Transcription

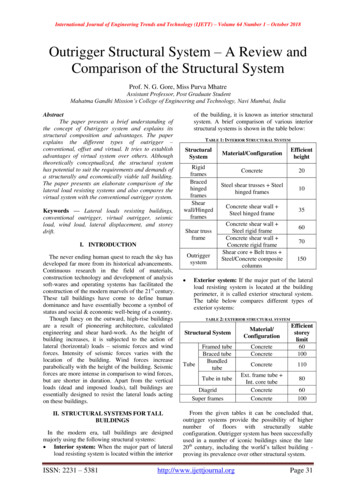

International Journal of Engineering Trends and Technology (IJETT) – Volume 64 Number 1 – October 2018Outrigger Structural System – A Review andComparison of the Structural SystemProf. N. G. Gore, Miss Purva MhatreAssistant Professor, Post Graduate StudentMahatma Gandhi Mission’s College of Engineering and Technology, Navi Mumbai, IndiaAbstractThe paper presents a brief understanding ofthe concept of Outrigger system and explains itsstructural composition and advantages. The paperexplains the different types of outrigger –conventional, offset and virtual. It tries to establishadvantages of virtual system over others. Althoughtheoretically conceptualized, the structural systemhas potential to suit the requirements and demands ofa structurally and economically viable tall building.The paper presents an elaborate comparison of thelateral load resisting systems and also compares thevirtual system with the conventional outrigger system.Keywords — Lateral loads resisting buildings,conventional outrigger, virtual outrigger, seismicload, wind load, lateral displacement, and storeydrift.of the building, it is known as interior structuralsystem. A brief comparison of various interiorstructural systems is shown in the table below:TABLE 1: INTERIOR STRUCTURAL sShearwall/HingedframesShear trussframeI. INTRODUCTIONThe never ending human quest to reach the sky hasdeveloped far more from its historical advancements.Continuous research in the field of materials,construction technology and development of analysissoft-wares and operating systems has facilitated theconstruction of the modern marvels of the 21st century.These tall buildings have come to define humandominance and have essentially become a symbol ofstatus and social & economic well-being of a country.Though fancy on the outward, high-rise buildingsare a result of pioneering architecture, calculatedengineering and shear hard-work. As the height ofbuilding increases, it is subjected to the action oflateral (horizontal) loads – seismic forces and windforces. Intensity of seismic forces varies with thelocation of the building. Wind forces increaseparabolically with the height of the building. Seismicforces are more intense in comparison to wind forces,but are shorter in duration. Apart from the verticalloads (dead and imposed loads), tall buildings areessentially designed to resist the lateral loads actingon these buildings.II. STRUCTURAL SYSTEMS FOR TALLBUILDINGSIn the modern era, tall buildings are designedmajorly using the following structural systems: Interior system: When the major part of lateralload resisting system is located within the interiorISSN: 2231 – 5381Outriggersystem el shear trusses Steelhinged frames10Concrete shear wall Steel hinged frame35Concrete shear wall Steel rigid frameConcrete shear wall Concrete rigid frameShear core Belt truss Steel/Concrete compositecolumns6070150Exterior system: If the major part of the lateralload resisting system is located at the buildingperimeter, it is called exterior structural system.The table below compares different types ofexterior systems:TABLE 2: EXTERIOR STRUCTURAL SYSTEMStructural SystemTubeFramed tubeBraced tubeBundledtubeTube in tubeDiagridSuper crete110Material/ConfigurationExt. frame tube Int. core tubeConcreteConcrete8060100From the given tables it can be concluded that,outrigger systems provide the possibility of highernumber of floors with structurally stableconfiguration. Outrigger system has been successfullyused in a number of iconic buildings since the late20th century, including the world’s tallest building proving its prevalence over other structural system.http://www.ijettjournal.orgPage 31

