Transcription

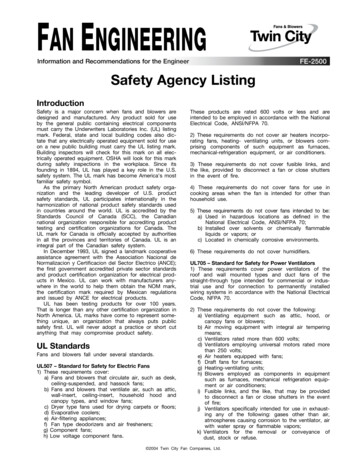

FAN ENGINEERINGInformation and Recommendations for the EngineerFE-2500Safety Agency ListingIntroductionSafety is a major concern when fans and blowers aredesigned and manufactured. Any product sold for useby the general public containing electrical componentsmust carry the Underwriters Laboratories Inc. (UL) listingmark. Federal, state and local building codes also dictate that any electrically operated equipment sold for useon a new public building must carry the UL listing mark.Building inspectors will check for this mark on all electrically operated equipment. OSHA will look for this markduring safety inspections in the workplace. Since itsfounding in 1894, UL has played a key role in the U.S.safety system. The UL mark has become America’s mostfamiliar safety symbol.As the primary North American product safety organization and the leading developer of U.S. productsafety standards, UL participates internationally in theharmonization of national product safety standards usedin countries around the world. UL is accredited by theStandards Council of Canada (SCC), the Canadiannational organization responsible for accrediting producttesting and certification organizations for Canada. TheUL mark for Canada is officially accepted by authoritiesin all the provinces and territories of Canada. UL is anintegral part of the Canadian safety system.In December 1993, UL signed a landmark cooperativeassistance agreement with the Association Nacional deNormalizacion y Certificacion del Sector Electrico (ANCE);the first government accredited private sector standardsand product certification organization for electrical products in Mexico. UL can work with manufacturers anywhere in the world to help them obtain the NOM mark,the certification mark required by Mexican regulationsand issued by ANCE for electrical products.UL has been testing products for over 100 years.That is longer than any other certification organization inNorth America. UL marks have come to represent something unique, an organization that always puts publicsafety first. UL will never adopt a practice or short cutanything that may compromise product safety.UL StandardsFans and blowers fall under several standards.UL507 – Standard for Safety for Electric Fans1) These requirements cover:a) Fans and blowers that circulate air, such as desk,ceiling-suspended, and hassock fans;b) Fans and blowers that ventilate air, such as attic,wall-insert, ceiling-insert, household hood andcanopy types, and window fans;c) Dryer type fans used for drying carpets or floors;d) Evaporative coolers;e) Air-filtering appliances;f) Fan type deodorizers and air fresheners;g) Component fans;h) Low voltage component fans.These products are rated 600 volts or less and areintended to be employed in accordance with the NationalElectrical Code, ANSI/NFPA 70.2) These requirements do not cover air heaters incorporating fans, heating- ventilating units, or blowers comprising components of such equipment as furnaces,mechanical-refrigeration equipment, or air conditioners.3) These requirements do not cover fusible links, andthe like, provided to disconnect a fan or close shuttersin the event of fire.4) These requirements do not cover fans for use incooking areas when the fan is intended for other thanhousehold use.5) These requirements do not cover fans intended to be:a) Used in hazardous locations as defined in theNational Electrical Code, ANSI/NFPA 70;b) Installed over solvents or chemically flammableliquids or vapors; orc) Located in chemically corrosive environments.6) These requirements do not cover humidifiers.UL705 – Standard for Safety for Power Ventilators1) These requirements cover power ventilators of theroof and wall mounted types and duct fans of thestraight-through type intended for commercial or industrial use and for connection to permanently installedwiring systems in accordance with the National ElectricalCode, NFPA 70.2) These requirements do not cover the following:a) Ventilating equipment such as attic, hood, orcanopy fans or blowers;b) Air moving equipment with integral air temperingmeans;c) Ventilators rated more than 600 volts;d) Ventilators employing universal motors rated morethan 250 volts;e) Air heaters equipped with fans;f) Draft fans for furnaces;g) Heating-ventilating units;h) Blowers employed as components in equipmentsuch as furnaces, mechanical refrigeration equipment or air conditioners;i) Fusible links, and the like, that may be providedto disconnect a fan or close shutters in the eventof fire;j) Ventilators specifically intended for use in exhausting any of the following: gases other than air,atmospheres causing corrosion to the ventilator, airwith water spray or flammable vapors;k) Ventilators for the removal or conveyance ofdust, stock or refuse. 2004 Twin City Fan Companies, Ltd.

