-End ConnectionClass 150Class 300Class 1500Class 600Class 8001234-Screwed NPTSocket-weldFlangedScrewed BSPparallel5 - Screwed BSPtaperOrdering Information - Y-pattern ValvesSize15 20 25 40 50 -15mm20mm25mm40mm50mmValve typePressure ClassEnd ConnectionGLOBE6 - Scr. Bonnet7 - Seal-weldedBonnet15- Class 150025- Class 25003 - Butt-weld4 - Screwed NPT5 - Socket-weldCHECK8 - Scr. Cap9 - Seal-weldedCapTrimBody Material01 - 13% Cr.05 - HF08 - 13% Cr. HFNIL - A105LF2F5F11F22F304 / F304LF316 / F316LF347MonelAPI Trim Nos.10, 12, etc.,also availableTrimU - ed / Standard BoreFull BoreWelded BonnetLocking ArrangementElectrical ActuatorBellows-SealedCryogenicOptionsBody materialNIL - A105F11F22F316F316LF347NIL - StandardIBR - IBR-certifiedFamiliarity with our catalogue numbering is not necessary when specif ying or ordering our valves. A fulldescription of the valve provided by you is translated into a catalogue number as per the system shown.For any other special requirement, add SPL to the catalogue number and provide details.03

L&T Straight-pattern ValvesStraight-pat tern Gate/Globe/Check ValvesSalient features Bolted body-bonnet design for valves up to Class 800.Valves with welded bonnet also available on request Screwed with seal-welded body-bonnet designfor valves of Class 1500 Bellows-sealed Gate and Globe valves available in Class800 Bolted body-bonnet joints provided with spiral-woundstainless steel gasket and graphite filler for maximumprotection against leaks Die-formed graphite inner packing rings and braidedgraphite end rings with Inconel wire reinforcement andcorrosion inhibitor T-head stem-disc connection of gate valve fully meetsstrength requirements of API 602 and API 598 Rolled ACME thread on stem for smooth operation Tapered shoulder on the stem for back seating Self-aligning type gland assembly with stud-and-nuttightening Integral hard-faced body seat for globe and check valves Spring-loaded disc on check valves suitable for nonhorizontal applications too Gate and globe valves can be of fered with electricalactuators Austenitic SS forging for body and bonnet of Cryogenicvalves, resulting in excellent impact strength, minimal heatloss and resistance to corrosion Valves can be of fered to NACE MR-0175 and other specialNACE requirements Valves can be supplied with IBR certificationBody and Trim CombinationsBody & Bonnet/CoverASTM A105ASTM A182 Gr. F5ASTM A182 Gr. F9ASTM A182 Gr. F11ASTM A182 Gr. F22ASTM A182 Gr. F304ASTM A182 Gr. F316ASTM A350 Gr. LF2Trim numbers01 / 08 / 0508 / 0508 / 0508 / 0508 / 0502 / 1510 / 12 / 1608 / 16Other materials of construction such as F316L / F304L also available.Trim MaterialsL&T Forged Steel Valves are of fered with trims shown below, to suit a variety of services.Trim No.(API 602)01Gate Valves08Gate, Globe and Check Valves050210121504Valve Type16StemMaterialSeating SurfacesDiscBody SeatASTM A479 Type 41013% Cr. Steel13% Cr. SteelGate, Globe and Check ValvesASTM A479 Type 410HFHFGate ValvesASTM A479 Type 304SS 304SS 304HFGate ValvesASTM A479 Type 410ASTM A479 Type 31613% Cr. SteelSS 316Gate, Globe and Check ValvesASTM A479 Type 316SS 316Gate, Globe and Check ValvesASTM A479 Type 316SS 316 HFGate, Globe and Check ValvesASTM A479 Type 304HF - Hard Faced with Cobalt-Chromium-Tungsten alloy (Stellite #6)SS 304 HFHFSS 316HFHF

Material Specification (Typical for Fig No. 28101)Sl. No.Part DescriptionSpecification12345BodyBonnetStemWedge DiscBody Seat RingASTM A105ASTM A105ASTM A479 Type 410ASTM A217 Gr. CA15ASTM A276 Type 4107GasketSpiral-wound SS type 304with graphite filler6Graphite moulded rings withbraided top / bottom ringsStem packing8910Cap ScrewsGland BushGland Flange11ASTM A193 Gr. B7ASTM A276 Type 410ASTM A105ASTM A276 Type 410 /ASTM A194 Gr. 2HGland Stud / Nut12131415Yoke SleeveIdentification PlateHandwheelHandwheel NutASTM A582 Type 416Aluminium (anodised)SG Iron / SteelSteelScrewed/Socket-weld ends (in inches, unless specified)Class800CValve size1/4 (8)**3/8 (10)1/2 (15)3/4 (20)1 (25)11/4 .946.010.010.011.410.02 (50)** 5.1211.44.70FB1/210GD 2.4060.627.25-4.005.505.507.25Flanged ends (in inches, unless specified)Class 600C L A S SValve sizeinch (mm)A1/2 (15)1 (25)3/4 (20)11/4 (32)11/2 (40)2 1.511.49.57.510.0-6 0 0G A T .751.502.00-Class 150/300C L A S SValve sizeinch (mm)A1/2 (15)1 (25)3/4 (20)11/4 (32)11/2 (40)2 (50)1 5 0 / 3 0 p. Wt. G A T 04.254.620.8213.519.2V A L V E S3.755.57.111.3EClass 3005.15.50øDClass 2.00.560.88Flanged ends (in inches, unless specified)1.6FB0.811.611.6RB0.621.38-V A L V E SE0.821.25SApp. Wt. 5AF0.6901.33011/4200.8553/410.0--3/86.27.54.7011/2 (40)ABAinch .070.887.25-7.510.011.45.006.12L&T Straight-pattern ValvesGate Valves1.610.815.507.2505

