Transcription

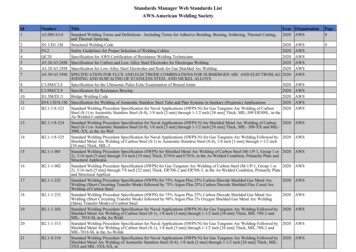

Standards Manager Web Standards ListAWS-American Welding B2.1-8-310TitleStandard Welding Terms and Definitions - Including Terms for Adhesive Bonding, Brazing, Soldering, Thermal Cutting,and Thermal SprayingStructural Welding CodeSafety Guidelines for Proper Selection of Welding CablesSpecification for AWS Certification of Resistance Welding TechniciansSpecification for Carbon and Low-Alloy Steel Electrodes for Electrogas WeldingSpecification for Low-Alloy Steel Electrodes and Rods for Gas Shielded Arc WeldingSPECIFICATION FOR FLUX AND ELECTRODE COMBINATIONS FOR SUBMERGED ARC AND ELECTROSLAGJOINING AND SURFACING OF STAINLESS STEEL AND NICKEL ALLOYSSpecification for the Ultrasonic Pulse-Echo Examination of Brazed JointsSpecification for Resistance BrazingBridge Welding CodeSpecification for Welding of Austenitic Stainless Steel Tube and Pipe Systems in Sanitary (Hygienic) ApplicationsStandard Welding Procedure Specification for Naval Applications (SWPS-N) for Gas Tungsten Arc Welding of CarbonSteel (S-1) to Austenitic Stainless Steel (S-8), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL-309 ER309L, in theAs-Welded Condition,Standard Welding Procedure Specification for Naval Applications (SWPS-N) for Shielded Metal Arc Welding of CarbonSteel (S-1) to Austenitic Stainless Steel (S-8), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL- 309-XX and MIL309L-XX, in the As-WelStandard Welding Procedure Specification for Naval Applications (SWPS-N) for Gas Tungsten Arc Welding Followed byShielded Metal Arc Welding of Carbon Steel (S-1) to Austenitic Stainless Steel (S-8), 1/8 inch [3 mm] through 1-1/2 inch[38 mm] Thick, MIL-3Standard Welding Procedure Specification (SWPS) for Shielded Metal Arc Welding of Carbon Steel (M-1/P-1, Group 1 or2), 3/16 inch [5 mm] through 3/4 inch [19 mm] Thick, E7016 and E7018, in the As-Welded Condition, Primarily Plate andStructural ApplicatioStandard Welding Procedure Specification (SWPS) for Gas Tungsten Arc Welding of Carbon Steel (M-1/P-1, Group 1 or2), 3/16 inch [5 mm] through 7/8 inch [22 mm] Thick, ER70S-2 and ER70S-3, in the As-Welded Condition, Primarily Plateand Structural ApplicatStandard Welding Procedure Specification (SWPS) for 75% Argon Plus 25% Carbon Dioxide Shielded Gas Metal ArcWelding (Short Circuiting Transfer Mode) followed by 75% Argon Plus 25% Carbon Dioxide Shielded Flux Cored ArcWelding of Carbon SteelStandard Welding Procedure Specification (SWPS) for 75% Argon Plus 25% Carbon Dioxide Shielded Gas Metal ArcWelding (Short Circuiting Transfer Mode) followed by 98% Argon Plus 2% Oxygen Shielded Gas Metal Arc Welding(Spray Transfer Mode) of Carbon SteelStandard Welding Procedure Specification for Naval Applications (SWPS-N) for Gas Tungsten Arc Welding Followed byShielded Metal Arc Welding of Carbon Steel (S-1), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL-70S-2 andMIL- 7018-M, in the As-WeldStandard Welding Procedure Specification for Naval Applications (SWPS-N) for Gas Tungsten Arc Welding Followed byShielded Metal Arc Welding of Carbon Steel (S-1), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL-70S-2 andMIL-7018-M, in the As-WeldeStandard Welding Procedure Specification for Naval Applications (SWPS-N) for Gas Tungsten Arc Welding Followed byShielded Metal Arc Welding of Austenitic Stainless Steel (S-8), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL3XX and MIL-3XX-XX, inYear Organization2020 2020AWS2020AWS2020AWS2020AWS2020AWS2020AWS2020AWS

