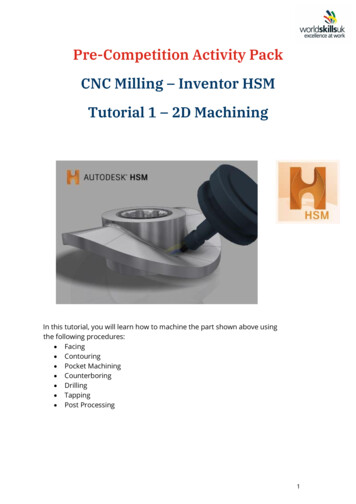

Transcription

Take control of your manufacturingAchieve higher productivity, reduced costs, and shortertime to market using Inventor HSMAutodesk Inventor HSM 2016 CAD/CAMsoftware helps CNC programmers, designers,and engineers rapidly produce machinedparts designed in virtually any CAD system.Whether you are working with multiple CADformats or starting from pencil sketches,Inventor HSM helps you get up to speed andbecome productive within minutes using atruly integrated design to manufacturingsolution. In addition to all the standardtoolpath strategies for milling and turningoperations, Inventor HSM includes advancedfeatures such as adaptive clearing, integratedsimulation and verification tools, and apowerful post processor system.Adaptive ClearingAnyCADModern architectureAdaptive clearing is an advanced roughing strategythat sets the bar for efficient, high-volume materialremoval. Using constant tool engagement andoptimized cutter paths, Inventor HSM reducesroughing time by a factor of 4 or more comparedto conventional roughing, and increases tool life byas much as a factor of 10, depending on materialhardness. Enhanced multi-core support andimproved linking make adaptive clearing the mostadvanced adaptive roughing technology to date.AnyCAD is a CAD interoperability solutionincluded in Autodesk Inventor that reducesthe need to maintain multiple CAD systems andeliminates manual file translation and updates.Parts and assemblies can be selectively importedinto Inventor from virtually any CAD system whilekeeping associativity. Design changes in thesource CAD system get automatically updated indownstream data such as drawings and toolpaths,saving you valuable time and resources andminimizing costly translation errors.Inventor HSM is designed to take advantageof latest workstation technologies to help youachieve superior performance, especially whenworking on large or complex designs.Multiprocessor/multi-core support dramaticallyspeeds up toolpath generation on supportedhardware. Distributed CAM server helps maximizeuse of your computing power by utilizing idlePCs on the local network to reduce toolpathcalculation time.

Inventor HSM – Take control of your manufacturing“ As a medical device company making cranial implants, we rely on Inventor HSMto give us the ability to make these products in a very predictable and linearmethod so we can depend on the results and produce the parts that we want.”— Aaron M. Noble,CEO of Poriferous, LLCStock simulationTool lists and setup sheetsPost processorsIntegrated stock simulation in Inventor HSMenables users to see stock being removed andto automatically check for shaft and clamp/fixturecollisions. Users can color the surface by toolnumber to inspect the resulting stock model,and they can slice the model to inspectdifferent sections.Tool lists, setup sheets and other productiondocuments are automatically generated and canbe exported in a variety of formats includingHTML, XML, Microsoft Excel , andMicrosoft Word.No CAM system is complete without apost processor that produces ready-to-runcode tailored to your machine, control, andprogramming style. Inventor HSM uses a flexible,open, and exceptionally fast post processor toperform this critical task.The target part comparison feature can be usedto highlight rest and gouge areas with differentcolors. 3 2 machining is supported and multipletoolpaths can be verified in a single operation.Toolpath simulationAfter generating a toolpath, users can easilyinspect results with the integrated backplot andinspection tool. Controls include simulation speedand direction, visibility and translucency of tool,shaft, tool holder, and coloring of rapid moves,lead moves, and cutting moves.Use the advanced analysis tool to measuredistances, or dynamically view all vital informationabout tools, and details such as feed/speed andestimated machining time. 3 2 machining issupported, and you can inspect multipletoolpaths in a single operation.Production documents are generated by theadvanced Inventor HSM post processor with highdegree of flexibility and user customization.Inventor HSM EditInventor HSM includes Inventor HSM Edit forinspecting and manually editing NC program files.Inventor HSM Edit provides a number of CNCcode-specific functions, including line numbering/renumbering, XYZ range finder, and file compare.Inventor HSM Edit features a DNC link for reliable RS232 communications with a variety of CNC controls.JavaScript programming language, enablingon-site customization by customers and resellers,resulting in a significant reduction in postdevelopment time.Inventor HSM comes with numerous generic postprocessor configurations. Each post processor iscustomizable to the user’s specific requirements.Our aim is to produce 100 percent ready-to-runcode for your machine. Fanuc Heidenhain Haas Hurco MillPlus Okuma Siemens Yasnac and many more.

