Transcription

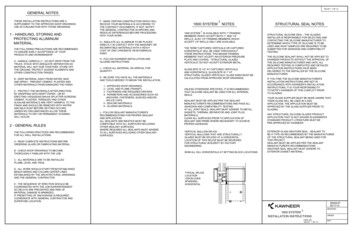

162-971 1 OF 12GENERAL NOTESTHESE INSTALLATION INSTRUCTIONS ARE ASUPPLEMENT TO THE APPROVED SHOP DRAWINGS.USE IN CONJUNCTION WITH THOSE DRAWINGS.1 - HANDLING, STORING ANDPROTECTING ALUMINUMMATERIAL.THE FOLLOWING PRECAUTIONS ARE RECOMMENDEDTO ASSURE EARLY ACCEPTANCE OF YOURPRODUCTS AND WORKMANSHIP.A - HANDLE CAREFULLY - DO NOT DROP FROM THETRUCK. STACK WITH ADEQUATE SEPARATION SOMATERIAL WILL NOT RUB TOGETHER. STORE OFFTHE GROUND. PROTECT AGAINST ELEMENTS ANDOTHER CONSTRUCTION TRADES.B - KEEP MATERIAL AWAY FROM WATER, MUDAND SPRAY - PREVENT CEMENT, PLASTER ANDOTHER MATERIALS FROM DAMAGING THE FINISH.C - PROTECT THE MATERIALS AFTER ERECTION,BY WRAPPING WITH KRAFT PAPER - OR BYERECTING VISQUEEN/CANVAS SPLATTER SCREENS.CEMENT, PLASTER, TERRAZZO AND OTHERALKALINE MATERIALS ARE VERY HARMFUL TO THEFINISH AND SHOULD BE REMOVED WITH WATERAND MILD SOAP BEFORE SETTING OCCURS.UNDER NO CIRCUMSTANCES ALLOW THESEMATERIALS TO DRY OR PERMANENT STAININGWILL OCCUR.2 - GENERAL RULESTHE FOLLOWING PRACTICES ARE RECOMMENDEDFOR ALL WALL INSTALLATIONS.A - READ COMPLETE INSTRUCTIONS BEFOREORDERING GLASS OR FABRICATING MATERIAL.B - CHECK SHOP DRAWINGS TO BECOMETHOROUGHLY FAMILIAR WITH THE JOB.F - MAKE CERTAIN CONSTRUCTION WHICH WILLRECEIVE YOUR MATERIALS IS ACCORDING TOTHE CONTRACT DOCUMENTS. IF NOT, NOTIFYTHE GENERAL CONTRACTOR IN WRITING ANDRESOLVE DIFFERENCES BEFORE PROCEEDINGWITH YOUR WORK.G - INSULATE ALL ALUMINUM TO BE PLACEDDIRECTLY IN CONTACT WITH THE MASONRY ORINCOMPATIBLE MATERIALS WITH A HEAVYCOAT OF ZINC CHROMATE OR BITUMINOUSPAINT.H - FOLLOW KAWNEER INSTALLATION ANDGLAZING INSTRUCTIONS.J - CHECK ALL MATERIAL ON ARRIVAL FORQUANTITY.K - BE SURE YOU HAVE ALL THE MATERIALSAND TOOLS NEEDED TO BEGIN THE INSTALLATION.1 - APPROVED SHOP DRAWINGS2 - LEVEL AND PLUMB (TRANSIT)3 - FASTENERS AND REQUIRED DRIVERS.4 - PERIMETERS AND ACCESSORIES SUCH ASANCHORS, FASTENERS, SLEEVES AND/ORSPLICE CAPS.5 - SEALING MATERIALS.6 - GLAZING MATERIALS.L - FOLLOW SEALANT MANUFACTURER'SRECOMMENDATIONS FOR PROPER SEALANTAND APPLICATION.ALL SEALANTS AND MASTICS MUST BECOMPATIBLE WITH ALL SURFACES INCLUDINGOTHER SEALANT SURFACES.WHERE REQUIRED ALL SEALANTS MUST ADHERETO ALL SURFACES INCLUDING OTHER