2.1-1-20952D17.2/D17.2MStandard Welding Procedure Specification for Naval Applications (SWPS-N) for Gas Tungsten Arc Welding Followed byShielded Metal Arc Welding of Austenitic Stainless Steel (S-8), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL3XX and MIL-3XX-XX, inGuide to Installation and Maintenance of Resistance Welding MachinesStandard Symbols for Welding, Brazing, and Nondestructive ExaminationStandard Procedures for Calibrating Magnetic Instruments to Measure the Delta Ferrite Content of Austenitic and DuplexFerritic-Austenitic Stainless Steel Weld MetalStandard Methods for Classification Testing of Positional Capacity and Root Penetration ofWelding Consumables in aFilletWeldStandard Method for Evaluation of Brazed Joints Using Visual andMetallographic TechniquesSpecification for the Design of Welded Joints in Machinery and EquipmentSpecification for Use and Performance of Transparent Welding Curtains and ScreensSpecification for Classification of Weld-Through Paint PrimersSpecification for Welding Earthmoving and Construction EquipmentRailroad Welding Specification for Cars and LocomotivesSpecification for Fabrication of Metal Components using Additive ManufacturingGuide for the Joining of Solid Solution Austenitic Stainless SteelsRecommended Practices for Resistance WeldingSpecification for the Qualification of Resistance Welding TechniciansStandard Method for Evaluating the Strength of Brazed JointsBridge Welding Code - 7th Edition; Interim RevisionWelding Consumables Procurement of Filler Metals and FluxesSpecification for Filler Metals for Brazing and Braze WeldingSpecification for Carbon Steel Electrodes and Fluxes for Submerged Arc WeldingSpecification for Nickel-Alloy Electrodes for Flux Cored ArcWeldingStandard Welding Procedure Specification (WPS) for Shielded Metal Arc Welding of Carbon Steel (M-1/P-1/S-1, Group 1or 2), 1/8 Through 3/4 Inch Thick, E6010 (Vertical Uphill) Followed by E7018 (Vertical UphillStandard Welding Procedure Specification (WPS) for Shielded Metal Arc Welding of Carbon Steel (M-1/P-1/S-1, Group 1or 2), 1/8 Through 3/4 Inch Thick, E6010 (Vertical Downhill) Followed by E7018 (Vertical UphiStandard Welding Procedure Specification (WPS) for Shielded Metal Arc Welding of Carbon Steel (M-1/P-1/S-1, Group 1or 2), 1/8 Through 3/4 Inch Thick, E6010 (Vertical Uphill), As-Welded Condition (Primarily PiStandard Welding Procedure Specification (WPS) for Shielded Metal Arc Welding of Carbon Steel (M-1/P-1/S-1, Group 1or 2), 1/8 Through 3/4 Inch Thick, E6010 (Vertical Downhill Root with the Balance Vertical UpStandard Welding Procedure Specification (WPS) for Shielded Metal Arc Welding of Carbon Steel (M-1/P-1/S-1, Group 1or 2), 1/8 Through 1-1/2 Inch Thick, E6010 (Vertical Uphill) Followed by E7018 (Vertical UphiStandard Welding Procedure Specification (WPS) for Shielded Metal Arc Welding of Carbon Steel (M-1/P-1/S-1, Group 1or 2), 1/8 Through 1-1/2 Inch Thick, E6010 (Vertical Downhill) Followed by E7018 (Vertical UpStandard Welding Procedure Specification (WPS) for Gas Tungsten Arc Welding of Carbon Steel (M-1/P-1/S-1, Group 1or 2), 1/8 Through 1-1/2 Inch Thick, ER70S-2, As- Welded or PWHT Condition (Primarily Pipe ApplStandard Welding Procedure Specification (WPS) for Shielded Metal Arc Welding of Carbon Steel (M-1/P-1/S-1, Group 1or 2), 1/8 Through 1-1/2 Inch Thick, E7018, As-Welded or PWHT Condition (Primarily Pipe AppliStandard Welding Procedure Specification (WPS) for Gas Tungsten Arc Welding Followed by Shielded Metal ArcWelding of Carbon Steel (M-1/P-1/S-1, Group 1 or 2), 1/8 Through 1-1/2 Inch Thick, ER70S-2 and E7018,Specification for Resistance Welding for Aerospace Applications - 3rd 019AWS02019AWS02019AWS02019AWS02019AWS02019AWS00

