Transcription

TECHNICAL RANGEThe Complete PipeFitting’s Handbook

CONTENTSPAGECompression Fittings Introduction1Copper Tubing for Economy2Making a Compression Joint3Compression Fittings4Gate Valves18Stop Taps19Capillary Fittings Introduction20Making a Capillary Joint22Capillary Fittings22Copper Tubing for Domestic Plumbing38

Branch 3Run 1Run 2Special NoteThroughout this booklet sizes for unequal ends of tees havebeen given in the number order as indicated above. Whenordering, use the same system, the branch size always beingstated last.All imperial sizes quoted refer to ends for BSP threadconnections. All metric sizes quoted refer to nominal sizes forcopper tubes to SABS.In the compression range both male and female connectingthreads are BSP parallel.In the capillary range all male connecting threads are BSPTaper. All female connecting threads are BSP parallel.

INTRODUCTIONCompression FittingsThe compression ring type copper tube joining system wasdesigned and introduced in the United Kingdom in 1933. Cobraintroduced it to the South African market in the early 1950's, underthe “Conex” brand at the time and in recent years under theCOBRA brand.The versatility, efficiency and jointing speed led to its rapidadoption by plumbing contractors. The introduction of Hard DrawnCopper Tube has led to the wider use of copper tube systems ininland areas. Cobra compression is suitable for use with harddrawn (SANS 460 class O) tubing as well. Inland contractors havediscovered that with Cobra compression fittings they can usecheaper, less skilled labour. It is a much faster system to installthan the ones used traditionally and the range of fittings iscomprehensive and all made locally. It has the added advantagethat the pipework can be dismantled and re-assembled, should theneed arise. Cobra compression fittings is ideally suited for use inemergency repairs as well, for instance with the slip couplings D1XL-15 S/C and D-1XL-22 S/C which can be used to make a repairconnection to rigid pipework mounted close to a wall.The fact that the complete connection is a metal to metalmechanical coupling makes it both permanent (no organic sealingmaterial that can deteriorate), as well as being suitable forapplications where the heat and open flames of solderedconnections can pose a hazard.With the introduction of SABS Specification 1067-2 in 1985 whichrequired the use of DEZINCIFICATION RESISTANT BRASS, Cobratook steps to ensure that Cobra compression fittings complied withthis specification.Cobra commpression fittings can be used in conjunction withCobra Safe Single Layer Polyethylene Pipe System as well asCobra Safe Multi Layer Polyethylene Pipe System.1

COPPER TUBING FOR ECONOMYDZR Brass: All Cobra compression fittings are manufacturedfrom Dezincification Resistant Brass as required by SANS 1067Part 1 and 2 Specification.Using Copper Tube Saves You Money In Many Ways: It is faster (over 50% in time can be saved) No thread cutting and extra costly labour – giving increasedoutput Prefabrication – on large repetitive installations the systemlends itself admirably to prefabrication – this is especially sowhen used in conjunction with Copcal capillary solder fittings No heavy equipment to transportAdvantages of Copper Tubing Systems: Excellent corrosion resistance, both internal and externalLow in service maintenance (no furring)Superior flow characteristics – even after many yearsSpace savingNeat appearance where exposedShallower chasing in wallsCost effective in terms of overall installed costNo heavy equipment requiredLight weight – facilitating transport, fabrication andinstallationCopper Builds Confidence!2

MAKING A COMPRESSION JOINT1. Copper Tube can be cut with a hacksaw:a fine toothed blade is best, or use a rollertube cutter; Do not use too much pressureon the cutting disk.2. Clean the ends of the tube with a file orde-burring tool, inside and outside.3. The parts of the joint can be laid out like thisbefore assembly.4. Slide the copper tube into the Cobracompression fitting until it stops against thefitting’s inner shoulder. Tighten the cap nut byhand, ensuring that the tube stays firmlyagainst the fitting’s inner shoulder.55. Following hand tightening of the cap nut,tighten with a spanner until the copper tube isdifficult to rotate in the compression fitting,thereafter tighten the cap nut through half aturn. Inspect and pressure test the joint pipe.This compression joint is designed to be a metal to metalmechanical coupling (also applicable to Cobra SLP & MLPsystems, no de-burring necessary); there is therefore noneed for any additional sealant material or compounds.3