SEALANTSURFACES.1600 SYSTEM2NOTESSTRUCTURAL SEAL NOTES21600 SYSTEM IS AVAILABLE WITH 1" FRAMINGMEMBERS WHICH ACCEPT BOTH 1" AND 1/4"INFILLS. ALSO 1/4" FRAMING MEMBERS WHICHACCEPT 1/4" INFILLS ONLY ARE AVAILABLE.THE TERM "CAPTURED VERTICALS OR CAPTUREDHORIZONTALS" WILL BE USED THROUGHOUTTHESE INSTRUCTIONS. THIS MEANS FRAMINGMEMBERS THAT ACCEPT AN EXTERIOR PRESSUREPLATE AND COVERS. "STRUCTURAL GLAZEDVERTICALS" DO NOT ACCEPT EXTERIOR METAL.GLASS BITE IS 1/2" AT CAPTURED VERTICALSAND HORIZONTALS. GLASS BITE IS 1" ATSTRUCTURAL GLAZED VERTICALS. GLASS SIZES MUST BECALCULATED FROM APPROVED SHOP DRAWINGS.UNLESS OTHERWISE SPECIFIED, IT IS RECOMMENDEDTHAT SILICONE SEALANT BE USED FOR ALL INTERNALSEALS.SEALANT MUST BE APPLIED PER THE SEALANTMANUFACTURER'S RECOMMENDATIONS AND PASS ALLADHESION AND COMPATIBILITY TESTING.AT ALL JOINT SEALS, SEALANT MUST ADHERE TO METAL,GASKETS, THERMAL SEPARATOR AND JOINT PLUGMATERIALS.CLEAN ALL SURFACES PRIOR TO APPLICATION OFSEALANT AND PRIME WHERE NECESSARY TO ACHIEVEPROPER ADHESION.VERTICAL MULLION SPLICE VERTICAL MULLIONS THAT ARE STRUCTURALLYGLAZED MUST BE SPLICED AT A HORIZONTAL.LOCATION OF THIS SPLICE MUST BE REVIEWEDFOR STRUCTURAL INTEGRITY BY FACTORYENGINEERING.SHIM ALL SILL HORIZONTALS AT SETTING BLOCK LOCATIONS.STRUCTURAL SILICONE SEAL - THE GLAZINGINSTALLER IS RESPONSIBLE FOR SELECTING ANDCONTACTING THE SILICONE MANUFACTURER TODETERMINE WHICH TYPE OF SILICONE IS TO BEUSED AND WHAT SAMPLES ARE REQUIRED TO BESUBMITTED FOR ADHESION AND COMPATIBILITYTESTING.THE SILICONE SEALANT SHALL NOT BE APPLIED TOKAWNEER PRODUCTS WITHOUT THE APPROVAL OFTHE SILICONE MANUFACTURER AND UNTIL ALLREQUIRED TESTING IS COMPLETED AND DETAILEDAPPLICATION INSTRUCTIONS HAVE BEENDELIVERED TO THE INSTALLER BY THE SILICONEMANUFACTURER.IF YOU FIND THE SILICONE MANUFACTURER'SINSTALLATION INSTRUCTIONS ARE NOT INACCORDANCE WITH KAWNEER'S INSTALLATIONINSTRUCTIONS, IT IS YOUR RESPONSIBILITYTO NOTIFY KAWNEER OF THIS CONFLICT PRIORTO GLAZING.YOUR GLASS SUPPLIER MUST BE MADE AWARE THATTHEIR GLASS WILL BE USED IN A SSGAPPLICATION. THE APPLICATION MUST BEAPPROVED BY THE GLASS SUPPLIER PRIOR TOGLAZING.ANY STRUCTURAL SILICONE GLAZED PRODUCTAPPLICATION THAT IS NOT SHOWN IN KAWNEER'SSTANDARD PRODUCT LITERATURE MUST