Transcription

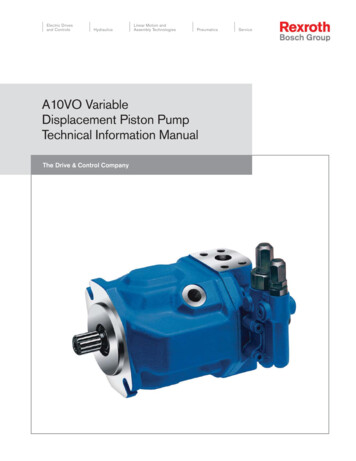

Axial piston variable pumpA10VO, A10VSOSeries 31Instruction manualReplaces: 01.2012RE 92701-01-B/04.2018English

Bosch Rexroth AG 2018. All rights reserved,also regarding any disposal, exploitation,reproduction, editing, distribution, as wellas in the event of applications for industrialproperty rights.The data specified within only servesto describe the product. No statementsconcerning a certain condition or suitabilityfor a certain application can be derived fromour information. The information given doesnot release the user from the obligation ofown judgment and verification. It must beremembered that our products are subjectto a natural process of wear and aging.The cover shows an example application.The product delivered may differ from theimage on the cover.The original instruction manual was created inthe German language.

Contents3/60Contents1About this documentation51.1Validity of the documentation51.2Required and supplementary documentation51.3Representation of information61.3.1Safety bbreviations82Safety instructions92.1About this chapter92.2Intended use92.3Improper use92.4Personnel qualifications102.5General safety instructions112.6Product-specific safety instructions122.7Personal protective equipment143General notices regarding property and product damage154Scope of delivery185About this product195.1Performance description195.2Product description195.2.1Axial piston unit layout195.2.2Functional description205.3Product identification216Transport and storage226.1Transporting the axial piston unit226.1.1Transporting by hand226.1.2Transporting with a lifting device226.2Storing the axial piston unit247Installation267.1Unpacking267.2Installation conditions267.3Installation position277.3.1Below-reservoir installation (standard)277.3.2Inside-reservoir installation287.3.3Above-reservoir installation307.4Installing the axial piston ral instructions317.4.4Installation with a coupling327.4.5Installation on a gearbox337.4.6Installation with cardan shaft337.4.7Remove the spacer (for version with through drive)34RE 92701-01-B/04.2018, A10VO, A10VSO Series 31, Bosch Rexroth AG

4/60 Contents7.4.8Completing installation357.4.9Hydraulically connecting the axial piston unit367.4.10 Electrically connecting the axial piston unit417.5Performing flushing cycle428Commissioning438.1Initial commissioning438.1.1Filling the axial piston unit438.1.2Testing the hydraulic fluid supply448.1.3Performing a functional test458.2Running-in phase458.3Recommissioning after standstill469Operation4710Maintenance and repair4710.1Cleaning and 910.5Spare parts4911Removal and replacement5011.1Required tools5011.2Preparing for removal5011.3Removal5011.4Preparing components for storage or further use5012Disposal5113Extension and conversion5114Troubleshooting5214.1How to proceed for troubleshooting5214.2Malfunction table5315Technical data5716Alphabetical index58Bosch Rexroth AG, A10VO, A10VSO Series 31, RE 92701-01-B/04.2018