Material Specification (Typical for Fig No. 25101)Sl. No.Part DescriptionSpecification1BodyASTM A1054Wedge DiscASTM A217 Gr. CA152Bonnet3Stem5Gland Bush10Gland Stud / Nut9ASTM A582 Type 416Aluminium (anodised)Handwheel14SG Iron / SteelHandwheel NutSteelF L A N G E DE N D SBCD 507.251.102 11.00 10.926.252.4060.6214.00 1.500 14.50 19.108.50(15)(25)11/4 (32)11/2 (40)2ASTM A276 Type 410 /ASTM A194 Gr. 2HAinch (mm)1ASTM A105Identification Plate133/4ASTM A276 Type 410Yoke Sleeve121/2Graphite moulded rings withbraided top/bottom ringsGland Flange113/8Spiral-wound SS type 304with graphite fillerStem packing8SCREWED / SOCKET-WELD ENDSASTM A276 Type 410Gasket7Valve sizeASTM A479 Type 410Body Seat Ring6Class 1500 Standard Port (in inches)ASTM 507.250.3758.509.000.625 10.007.327.501.102 12.00 1.127.251.1022.001.5014.00 1.5001.501.25Class 800 - Reduced Bore and Full Bore (for dimensions, refer to L&T)Material Specification (Standard)06Part Description123BodyPipe (top/bottom)Stem0.3751.00Bellows-Sealed Gate and Globe ValvesSl. No.4.00SpecificationASTM A105, in-situ stellited seatASTM A105ASTM A479 Type 316ASTM A351 Gr. CF8M,4Discseat face stellitedASTM A276 Type 316,5Seat Ringseat face stellitedSpiral-wound SS 3166Gasketwith graphite filler7BellowsSS 316L8Cap ScrewASTM A193 Gr. B79GuideASTM A276 Type 31610BonnetASTM A10511PackingGraphite rings with braided end rings12GlandASTM A276 Type 31613Gland FlangeASTM A10514StudASTM A276 Type 41015NutASTM A194 Gr. 2H16Yoke SleeveASTM A582 Type 41617HandwheelSG Iron / Mall. Iron18Plug (1/16 NPT)Carbon SteelNote : Valves are available with screwed and socket-weld ends.For dimensions, refer to L&T5.507.250.6251.102For weights, refer to L&TL&T Straight-pattern ValvesGate Valves

Material Specification (Typical for Fig No. 58108)Sl. No.Part Description1Body2ASTM A1053StemASTM A479 Type 4105Stem packingPlug Disc6ASTM A217 Gr. CA15Graphite moulded rings withbraided top / bottom ringsSpiral-wound SS type 304with graphite fillerGasket7Cap Screws8ASTM A193 Gr. B7Gland Bush9ASTM A276 Type 410Gland FlangeASTM A10510Gland Stud / Nut12Identification Plate11ASTM A276 Type 410 /ASTM A194 Gr. 2HYoke Bush13ASTM A582 Type 416Aluminium (anodised)Handwheel14Class800ASTM A105, in-situ stellited seatBonnet4SpecificationSG Iron / SteelHandwheel NutSteelScrewed/Socket-weld ends (in inches, unless specified)CValve sizeinch (mm)A1/4 (8)3.203/8 (10)1/2 (15)3/4 (20)1 (25)11/4 (32)11/2 (40)2 (50)Class 600Class150/300SRBFB5.8-1/4-6.47.75.83 /81 0SC5.89.611.6-111/42G11/2E0.5550.38OC L A S SValve sizeABinch (mm)RBFBRBFB1/2 (15)6.56.55.86.41 (25)8.58.57.79.69.511.5*9.611.611/4 (32)11/2 (40)2 (50)7.59.011.57.59.0-6.47.79.69.611.6-C L A S Sinch 4.003.251.442.4060.626 0 07.25G L O B .750.821.251.381.501.612.00-10.8-V A L V E SøFApp. Wt. .620.810.881.00G L O B 9.554.259.011.5*9.5511.605.256.126.507.413.5-V A L V E 2.4RB1 .256.010.56.75.506.02 (50)6.80.505.50C9.551.171.9155.501/2 (15)9.553.60.94Class 3008.52.40.69Class 1508.50.695.50FB11/2 (40)1.74.00RB11/4 (32)0.50-1.70.501 5 0 / 3 0 07.700.381.330FB6.350.25SApp. Wt. langed ends (in inches, unless specified)Valve sizeB0.6901.675-LD (min)0.8553 /49.60Flanged

Y-Globe and ASME B16.34 ASME 16.34 API 598 Check Valves MSS SP 84 L&T Standard (screwed/socket-weld/ butt-weld) ASME B16.10 BS 2080 (flanged) ASME B1.20.1 (NPT) BS 21 / ISO 7 (screwed - taper) ASME B16.5 RF 125-250 Ra (flanged) L&T Standard ASME B16.11 (socket-weld) BS 2779 / ISO 228 BS 21 / ISO 7 (screwed - parallel) API 602* BS 5352 For Class 150 valves, the