BEPRE-APPROVED BY KAWNEER.EXTERIOR GLASS WEATHER SEAL - SEALANT TOBE A TYPE AS RECOMMENDED BY THE MANUFACTUREROF THE STRUCTURAL SEALANT BEING USED FORTHIS PROJECT.SEALANT MUST BE APPLIED PER THE SEALANTMANUFACTURER'S RECOMMENDATIONS.WEATHER SEAL SEALANT MUST ADHERE TOEXTERIOR GASKET MATERIAL.C - ALL MATERIALS ARE TO BE INSTALLEDPLUMB, LEVEL AND TRUE.D - ALL WORK SHOULD START FROM ESTABLISHEDBENCH MARKS AND COLUMN CENTER LINESESTABLISHED BY THE ARCHITECTURAL DRAWINGSAND THE GENERAL CONTRACTOR.E - THE SEQUENCE OF ERECTION SHOULD BECOORDINATED WITH THE JOB SUPERINTENDENTSO DELAYS ARE PREVENTED AND RISK OFMATERIAL DAMAGE IS MINIMIZED.IF PRESETTING OF ANCHORAGE IS REQUIRED,COORDINATE WITH GENERAL CONTRACTOR ANDSUPERVISE LOCATION.TYPICAL SPLICELOCATIONVISION 0 SYSTEMINSTALLATION INSTRUCTIONSPART NO.162-971 1 OF 12ORDER:SHT:

162-971 3 OF 12STEP - 4 FRAME ASSEMBLYSTEP - 4 FRAME ASSEMBLYATTACH SHEAR BLOCKS.ATTACH ANCHORS TO MULLIONS WHEREAPPLICABLE.162-310THERMAL BREAKANCHOR PREP MAY BE FABRICATED IN THE FIELDOR FACTORY. CONSULT APPROVED SHOPDRAWINGS FOR CORRECT METHOD.STANDARD ANCHOR PREP IS THRU-BOLTED ATINTERMEDIATE VERTICALS AND TAPPING PLATESARE USED AT JAMB VERTICALS. REFER TOAPPROVED SHOP DRAWINGS FOR CORRECT METHOD.WHEN WELDING ANCHORS, PROTECT INSTALLEDGLASS AND METAL FROM WELD SPLATTER.027-477SEPARATORBETWEEN ANCHORAND MULLIONWELDPLATEOPTION TOINSTALL THERMALBREAK AFTERVERTICALS ANDHORIZONTALSARE INSTALLED128-394SCREWS#12 x 1 7/8"PAN HEAD TYPE BDETAILS SAME FOR "CAPTURED VERTICALS"STRUCTURALGLAZEDVERTICALHEAD/SILL SHEAR BLOCK/ANCHORWHERE APPLICABLE AND SHOWN BELOW.162-314 6" SYSTEM AT JAMBS162-315 7 1/2" SYSTEM AT JAMBS162-342 6" SYSTEM AT MULLIONS162-343 7 1/2" SYSTEM AT MULLIONSTHERMAL BREAKTO BE SAMELENGTH ASVERTICALMULLIONSSTRUCTURAL INTEGRITY OFANCHOR AND FASTENERS MUST BECHECKED BY FACTORY ENGINEERS.NOTESIZE AND SPACINGOF WELD PER APPROVED SHOP DRAWINGSANCHOR FASTENERLOCATIONS PERAPPROVEDSHOP DRAWINGSDO NOT OVER TIGHTEN ANCHOR CONNECTIONS.TIGHTEN TO A "SNUG TIGHT" POSITIONWITH PARTS BROUGHT INTO GOOD CONTACT.BE SURE ANY SPRING TYPE LOCK WASHERS ARECOMPRESSED. THEN TIGHTEN APPROXIMATELY1/2 MORE TURN.SHEAR BLOCK/ANCHOR128-396 SCREWS#12 x 7/16"PAN HEAD TYPE BDETAILS SIMILAR FOR "CAPTURED VERTICALS"162-377 