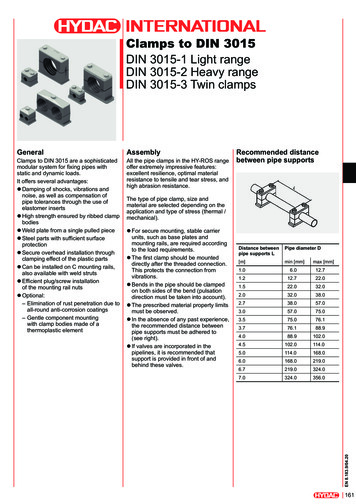

COMPRESSION FITTINGSD-1XSStraight Coupler.Copper to Copper connections.15mm; 22mm;28mm; 35mm;42mm; 54mm* Also available D-1XL-12 S/C,D-1XL-15 S/C, D-1XL-18 S/Cand D-1XL-22 S/C Slip Couplings(without internal pipe stops) forrepairs or alterations to rigid pipework.D-2XSStraight Coupler.Copper to Male Iron connections.15mm x ½”; 22mm x ¾”;28mm x 1”; 35mm x 1¼”;42mm x 1½”; 54mm x 2”4

COMPRESSION FITTINGSD-3XSStraight Coupler.Copper to Female Iron connections.15mm x ½”; 22mm x ¾”;28mm x 1”; 35mm x 1¼”;42mm x 1½”; 54mm x 2”D-1RXSReducing Straight Coupler.Copper x Copper connections.22mm x 15mm;28mm x 22mm5

COMPRESSION FITTINGSD-4XSElbow, 90 .Copper to Copper connections.15mm; 22mm;28mm; 35mm;42mm; 54mmD-4RXSReducing Elbow, 90 .Copper to Copper connections.22mm x 15mm6

COMPRESSION FITTINGSD-2RXSReducing Straight CouplerCopper to Male Iron connections.15mm x ¾”;22mm x 1”D-3RXSReducing Straight CouplerCopper to Female Iron connections.15mm x ¾”7

COMPRESSION FITTINGSD-8XSElbow, 90 .Copper to Male Iron connections.15mm x ½”; 22mm x ¾”;28mm x 1”; 35mm x 1¼”;42mm x 1½”; 54mm x 2”D-10XSElbow, 90 .Copper to Female Iron connections.15mm x ½”; 22mm x ¾”;28mm x 1”; 35mm x 1¼”;42mm x 1½”; 54mm x 2”8

COMPRESSION FITTINGSD-33XSWallplate Elbow, 90 .Copper to Female Iron connections.15mm x ½”; 22mm x ¾”D-37XSSwivel Elbow, 90 .Copper to Female Iron connections.15mm x ½”9

COMPRESSION FITTINGSD-10RXSReducing Elbow, 90 .Copper to Female Iron connections.15mm x ¾”D-12XSEqual Tee.Copper toCopper connections.15mm; 22mm;28mm; 35mm;42mm; 54mm10

COMPRESSION FITTINGSD-15XSTee.Copper to Copper to Male Iron connections.15mm x 15mm x ½”;22mm x 22mm x ¾”D-17XSTee.Copper to Copper to Female Iron connections.15mm x 15mm x ½”;22mm x 22mm x ¾”11

COMPRESSION FITTINGSD-29XSWallplate Tee.Copper to Copper to Female Iron connections.15mm x 15mm x ½ “D-17RXSReducing Tee.Copper to Copper to Female Iron connections.22mm x 22mm x ½”12

COMPRESSION FITTINGSD-279XSReducing Tee.All ends Copper. Run equally reduced.15mm x 15mm x 22mm;22mm x 22mm x 28mmD-280XSReducing Tee.All ends Copper. Run and Branch equally reduced.22mm x 15mm x 15mm13

COMPRESSION FITTINGSD-79XSReducing Tee.All ends Copper. One end on Run reduced.22mm x 15mm x 22mmD-80XSReducing Tee.All ends Copper. Branch reduced.22mm x 22mm x 15mm;28mm x 28mm x 22mm14

COMPRESSION FITTINGSD-68XSSingle Step Reducer (for adapting a fitting)22mm x 15mm; 28mm x 22mm;35mm x 28mm; 42mm x 35mm;54mm x 42mmD-268XSMulti-Step Reducer28mm x 15mm; 35mm x 22mm;42mm x 22mm; 42mm x 28mm;54mm x 22mm; 54mm x 28mm;54mm x 35 mm15

