Transcription

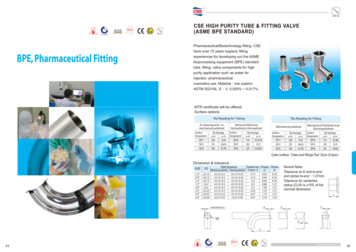

RQA:0410091424BPE, Pharmaceutical FittingCSE HIGH PURITY TUBE & FITTING VALVE(ASME BPE STANDARD)Pharmaceutical/Biotechnology fitting. CSEhave over 15 years hygienic fittingexperiences for developing out the ASMEbioprocessing equipment (BPE) standardtube, fitting, valve components for highpurity application such as water forinjection, pharmaceutical,cosmetics use. Material:low sulphurASTM SS316L, S: 0.005% 0.017%,MTR certificate will be offered.Surface options:Ra Reading for TubingAs drawing and / ormechanical polishedSurfaceRa SF3Ra Reading for FittingMechanical Polished andElectropolished or ElectropolishedSurfaceRa 0.635Mechanical polishedSurfaceDesignationSF1SF2SF3Ra Averageµ-inµ-m2025300.50.630.76Mechanical Polished andElectropolishedSurfaceRa SF6Outer surface: Tubes and fittings Ra 32uin (0.8µm)Dimension & tolerance:SIZEOD1/2"3/4"1.0"1.5"2.0"2.5"3.0"4.0" 0.13 0.13 0.13 0.2 0.2 0.25 0.25 0.38General Notes:Tolerance on E end-to-endand center-to-end:1.27mmTolerance for centerlineradius (CLR) is 10% of thenominal dimension.Squareness face Off angle Off planeWall thickenssMechanical polished Electropolished To tangent,BOP 0.13/-0.2 0.13/-0.2 0.13/-0.2 0.13/-0.2 0.13/-0.2 0.13/-0.2 0.13/-0.2 0.2/-0.25 0.13/-0.25 0.13/-0.25 0.13/-0.25 0.13/-0.25 0.13/-0.25 0.13/-0.25 0.13/-0.25 .20.20.20.250.410.41wall http://www.csee.com.twQA:041009142466

BPE Stainless Steel TubingAbsolutely hygienic conditions are necessary for the entire production cycle ofpharmaceutical and ultra-high industries.Therefore, tubes, fittings, and valves with a smooth internal surface are extensively installedwith the advantages of cleaning easily and avoiding bacteria contamination.Marking:CSE only offers tubes that are manufactured, quality controlled, marked, and certifiedaccording to the highest standards for hygienic equipment design and guarantees extendedquality and traceability.CSE BPE tubing significantly reduces inspection requirements prior to installation by utilizingonly the highest quality stainless steel materials.ASME BPE (BPE REFERENCE NO.)TP316L size SFX(H.T.NO.)CSE delivers directly from stock the following stainless steel tubes in grade TP316L with lowsulfur content of 0.005% to 0.0017% and SF1 and SF4 finishes (according to the ASME BPEspecification)STANDARDS:ASTM A270-2015 S2SURFACE FINISH: SF0 SF6SF1 ID Pol. Ra 0.5μm/ OD Pol. Ra 0.8μmSF4 ID EP Finished Ra 0.38μm/ OD Pol. Ra 0.8μmPackage Type:SF1SF4ØDTCSE BPE EP products with following advantages:Homogeneously EP layer to minimize rougingHigher chrome concentration for better corrosionresistanceGuaranteed smoothness of all internal surfaces toreduce Bio filmASTM A270 S2 2015 TP316L ASME-BPE DT-4-1 SF-X WLD NDE Size X length X Heat NO ttp://www.csee.com.twQA:041009142468

LDT-4.1.1-1 LONG WELD 90 ELBOW (DT-7)TØDBPE FittingsDT-4.1.3-1 CONCENTRIC REDUCER 51.652.112.77ØdtLBPE 2.112.77R69(b)tØdLØDL1TDT-4.1.2-1T TEE .652.11DT-4.1.3-1 ECCENTRIC REDUCER (DT11)ØdLØDTDT-4.1.2-1C CROSS (DT-9)LØdtL1LLDT-4.1.1-4 LONG 45 ELBOW p://www.csee.com.twQA:041009142470

BPE FittingsBPE FittingsLDT-4.1.2-6 REDUCING TEE (DT-10)DT-4.1.1-2 90 CLAMP/WELD ELBOW 6.2101.6152.4ØDL1SIZELL1DT-4.1.1-5 45 CLAMP/WELD ELBOW /2"3/4"1"1.5"2"2.5"3"4"6"LLLDT-4.1.1-6 45 CLAMP ELBOW 1.651.651.651.651.651.651.651.651.652.11DT-4.1.2-7 SHORT OUTLET W/C REDUCING TEE (DT-14)DT-4.1.1-3 90 CLAMP ELBOW 41009142472

BPE FittingsBPE 51.651.651.652.112.77L1SIZEØDL1TTTDT-4.1.2-2 EQUAL OUTLET WELD/CLAMP TEE (DT-15)ØDLDT-4.1.2-8 REDUCING TEE CLAMP END (DT-19)DT-4.1.2-4T CLAMP TEE IZESIZELDT-4.1.2-9 REDUCING TEE CLAMP END (DT-20)ØDTDT-4.1.2-4C CLAMP CROSS ://www.csee.com.twQA:041009142474

BPE FittingsDT-4.1.3-3 CLAMP CONCENTRIC REDUCER 7BPE Fittings(Type A)(Type B)1/2" 1"1" 4.1.4-1WELD FERRULE a, b, cØd(a)SIZEa, b, cDT-4.1.3-3 CLAMP ECCENTRIC REDUCER :041009142476