UL762 – Power Roof Ventilators for Restaurant ExhaustAppliances1) These requirements cover roof or wall mounted ventilators for restaurant exhaust appliances.2) Power ventilators for restaurant exhaust appliancescovered by these requirements are intended for installation in accordance with the Standard of the National FireProtection Association for the installation of Equipmentfor the removal of Smoke and Grease-Laden Vaporsfrom Commercial Cooking Equipment.3) Power ventilators for restaurant appliances shall comply with ANSI/UL 705: Power Ventilators, modified in thatwiring system shall not be located in the path of travelof exhaust products.UL793 – Automatically Operated Roof Vents for Smokeand Heat1) These requirements cover automatically operated roofvents for smoke and heat that fall into two general categories: mechanically-opened and gravity-opened.Mechanically-opened vents consist primarily of a bodyframe, one or more damper covers and hatches, andoperating mechanisms that generally include a heatresponsive device and spring(s). The vents covered bythese requirements are operated manually or automatically in the event of fire to remove smoke and heat fromthe building. Automatic operation does not depend onelectrical power or other energy sources that may beinterrupted during a fire, but rather depends uponoperation of a heat responsive device or on the actionof a plastic cover shrinking and falling from place dueto fire exposure, or the like. These vents are not intended for use as general-purpose building ventilationdevices. Fans use the mechanically-opened type installedon the discharge of a fan discharging air up and awayfrom the building.A product that contains features, characteristics, components, materials or systems new or different fromthose covered in these standards and involves a risk offire, electric shock, or injury to persons shall be evaluated using the appropriate additional component andend product testing standards as determined necessaryto maintain an acceptable level of safety as originallyanticipated by the intent of the standards.Canadian StandardsCSA C22.2 No. 100-95 Motors and Generators1) This standard applies to electric motors and generators for installation and use, in accordance with the rulesof the Canadian Electrical Code, Part 1, in nonhazardouslocations.2) Clause 7 – AC and DC motors (including universalmotors), in IEC frame size 80 and smaller.Clause 8 – AC motors (including universal motors) in IECframe sizes 90 to 280 inclusive and rated 750 V andless. Clause 9 – AC motors rated over 750 V or in IECframe size 315 and larger.Clause 10 – all DC motors in IEC frame size 90 andlarger.Clause 12 – Inverter duty variable speed AC motors.3) This standard provides basic requirements for motorsand does not exclude any additional requirements givenin other Standards of the Canadian Electrical Code.4) This standard does not apply to:a) sealed (hermetic) type motors such as those usedin refrigerant compressors2b) electric motors for use in aircraft, marine serviceinstallations, drives for land transportation equip ment or motors used in underground mining.CSA C22.2 No. 113-M1984 Fans and Ventilators1) This standard applies to cord connected and permanently connected fans and ventilators intended to beconnected to supply circuits of 600 V and less, for usein nonhazardous locations and intended to be used inaccordance with the Rules of the Canadian ElectricalCode, Part 1.2) This Standard applies to fans and ventilators for ventilating or exhaust purposes and filter units consisting ofan air circulating fan and a mechanical filter.3) This standard applies to fans and ventilators of theair circulating type such as desk, pedestal, hassock,utility, suitcase and pendent ceiling fans.4) This standard applies to fans and ventilators of theventilating type such as wall insert, ceiling insert, attic,household hoods, or canopy and window fans.5) This standard does not apply to air conditioningequipment, electric air heaters, fan coil units, humidifiers,evaporative coolers, or electrostatic air cleaners.UL has developed more than 800 standards forsafety. They also have been accredited by the StandardsCouncil of Canada to test products to Canadian standards and authorize the use of the UL mark for Canada(cUL). UL tests more than 14,000 products every year.UL uses many other agencies and standards to helpguarantee safety in products. Some of those are NEMA(National Electrical Manufacturers Assoc.), NFPA (NationalFire Protection Agency), IEC (International ElectrotechnicalCommission), IEEE (Institute of Electrical and ElectronicEngineers), IBI (Intelligent Building Institute), ASME(American Society of Engineers), and so forth.UL standards are developed using an open processthat gives all interested parties the opportunity to comment as Standards are developed or revised. This process results in the development of Standards that arepractical for the manufacturer, compatible with otherstandards and installation codes, and effective inaddressing public safety issues.Product Evaluations and LabTesting per UL507 and 705UL Lists