Transcription

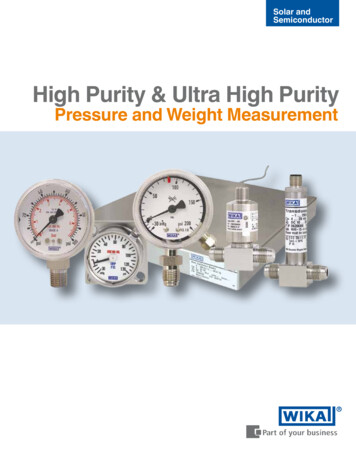

Solar andSemiconductorHigh Purity & Ultra High PurityPressure and Weight MeasurementR

Electronic Pressure MeasurementHigh Purity & Ultra High Purity - Pressure and Weight MeasurementWIKA offers a wide variety of gas and chemicaldelivery products engineered to the demandingstandards of the semiconductor and photovoltaicindustries.Superior QualityIndustry Driven ProductsApplication ExamplesComprehensive quality control and engineering effortsensure that every WIKA instrument is built to last.WIKA’s High Purity and Ultra High Purity productsare designed to the rigorous standards andrecommendations relevant to the manufacturing ofphotovoltaic cells and modules (ASME, SEMATECH,SEMI, RoHS and NEMA) and to the semiconductormarket and its governing agencies (ASME,SEMATECH and SEMI). Photovoltaic production Semiconductor, microelectronics and flat paneldisplay production Gas panels for OEM tools Specialty and bulk-gas distribution Gas cabinets, gas panels, gas sticks and valvemanifold boxes (VMB) Chemical distribution systemsInnovative Custom DesignsA team of development engineers provide customizeddesigns to meet customer specific applications andrequirements.Gas Cylinder ScalesAttachable IndicatorsGCS-1WUR-1WIKA’s Gas Cylinder Scales are engineered anddesigned for liquid delivery sources used in both indoorand outdoor hazardous and nonhazardous applications.WIKA’s Attachable Indicators provide a local display of theprocess pressure measured by the transducer. In addition,the indicators provide an analog output signal (current orvoltage as provided by the transducer) and two programmableswitch points.Ranges0 300 lbs(approximately 136 kg)0 100 lbs(approximately 45 kg)0 60 lbs(approximately 27 kg)Display Design7-segment LED (red); 4 digitsProgrammable Pressure UnitsBar, PSI, kg/cm², MPa, kPaFrontViewOutputs4-20mA, 0-5VDC, 0-10VDC2 NPN (open collector) switch pointsOutput4-20mA (all units), 0-5VDC(only for 300 lbs units)Accuracy 0.5% RSS /- 1 digitAccuracy 0.1% RSSIngress ProtectionIP65Dimensions9.25” x 9.25” x 1.25”(235 mm x 235 mm x 32 mm)SideViewIngress ProtectionNEMA 4 / IP65-2-c all 1-888-WIKA-USA or

Electronic Pressure MeasurementUltra High Purity TransducersWUC-10, WUC-15, WUC-16WU-20, WU-25, WU-26The ultra compact design of the WUC series transducer meetsthe smallest product footprint requirements. The space-savingdesign easily replaces comparable transducers, making it theperfect fit for new equipment and retrofit projects.The WU-2 series transducer combines state-of-the-artdigital transducer concepts with analog-like output signals toprovide the safest and most accurate pressure measurementsnecessary for today’s demanding market requirements.Ranges15 psi to 5,000 psi(and other equivalent pressure units)Vacuum, compound, absolute, gaugeRanges15 psi to 5,000 psi(and other equivalent pressure units)Vacuum, compound, absolute, gaugeWUC-16Output4-20mA, 0-5VDC, 0-10VDCAccuracy 0.20% RSSWU-26Output4-20mA, 0-5VDC, 0-10VDCAccuracy 0.15% RSSWUC-10Ingress ProtectionNEMA 4 / IP65(side access zero point adjustment)WU-20Ingress ProtectionNEMA 4 / IP65(side access zero point adjustment)WU-25WUC-15WU-10, WU-15, WU-16Ranges15 psi to 5,000 psi(and other equivalent pressure units)Vacuum, compound, absolute, gaugeWU-15Output4-20mA, 0-5VDC, 0-10VDCAccuracy 0.25% RSSIngress ProtectionWU-10NEMA 3 / IP54(side access zero point adjustment)WU-16v i si t w ww.wika.com/uhp-3-