53B2.1-1-0265455F3.2NAVSEA B2.11-30156B2.1-8-02357NAVSEA EA 31678B2.1-1-022Standard Welding Procedure Specification (SWPS) for Shielded Metal Arc Welding of Carbon Steel (M-1/P-1, Group 1 or2) 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, E6010 (Vertical Downhill) Followed by E7018, in the As-Welded orPWHT Condition, PrimaVentilation Guide for Weld Fume - 2nd EditionStandard Welding Procedure Specification for Naval Applications (SWPS-N) for Gas Tungsten Arc Welding of CarbonSteel (S-1), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL-70S-2, in the As-Welded or PWHT Condition,Primarily Plate and Structural NaStandard Welding Procedure Specification (SWPS) for Shielded Metal Arc Welding of Austenitic Stainless Steel (M-8/P-8Group 1) 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, in the As-Welded Condition, Primarily Plate and StructuralApplications - 2ndStandard Welding Procedure Specification for Naval Applications (SWPS-N) for Gas Tungsten Arc Welding of CarbonSteel (S-1), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL-70S-2, in the As-Welded or PWHT Condition,Primarily Pipe for Naval ApplicatBridge Welding Code - 7th Edition; Interim RevisionSpecification for Robot Arc Welding Training and Testing Cell - 1st EditionSpecification for Carbon and Low-Alloy Steel Rods for Oxyfuel Gas Welding - 9th EditionStandard Welding Procedure Specification (SWPS) for Shielded Metal Arc Welding of Carbon Steel (M-1/P-1, Group 1 or2) 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, E7018, in the As-Welded or PWHT Condition, Primarily Plate andStructural ApplicationsSpecification for Nickel and Nickel-Alloy Welding Electrodes for Shielded Metal Arc WeldingSpecification for Nickel and Nickel-Alloy Bare Welding Electrodes and RodsStandard Welding Procedure Specification (WPS) for Self-Shielded Flux Cored Arc Welding of Carbon Steel (M-1/P-1/S1, Group 1 or 2), 1/8 Through 1/2 Inch Thick, E71T-11, As-Welded Condition Site LicenseSpecification for the Qualification of Welding Inspector Specialists and Welding Inspector AssistantsRecommended Practices for Safe Oxyfuel Gas Heating Torch Operation - Third EditionNULLSheet Metal Welding CodeGuide forWelding Ferritic/Austenitic Duplex Stainless Steel Piping andTubingMethod for Sampling Airborne Particulates Generated by Welding and Allied ProcessesVentilation Guide for Weld FumeStandard Welding Procedure Specification for Naval Applications (SWPS-N) for 75% Argon Plus 25% Carbon DioxideShielded Flux Cored Arc Welding of Carbon Steel (S-1), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL-70T-1and MIL-71T-1, in the As-WeldSpecification for the Application of Thermal Spray Coatings (Metallizing) of Aluminum, Zinc, and Their Alloys andComposites for the Corrosion Protection of Steel - 2nd EditionStandard Welding Procedure Specification (SWPS) for Gas Tungsten Arc Welding Followed by Shielded Metal ArcWelding of Carbon Steel (M-1/P-1, Group 1 or 2) 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, ER70S-2 and E7018,in the As-Welded or PWHT CondiStandard Welding Procedure Specification for Naval Applications (SWPS-N) for Argon Plus 2% Oxygen Shielded GasMetal Arc Welding (Spray Transfer Mode) of Carbon Steel (S-1), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick,MIL-70S-3, in the As-Welded orStandard Welding Procedure Specification (SWPS) for Shielded Metal Arc Welding of Carbon Steel (M-1/P-1, Group 1 or2) 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, E6010 (Vertical Uphill) Followed by E7018, in the As-Welded orPWHT Condition, 018AWS02018AWS0

2103NAVSEA B2.1- Standard Welding Procedure Specification for Naval Applications (SWPS-N) for Shielded Metal Arc Welding of8-309Austenitic Stainless Steel (S-8), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL-3XX-XX, in the As-WeldedCondition, Primarily Plate and StruB2.1-1-317Standard Welding Procedure Specification for Naval Applications (SWPS-N) for 75% Argon Plus 25% Carbon DioxideShielded Flux Cored Arc Welding of Carbon Steel (S-1), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL-70T-1and MIL-71T-1, in the As-WeldNAVSEA B2.1- Standard Welding Procedure Specification for Naval Applications (SWPS-N) for Shielded Metal Arc Welding of8-319Austenitic Stainless Steel (S-8), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL-3XX-XX, in the As-WeldedCondition, Primarily Pipe for NavalB2.1-1-314Standard Welding Procedure Specification for Naval Applications (SWPS-N) for Gas Tungsten Arc Welding withConsumable Insert Root of Carbon Steel (S-1), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL-MS-1 and MIL70S-2B2.1-1-315Standard Welding Procedure Specification for Naval Applications (SWPS-N) for Gas Tungsten Arc Welding withConsumable Insert Root of Carbon Steel (S-1), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL-MS-1 and MIL70S-2B2.1-8-321Standard Welding Procedure Specification for Naval Applications (SWPS-N) for Gas Tungsten Arc Welding withConsumable Insert Root of Austenitic Stainless Steel (S-8), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL-3XX,in the As-Welded ConditionB2.1-8-322Standard Welding Procedure Specification for Naval Applications (SWPS-N) for Gas Tungsten Arc Welding withConsumable Insert Root of Austenitic Stainless Steel (S-8), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, MIL-3XX,in the As-Welded Conditi

2018 AWS 0 56 B2.1-8-023 Standard Welding Procedure Specification (SWPS) for Shielded Metal Arc Welding of Austenitic Stainless Steel (M-8/P-8 Group 1) 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, in the As-Welded Condition, Primarily Plate and Structural Applications - 2nd 2018 AWS 0 57 NAVSEA B2.1