International Journal of Engineering Trends and Technology (IJETT) – Volume 64 Number 1 – October 2018III.OUTRIGGER STRUCTURAL SYSTEMIV. LITERATURE REVIEWThe outrigger structural system is a lateral loadresisting system in which the external peripheralcolumns are tied to the central core with very stiffoutriggers and belt truss at or more levels. The belttrusses are tied to the peripheral columns of thebuilding while the outriggers engage them with mainor central shear wall. This structural system iscommonly used as one of the structural systems toefficiently control excessive drift due to lateral load,so that during small or medium lateral load due toeither wind or earthquake, the risk of structural andnon-structural damage is minimized. The structuralresponse of an outrigger system is based on tensioncompression couple induced in the outer columns.The outrigger acts as a stiff arm engaging outercolumns and central core. The lateral load wheninduced in the central core is transferred to peripheralcolumns via outriggers and the overturning momentreduced.The concept of outrigger system is drawn from theuse of a contraposing float rigging beyond the side ofa boat to improve the vessel’s stability against windin the sea. This simple mechanism sophisticatedmodern researchers’ minds to develop outriggerstructural system. Successful projects have been builtwith the outrigger concept. A lot of research has beendone in understanding outrigger typologies, materialuse, placing and connections and efficient positioningof outriggers.Andrew J. Horton in ‘Virtual Outriggers in TallBuildings’ has given an elaborate overview ofconventional, offset and alternative offset outriggers.His paper concludes that virtual outriggers can beused with the same efficiency as conventionaloutriggers when efficiently proportioned perimeterbelt truss and floor diaphragms are used.Smith and Coull made a hypothetical assumptionthat the outriggers are flexurally rigid and devised forthe optimum – the outriggers should be placed at1/(n 1), 2/(n 1), up to the n/(n 1) height locations,i.e. for one-outrigger structure at approximately halfheight, for two-outrigger structure at one-third andtwo-third height, for three-outrigger structure at onequarter, one-half and three-quarter heights, and so on.R Shankar Nair explained the advantages ofvirtual outrigger system over the conventional typeand explained the ways of using virtual outriggersystem. The paper compared lateral displacement of75 - storey model subjected to wind load for differentstructural designs. The results obtained are as follows:.Fig 1: Structural response of OutriggerTABLE 3: COMPARISON FOR LATERAL DISPLACEMENTFor high-rise buildings, particularly in seismicallyactive zone or wind dominant regions, outriggersystem is chosen to be appropriate structural system.Outrigger structural system is broadly classified intothe following: Conventional outrigger system: In this system,the outrigger trusses or girders are connecteddirectly to shear walls or braced frames at thecore and to the columns located at the peripheryof the structure. Offset outrigger system: In offset outriggersystem, the outriggers are located elsewhere thanin the planes of the core walls while retaining allthe advantages and mitigating some of thedisadvantages of the conventional outriggersystem. Virtual outrigger system: In virtual outriggersystem the transfer of overturning moment fromcore to peripheral columns is achieved without adirect connection between the peripheral columnsand the core. This is achieved using floordiaphragms which transfer overturning momentin the form of a horizontal couple from core tothe outboard. A belt truss connecting theperipheral is also added.ISSN: 2231 – 5381Structural SystemNo outriggerConventional OutriggerBelt truss as virtual OutriggerBelt truss as virtual Outrigger: 10fold increase in floor diaphragmstiffnessBelt truss as virtual Outrigger: 10fold increase in floor diaphragmstiffness, 10 fold increase in floorbelt truss stiffnessLateraldisplacement108.5 inch25.3 inch37.1 inch31.0 inch26 inchPo Seng Kian and Frits Torang Siahaan studiedthe use of outrigger and belt truss system in high-riseconcrete buildings of 40 and 60 storeys subjected towind and seismic load. The paper concluded that theuse of outrigger and belt-truss system in high risebuildings increases the stiffness and made structuralform efficient under lateral loads.J. R. Wu and Q. S. Li presented designs of multioutriggers in tall buildings and also gave an elaboratedescription of the structural performance of outriggerbraced frame-core structures. The paper presentshttp://www.ijettjournal.orgPage 32