6" SYSTEM162-378 7 1/2" SYSTEMSTEP - 5 INSTALL 162-310THERMAL BREAK162-310HEAD AND SILL SHEAR BLOCKS162-331 6" SYSTEM162-332 7 1/2" SYSTEMREFERENCE INSTRUCTIONS 162-983FOR EXTERIOR FRAME PERIMETERSHEAD AND SILL SHEAR BLOCKS162-384 6" SYSTEM162-385 7 1/2" SYSTEMTHERMAL BREAKTO BE THE SAMELENGTH AS THEHORIZONTAL ATSTRUCTURAL GLAZEDVERTICALSNOTEATTACH SHEAR BLOCKS.STRUCTURAL GLAZED VERTICALTYPICAL INTERMEDIATE SHEAR BLOCKSSTEP - 5 INSTALL 162-310THERMAL BREAKTHERMAL BREAKTO BE 1/4"SHORT AT EACHEND OFHORIZONTAL ATCAPTURED VERTICALSFOR CAPTURED VERTICALSINSTALL HEAD AND SILL END CAPS162-388 1" FRAMING162-389 1/4" FRAMINGSET IN SEALANTINSTALL PERIMETER MEMBERS PER APPROVEDSHOP DRAWINGS. PERIMETER MEMBERS CANOCCUR AT HEAD, SILL OR JAMB CONDITIONS.BENCHMARK TO FACE OFPERIMETER MEMBERPER APPROVED SHOPDRAWINGSCONTINUOUS "F" PERIMETER162-017 1" GLASS162-176 1/4" GLASSMAXIMUM TEMPORARYSPACING IS 30".IF MORE THAN A50 MPH WIND ISEXPECTED INSTALLPRESSURE PLATES.USE GLAZING 162-350 TEMPORARIESWITH 128-406 SCREWS.STEP - 7 INSTALL VERTICALMULLIONSDIMENSION BUILDUP CHECKCHECK OVERALL FRAME DIMENSIONS ABOUTEVERY FIVE MULLIONS ON LONG RUNS.THIS IS TO AVOID DIMENSION BUILDUP.10 UNITS CHECK DIMENSIONCAPTUREDVERTICALS/HORIZONTALSDO NOTSTRETCHWHEN REMOVINGFROM COILAND CARTONDO NOTSTRETCHDURINGINSTALLATIONSTEP - 6 PERIMETERS WHEREAPPLICABLE5 UNITS CHECK DIM.162-310THERMAL BREAKNOT REQUIRED AT EXTERIORFRAME PERIMETERS SHOWN ININSTRUCTIONS 162-983 AND ATOPTIONAL PERIMETER FILLERS162-022 AND 162-023.95449-6910/20/07DRAWING:21600 SYSTEMINSTALLATION INSTRUCTIONSPART NO.162-971 3 OF 12ORDER:SHT:

162-971 4 OF 12STEP - 7 INSTALL VERTICALMULLIONSSTRUCTURAL GLAZED VERTICALSSTRUCTURAL GLAZED VERTICALSDETAILS SIMILAR FOR "CAPTURED VERTICALS""F" OR "T" ANCHORSWHERE APPLICABLE"F" AND "T"ANCHOR FASTENERLOCATIONS PERAPPROVEDSHOP DRAWINGSREFERENCEINSTRUCTIONS162-983 FOREXTERIOR FRAMEPERIMETERSSTEP - 7 INSTALL VERTICALMULLIONSDETAILS SIMILAR FOR "CAPTURED VERTICALS"STEP - 7 INSTALL VERTICALMULLIONSVERTICAL SPLICE JOINTS WHEREAPPLICABLE.HEAD/SILL SHEAR BLOCK/ANCHORWHERE APPLICABLE.CAPTURED VERTICALSVERTICAL SPLICE JOINTS WHEREAPPLICABLE.STRUCTURAL GLAZEDVERTICALSCAN NOT BE USED WITH EXTERIOR FRAMEPERIMETERS SHOWN ON INSTRUCTIONS 162-983162-314 6" SYSTEM