or Classifies products depending on the typeof product and intended use. Listing, the most comprehensive UL service, means that samples of the producthave been evaluated and found to comply with all applicable UL requirements. Products distributed in Canadaare evaluated to Canadian standards and carry the listing mark for Canada (the cUL mark), which specificallyindicates compliance with Canadian standards.Classification means that samples of the product havebeen evaluated with respect to standards of other organizations, specific properties of the product, a limitedspectrum of hazards, suitability for certain uses, or otherspecial conditions.Fans and blowers are tested in accordance with thetesting requirements listed in the Standards that pertainto their intended usage. Those standards are listed previously in sections II and III. The tests and testing processes are as follows:Fan Engineering FE-2500

Starting Current TestA ventilator shall start and attain normal running speedwithout opening a fuse when energized on a circuitprotected by a fuse of other than the time delay type.The fuse is to have a current rating corresponding tothat of the motor branch circuit to which the ventilatormay be connected in accordance with NEC, ANSI/NFPA70 – 1993. The ventilator is to be started three timeswhen connected to a circuit of minimum rated voltage.The motor is allowed to come to a rest then must berestarted immediately.Input TestThe current input to a ventilator shall not be more than110 percent of the rated value when the ventilator isoperated under conditions of actual service and connected to a supply circuit of maximum rated voltage andrated frequency. Unless otherwise specified, each ventilator is to be tested at the appropriate potential voltage.Table 1. Input Test VoltageRATED VOLTAGETEST VOLTAGE110 - 120120200 - 208208220 - 240240254 - 277277440 - 480480550 - 600600For the input test, the ventilator is to be connectedto a structure that can be adjusted to uniformly restrictthe air supply. The input is considered to be the maximum input measured while restricting the ventilator inletto not more than one-half the cross sectional area ofthe inlet.Temperature TestA ventilator shall be tested and shall not reach temperatures high enough to cause a risk of fire, to damagematerials used, or to exceed the temperature risesspecified. A protection device shall not operate when theventilator is tested. See Table 2 below.All values of temperature rise are based on an ambient of 86 F. however, tests may be conducted at anyambient within the range of 50 – 104 F.A thermocouple is to be used for determining temperature of the winding if it can be mounted withoutremoval of the encapsulating compound of the integrally applied insulation on the motor. The change ofresistance method is to be used if the thermocouplemeasurement cannot be conducted.The standard covers the attachment, placement, sizeof wires to be used, calibration of the instrumentationused, and the procedure for running the tests.The ventilator is to be operated under load conditions.Multiple speed motors are to be tested at each speed.Reversible ventilators are to be tested in both directions.This is to be done until a constant motor temperatureis attained. The test voltages are also dictated.Undervoltage TestThe ventilator shall start and operate continually with arestricted inlet as described previously, which producemaximum loading, but with the voltage reduced to 85percent of the rated voltage of the motor.Dielectric Voltage Withstand TestA ventilator shall withstand for one minute without breakdown the application of a 60 Hz electrical chargebetween live parts and dead metal parts with the ventilator at the maximum temperature reached in normaluse. The test voltage shall be:a) One thousand volts for a ventilator employing amotor rated 1 2 hp or less and 250 volts or less.b) One thousand volts plus twice the rated voltage fora ventilator employing a motor rated more than 1 2hp or more than 250 volts.To determine if the ventilator complies with therequirements, it is tested with a 500-volt ampere orlarger capacity transformer in which the output voltagecan be varied. The applied load is increased graduallyfrom zero to the required test voltage and is held atthat value for one minute. The increase in load is to beat a uniform rate and as rapid as is consistent withcorrect indication of its value by a voltmeter.Water Spray TestA ventilator is to be mounted as in actual service andis to be subjected to a water spray as described in thestandard for a period of 4 hours. If the ventilator drawsair into the unit for motor cooling then the unit must beoperating during the test period. An insulation resistanceand dielectric test are to be performed immediately uponconclusion of exposure to the water spray and are tobe repeated 1 2 hour later.After the test there shall be no water at any pointthat may be contacted by a splice in field-installed wiring and on uninsulated live parts or on film-coated wireother than motor windings.Metallic Coating Thickness TestThis test is used for determining the thickness of zincand cadmium coatings to ensure against the effects ofdamaging rust and corrosion on metal surfaces.Permanence of Marking TestingThese series of tests were developed to insure that anylabels used for identification or warnings on a UL listedproduct demonstrate good adhesion and resists defacement or removal by scraping. These tests include ovenaging, immersion, standard atmosphere, unusual condition exposure and outdoor exposure tests.Table 2. Temperature Test ValuesMETHODResistanceThermocouple3MOTORTYPEOpen MotorTotally EnclosedTotally EnclosedFan CooledOpen MotorTotally EnclosedTotally EnclosedFan CooledCLASS A INSULATION MOTORSDIA. 