International Journal of Engineering Trends and Technology (IJETT) – Volume 64 Number 1 – October 2018numerical equations for analysis of multi-outriggersystems subjected to uniformly distributed load,horizontal load and triangular load.Z. Bayati gave light on the use of optimumnumber of outrigger systems in a building using a 80storey model and investigating on drift reduction. Theresults imply that optimized use of multi-outriggersystem effectively reduces the seismic response of abuilding.N. Herath reviewed the behaviour of outriggerbeams in high rise buildings under the influence ofseismic loads. The optimum outrigger location isdetermined at 0.44-0.48 times the height of thebuilding.S. Fawzia, et al studied the effects of cyclonicwinds on 28, 42 and 47 storey buildings of L –shapedlayout. The results show that the plan dimensionshave vital impact on structural heights. Also, increasein height with same plan dimensions leads toreduction in lateral rigidity.Hi Sun Choi and Leonard Joseph outlined adetailed approach for design considerations inoutrigger system. It gives design guidelines forconventional and virtual outrigger system. It explainsfactors like structural aspects, load transfer paths,optimum location of outrigger, diaphragm floors,stiffness reduction, differential shortening of columnsand thermal impact.V. EXISTING TALL BUILDINGS WITHOUTRIGGERTechnological advancements and continuousresearch have metamorphically made reaching thestars a reality. Buildings with heights as high as 800m have been conveniently built. But at such heights,resisting lateral loads are a challenge; which arevigilantly tackled by engineers by careful selection ofsuitable lateral load resisting system. A number ofnoted buildings around the world have outriggerframe structural system which has proven efficiencyto effectively resist lateral loads and providestructural serviceability. Existing buildings havemade use of conventional outrigger system as well asoffset outrigger system. The table below lists few ofthe popular tall-buildings round the globe usingoutrigger system:CityBurj KhalifaDubaiTaipei 101TaipeiShanghai WorldsFinancial CentreInternationalISSN: 2231 – 5381ShanghaiHongDetails828 m160 floors509 m101 floors492 m101 floors483 m133The 163 storey and 828 m tall Burj Khalifa is a‘Y’ shaped building constructed in 2010 in Dubai,UAE.The world’s tallest building is a reinforcedconcrete structure using high strength concrete of 6080 MPa throughout the height of the building. Thecentral hexagonal core is buttressed by wing shearwalls with each wing having outriggers connectingshear walls to external columns.Taipei 101 is an office building with 101 storeysand is 508 m tall.TABLE 4: SKYSCRAPERS WITH CONVENTIONALOUTRIGGER SYSTEMBuildingCommerce CentreKong118 floorsPetronas TwinKuala452 mTowersLumpur88 floorsNanjing Greenland450 mNanjingFinancial Centre89 floorsTrump International423 mChicagoHotel & Tower96 floors#: Number of Outrigger levels in the building#51184http://www.ijettjournal.orgPage 33

International Journal of Engineering Trends and Technology (IJETT) – Volume 64 Number 1 – October 2018A composite building with a 63.5 x 63.5 m squarecross section at the base, the building has 8 modulesof truncated pyramid. High strength concrete of 70MPa is used and the structure has 8 perimeter megacolumns and 16 core columns – all composite.Constructed in 1998, the Petronas Towers is a452-m tall, 88- storey building reinforced concretebuilding in the shape of an 8-pointed star. Bothtowers of the building have identical shape and areconnected at 38th floor by a two-storey deep outrigger.The diameter of 16 perimeter columns varies from240 cm at the bottom to 120 cm at the top. Thereinforced concrete cores of both the buildings aresized 22.9 x 22.9 mAlthough successfully used, the conventionaloutrigger system has its own disadvantages. Also, incontrast to the wealth of information and real lifeexamples of conventional outriggers, there is arelative dearth in the exploration in the field of virtualand offset outrigger. Very few buildings have beenmade using these structural systems. They are:TABLE 4: SKYSCRAPERS WITH OUTRIGGER SYSTEMBuildingDetailsDubai Tower, Doha438 m90 floorsPlaza Rakyat OfficeTower, Malaysia382 m79 floorsISSN: 2231 – 5381Outriggerinformation1 Conventional;2 Alternativeoffset1 Conventional;2 VirtualAston ApartmentsResidential Tower,Sydney90 m30 floors1 AlternativeOffsetThe only skyscraper with a virtual outrigger systemis Plaza Rakyat in Kuala Lumpur. The construction ofthe 382 m tall-building started in 1990s but is stillpending.VI. VIRTUAL OUTRIGGER SYSTEMVirtual outrigger provides lateral stability to thebuilding by no direct connection between the core andthe peripheral columns. The load is transferred toperipheral columns via floor diaphragms which arestiffer in their plane. The concept of virtual outriggerpresents a reasonably unique solution to the problemsposed by conventional outrigger.The main feature of virtual outriggers is the use ofdiaphragm floors. Understanding the behaviour offloor diaphragms is important for efficientfunctioning of a structure with virtual outrigger aslateral load resisting system. Diaphragm floor is astiff & strong floor placed at the top and bottom ofthe virtual outrigger storey, at the periphery of whichbelt wall or belt truss is used to connect externalcolumns. The diaphragm transfers the overturningmoment from the core to external

Bundled tube Concrete 110 Tube in tube Ext. frame tube Int. core tube 80 Diagrid Concrete 60 Super frames Concrete 100 From the given tables it can be concluded that, outrigger systems provide the possibility of higher configuration. Outrigger system has been successfully used in a number of iconic buildings since the late 20th-proving its prevalence over other structural system .