AT JAMBS162-315 7 1/2" SYSTEM AT JAMBS162-342 6" SYSTEM AT MULLIONS162-343 7 1/2" SYSTEM AT MULLIONSTHESE SHEARBLOCKS MAY NEEDTO BE REMOVEDTO INSTALL AANCHOR FASTENERTHAT MIGHT BELOCATED CLOSE TOTHE MULLIONSTEP - 7 INSTALL VERTICALMULLIONSSLEEVE IS FACTORYTAPED INTO THEBOTTOM OF THE TOPVERTICAL.128-396 SCREWS#12 x 7/16"PAN HEAD TYPE BSLEEVE IS FACTORYTAPED INTO THEBOTTOM OF THE TOPVERTICAL.REMOVE THE TAPEAND LET THE SLEEVESLIDE DOWN TOTHE FACTORYAPPLIED STOP SCREW128-284 SCREWS#12 x 1 1/2FLAT HEADTYPE ABFOR HORIZONTALATTACHMENTTHE ABOVE SCREWS ARE ONLY USED AT THEOPTIONAL SHEAR BLOCK/ANCHORS.STRUCTURAL SHIMMING IS REQUIRED ATSILL TO ACCOMPLISH DESIGNEDPERIMETER SEAL WIDTH.FIELD APPLIEDFIXING SCREW128-348#10 x 1 1/4"FLAT HEADSELF DRILLING.ANCHOR FASTENERLOCATIONS PERAPPROVEDSHOP DRAWINGS"F" AND "T"ANCHOR FASTENERLOCATIONS PERAPPROVEDSHOP DRAWINGSREMOVE THE TAPEAND LET THE SLEEVESLIDE DOWN TOTHE FACTORYAPPLIED STOP SCREWUSE TEMPORARYSPACERS FORJOINT DIMENSIONFIELD APPLIEDFIXING SCREW128-348#10 x 1 1/4"FLAT HEADSELF DRILLING.SHOP APPLIED STOPSCREW 128-267#12 x 1" PANHEAD TYPE ABSHOP APPLIED STOPSCREW 128-267#12 x 1" PANHEAD TYPE ABUSE TEMPORARYSPACERS FORJOINT DIMENSIONAT MULLION JAMBSIDE, APPLY (2) 128-396SCREWS AS SHOWNTO CENTER F-CLIPS ASREQUIRED.SPLICE JOINTWHEN IT OCCURSAT A HORIZONTAL.1 1/4"1/8"95449-6910/20/07SILL SHOWNHEAD SIMILARANCHOR FASTENERLOCATIONS PERAPPROVEDSHOP DRAWINGSDRAWING:21600 SYSTEMINSTALLATION INSTRUCTIONSPART NO.162-971 4 OF 12ORDER:SHT:

162-971 5 OF 12STEP - 8 INSTALL HEAD/SILLAND INTERMEDIATETUBULARHORIZONTALS HORIZONTALSSTRUCTURAL GLAZED VERTICALSDETAILS SAME FOR "CAPTURED VERTICALS"EXCEPT HORIZONTAL THERMAL BREAKCUT 1/4" SHORT EACH END.128-405 SCREWS#12 X 7/8" FLAT HEADTYPE ABSTEP - 8 INSTALL HEAD/SILLAND INTERMEDIATEHORIZONTALSREFERENCE INSTRUCTIONS 162-983 FOREXTERIOR FRAME PERIMETERSAOPEN BACK HORIZONTALS AND LAST BAYHORIZONTALS.FILLER AVAILABLE WHEN OPEN BACK ISEXPOSED AND AT EYE LEVEL.STRUCTURAL GLAZED VERTICALSDETAILS SAME FOR "CAPTURED VERTICALS"EXCEPT HORIZONTAL THERMAL BREAKCUT 1/4" SHORT EACH END.HEADAINSTALLING CEILING INTERMEDIATEOPEN BACK HORIZONTALINSTALLING STOOL INTERMEDIATEOPEN BACK HORIZONTAL128-405 SCREWS#12 X 7/8" FLAT HEADTYPE ABJOINT PLUG162-321 1" FRAMING162-322 