Inventor HSM – Take control of your manufacturingAutodesk Inventor - professional grade CAD systemAutodesk Inventor helps you to complete your design quickly, easily, andwith flexibility by combining parametric, freeform, and direct editing tools.Design and documentproducts digitallyAutodesk Inventor provides an intuitive parametricdesign environment for developing initialconcept sketches and kinematic models of partsand assemblies. Inventor software automatesthe advanced geometry creation of intelligentcomponents, such as plastic parts, steel frames,rotating machinery, tube and pipe runs, andelectrical cable and wire harnesses. Inventoralso helps reduce the geometry burden so youcan rapidly build and refine digital prototypesthat validate design functions and help minimizemanufacturing costs.Full associativitybetween the modeland machiningoperationsSeamless workflow experiencefrom design to manufacturingAnyCAD in Inventor enables users to maintain fullassociativity between the non-native model andmachining operations, so any changes to themodel are automatically reflected in the toolpath.Late design changes no longer mean missingdelivery deadlines or introducing last-minuteprogramming errors.Key advantages ofAutodesk Inventor: Instant association with the CAD model No data translation errors Fewer files to manage Superior CAD tools Lower training costs Superior machining flexibilitySeamlessworkflowsEngineeringChange OrderManufacturingimprovements

Inventor HSM – Take control of your manufacturing2D / 2.5D milling2D machining can range from the very simple to the very complex. Inventor HSM solutionsinclude the tools you need for precise control over all aspects of 2D machining, including leadin/out and transitions between passes.ContouringEasily machine 2D and 3D contours. Controllead-in and lead-out, and choose multipleroughing and finishing passes and multipledepth cuts for any contour. Machine open andclosed contours without creating additionalgeometry, and eliminate sharp motion with cornersmoothing.Adaptive clearingPocket toolpaths machine closed areas with andwithout islands. Entry can be selected anywhereon the model and set for plunge, ramp, or at apredrilled position. The special high-speed optioncreates smooth toolpaths that support constanttool engagement, significantly higher feedrates,and reduced machining time and tool life.Drilling and hole makingInventor HSM includes powerful tools forgenerating drilling, counterboring, and tappingoperations. All operations are optimized tominimize tool travel and overall cycle time.Both standard and customized cycles aresupported for all point-to-point operations,including spot-drilling, deep drilling with chipbreak, and boring cycles.Simply powerful2D machiningComplete control over every aspect of the toolpath

Inventor HSM – Take control of your manufacturingDefine all relevant tool parameters in the Inventor tool library3D millingHSM stands for high-speed machining. The main goal of high-speed machining is minimizingrun time. Other factors, including surface quality and tool life, are also important.Manage tools and holders with the Inventor tool libraryInventor HSM toolpaths are optimized to address all these factors by reducing cycle times,improving surface quality, and extending tool life.High speedmachining foreverybodyBest-in-class 3D strategiesInventor HSM strives to generate the shortest andsmoothest toolpaths possible, resulting in reducedmachining time, improved surface quality, less toolwear, and extended machine tool life.In addition to the traditional pocket clearing strategy,Inventor HSM features the innovative adaptiveclearing strategy that reduces roughing time bya factor of 4 or more compared to conventionalroughing, and increases tool life by as much as afactor of 10, depending on material hardness.Finish paths follow part faces to create the finalpart shape. Many machining strategies are availableto suit the part topology. Inventor HSM providessuperior finish machining technologies thatincorporate smooth/tangent lead in/out moves tokeep the tool moving in a smooth motion, helpingto reduce machine wear and tool marks. Pocket Adaptive clearing Contour Parallel Pencil Scallop/constant stepover Spiral Radial Horizontal 3 2 machiningTool libraryTool information can be specified directly usingthe Inventor HSM tool library, or imported fromthird-party tool databases. Production documents,including tool lists, are automatically generatedand can be exported in a number of differentformats including HTML, XML, Microsoft Excel and Microsoft Word.3 2 machiningAll 2D and 3D strategies support 3 2 machining(5-axis positioning) by rotating the part or thehead of the machine tool through a combinationof A, B, or C axis motions. Create 3 2 operationsby simply selecting a work plane for the operation.Inventor HSM takes care of the rest by finding themost efficient rotations to orient the part. Onceparts are positioned, all machining strategies areavailable. Tools and holders are gouge protectedfor all strategies that normally support this feature.