7"DIA. 7"126 F126 F135 F135 FCLASS B INSULATION MOTORSDIA. 7"DIA. 7"162 F162 F171 F171 F126 F—162 F—108 F117 F126 F135 F144 F153 F162 F171 F117 F—153 F—Fan Engineering FE-2500

Capacitor TestsCapacitor burnout and leakage current testing are usedto force a breakdown in the insulation surrounding acapacitor. If the capacitor attains a temperature duringthe test hot enough to ignite the testing material, thenit fails. If the capacitor exceeds a certain leakage current, it fails.Overload Testing of Switches and ControlsThese tests are used to ensure that no electrical ormechanical breakdown or undue pitting or burning of thecontacts of a motor switch or control occurs duringrepeated cycling.Manufacturing and ProductionTesting per UL 507 & 705Production Dielectric Voltage-Withstand TestEach ventilator shall withstand without electrical breakdown as a routine production line test, the applicationof an electrical charge as previously described. The testis conducted with the ventilator fully assembled.RatingA ventilator shall be rated in volts, amps, horsepower,frequency in hertz, the number of phases and a codeletter, in accordance with the NEC, ANSI/NFPA 70-1993,indicating the locked rotor motor input.MarkingA ventilator shall be legibly and permanently marked,where visible after installation, with the manufacturer’sname, trademark, trade name or other descriptive marking which may identify the product manufacturer. Theproduct must also contain a date code, distinctive catalog or model number, and the electrical rating.A ventilator that incorporates motor-overload protection shall be marked to indicate the presence of suchprotection. A ventilator that does not incorporate motoroverload protection must be marked to indicate that theunit should be installed with remote overload protectionand the motor rating data shall be listed so that properprotection may be determined.Other typical markings are as follows: A wiring diagram for connecting the motor to the field suppliedpower or other voltages. A direction of rotation arrow.A distinctive marking for point of manufacture whenmultiple facilities are involved. A ventilator not intendedfor outdoor use shall be so marked. Pertinent warningand mounting labels shall also be used.A ventilator is intended to be shipped from the pointof manufacture fully assembled and labeled. A ventilatorthat is shipped without the motor and drives assembledshall be permanently and plainly labeled with all of themotors suitable for installation on that ventilator. Thismarking must identify the motors requiring remote overload protection and the ones containing overload protection. A provision for marking the unit to indicate whichmotor has been installed must also be provided. Thisbecomes a very complex system for the manufacturerand the installer with ventilators containing hundreds ofcombinations of motors. It is generally intended for fanswhere just one or two motors are involved. These areusually shipped in a box or boxes broken down andfield assembled.Product Evaluations and LabTesting per UL 762A ventilator to be used for restaurant exhaust must firstbe listed under UL705. This means that it has already4undergone a battery of testing. UL subject 762 is basically a test procedure for elevated temperature testing.Normal Temperature TestA representative sample of a ventilator is installed inaccordance with the manufacturer's instructions. A gasfired generator is used to supply hot gases to a 4-footduct connected to the ventilator. When the generator isfired it will establish and maintain a minimum temperaturethrough the duct of 300 F or higher if specified by themanufacturer. Thermocouple grids are placed at pointsall over the fan and in the duct leading to the ventilator.The ventilator and gas-fired generator are started tosimulate a restaurant exhaust. During the test, the maximum temperature at any portion of the ventilator shallnot exceed the maximum specified in the standard.Abnormal Flare Up TestOnce the ventilator reaches equilibrium conditions duringthe normal temperature test, one pint of liquified refinedpork lard is then placed in a shallow pan in the centerof the inlet duct. The grease is heated to 600 F andignited

where in the world to help them obtain the NOM mark, . Fans and blowers that circulate air, such as desk, ceiling-suspended, and hassock fans; b) Fans and blowers that ventilate air, such as attic, . vents for smoke and heat that fall into two general