COMPRESSION FITTINGS64XSCap Nut15mm; 22mm;28mm; 35mm;42mm; 54mmD-65XSBrass Compression Ring15mm; 22mm;28mm; 35mm;42mm; 54mm16

COMPRESSION FITTINGSD-23XSStop End15mm; 22mm; 28mm62XSBrass Holderbat for Copper Tube15 mm; 22mm17

GATE VALVES1003/125Fullway Gate Valve.Copper to Copper with non-rising spindle and guided wedge.15mm; 22mm;28 mm; 35mm;42mm; 54mmUse as an isolating valve ONLYSABS 776-1976, Class 818

STOP TAP131Stop Tap.Rough Brass. Copper to Copper15mm; 22mm; SABS28 mm; BS 1010SABS 226 Class 1 Heavy duty* Also available 231-15 Stop tap,Rough Brass, Copper to Copper;SABS 226 Class 2;SABS 226-1987, Type 119

INTRODUCTIONCapillary FittingsCobra introduced Capillary (or Solder) fittings to the SouthAfrican market in 1972. These fittings were, at that time,imported and did not have much impact on the traditionalcompression type copper tube market. However, with theintroduction of Hard Drawn Copper tubing, this system hasgained in popularity, particularly in those areas wheregalvanised piping has been used traditionally. Hard DrawnCopper tubing, when used with Cobra “Copcal” fittings, cancompare in cost with any conventional system.In 1984 Cobra began local manufacture of these fittings toSABS Specification 1067 Part 2, and today still manufacture theforged and cast DZR brass fittings.20

CAPILLARY FITTINGSThe comprehensive range of COBRA Capillary fittingsconforms to SABS 1067 Part 2 1985 as well as to DIN 2856.ISO 2016 and BS 864 standard specifications.The simple joining technique is a readily acquired skill andcan be mastered with little difficulty. Users of CobraCapillary fittings find this domestic plumbing much fasterthan any other.The introduction of a Hard Drawn Copper tube, lessexpensive than the widely used domestic copper tube andconforming to SABS 460 Class “O”, has made the choice ofa copper tube installation a most economic proposition.The hard drawn tube when used with COBRA fittings, cancompare in cost with any conventional system.The savings in installation time, the competitive price ofHard Drawn Copper tube and Cobra Capillary fittings andthe undeniable longevity of copper, all go to make theselection of this system sound economic sense.NOTE:Fittings with a “D-” prefix are manufactured from DezincificationResistant Brass.21

MAKING A CAPILLARY JOINT1. Copper Tube can be cut with a hacksaw: a finetoothed blade is best, or use a roller tubecutter; Do not use too much pressure on thecutting disk.2. Clean the ends of the tube with a file orde-burring tool, inside and outside.3. Apply flux to the outside of tube and inside cupof fitting so that the surfaces to be joined arecompletely covered. Use flux carefully andsparingly.4. Bend over end of solder wire - about thelength of the size of the fitting. 15mm solderfor 15mm fittings, etc. Over 50mm diameterapproximately three times the diameter ofthe fitting is required.5. Apply flame to the fitting to heat the tube andthe cop of the fitting until solder melts whenplaced at the joint, and then pass the flametowards the centre of the fitting until solder isabsorbed and joint completed.6. Remove excess solder with small brush (or adump cloth) while the plastic is leaving a filletaround end of fitting while it cools.22

CAPILLARY FITTINGS600MStraight Slip CouplerCopper to Copper connections.15mm, 22mm,28mm, 35mm,42mm, 54mm,67mm, 76mm,108mm.601MStraight CouplerCopper to Copper connections.15mm, 22mm,28mm, 35mm,42mm, 54mm,67mm, 76mm,108mm.23

CAPILLARY FITTINGS601MReducing Straight CouplerCopper to Copper connections.22mm x 15mm, 28mm x 15mm,28mm x 22mm, 35mm x 28mm,42mm x 35mm, 54mm x 42mm,76mm x 35mm, 76mm x 42mm,76mm x 54mm.601M-TCStraight Tap Connector.Copper to Female Iron connections.15mm x ½”; 22 x ¾”24

CAPILLARY FITTINGS601-2MReducing Straight Coupler.Copper to Copper connections.(To reduce a fitting)22mm x 15mm; 28mm x 15mm;28mm x 22mm; 35mm x 15mm;35mm x 22mm; 35mm x 28mm;42mm x15mm; 42mm x 22mm42mm x 28mm; 42mm x 35mm;54mm x 15mm; 54mm x 22mm;54mm x 28mm; 54mm x 35mm;54mm x 42mm; 67mm x 35mm;67mm x 54mm; 76mm x 35mm;76mm x 54mm; 76mm x 67mm;108mm x 76mm25

