Transcription

NRC ISFSI PadConstruction InspectionTaiwan ISFSI WorkshopDecember 9, 2008Ray Kellar, P. E., RIV Inspector817-860-8164Ray.Kellar@nrc.gov1

Outline ISFSI Inspection Procedure 60853 Important-To-Safety (ITS) vs. Not-Important-To-Safety(NITS) Design Considerations–––––––Concrete and Subgrade StiffnessSeismic IssuesAnchored casksCoefficient of Friction between cask and padDifferential settlementLiquefactionStrength and Durability Concrete Construction– American Concrete Institute Codes (ACI) 318 & (ACI) 349– Additional ACI Codes– ASTM Standards NRC Findings2

ISFSI Inspection Procedure60853IP 60853 – On-Site Fabrication of Components and Construction ofan ISFSI Determine if the licensee has applied an appropriate safetyclassification (ITS vs. NITS) The vendor typically specifies the ISFSI pad classification (ITS orNITS) For NITS, the licensee may use commercial grade practices butmust still conform with design requirements The general licensee will have to address whether the ISFSI padwill support the static and dynamic loads from the casks,consider seismic interaction and address soil liquefaction asrequired by 10 CFR 72.212 (b)(2)(i)(B)3

ITS vs. NITS Classification Important-To-Safety (ITS) classification is normallyused for high seismic regions in the U.S. ITS requirements include:– Design using American Concrete Institute (ACI) 349Code requirements– Increased Quality Assurance oversight– Dedication of materials, including concrete andreinforcing bars– Documentation for materials and testing– Strict adherence to design requirements– Construction in accordance with ACI 349 Coderequirements– Strict adherence to ACI Code requirements - changeshave to be documented and approved4

ITS vs. NITS Classification Not-Important-To-Safety (NITS)classification normally specified forISFSI pad design and construction NITS requirements include:– Design using ACI 318 Code requirements– Construction using commercial gradeprocesses– Construction in accordance with ACI 318Code requirements.– Less documentation5

Design ConsiderationsConcrete and Subgrade Transport Evaluation Program established toensure that design basis drop limits are notexceeded Some cask vendors place a upper limit on theconcrete strength and the subgrade stiffness tokeep the design basis drop impact loadingbelow a specified limit Lower limits on concretestrength and subgrade stiffness are alwaysappropriate to ensure that the ISFSI pad willperform adequately (settlement) Subgrade tests are necessary to determinestiffness. Variety of tests are availableincluding plate test and penetration test6

Design ConsiderationsSeismic Issues The ISFSI design basis earthquake must beequivalent to or be enveloped by the safeshutdown earthquake of the nuclear plant The seismic response must be translated to thebase of the ISFSI pad The ISFSI pad must be sufficiently imbedded inthe ground such that vertical seismic loads willnot cause slab uplift Seismic analysis may be performed by eitherdynamic or static methods. Static methods arenormally used in low seismic zones A Soil-Structure-Interaction (SSI) analysis isrequired by 10 CFR 72.212(b)(2)(i)(B)7

Design ConsiderationsAnchored Casks High seismic zones may require that theISFSI pad be classified as Important-ToSafety If the seismic forces may overturn orcause excessive sliding of free-standingcasks then cask anchorage must be used If cask anchorage is necessary, theanchor bolts will also be classified as ITSand require adequate material testreports8

Design ConsiderationsCoefficient of Friction During a seismic event, the friction between theunanchored cask and the ISFSI concrete isincluded in the design calculations to ensure thatthe cask does not slide off the ISFSI pad oroverturn A layer of ice was discovered between a portionof the cask bottom and the concrete ISFSI pad.During a seismic event, the frictional forces couldhave been overcome and the cask could slide offthe ISFSI pad Precautions were implemented by licensees tokeep water and ice from underneath the casks9