Mechanical Pressure MeasurementHigh Purity GaugesUltra High Purity Gauges130.15230.15The 130.15 is the ideal gauge for specialty gas, high purityand PV applications in systems using NPT connections.The 230.15 is the right choice for specialty gas, high purity, PVand SEMI applications in systems using face-seal connections.Gauge TypeBourdon tubeGauge TypeBourdon tubeSize2” (53 mm)1½” (40 mm)Size2” (53 mm)1½” (40 mm)Accuracy2”: 2/1/2 % of span (ASME B40.100 Grade A)1½”: 3/2/3 % of span (ASME B40.100 Grade B)Accuracy2”: 2/1/2 % of span (ASME B40.100 Grade A)1½” 3/2/3 % of span (ASME B40.100 Grade B)Case304 stainless steel, electropolishedCase304 stainless steel, electropolishedWetted Surface316L stainless steelRa 1.0µm (Ra 40µinch)-internalWetted Surface316L stainless steel electropolishedRa 0.25µm (Ra 10µinch)Connection Type and Position¼” NPT Lower Mount and Center Back MountConnection Type and Position¼” face seal, Lower Mount and Center Back MountTestingHelium leak tested 1 x 10-9 scc/sec (inboard)TestingHelium leak tested 1 x 10-9 scc/sec (inboard)CleanlinessASME B40.1, level IV (for oxygen service)CleanlinessSpecial cleaning according to SEMI specPackagingSingle nylon bag, nitrogen purgedPackagingCleaned, nitrogen purged and double bagged in clean roomUltra High Purity GaugesUltra High Purity GaugesThe 230.25 is best suited for applications that insist on VIM/VARwetted parts and face-seal connections.The 430.25 is the perfect gauge for low pressure, point-of-useapplications. The gauge’s diaphragm design reduces particlegeneration and increases dry-down times.432.25230.25Gauge TypeBourdon TubeGauge TypeDiaphragmSize2” (53 mm)1½” (40 mm)Size2” (53 mm), 1½” (40 mm), 11/8” (28 mm)Accuracy2”: 3/2/3 % of span (ASME B40.100 Grade B)1½”: 4/3/4 % of span (ASME B40.100 Grade C)11/8”: 4/3/4 % of span (ASME B40.100 Grade C)Accuracy2”: 2/1/2 % of span (ASME B40.100 Grade A)1½”: 3/2/3 % of span (ASME B40.100 Grade B)Case304 stainless steel, electropolished432.25, 2”Case304 stainless steel, electropolishedWetted Surface316L stainless steel VIM/VAR, electropolishedRa 0.25µm (Ra 10µinch)Wetted Surface316L stainless steel electropolishedRa 0.25µm (Ra 10µinch)Connection Type and Position¼” face seal, Lower Mount and Center Back MountConnection Type and Position1/4” face seal, flow-through11/8” C sealTestingHelium leak tested 1 x 10-9 scc/sec (inboard)432.25, 11/2”TestingHelium leak tested 1 x 10-9 scc/sec (inboard)CleanlinessSpecial cleaning according to SEMI specCleanlinessSpecial cleaning according to SEMI specPackagingCleaned, nitrogen purged and double bagged in clean room-4-432.25, 11/8”PackagingCleaned, nitrogen purged and double bagged in clean roomc all 1-888-WIKA-USA or