CAPILLARY FITTINGSD603MStraight Coupler.Copper to Female Iron connections.15mm x ½”; 22mm x ¾”;28mm x 1”; 35mm x 1¼”;42mm x 1½”; 54mm x 2”;76mm x 3”D603MReducing Straight Coupler.Copper to Female Iron connections.15mm x ¾”26

CAPILLARY FITTINGS604MReducing Straight Coupler.Copper to Male Iron connections.15mm x ¾”D604MStraight Coupler.Copper to Male Iron connections.15mm x ½”, 22mm x ¾”,28mm x 1”, 35mm x 1¼”,42mm x 1½”, 54mm x 2”,76mm x 3”.27

CAPILLARY FITTINGSD606MElbow 45 .Copper to Copper connections.15mm; 22mm;28mm; 35mm;42mm; 54mm;76mm; 108mm607MElbow 90 .Copper to Copper connections.15mm; 22mm;28mm; 35mm;42mm; 54mm;67mm; 76mm;108mm28

CAPILLARY FITTINGS607MReducing Elbow 90 .Copper to Copper connections.22mm x 15mm607M-TCBent Tap ConnectorCopper to Female Iron connections15mm x ½”; 22mm X ¾”29

CAPILLARY FITTINGSD707-3MReducing Elbow 90 .Copper to Female Iron connections.15mm x ¾”D707-3MElbow 90 .Copper to Female Iron connections.15mm x ½”; 22mm x ¾”;28mm x 1”; 35mm x 1¼”;42mm x 1½”; 54mm x 2”30

CAPILLARY FITTINGSD707-3-5MWallplate Elbow 90 .Copper to Female Iron connections.15mm x ½” ; 22mm x ¾”D707-4MElbow 90 .Copper to Male Iron connections.15mm x ½”; 22mm x ¾”;28mm x 1”; 35mm x 1¼”;42mm x 1½”; 54mm x 2”31

CAPILLARY FITTINGS611MReducing Tee.All ends Copper. Run equally reduced.15mm x 15mm x 22mm611MEqual Tee.All ends Copper.15mm; 22mm;28mm; 35mm;42mm; 54mm;67mm; 76mm;108mm32

CAPILLARY FITTINGS611MReducing Tee.All ends Copper. Branch reduced.22mm x 22mm x 15m; 28mm x 28mm x 15mm;28mm x 28mm x 22mm; 35mm x 35mm x15mm;35mm x 35mm x 22mm; 35mm x 35mm x 28mm;42mm x 42mm x 15mm; 42mm x 42mm x 22mm;42mm x 42mm x 28mm; 42mm x 42mm x 35mm;54mm x 54mm x 22mm; 54mm x 54mm x 28mm;54mm x 54mm x 35mm; 54mm x 54mm x 42mm;67mm x 67mm x 54mm; 76mm x 76mm x 35mm;76mm x 76mm x 42mm;76mm x 76mm x 54mm;108mm x 108mm x 54mm;108mm x 108mm x 76mm33

CAPILLARY FITTINGS611MReducing Tee.All ends Copper. One end on Run reduced.22mm x 15mm x 22mm;28mm x 22mm x 28mm611MReducing Tee.All ends Copper. Run and Branch equally reduced.22mm x 15mm x 15mm;28mm x 22mm x 22mm34

CAPILLARY FITTINGSD712MReducing Tee.Copper to Copper to Female Iron connections.15mm x 15mm x ½”;22mm x 22mm x ¾”D617MTube End Cap15mm; 22mm;28mm; 35mm;42mm; 54mm35

CAPILLARY FITTINGSD733MUnion Coupler.Copper to Copper connections.15mm; 22mm733-3MUnion Coupler.Copper to Female Iron connections.15mm x ½”36

CAPILLARY FITTINGSD733-4MUnion Coupler.Copper to Male Iron connections.15mm x ½”; 22mm x ¾”636MFull Crossover.Copper to Copper connectio

around end of fitting while it cools. Clean the ends of the tube with a file or de-burring tool, inside and outside. 2. 3. Apply flux to the outside of tube and inside cup of fitting so that the surfaces to be joined are completely covered. Use flux carefully and sparingly. 4. Bend over end of solder wire - about the