About this documentation5/601 About this documentation1.1 Validity of the documentationThis documentation applies to the following products: Axial piston variable pump A10VO Series 31 Axial piston variable pump A10VSO Series 31This documentation is intended for machine/system manufacturers, assemblers andservice engineers.It contains important information on the safe and appropriate transport, installation,commissioning, operation, maintenance, removal and simple troubleshooting of theaxial piston unit. Read this manual completely, in particular chapter 2 “Safety instructions” onpage 9 and chapter 3 “General notices regarding property and productdamage” on page 15 before you start work with the axial piston unit.1.2 Required and supplementary documentation Only commission the axial piston unit if the documentation marked with the booksymbolis available to you and you have understood and observed it.Table 1: Required and supplementary documentationTitleDocument numberDocument typeOrder confirmationContains the order-related technical data of your axial piston variable pumpA10VO or A10VSO.–Order confirmationInstallation drawingContains the outer dimensions, all connections and the hydraulic circuit diagramfor your axial piston variable pump A10VO or A10VSO.Please request theinstallation drawingfrom your contact atBosch Rexroth.Installation drawingAxial piston variable pump A10V(S)O,size 18 (A10VSO),size 28 to 140 (A10VO)Contains the permissible technical data.92701Data sheetAxial piston variable pump A10VSO, size 18 to 140Contains the permissible technical data.92711Data sheetHydraulic fluids based on mineral oils and related hydrocarbons90220Describes the requirements on a hydraulic fluid based on mineral oil and relatedhydrocarbons for operation with Rexroth hydraulic components, and assists you inselecting a hydraulic fluid for your system.Data sheetEnvironmentally acceptable hydraulic fluidsDescribes the requirements on an environmentally acceptable hydraulic fluidfor operation with Rexroth hydraulic components and assists you in selecting ahydraulic fluid for your hydraulic system.90221Data sheetFire-resistant, water-free hydraulic fluids (HFDR/HFDU)Describes the requirements on fire-resistant, anhydrous hydraulic fluids(HFDR/HFDU) for operation with Rexroth hydraulic components and assists you inselecting a hydraulic fluid for your hydraulic system.90222Data sheetFire-resistant hydraulic fluids – hydrous (HFAE, HFAS, HFB, HFC)Describes the requirements on fire-resistant, hydrous hydraulic fluids(HFAE, HFAS, HFB, HFC) for operation with Rexroth hydraulic components andassists you in selecting a hydraulic fluid for your hydraulic system.90223Data sheetRE 92701-01-B/04.2018, A10VO, A10VSO Series 31, Bosch Rexroth AG

6/60About this documentationTable 1: Required and supplementary documentationTitleDocument numberDocument typeAxial piston units for operation with fire-resistant hydraulic fluids – anhydrousand hydrous (HFDR, HFDU, HFA, HFB, HFC)Describes the requirements on fire-resistant, anhydrous and hydroushydraulicfluids (HFDR, HFDU, HFA, HFB, HFC) and contains the technical data foroperation with Rexroth hydraulic components.90225Data sheetInformation on the use of hydrostatic drives at low temperaturesContains additional information on the use of Rexroth axial piston units at lowtemperatures.90300-03-BManualStorage and preservation of axial piston unitsContains additional information on storage and preservation.90312Data sheetAxial piston variable pump A10V(S)O, A10VO series 3x and 5x with electroproportional differential pressure control EF92709Data sheetPressure relief valve, direct controlled25402Data sheetProportional pressure relief valve29166Data sheetPump safety block25880Data sheetPump safety block25891Data sheetPressure and flow control system30030Data sheet1.3 Representation of informationStandardized safety instructions, symbols, terms and abbreviations are usedthroughout this documentation so that you can work quickly and safely with yourproduct. For clarification, they are explained in the sections below.1.3.1Safety instructionsThis manual contains safety instructions in chapter 2.6 “Product-specific safetyinstructions” on page 12 and in chapter 3 “General notices regarding propertyand product damage” on page 15, as well as before a sequence of actions or aninstruction for action involving a risk of personal injury or property damage.Always follow the instructions on avoiding the dangers associated with the use ofthis product.Safety instructions are set out as follows:Signal wordType and source of danger!Consequences of noncompliance Measures to prevent danger Warning sign: draws attention to the danger Signal word: identifies the degree of the danger Type and source of danger: indicates the type and source of the danger Consequences: describes what occurs if safety instructions are disregarded Precautions: states how the danger can be avoidedBosch Rexroth AG, A10VO, A10VSO Series 31, RE 92701-01-B/04.2018

About this documentation7/60Table 2: Danger classes as defined in ANSI Z535.6Warning sign, signal wordMeaningDANGERIdentifies a dangerous situation that will result in death orserious injury if it is not avoided.WARNINGIdentifies a dangerous situation that may result in death orserious injury if it is not avoided.Identifies a dangerous situation that may result in minor tomoderate injury if it is not avoided.CAUTIONNOTICE1.3.2Property damage: The product or surrounding area may bedamaged.SymbolsThe following symbols indicate information that is not safety-relevant but increasesunderstanding of the documentation.Table 3: Meaning of symbolsSymbolMeaningIf this information is disregarded, the product cannot be used and/oroperated to its full extent. Single, independent action1.Numbered instruction:The numbers indicate that the actions must be completed in order.2.3.RE 92701-01-B/04.2018, A10VO, A10VSO Series 31, Bosch Rexroth AG

