Transcription

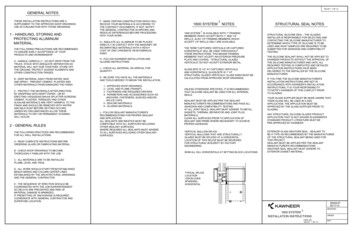

166-970 1 OF 10GENERAL NOTESTHESE INSTALLATION INSTRUCTIONS ARE ASUPPLEMENT TO THE APPROVED SHOP DRAWINGS.USE IN CONJUNCTION WITH THOSE DRAWINGS.1 - HANDLING, STORING ANDPROTECTING ALUMINUMMATERIAL.THE FOLLOWING PRECAUTIONS ARE RECOMMENDEDTO ASSURE EARLY ACCEPTANCE OF YOURPRODUCTS AND WORKMANSHIP.A - HANDLE CAREFULLY - DO NOT DROP FROM THETRUCK. STACK WITH ADEQUATE SEPARATION SOMATERIAL WILL NOT RUB TOGETHER. STORE OFFTHE GROUND. PROTECT AGAINST ELEMENTS ANDOTHER CONSTRUCTION TRADES.B - KEEP MATERIAL AWAY FROM WATER, MUDAND SPRAY - PREVENT CEMENT, PLASTER ANDOTHER MATERIALS FROM DAMAGING THE FINISH.C - PROTECT THE MATERIALS AFTER ERECTION,BY WRAPPING WITH KRAFT PAPER - OR BYERECTING VISQUEEN/CANVAS SPLATTER SCREENS.CEMENT, PLASTER, TERRAZZO AND OTHERALKALINE MATERIALS ARE VERY HARMFUL TO THEFINISH AND SHOULD BE REMOVED WITH WATERAND MILD SOAP BEFORE SETTING OCCURS. UNDERNO CIRCUMSTANCES ALLOW THESE MATERIALS TOTO DRY OR PERMANENT STAINING WILL OCCUR.2 - GENERAL RULESTHE FOLLOWING PRACTICES ARE RECOMMENDEDFOR ALL WALL INSTALLATIONS.G - INSULATE ALL ALUMINUM TO BE PLACEDDIRECTLY IN CONTACT WITH THE MASONRY ORINCOMPATIBLE MATERIALS WITH A HEAVYCOAT OF ZINC CHROMATE OR BITUMINOUSPAINT.H - FOLLOW KAWNEER INSTALLATION ANDGLAZING INSTRUCTIONS.J - CHECK ALL MATERIAL ON ARRIVAL FORQUANTITY.1600 SYSTEM 5 NOTES1600 SYSTEM 5 IS AVAILABLE WITH 1" FRAMINGMEMBERS WHICH ACCEPT BOTH 1" AND 1/4"INFILLS.1600 SYSTEM 5 IS DESIGNED AS AN INTERIORGLAZED SYSTEM. EXTERIOR GLAZING IS AOPTION. SEE EXTERIOR GLAZING STEPS.K - BE SURE TO HAVE ALL THE MATERIALSAND TOOLS NEEDED TO BEGIN THE INSTALLATION.1 - APPROVED SHOP DRAWINGS2 - LEVEL AND PLUMB (TRANSIT)3 - FASTENERS AND REQUIRED DRIVERS.4 - PERIMETERS AND ACCESSORIES SUCH ASANCHORS, FASTENERS, SLEEVES AND/ORSPLICE CAPS.5 - SEALING MATERIALS.6 - GLAZING MATERIALS.L - FOLLOW SEALANT MANUFACTURER'SRECOMMENDATIONS FOR PROPER SEALANTAND APPLICATION.ALL SEALANTS AND MASTICS MUST BECOMPATIBLE WITH ALL SURFACES INCLUDINGOTHER SEALANT SURFACES.WHERE REQUIRED ALL SEALANTS MUST ADHERETO ALL SURFACES INCLUDING OTHER SEALANTSURFACES.GLASS BITE IS 7/16" AT VERTICALS.LAY OUT ANCHORAND MULLIONCENTERLINESUSE WALL LINES ESTABLISHED BY THEGENERAL CONTRACTOR. ON EACH FLOOR LAY OUTA REFERENCE LINE TO ESTABLISH IN ANDOUT WALL LOCATIONS.USE COLUMN CENTER LINES ESTABLISHED BYTHE GENERAL CONTRACTOR. ON EACH FLOOR LAYOUT MULLION CENTER LINES AND ANCHORCENTER LINES.GLASS BITE IS 7/16" AT HORIZONTALS.GLASS SIZES MUST BE CALCULATED FROMAPPROVED SHOP DRAWINGS. GASKET ASSEMBLIESARE PREFERRED REFERENCE SHEET #9.UNLESS OTHERWISE SPECIFIED, IT IS RECOMMENDEDTHAT SILICONE SEALANT BE USED FOR ALL INTERNALSEALS.SEALANT MUST BE APPLIED PER THE SEALANTMANUFACTURER'S RECOMMENDATIONS AND PASS ALLADHESION AND COMPATIBILITY TESTING.AT ALL JOINT SEALS, SEALANT MUST ADHERE TO METAL,GASKETS, THERMAL SEPARATOR AND JOINT PLUGMATERIALS.CLEAN ALL SURFACES PRIOR TO APPLICATION OFSEALANT AND PRIME WHERE NECESSARY TO ACHIEVEPROPER ADHESION.C/L OF MULLION 1/32"EXTERIORFACE OFBEAM ORFLOOR SLABVARIES WITHJOBCONDITIONSTYPICALMULLIONA - READ COMPLETE INSTRUCTIONS BEFOREORDERING GLASS OR FABRICATING MATERIAL.B - CHECK SHOP DRAWINGS TO BECOMETHOROUGHLY FAMILIAR WITH THE JOB.C - ALL MATERIALS ARE TO BE INSTALLEDPLUMB, LEVEL AND TRUE.CHECK OPENINGSD - ALL WORK SHOULD START FROM ESTABLISHEDBENCH MARKS AND COLUMN CENTER LINESESTABLISHED BY THE ARCHITECTURAL DRAWINGSAND THE GENERAL CONTRACTOR.ELEVATIONS AND SLABS MUST BE WITHINADJUSTMENT OF ANCHORING SYSTEM.SEE APPROVED SHOP DRAWINGS FOR ALLOWABLEADJUSTMENT.E - THE SEQUENCE OF ERECTION SHOULD BECOORDINATED WITH THE JOB SUPERINTENDENTSO DELAYS ARE PREVENTED AND RISK OFMATERIAL DAMAGE IS MINIMIZED. IF PRESETTINGOF ANCHORAGE IS REQUIRED, COORDINATE WITHGENERAL CONTRACTOR AND SUPERVISE LOCATION.ANCHORING SURFACES OF PERIMETERCONSTRUCTION MUST BE LEVEL AND PLUMBWITHIN THE ADJUSTMENT LIMITS OF THEHEAD, SILL AND JAMB. SEE APPROVED SHOPDRAWINGS FOR ALLOWABLE ADJUSTMENT.F - MAKE CERTAIN CONSTRUCTION WHICH WILLRECEIVE YOUR MATERIALS IS ACCORDING TOTHE CONTRACT DOCUMENTS. IF NOT, NOTIFYTHE GENERAL CONTRACTOR IN WRITING ANDRESOLVE DIFFERENCES BEFORE PROCEEDINGWITH YOUR WORK.SEE APPROVED SHOPDRAWINGS FORANCHOR LAYOUTSTHESE INSTRUCTIONS SHOW THE6" SYSTEM. THE 7 1/2" SYSTEMIS SIMILAR95488-3107/25/07DRAWING:1600 SYSTEM 5 INSTALLATIONTYPE "B" UNITS - HEAD/SILLPART NUMBERRUNS THRU166-970 1 OF 10ORDER:SHT:

166-970 2 OF 10LENGFRAME ASSEMBLYFRAME ASSEMBLYATTACH INTERMEDIATE HORIZONTALSHEAR BLOCKS WHERE APPLICABLETYPICAL SHEAR BLOCKS163-310 6" SYSTEM163-311 7-1/2" SYSTEMFOR INTERMEDIATEHORIZONTALS.THINSTALL JOINT PLUGS.NOTE JOINT PLUG LOCATIONS1APPLY SEALANT AT JOINT PLUG LOCATIONSFILLING GASKET POCKETS AND GROOVES2INSTALL JOINT PLUGS INTO SEALANT3TOOL SEALANT TO SEAL ALL VOIDSJOINT PLUG 163-305LENGTH 1-1/8"ADDITIONALJOINT PLUG 166-331LENGTH 5/8" AT JAMB VERTICALASEE BELOW FOR JAMB JOINT PLUGINTERMEDIATE E BOTTOMOF JOINT PLUGSWITH BOTTOM OFSHEAR BLOCK128-394SCREWS#12 X 1-7/8"PAN HEAD TYPE B11163-305163-3052SECTION A-AA2JAMB VERTICALJAMB VERTICAL166-331 JOINT PLUGIS 1-5/8" X 2" X3/8" THICK SPONGEPRESS FIT INTO ING:1600 SYSTEM 5 INSTALLATIONTYPE "B" UNITS - HEAD/SILLPART NUMBERRUNS THRU166-970 2 OF 10ORDER:SHT:

166-970 3 OF 10FRAME ASSEMBLYBEFORE ASSEMBLY REFERENCE APPROVED SHOP DRAWINGS FOR ANCHOR ATTACHMENTSAPPLY SEALANT ASSHOWN TO TOPOF VERTICALS128-510 SPLINE SCREWS#12 x 1 1/2" HEX WASHER HD TYPE ABSEALANTAFTER ASSEMBLY SEAL OVERSCREW HEADS AT HEAD MBVERTICALHEADHORIZONTALAPPLY ENOUGH SEALANTTO EXTERIOR LEG TOFILL 1/8" IATEVERTICALSEALANT2-1/2"TOOL ALL SEALANTAFTER ASSEMBLYCROSS SECTION THRUASSEMBLED UNIT2-1/2"128-510 SPLINE SCREWS#12 x 1 1/2"HEX WASHER HD TYPE ABAPPLY SEALANT AS SHOWN ATEACH VERTICAL OR APPLY TOBOTTOM OF VERTICALS95488-3107/25/072-1/2"DRAWING:1600 SYSTEM 5 INSTALLATIONTYPE "B" UNITS - HEAD/SILLPART NUMBERRUNS THRU166-970 3 OF 10ORDER:SHT:

166-970 4 OF 10FRAME ASSEMBLYSTANDARD END CAPS SHOWN REFERENCE APPROVED SHOP DRAWINGS FORJOB REQUIREMENTS FOR END CAPSINSTALL HEAD AND SILL END CAPSAPPLY SEALANT AS SHOWNTO ENDS OF HORIZONTALSHEADHORIZONTALJANB VERTICALJANB VERTICALSEALANTSEALANT FILL NT128-293 SCREWS#12 x 5/8"PAN HD TYPE AB128-293 SCREWS#12 x 5/8"PAN HD TYPE AB166-316 HEAD END CAP6" SYSTEM166-303 HEAD END CAP7 1/2" SYSTEMAPPLY WITH 128-293SCREWS AS SHOWNTOOL SEALANT AFTERINSTALLATION166-317 SILL END CAP6" SYSTEM166-304 SILL END CAP7 1/2" SYSTEMAPPLY WITH 128-293SCREWS AS SHOWNTOOL SEALANT AFTERINSTALLATION95488-3107/25/07DRAWING:1600 SYSTEM 5 INSTALLATIONTYPE "B" UNITS - HEAD/SILLPART NUMBERRUNS THRU166-970 4 OF 10ORDER:SHT:

166-970 5 OF 10FRAME ASSEMBLYBEFORE ASSEMBLY REFERENCE APPROVED SHOP DRAWINGS FOR ANCHOR ATTACHMENTSAT EXTERIOR GLAZED HEADINSTALL HEAD AND SILL END CAPS128-510 SPLINE SCREWS#12 x 1 1/2" HEX WASHER HD TYPE ABAPPLY SEALANT AS SHOWNTO ENDS OF HORIZONTALS163-303 THERMAL BREAKHORIZONTAL LENGTH MINUS3/16" EACH ENDHEADHORIZONTALJAMBVERTICALEXTERIOR LY SEALANT ASSHOWN TO TOPOF VERTICALSJAMBVERTICALJAMBVERTICALSEALANTCROSS SECTION THRUASSEMBLED UNITJAMBVERTICALTOOL ALL SEALANTAFTER ASSEMBLY166-316 HEAD END CAP6" SYSTEM166-303 HEAD END CAP7 1/2" SYSTEMAPPLY WITH 128-293SCREWS AS SHOWNTOOL SEALANT 3 SCREWS#12 X 5/8"PAN HD TYPE ABSEALANT95488-3107/25/07JAMBVERTICALDRAWING:1600 SYSTEM 5 INSTALLATIONTYPE "B" UNITS - HEAD/SILLPART NUMBERRUNS THRU166-970 5 OF 10ORDER:SHT:

166-970 6 OF 10INSTALL INTERMEDIATEHORIZONTALSINSTALL EXTERIOR THERMAL CLIPSAND EXTERIOR COVERSINSTALL HORIZONTALSWITH 128-293 SCREWS AS SHOWN#12 x 5/8" PAN HEAD TYPE ABDEEP EXTERIOR COVER PINNINGINSTALL COVERS THAT RUN THRU FIRSTINSTALL 165-301 THERMAL CLIPS AT DLO MINUS 2". CENTER PART ON DLO. RUNCONTINUOUS AROUND ELEVATION OUTSIDE PERIMETER WHERE POSSIBLE. BUTTSPLICED PARTS ARE ACCEPTABLE.FOR COVERS DEEPER THAN A1 1/2" PROJECTION UNLESSNOTED OTHERWISEVERTICALVERTICAL165-301CLIPSHEAD CLIPSEXTERIOR GLAZED HEADINTERMEDIATEHORIZONTALSCREWS INSERT THRUSHEAR BLOCK ANDTAP INTO HORIZONTALAT EXTERIOR GLAZINGCOVERS ARE INSTALLEDAFTER GLAZINGCOVER165-301CLIPSDEEP VERTICAL COVER PINNINGLOCATE CLIPS AT HEAD AND SILL HORIZONTALSSILL HORIZONTALCRIMP INTO PLACE AT CLIP BOTTOMDRILL .177" DIA HOLES #16 DRILL INTO COVERAPPLY 28-808 SCREWSJUST SNUG SCREW INTO PLACE DO NOT OVER TIGHTENEXTERIOR GLAZED HORIZONTALSEAL EXTERIOR HORIZONTALTO VERTICAL JOINTJAMBVERTICALINTERMEDIATEVERTICALINSTALL HORIZONTAL COVERSWITH THE WEEP HOLES AT THEBOTTOM.DO THIS STEP JUST PRIOR TOINSTALLING EXTERIOR COVERSSEAL JOINTTOOLSEALANT11/16"28-808 SCREWVERTICALAT EXTERIORGLAZEDHORIZONTALSTHIS SEALIS DONEAFTERGLAZING11/16"165-301CLIPS165-301 NTALDEEP HORIZONTAL COVER PINNINGLOCATE CLIPS AT EACH END OF HORIZONTALCRIMP INTO PLACE LEAVING A SPACE FOR COVER EXPANSIONDRILL .177 DIA HOLES #16 DRILL INTO COVERAPPLY 28-808 SCREWS#8 x 1/2" PAN HEAD TYPE AJUST SNUG SCREW INTO PLACE DO NOT OVER TIGHTENENGAGE ONE SIDE OF COVER ANDINSTALL USING WOOD BLOCKINGAND MALLET95488-3406/30/10DRAWING:1600 SYSTEM 5 INSTALLATIONTYPE "B" UNITS - HEAD/SILLPART NUMBERRUNS THRU166-970 6 OF 10ORDER:SHT:

166-970 7 OF 10VERTICALINSTALL 1/4" INFILL ADAPTERSSEAL JOINT PLUG TO HORIZONTALINSTALL VERTICALADAPTERS FIRSTVERTICALSEAL ADAPTERCORNERSAS REQUIREDAPPLY SEALANT TO JOINT PLUGAND HORIZONTAL ENDTOOLING ONTO SEAL MADE WHENINSTALLING JOINT PLUGSAS REQUIREDTOOL A SMALL AMOUNT OFSEALANT ONTO THEFACE OF THE HORIZONTALTO VERTICAL JOINT.THE REMAINDER OF THEJOINT WILL BE SEALEDWHEN THE GLAZINGGASKETS ARE INSTALLED.SEAL THE BOTTOM ADAPTERCONTINUOUS AND THE JAMBADAPTERS UP 6" FROM THEBOTTOMINTERMEDIATE HORIZONTALJUST PRIOR TO INSTALLINGADAPTERS SEAL FACE OFINTERIOR HORIZONTAL TOVERTICAL JOINTSEALPOCKETADAPTER164-007VERTICALSECTION A-AAS REQUIREDTOOL SEALANT AS FLUSH AS POSSIBLESO GLAZING POCKET IS NOT PLUGGEDAFTER GLASS IS ILL TALS95488-3107/25/07INTERMEDIATE HORIZONTALADRAWING:1600 SYSTEM 5 INSTALLATIONTYPE "B" UNITS - HEAD/SILLPART NUMBERRUNS THRU166-970 7 OF 10ORDER:SHT:

166-970 8 OF 10INTERIOR GLAZINGIT IS ESSENTIAL THAT ALL GUTTERS ATHORIZONTALS BE CLEANED PRIOR TO GLAZING.THIS IS NECESSARY TO AVOID CLOGGINGOF WEEP SYSTEMS AS WELL AS STAINING OFEXTERIOR METAL AND GLASS SURFACES.INSTALL SETTING BLOCKS LOCATING PERAPPROVED SHOP DRAWINGS.SETTING BLOCK127-0161" INFILLSETTING BLOCK127-0171/4" INFILLINTERMEDIATE HORIZONTALSSETTING BLOCK127-016 ANDSETTING BLOCKCHAIR 166-3081" INFILLSETTING BLOCK127-017 ANDSETTING BLOCKCHAIR 166-3091/4" INFILLINTERIOR GLAZINGINSTALL EXTERIOR GASKET ASSEMBLIES.INSTALL GLASS BY LIFTING ABOVE SILLAND INSERTING INTO VERTICAL POCKETAS SHOWN.GASKET ASSEMBLIES SHOULD BE INSTALLEDJUST PRIOR TO GLASS TO AVOID GASKETCONTAMINATION BY JOB SITE DEBRIS.INTERIOR GLAZINGAFTER THE GLASS IS LOWERED ONTO THESETTING BLOCKS AND CENTERED HORIZONTALLYLIFT THE GLASS SLIGHTLY AND PUSHFORWARD INTO THE EXTERIOR GASKETS.REFERENCE - FGMA GLAZING MANUAL IN THE"GLASS SETTING" SECTION.IN TEMPERATURES COLDER THAN 50 DEGREES F,ARRANGEMENTS SHOULD BE MADE TO KEEP THEGASKETS WARM UNTIL INSTALLATION OFGASKETS AND GLASS. THIS WILL PREVENTEXCESSIVE GLAZING PRESSURE ON THE GLASSEDGE DUE TO COLD, STIFF GASKETS.THE ABOVE WILL KEEP THE GLASS EDGE FROMDIGGING AND DEFORMING THE SETTING BLOCK.INSTALL A SHORT PIECE OF GLAZING WEDGEAT THE SETTING BLOCKS AS A TEMPORARY.GASKETS CAN BECOME DEFORMEDDURING STORAGE IN CARTONS. REMOVEGASKETS FROM CARTONS SEVERAL HOURSPRIOR TO USE AND ALLOW TO LAY FLAT ORHANG OVER RACK. TEMPERATURES SHOULD BEAT LEAST 50 DEGREES F.INSTALL A SHORT PIECE OF GLAZINGWEDGE AT THE TWO VERTICALS AS A TEMPORARY.LOCATE TOWARDS THE TOP OF THE LITE.LUBRICATE WITH WATERAS REQUIREDGLAZING WEDGE 027-851FOR 1/4" SPACEINSTALL GASKET ASSEMBLIES BY STARTING ATTHE CORNERS AND WORKING TOWARDS THE CENTER,MAKING SURE THE CORNERS ARE SQUARE. GASKETASSEMBLIES WILL BE SLIGHTLY LARGE TO ALLOWFOR SOME CROWD-IN. DO NOT STRETCH, CUT ORSPLICE GASKETS.INSTALL TOP INTERIOR HORIZONTAL STOPS1-1/8"INTERIOR GLAZING027-850 GASKET EXTRUSION163-301 GASKETASSEMBLYTOP OFDLOLINEVERTICALHORIZONTAL1" INFILLAT BOTH JAMBS APPLY A BEADOF SEALANT FOR AN AIR SEALREMAINDER WILLBE SEALED WITHGASKET CORNERSEALSTART AT GASKET ASSEMBLYCORNERSGASKET "CROWD-IN"3SILL HORIZONTALS21NOTE - GASKET ASSEMBLIES ARE PREFERRED INORDER TO MAINTAIN THE GASKET CORNERS WHENINSTALLING THE GLASS.IF ASSEMBLIES ARE NOT USED SEAL GASKETCORNERS AND ALLOW SEALANT TO SKIN OVERBEFORE INSTALLING THE GLASS.AFTER THE STOP IS INSTALLED USE GLAZINGWEDGE TEMPORARIES.1/4" INFILLAPPLY FRESH SEALANTTO JOINT CORNERSINSTALL COMPLETE GASKET ASSEMBLYTHEN PULL BACK CORNERS AND APPLY SEALANTJUST PRIOR TO INSTALLING GLASS95488-3107/25/07DRAWING:1600 SYSTEM 5 INSTALLATIONTYPE "B" UNITS - HEAD/SILLPART NUMBERRUNS THRU166-970 8 OF 10ORDER:SHT:

166-970 9 OF 10INTERIOR GLAZINGINTERIOR GLAZINGRE-GLAZINGINSTALL GLAZING WEDGE GASKETINSTALL "W" SIDE BLOCKS INTO BOTHVERTICAL POCKETS.INTERIOR GLAZED LITEGLAZING WEDGE 027-851FOR 1/4" SPACE480-520"W"SIDEBLOCKINSTALLEDPOSITION1" INFILLFLATTEN "W" BLOCKAND INSERT INTOGLAZING POCKETINSTALLEDPOSITION1" INFILLINTERIOR GLAZINGLOCATE AT CENTEROF GLASS HEIGHT123-392 W BLOCKAT JAMB VERTICALSWIDTHUSING PRUNERSTRIM THEWIDTH OF123-392ABOUT 1/8"ORDER NEWIN TEMPERATURES COLDER THAN 50 DEGREES F.ARRANGEMENTS SHOULD BE MADE TO KEEP THE GASKETSWARM UNTIL INSTALLATION OF GASKETS AND GLASS. THISWILL PREVENT EXCESSIVE GLAZING PRESSURE ON THEGLASS EDGE DUE TO COLD, STIFF GASKETS.GASKETS CAN BECOME DEFORMED DURING STORAGE INCARTONS. REMOVE GASKETS FROM CARTONS SEVERALHOURS PRIOR TO USE AND ALLOW TO LAY FLAT ORHANG OVER RACK. TEMPERATURES SHOULD BE ATLEAST 50 DEGREES F.APPLY WEDGE GASKETS IN THE SHALLOW POCKETSIDES FIRST TO REDUCE ANY POSSIBLEROTATION OF THE APPLIED PRESSURE PLATE.WHEN STARTING THE WEDGE GASKET THE BEST PLACETO START IS NEAR A TEMPORARY. CUT THE WEDGE 1/8"TO 1/4" PER FOOT LONG FOR GASKET "CROWD-IN". THE"CROWD-IN" TO BE BETWEEN STARTING POINTS AND ATCORNERS. DO NOT STRETCH TO FIT.CORNERS GET SEALED SEE DETAIL BELOW.IT IS IMPORTANT THEWEDGE GASKET BECOMPLETELY SEATED WHENINSTALLED. A GOOD CHECKIS TO LIFT UP THE TRIMLIP TO SEE HOW IT ISINSTALLEDWATER MAY BE USED TO LUBRICATE WEDGEGASKET. BEFORE SEALING CORNERS WIPE GASKETAND CORNER WITH A CLEAN RAG. BEST METHOD ISTO LEAVE CORNERS OUT FOR SOME TIME TO LETWATER EVAPORATE AND WIPE CLEAN.1 - FIXED GASKET ASSEMBLY2 - WEDGE GASKET MATERIALBEFORE SEATINGCORNERS APPLYSEALANT ATCORNERS.THIS SEAL ISFOR SEALINGGASKET CORNERSAND HORIZONTALTO VERTICALJOINT1THIS SEAL IS BEST DONE INTWO STEPS - APPLY SOMESEALANT AND SEAT THEHORIZONTAL GASKET - THENAPPLY MORE SEALANT WHENSEATING THE VERTICAL GASKET23REMOVE1 - EXISTING WEDGE GASKET2 - TOP INTERIOR STOPINSTALLEDPOSITION1/4" INFILLINSTALLEDPOSITION1/4" INFILL3 - GLASS TO BE REPLACED"CROWD-IN"BETWEEN STARTINGPOINTS AND ATCORNERSCLEAN METAL AND RE-GLAZEPER GLAZING INSTRUCTIONSLOCATE AT CENTEROF GLASS HEIGHTIF THE INSTALLATION OF THE WEDGE REQUIRES EXCESSIVEFORCE OR THE WEDGE DOES NOT PROVIDE ENOUGHCOMPRESSION ON THE EXTERIOR FIXED GASKET, CONTACTYOUR KAWNEER PROJECT MANAGER IMMEDIATELY.95488-3107/25/07DRAWING:1600 SYSTEM 5 INSTALLATIONTYPE "B" UNITS - HEAD/SILLPART NUMBERRUNS THRU166-970 9 OF 10ORDER:SHT:

166-970 10 OF 10RE-GLAZINGEXTERIOR GLAZINGEXTERIOR GLAZED HEAD AND INTERMEDIATE HORIZONTAL DETAILSEXTERIOR GLAZED LITESSILL DETAILS THE SAME AS INTERIOR GLAZINGEXTERIORCOVER162-006PERIMETER PRESSUREPLATE 166-302INSTALL GLASS BY LIFTING ABOVE SILLAND INSERTING INTO VERTICAL POCKETAS SHOWN.PERIMETERGASKET 027-916ORDER NEW1 - FIXED GASKET ASSEMBLY OR MATERIAL2 - WEDGE GASKET MATERIALAND SILLHEADHORIZONTAL4 - NEW EXTERIOR COVER IFEXISTING COVER CAN NOT BE SAVEDCOVERS CAN BE SAVED IF TOLERANCES ARENOT TOO TIGHT AND THE COVER IS REMOVEDWITH EXTREME CARESCREWS 128-4061/4 x 1" HEX WASHERHEAD TYPE ABLOCATE 3" FROMEACH END AND6" ON CENTERTHERMAL BREAK163-3031" OR 1/4" INFILL STOPSTEMPORARILY TAPE IN PLACEWOOD ORPLASTICSHIMINTERMEDIATE PRESSURE PLATE 163-317PRY BAR WITH SHARPPOINT AND FLAT THIS SIDE1/4" INFILL ADAPTERSINTERMEDIATE HORIZONTAL1" INFILLEXTERIORCOVER162-006THERMAL BREAK163-303PUSH BACK THE GASKETTRIM LIPSTART AT ONE END TODISENGAGEDO THIS IN PROGRESSIONFOR THE COMPLETELENGTH1" OR 1/4" INFILL STOPSTEMPORARILY TAPE IN PLACENEXT REMOVE PRESSURE PLATE,GASKETS AND GLASS.INSTALL SETTING BLOCKS SAME AS SHOWN AT INTERIOR GLAZINGINSTALL INTERIOR FIXED GASKETS SAME AS EXTERIOR GASKETS SHOWN AT INTERIOR GLAZINGINSTALL GLASS AS SHOWN ON THIS SHEETINSTALL SIDE BLOCKS FROM THE EXTERIOR SAME AS AT INTERIOR GLAZING1/4" INFILLCLEAN METAL AND RE-GLAZEPER EXTERIOR GLAZING INSTRUCTIONSINSTALL HORIZONTAL PRESSURE PLATES - TORQUE SCREWS TO 50 INCH POUNDS- WITH WEEPS TOWARDS TOP OF HORIZONTALSEAL ALL EXTERIOR PRESSURE PLATE JOINTSINSTALL EXTERIOR COVERS - INSTALL HORIZONTAL COVERS WITH THE WEEP HOLES DOWNINSTALL EXTERIOR WEDGE GASKET SAME AS AT INTERIOR GLAZING95488-3107/25/07DRAWING:1600 SYSTEM 5 INSTALLATIONTYPE "B" UNITS - HEAD/SILLPART NUMBERRUNS THRU166-970 10 OF 10ORDER:SHT:

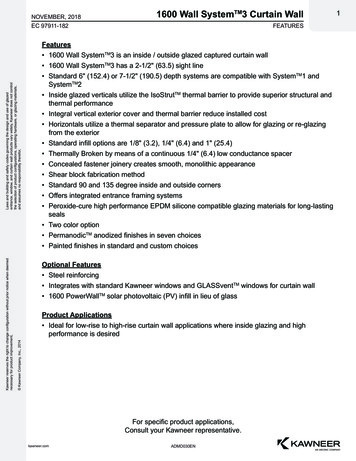

1600 system 5 is designed as an interior glazed system. exterior glazing is a option. see exterior glazing steps. are preferred reference sheet #9. 166-970 1 of 10 part number glass bite is 7/16" at horizontals. these instructions show the 6" system. the 7 1/2" system is similar 1600 system 5 installation type "b" units - head/sill runs thru