Mechanical Pressure MeasurementIndicating Pressure Switch GaugesUsed in gas delivery applications, WIKA’s Indicating Pressure Switch (IPS) Gauges are available with either a magnetic reedor inductive switch alarm contact. Alarm contacts provide safe and reliable monitoring and control of process gases.Magnetic Reed Switch GaugesInductive Switch Gauges230.15, 230.25 851.3 Alarm Contact130.15, 230.15, 230.25 830.1E Alarm ContactGauge TypeBourdon tubeGauge TypeBourdon tubeSwitch TypeMagnetic ReedSwitch TypeInductive, NPN or PNPSize2” (53 mm)Size2” (53 mm)Accuracy2”: 2/1/2 % of span(ASME B40.100 Grade A)Accuracy2”: 2/1/2 % of span(ASME B40.100 Grade A)Case304 stainless steel, electropolishedCase304 stainless steel, electropolished230.25 851.3130.15 830.1EAlarm Contact shownWetted SurfaceAlarm Contact shown230.15: 316L stainless steelelectropolished Ra 0.25µm (Ra 10µinch)Wetted Surface130.15: 316L stainless steelRa 1.0µm (Ra 40µinch)-internal230.25: 316L stainless steel VIM/VARelectropolished Ra 0.25µm (Ra 10µinch)230.15: 316L stainless steel electropolishedRa 0.25µm (Ra 10µinch)Connection Type and Position230.15: ¼” face seal Lower Mount andCenter Back Mount (NPT option available)230.25: 316L stainless steel VIM/VAR, electropolishedRa 0.25µm (Ra 10µinch)Connection Type and Position130.15: ¼” NPT Lower Mount and Center Back Mount230.25: ¼” face seal Lower Mount and Center Back MountTestingHelium leak tested 1 x 10-9 scc/sec (inboard)230.15: ¼” face seal Lower Mount and Center Back MountCleanlinessSpecial cleaning according to SEMI specTestingHelium leak tested 1 x 10-9 scc/sec (inboard)230.2:5 ¼” face seal Lower Mount and Center Back MountPackagingCleaned, nitrogen purged and double bagged in clean roomCleanliness130.15: ASME B40.1, level IV (for oxygen service)230.15: Special cleaning according to SEMI spec230.25: Special cleaning according to SEMI specPackaging130.15: Single nylon bag, nitrogen purged230.15: Cleaned, nitrogen purged anddouble bagged in clean room230.25: Cleaned, nitrogen purgedand double bagged in clean roomv i si t w ww.wika.com/uhp-5-

Pressure GaugesPressure Gauges for High Purityand Ultra High Purity ApplicationsHPModelNominal sizeWindow type / material1½” (40 mm)130.151½” (40 mm)230.152” (53 mm)twist-lock / polycarbonatesnap-in / polycarbonatetwist-lock / polycarbonateGrade BGrade AGrade BGrade A 3/2/3 2/1/2 3/2/3 2/1/2-1 0 bar0 1000 barAccuracy% of span2” (53 mm)snap-in / polycarbonateScale rangeClass according to ASMEB40.1UHPDesign-30 inHG . 0 psi0 . 14,500 psiBourdon tube gaugeGauge type316L stainless steelTube or diaphragm materialMeasurement systemdesignstandard designgap free designSocket or lower partmaterial316L stainless steelblack, aluminumPointerwhite, aluminumDial304 stainless steel electropolishedCasepolycarbonateWindowWetted surface treatmentBourdon tubeMeasuring systemDynaflow extrude hone passivated after weldingRa 0.5µm (Ra 20µinch)1/4” NPT male1/4” face sealProcess connectionStandardinternal surface passivated (ASTM A967)O2 cleaned acc. ASME Level IVwetted surface finish: Ra 1.0µm (Ra 40µinch) - internalwetted surface electropolished Ra 0.25µm (Ra 10µinch)weld stubweld stub1/4” face sealOptionCleaning treatmentProduction environmentCalibration mediummanufactured on standard work floorpure nitrogenASME B40.1, level IV (for oxygen service)Cleanlinesssingle nylon bag, nitrogen purgedPackingAlarm contactsInductive switchMagnetic reed switchLegend:Standard1/4” NPT male851.3-6-special cleaning according to SEMI speccleaned, nitrogen purged and double bagged in cleanroom830.1E(NPN)830.1E(PNP)Standard manufactured in cleanroom830.1E(NPN)830.1E(PNP)851.3Standard c all 1-888-WIKA-USA or