8/60About this documentation1.3.3DesignationsThis documentation uses the following designations:Table 4: DesignationsDesignationMeaningA10VOAxial piston variable pump, open circuit, maximum pressure 350 bar,for mobile applicationsA10VSOAxial piston variable pump, open circuit, maximum pressure 350 bar,for stationary applicationsThreaded plugMetal screw, pressure-resistantProtective plugMade out of plastic, not pressure-resistant, only for transportationAs an umbrella term for “axial piston variable pump A10VO” and/or “A10VSO” thedesignation “axial piston unit” is used in the following.1.3.4AbbreviationsThis documentation uses the following abbreviations:Table 5: AbbreviationsAbbreviationMeaningATEXEC directive on explosion protection (Atmosphère explosible)DGTwo-point control, directly controlledDFLRPressure flow power controllerDFR/DFR1/DRSCPressure flow controllerDINDeutsches Institut für Normung (German Institute for Standardization)DRGPressure controller, remotely controlledEFElectro-proportional differential pressure controlISOInternational Organization for StandardizationJISJapan Industrial StandardRERexroth document in the English languageVDI 2230Directive for the systematic calculation of high duty screwed joints andcylindrical screw joints from the VDI (Verein Deutscher Ingenieure Association of German Engineers)Bosch Rexroth AG, A10VO, A10VSO Series 31, RE 92701-01-B/04.2018

Safety instructions9/602 Safety instructions2.1 About this chapterThe axial piston unit has been manufactured to generally accepted engineeringstandards. There is still, however, a risk of personal injury or property damage if thischapter and the safety instructions in this documentation are not observed. Read this documentation completely and thoroughly before working with the axialpiston unit. Keep it in a location where it is accessible to all users at all times. Always include the required documentation when you pass the axial piston uniton to third parties.2.2 Intended useAxial piston units are hydraulic components, meaning that in their applicationarea they are classified neither as complete nor as partly completed machinery asdefined in the EC Machinery Directive 2006/42/EC. The component is exclusivelyintended to form partly completed machinery or complete machinery together withother components. The component should only be commissioned after it has beeninstalled in the machine/system for which it is intended and the safety of the entiresystem has been established in accordance with the Machinery Directive.This product is intended for the following use:The axial piston unit is only approved as a pump for hydrostatic drives in an opencircuit. Observe the technical data, application and operating conditions andperformance limits as specified in data sheet 92701 and 92711 and in the orderconfirmation. Information about approved hydraulic fluids can be found in datasheet 92701 and 92711.The axial piston unit is only intended for commercial use and not for private use.Intended use includes having fully read and understood this manual, especiallychapter 2 “Safety instructions” on page 9.2.3 Improper useAny use other than that described as intended use is considered improper.Bosch Rexroth AG is not liable for damages resulting from improper use. The user issolely responsible for any risks arising from improper use.The following foreseeable misuses are also considered improper (this list is notexhaustive): Use outside the operating parameters approved in the data sheet or in the orderconfirmation (unless specifically approved by the customer) Use of non-approved fluids, e.g. water or polyurethane components Changes to factory settings by unauthorized persons Use of assembled parts (e.g. attachment filter, control unit, valves) other than thespecified Rexroth components Use of the axial piston unit with assembled parts under water at a depth ofmore than 10 meters without the necessary additional measures, e.g. pressureequalization. Units with electrical components (e.g. sensors) generally cannotRE 92701-01-B/04.2018, A10VO, A10VSO Series 31, Bosch Rexroth AG

10/60Safety instructionscome into contact with water. Axial piston units may only be used on a case-to-casebasis for this application. The maximum permissible case pressure specified in the data sheet must not beexceeded. Use of the axial piston unit in explosive environments unless the component ormachine/system has been certified as compliant with the ATEX Directive 2014/34/EU Use of the axial piston unit in a corrosive atmosphere Use of the axial piston unit in aircraft or spacecraft2.4 Personnel qualificationsThe activities described in this manual require a basic understanding of mechanics,electricity and hydraulics, as well as familiarity with associated technical terms.For transporting and handling the product, additional fam

Bosch Rexroth AG, A10VO, A10VSO Series 31, RE 92701-01-B/04.2018 7.4.8 Completing installation 35 7.4.9 Hydraulically connecting the axial piston unit 36 7.4.10 Electrically connecting the axial piston unit 41 7.5 Performing flushing cycle 42 8 Commissioning 43 8.1 Initial commissioning 43 8.1.1 Filling the axial piston unit 43 8.1.2 Testing the hydraulic fluid supply 44 8.1.3 Performing a .