Inventor HSM – Take control of your manufacturingMulti-axis millingInventor HSM integrates multi-axis simultaneous machining into its milling and mill/turnenvironment using the same intuitive approach to toolpath programming found in our 2D/3Dmachining strategies. Multi-axis machining has traditionally been regarded as an advancedtechnology best suited to the aerospace and automotive industry.Inventor HSM improves production machining by breaking down this barrier and makingmulti-axis machining accessible to everybody. Swarf Multi-axis contour 3D toolpath tilting3D toolpath tiltingMulti-axis simultaneous machiningMany parts contain deep cavity areas and smallradii that need to be machined with smalldiameter tools. With Inventor HSM these areascan be machined effectively by automaticallytilting the tool and holder away from theworkpiece, enabling the use of shorter toolsto reduce vibration and deflection.Inventor HSM offers a number of multi-axisstrategies that provide the programmer withproductive solutions for easily creating highlyefficient multi-axis toolpaths with advancedcollision control for the most complex 3D models.

Inventor HSM – Take control of your manufacturingTurningWhether you are looking for a CAM system to help you improve your productivity withtraditional turning operations like roughing, grooving, or finishing – or you want to starttaking full advantage of your multi-axis machine tools, Inventor HSM offers an intuitiveapproach to creating high-quality turning toolpaths. Facing Roughing Profiling Grooving Drilling PartingTwin-turret, sub-spindle and mill/turnTraditional turningInventor HSM supports programming twin-turretand twin-spindle lathes using all traditional turningoperations. Mill/turn operations are supportedwhen combined with the Inventor HSM 2D or 3Dmilling option.Inventor HSM features all the traditional turningtoolpaths, including facing, roughing, grooving,threading, drilling, and profiling. For drilling andhole making, choose between pre-programmedmachining cycles and canned cycles, or use acombination of both.

Inventor HSM – Take Control of your ManufacturingProfessional machining made easy and accessibleChoose the right CAD/CAM solution for your machining needs and take advantage of flexible pricing options.Download the free 2.5D solution, or a 30-day trial of our advanced 3D and 5-axis solutions today.Download your Inventor HSM CAD/CAM solution today or contact a reseller near you.Visit: cam.autodesk.com/inventor-hsmCNC ProgrammersFree* Professional 2.5 axis millingand drilling applicationsRequires Autodesk Inventor 2.5D, advanced 3D and 3 2 millingand turning applications2.5D, advanced 3D and 5-Axis milling,and turning applicationsIncreased speeds and feeds with Adaptive ClearingInventor HSM CAD/CAM solutions deliverunbeatable performance and qualitythat puts you in control of your CNCprogramming operations.Designers & EngineersWhether you are prototyping or producingfinished parts, Inventor HSM provides aseamless integrated CAD/CAM experiencethat puts you in control of the design tomanufacturing workflow.Subscribe to AutodeskSubscribing to Autodesk products is themost flexible and cost-effective way toaccess the latest design, engineering, andentertainment software and services youneed to help grow your business. Autodesksubscribers get access to the latest releasesand product enhancements, flexible licensingrights, cloud services, and technical support.Learn more at www.autodesk.com/subscriptionAdvanced simulation and verification toolsIncludes posts for industry standard machinesProduct updates for the duration of licenseExpert technical support*Free Autodesk software licenses and/or cloud-based services are subject to acceptance of and compliance with the terms and conditions of the licenseagreement or terms of service, as applicable, that accompany such software or cloud-based services.** Actual retail price is determined by your rese

Inventor HSM toolpaths are optimized to address all these factors by reducing cycle times, improving surface quality, and extending tool life. Best-in-class 3D strategies Inventor HSM strives to generate the shortest and smoothest toolpaths possible, resulting in reduced machining time, improved surface quality, less tool wear, and extended machine tool life. In addition to the traditional .File Size: 1MBPage Count: 9