Presure GaugesUHP1½” (40 mm)UHP Flow-through gauges230.25snap-in / polycarbonate-1 0 bar0 400 bar2” (53 mm)twist-lock / polycarbonate432.2511/8” (28 mm)-30 inHG . 0 psi0 . 6000 psi1½” (40 mm)2” (53 mm)snap-in / polycarbonatetwist-lock / polycarbonate-1 . 4 bar-1 . 9 bar-30 inHG . 60 psi-30 inHG . 130 psiGrade BGrade AGrade CGrade B 3/2/3 2/1/2 4/3/4 3/2/3higher accuracy on requestBourdon tube gaugeDiaphragm gaugegap free designno dead space - excellent to purge316L VIM/ VAR316L stainless steel316L stainless steelInconelblack, aluminumwhite, aluminum304 stainless steel electropolishedpolycarbonateinternal surface passivated (ASTM A967)---Dynaflow extrude hone, passivated and electropolishedafter welding. Ra 0.25µm (Ra 10µinch)1/4” face sealall wetted surface of lower part electropolished.Ra 0.25µm (Ra 10µinch)MSM 1 1/8”316L VIM/VAR gland1/4“ face seal fixed male onlywetted surface electropolished Ra 0.25µm (Ra 10µinch)weld stub1/4‘‘ or 1/2‘‘ face sealweld stubmanufactured in cleanroompure nitrogenspecial cleaning according to SEMI specificationcleaned, nitrogen purged and double bagged in cleanroomv i si t w ww.wika.com/uhp830.1E(NPN)830.1E(PNP)851.3-7-

For over 60 years, WIKA Instrument Corporation has continuouslyadvanced pressure gauge, transmitter and temperature measurementinstrumentation. As the global leader in lean manufacturing, WIKAoffers a broad selection of stock and custom instrumentation solutions,which are often available for distribution within days. Producing over40 million gauges, diaphragm seals, transmitters and thermometersworldwide annually, WIKA’s extensive product line provides measurement solutions for any application. The WIKA sales team, along withits customer service and technical staff members, are ready to sharetheir extensive product and industry knowledge to make your businessexperience with WIKA productive and progressive.UHP Gauge230.15UHP TransducerWUC-15WIKA Instrument CorporationPressure and Temperature Measurement1000 Wiegand BoulevardLawrenceville, GA 30043Toll Free (888) WIKA-USA (888-945-2872)Tel (770) 513-8200 Fax (770) 338-5118uhp@wika.com www.wika.com/uhpB003 - 1000 07/10 WIKA Instrument CorporationAll rights reservedWIKA provides distinctive service and support to our channelpartners and customers: Award winning U.S.-based manufacturing, sales and orderingcustomer service and technical support Certified technical specialists who conduct Best PracticeInstrument Reviews with performance improvement reports An in-house engineering team for product customization and innovation Proven capabilities to connect with customer business processesfor ordering and inventory management Web-based customer service features, including RFQs, literaturerequest and competitor product cross referenceR

ASME B40.1, level IV (for oxygen service) Packaging Single nylon bag, nitrogen purged 230.15 The 230.15 is the right choice for specialty gas, high purity, PV and SEMI applications in systems using face-seal connections. Gauge Type Bourdon tube Size 2” (53 mm) 1½” (40 mm) Accuracy 2”: 2/1/2 % of span (ASME B40.100 Grade A) 1½” 3/2/3 % of span (ASME B40.100 Grade B) Case 304 stainless .