Design ConsiderationsDifferential Settlement The pad must be designed to limitdifferential settlement Many licensees perform calculationsto determine the predicted differentialsettlement based on the sequentialplacement of the casks The analysis determines an optimumcask placement sequence to limit thedifferential settlement of the ISFSIpad10

Design ConsiderationsLiquefaction 10 CFR 72.212 requires that thepotential for liquefaction be analyzedfor the ISFSI pad Loose material, such as sand and siltcan cause the ISFSI pad/casks tosettle during a seismic event Some sites have had to useelaborate methods to support thepad including piles and piers11

Design ConsiderationsStrength and Durability The strength and durability of the concreteare important design and installationconcerns Strength:– Pad must be sufficiently rigid (strength at 28days)– Affected by mix design and amount of wateradded at jobsite Durability– Types of aggregates selected and amounts ofcontaminants present (chlorides, etc.)– Affected by rebar spacing and concreteplacement methods12

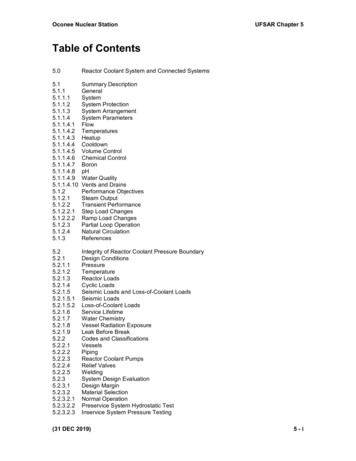

Concrete ConstructionACI 318 & ACI 349 Codes American Concrete Institute (ACI) 318provides building code requirements forstructural concrete ACI 349 provides code requirements fornuclear safety related structures The ISFSI and cask concrete areclassified as either Important-To-Safety orNot-Important-To-Safety The requirements of both ACI Codes arevery similar and reference numerous otherACI Codes and American Society forTesting and Materials (ASTM) standards13

Concrete ConstructionACI 318 & ACI 349 Codes The major construction requirementscontained in ACI 318 and 349 are: Testing of materials––––– CementAggregatesWaterReinforcing steelAdmixturesConcrete durabilityConcrete quality, mixing and placingConcrete formworkDetails of reinforcement14

Concrete ConstructionAdditional ACI Codes Additional ACI Codes that arereferenced and need to beaddressed are:– ACI 305 – Hot Weather Concreting– ACI 306 – Cold Weather Concreting– ACI 308 – Concrete Curing– ACI 309 – Concrete Consolidation15

Concrete ConstructionASTM Standards The American Society for Testing and Materials(ASTM) provide standards for testing methodsand concrete components The major ASTM standards that apply toconcrete are:–––––––ASTM C31 – Making & curing concrete samplesASTM C33 – Aggregate testingASTM C39 – Compressive strength testsASTM C94 – Ready-mixed concreteASTM C150 – Portland cementASTM C494 – Chemical admixturesASTM A615 – Reinforcing bars16

ISFSI Construction17

ISFSI Construction18

ISFSI Construction19

ISFSI Construction20

ISFSI Construction21

ISFSI Construction22

ISFSI Construction23

ISFSI Construction24

ISFSI Construction25

ISFSI Construction26

ISFSI Construction27

Cask Construction28

Cask Construction29

Cask Construction30

Cask Construction31

Cask Construction32

Cask Construction33

NRC Findings Design– Soil Structure Interaction not being completed Construction– Concrete compressive strength is either too low ortoo high– Adherence to ACI Code and ASTM Standardrequirements– Reinforcement bar tolerances not being achieved– Concrete slump outside specified range on VCCcask placement34

– American Concrete Institute Codes (ACI) 318 & (ACI) 349 – Additional ACI Codes – ASTM Standards NRC Findings. 3 ISFSI Inspection Procedure 60853 IP 60853 – On-Site Fabrication of Components and Construction of an ISFSI Determine if the licensee has applied an appropriate safety classification (ITS vs. NITS) The vendor typically specifies the ISFSI pad classification (ITS .