BPE FittingsDT-4.1.1-7 180 WELD ELBOW 2.112.77L1T(a)DT-4.1.1-8 180 CLAMP ELBOW -4.1.2-5 SHORT OUTLET TEE CLAMP END .5212.7161.9228.6228.6DT-4.1.3-2AE ECCENTRIC REDUCER "*3"6"*3"6"*4"Ød(a)LØDLTDT-4.1.2-3 SHORT OUTLET RUN WELD/CLAMP TEE (DT-25)LDT-4.1.3-2AC CONCENTRIC REDUCER (DT-26)ØdLBPE 10091424http://www.csee.com.twQA:041009142478

BPE FittingsBPE FittingsDT-4.1.2-11 (DT-29)DT-4.1.5-1 AUTOMATIC TUBE WELD CAP(DT-30)ØDDT-4.1.2-10 8.138.138.144.4550.863.5ØDL1ØdL1ØdLDT-4.1.5-2 SOLID END CAP HYGINICCLAMP 51.651.651.651.651.65RØAINSTRUMENT TEE WELD/CLAMP p://www.csee.com.twQA:041009142480

BPE FittingsDIN 11853-1 Unions Form AØBDNØAØB1/2" 3/4"1.0" 175.1225.9DN10 DN20DN25 0123134159187237.5272323DIN-13R ROUND NUTØAØABImperialØCBØØA13SC SAFETY CLAMPSLSafety DeviceMeasuring temperature or bio-activity is necessary for validation processes.CSE’s gap clamp with single slot or double slots has proven its value when validatingsterility in a high-purity pharmaceutical system.Two 36424962708094104115138164RD 28*1/8RD 34*1/8RD 44*1/6RD 52*1/6RD 58*1/6RD 65*1/6RD 78*1/6RD 85*1/6RD 225293031354044444444666666ØAØB1/2" 3/4"1.0" NCHØA ØB 88.91/2"3/4"9.4 12.7 21.915.75 19.5 27.935.922.1 25.4 42.948.934.8 38.1 54.947.5 50.8 66.960.2 63.5 84.972.9 76.2 98.997.38 101.6 EØCHEAVY DUTY SINGLEPIN CLAMPØAØBØALINER PARTSØAOne gapSIZEMALE PARTSInformation about Stainless steel DIN 11864/ DIN 11853DIN 11864 nFlangeTri-ClampDIN 11853 onFlangeTri-ClampLR81ØBCØADINØA ØBDN10 10DN15 16DN20 20DN25 26DN32 32DN40 38DN50 50DN65 66DN80 81DN100 INCH ØA ØBC1/2" 9.4 12.7 RD28*1/83/4" 15.75 19.5 RD34*1/8RD44*1/622.1 25.4 RD52*1/61"RD58*1/61.5" 34.8 38.1 RD65*1/647.5 50.8 RD78*1/62"2.5" 60.2 63.5 RD95*1/672.9 76.2 RD110*1/43"4" 97.38 101.6 482

DIN 11853-1 & 11864-1 Unions Form ADIN 11864-1 Unions Form ADIN-13R ROUND DN100ØBBØBØCSIZEØCDIN/ISO/IMPERIAL- LINER BLANK 136424962708094104115138164RD 28*1/8RD 34*1/8RD 44*1/6RD 52*1/6RD 58*1/6RD 65*1/6RD 78*1/6RD 85*1/6RD N80DN100ØBLISOØAØBLINCH ØAØBLØC10 1316 1920 2326 2932 3538 4150 5366 7081 85100 47486261681/2" 9.4 12.73/4" 15.75 �A1"22.1 25.41.5" 34.82" 47.52.5" 60.23" 72.94" 97.3838.150.863.576.2101.64046.547.5636165MALE PARTSDINØAØBØACDINR83BDINDIN/ISOSEALLØALINER PARTSDIN/ISO/IMPERIAL- MALE BLANK ØA ØB 5DN80ØA 1.326.933.742.448.360.376.188.9LINCH ØA414143434848496064641/2" 9.4 12.7 41 RD28*1/83/4" 15.75 19.5 41 RD34*1/8RD44*1/61" 22.1 25.4 43 RD52*1/6RD58*1/61.5" 34.8 38.1 48.5 RD65*1/62" 47.5 50.8 48.5 RD78*1/62.5" 60.2 63.5 60 RD95*1/63" 72.9 76.2 64 RD110*1/44" 97.38 101.6 64 http://www.csee.com.twQA:041009142484

DIN Tubular items (DIN11865)DIN 11864-2 Unions Form AL45 LONG .555.557.559.559.5LISO Nutflansch (NF)LØAØCØBDIN Nutflansch (NF)TIMPERIAL Nutflansch .559.5ISO Bundflansch 45454554565858LIMPERIAL Bundflansch 1.51.51.51.51.5222222TEE & PULL TEEL1ØATSIZEØDØALØBØGDIN Bundflansch (BF)ØD90 LONG http://www.csee.com.twQA:041009142486

DIN Tubular items (DIN11865)DIN Tubular items (DIN11865)REDUCING TEE & REDUCING PULL NTRIC REDUCER/ECCENTRIC QA:041009142488

sulfur content of 0.005% to 0.0017% and SF1 and SF4 finishes (according to the ASME BPE specification) STANDARDS: ASTM A270-2015 S2 SURFACE FINISH: SF0 SF6 SF1 ID Pol. Ra 0.5μm/ OD Pol. Ra 0.8μm SF4 ID EP Finished Ra 0.38μm/ OD Pol. Ra 0.8μm CSE BPE EP products with followi