Transcription

AWS Welding/FabricationQuality Manual Sample(No Field Installation)Selected Pages Not a Complete PlanContact:First Time Quality410-451-8006Pat[Pick the date]

Questions? Call First Time Quality yAddress1] [CompanyAddress2][CompanyPhone] [CompanyPhone2]Fabrication Quality ManualPagesFor Compliance with:Operating Policies of the[CompanyName] Quality SystemedVersion: 20150308Version notesInitial issuele20141228ctVersionSeApproval Signature and Date:President/ DateDocuments provided by [CompanyName] disclose proprietary information as well as copyright informationregistered with the U.S. Patent and Trademark Office. Please hold these documents in confidence and donot share them with other organizations, even if you do not charge a fee. Submittal of documents does nottransfer copyright ownership.Page 1Quality ManualCopyright

Questions? Call First Time Quality 410-451-8006[CompanyName] Quality ManualQUALITY MANUALTABLE OF CONTENTS1. Quality System Management and Responsibilities . 71.1. Overview . 71.2. [CompanyName] Quality Policy . 71.3. Quality Duties, Responsibilities, and Authority . 71.4. Quality System Performance Measures . 91.5. Customer Satisfaction Performance Measures . 101.6. Exceptions. 10s2. Job Quality Assurance/Quality Control Planning . 11edPage2.1. Overview . 112.2. [CompanyName] License and Qualification Requirements . 112.3. QA/QC Personnel and Qualifications . 12.4. Planning of Quality Controlled Work Tasks . 32.5. Quality Inspection and Test Planning . 42.6. Quality Training Planning. 42.7. Customer Training On Operation and Maintenance . 42.8. Records and Documentation Plan . 42.9. Quality Audit Plan . 4ct3. Contract Specifications . 6Sele3.1. Overview . 63.2. Contract Technical Specifications . 63.3. Contract Drawings . 63.4. Contract Submittals . 63.5. Customer Submittal Approval . 83.6. Contract Warranty . 93.7. Contract Review and Approval . 94. Design Review and Control . 104.1. Overview . 104.2. Design Input Review . 104.3. Design Quality Assurance/Quality Control Planning . 104.4. Design Progress Reviews . 114.5. Design Output Verification and Approval . 115. Quality Standards. 125.1. Overview . 125.2. Regulatory Codes . 125.3. Industry Quality Standards . 125.4. Material and Equipment Specifications . 14Page 2Quality ManualCopyright

Questions? Call First Time Quality 410-451-8006[CompanyName] Quality Manual5.5. Work Process Specifications . 145.6. Controlled Material Identification and Traceability . 155.7. Measuring Device Control and Calibration . 155.8. [CompanyName] Quality Standards . 155.9. Application of Multiple Sources of Specifications . 166. Purchasing . 176.1. Overview . 176.2. Purchase Order Requirements . 176.3. Purchase Order Approvals . 177. Process Controls . 18Pages7.1. Overview . 187.2. Startup and Quality Control Coordination Meeting . 187.3. Preparatory Job Quality Assurance/Quality Control Plan Planning . 187.4. Weekly Quality Planning and Coordination Meetings . 197.5. Process Control Standards . 198. Inspections and Tests . 22Selected8.1. Overview . 228.2. Required Work Task Quality Inspections and Tests. 228.3. Material Inspections and Tests . 228.4. Work in Process Inspections . 238.5. Work Task Completion Inspections . 238.6. Inspection of Special Processes . 248.7. Independent Measurement and Tests . 248.8. Commissioning Functional Acceptance Tests . 248.9. Hold Points for Customer Inspection . 248.10. Quality Inspection and Test Specifications . 248.11. Inspection and Test Acceptance Criteria . 248.12. Inspection and Test Status. 268.13. Independent Quality Assurance Inspections . 268.14. Inspection and Test Records . 268.15. Job Completion and Closeout Inspection . 279. Nonconformances and Corrective Actions . 299.1. Overview . 299.2. Nonconformances . 299.3. Corrective Actions . 3010. Preventive Actions . 3110.1. Overview . 3110.2. Identify Preventive Actions for Improvement . 3110.3. Train Preventive Actions for Improvement . 3111. Quality System Audits . 3311.1. Overview . 33Page 3Quality ManualCopyright

Questions? Call First Time Quality 410-451-8006[CompanyName] Quality Manual11.2. Company-wide Quality System Audit . 3312. Record and Document Controls. 3412.1. Overview . 3412.2. Quality System Documents . 3412.3. Document Controls . 3412.4. Record Controls . 3513. Appendix . 3713.1. Definitions of Terms . 37SelectedPages14. Forms . 40Page 4Quality ManualCopyright

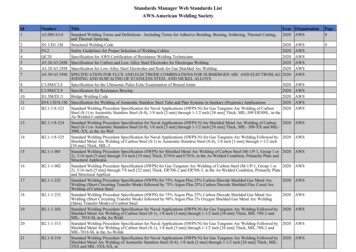

Questions? Call First Time Quality 410-451-8006[ImagePlaceHolder] [CompanyName] Quality Manual5. QUALITY STANDARDSAPPLICABLE REGULATIONS, INDUSTRY, and COMPANY STANDARDS5.1. OVERVIEW[CompanyName] personnel and suppliers are accountable for compliance to standards-based writtenspecifications.To achi

The WPSs and PQRs are controlled by the Quality Manager according by the document and record control procedures specified in the relevant section of this Quality Manual. The applicable WPSs shall be available to welders or welding operators during testing and production