1/4" FRAME MEMBERSHEADAPPLY SEALANT TO THISFACE OF JOINT PLUGSTEP - 9 INSTALL JOINTPLUGSINTERMEDIATECAPTURED GLAZED VERTICALSCEILINGALL SURFACES AND GROOVES MUST BECLEANED PER THE SEALANT MANUFACTURER'SRECOMMENDATIONS.JUST BEFORE INSTALLING JOINT PLUGSAPPLY SEALANT AS SHOWN FILLINGGASKET POCKET AND ADAPTER GROOVE.SILLSECTION A-ASTOOLTHERMAL BREAKTO BE SAMELENGTH AS HORIZONTALAT SSG VERTICALTHERMAL BREAKTO BE 1/4"SHORT AT EACHEND OFHORIZONTALS AT CAPTURED VERTICALSEAL AROUNDJOINT PLUGEDGESTOOL SEALANTFILLGASKETPOCKETFILLADAPTERGROOVESEAL AROUNDJOINT PLUGEDGESTOOL SEALANTREFERENCE INSTRUCTIONS 162-983 FOREXTERIOR FRAME PERIMETERSSILL95449-6910/20/07DRAWING:2FACE VIEW1600 SYSTEMINSTALLATION INSTRUCTIONSPART NO.162-971 5 OF 12ORDER:SHT:

162-971 6 OF 12STEP - 9 INSTALL JOINTPLUGSSTRUCTURAL GLAZED VERTICALSSTEP - 10 INSTALL PERIMETERFILLERS ANDSPANDREL ADAPTERSWHERE APPLICABLECAPTURED VERTICALSAPPLY SEALANTAS SHOWNFILLINGGASKETPOCKETSAND VERTICALGROOVESJOINT PLUG162-324 1" FRAMING162-325 1/4" FRAMINGALL SURFACES AND GROOVESMUST BE CLEANED PER THESEALANT MANUFACTURER'SRECOMMENDATIONS.JUST BEFOREINSTALLING FILLERSAND SPANDRELADAPTERS FACE SEALJOINTS AT ALL 4CORNERS. ALSOSEAL SCREW HEADAT TOP HALF OFHORIZONTALSTEP - 10 INSTALL PERIMETERFILLERS ANDSPANDREL ADAPTERSWHERE APPLICABLECAPTURED VERTICALSSTRUCTURAL GLAZED VERTICALSSPANDRELADAPTERPERIMETER FILLERAPPLY SEALANT TOBOTH SIDES OF PLUGPERIMETER FILLERINSTALL VERTICAL ADAPTERWITH 128-348 SCREWS#10 X 1-1/4" FLAT HEADSELF DRILLING SCREW.LOCATE A MAXIMUM 6"AND A MINIMUM 4" FROMEACH END AND 9" ON CENTERGROOVE FORINSTALLATIONTOOLAT STEEL REINFORCING USE 128-401 #10 X 1"FLAT HEAD TYPE B SCREW. DRILL .154 DIA.#23 DRILL INTO MULLION USING ADAPTERHOLES AS A PILOTSTRUCTURAL GLAZED VERTICALSSEAL AROUNDJOINT PLUGEDGESTOOL SEALANTSTEP - 10 INSTALL PERIMETERFILLERS ANDSPANDREL ADAPTERSWHERE APPLICABLEGROOVE FORINSTALLATIONTOOLUSE PUTTY KNIFE,SMALL PRY BAROR SCREW DRIVERSPANDRELADAPTER95449-6910/20/07DRAWING:21600 SYSTEMINSTALLATION INSTRUCTIONSPART NO.162-971 6 OF 12ORDER:SHT:

162-971 9 OF 12STEP - 16 INSTALL GLASSSTRUCTURAL GLAZED VERTICALSSTEP - 17 INSTALL EXTERIORPRESSURE PLATESCAPTURED VERTICALSINSTALL VERTICAL PRESSURE PLATESAT CAPTURED VERTICALSNOTE - THE TORQUE LIMIT TOOL WAS DESIGNEDTO BE USED WITH A HAND DRIVEN DEVICE.THE TOOL CAN BE ADAPTED TO A DRILL MOTORIF USED AT A MAXIMUM SPEED OF APPROX.300 RPM. HIGHER SPEEDS CAN CAUSEOVERHEATING AND AFFECT THE ACCURACY. AFTERAPPROX. 1 HOUR OF TOOL USAGE CHECKTORQUE SETTINGS WITH A TORQUE WRENCH.RECOMMEND USING TORQUE LIMITTOOL 162-399 SEE NOTE.AHOW TO SET TORQUE LIMITAVISIONGLASSINTERMEDIATE HORIZONTALVISION OVER SPANDREL1. ATTACH ANY CALIBRATED TORQUE INDICATOR TOOUTPUT STUB (1) AND DETERMINE PRESENT TORQUESETTING WHILE HOLDING THE BODY (5), OR VICE-VERSA.2. REMOVE SNAP RING (2) AND LOCKING PLATE (3).3. ADJUST NUT (4) WITH OPEN-END WRENCH : CLOCKWISETO INCREASE TORQUE, COUNTER- CLOCKWISE TODECREASE TORQUE.JUST BEFORE INSTALLING VERTICAL PRESSUREPLATES APPLY A GENEROUS AMOUNT OFSEALANT TO THE JOINT PLUG FACE FILLINGJOINTS AS SHOWN.4. OBTAIN NEW TORQUE READING WITH THE CALIBRATEDTORQUE INDICATOR. REPEAT PRECEDING STEP IF MOREADJUSTMENT IS NECESSARY TO REACH DESIRED LIMIT.SPANDRELGLASSCLEAN JOINT PER SEALANTMANUFACTURER'S RECOMMENDATIONS5. REPLACE LOCKING PLATE INTO NOTCHES AND INSTALLSNAP RING. IF LOCKING PLATE DOES NOT "SEAT", MOVE THEADJUSTING NUT SLIGHTLY UNTIL IT DROPS IN PLACE. THEDIRECTION IS BEST DETERMINED BY WHETHER A MINIMUMTORQUE APPLICATION OR A MAXIMUM ONE IS DESIRED.TOOL EXCESSSEALANTVERTICAL GASKETSTOPS 1/2" SHORTAT HEAD AND SILLCONDITIONSHEAD CONDITIONSILL SAMEA-ASTRUCTURAL GLAZED VERTICALSTEMPORARY RETAINERS FOR STRUCTURAL GLAZEDVERTICALS.THE LOCATION OF TEMPORARY EXTERIOR INFILLRETAINERS SHOULD BE AT A MAXIMUM SPACING OF30" ON CENTER.IF WINDS GREATER THAN 50 MPH (80KPH) ARE EXPECTED,ADDITIONAL TEMPORARIES MAY BE REQUIRED. CONSULT YOURSEALANT AND/OR INFILL SUPPLIER FOR SPACINGRECOMMENDATIONS.GLAZING TEMPORARY162-35352314BBTOOL EXCESSSEALANTVERTICAL GASKETSTOPS 1/2" SHORTAT HEAD AND SILLCONDITIONSPERIMETER FILLERINSTALL PRESSURE PLATES USING SCREWS 128-406 1/4-14 X 1"HEX WASHER HEAD TYPE AB.HEAD CONDITIONSILL SAMESCREWS ARE TO BE LOCATED 9" ON CENTER.ALWAYS LOCATE A SCREW AS CLOSE AS POSSIBLE TO AHORIZONTAL JOINT. THIS WILL PROVIDE MAXIMUM PRESSUREFOR THE CRITICAL JOINT SEALS.INSTALL HORIZONTAL PRESSURE PLATES WITH WEEP HOLESTOWARDS TOP OF HORIZONTAL.INSTALL WITHSCREWS 128-400AT 1" GLASS#12 X 2-1/4 PH HD TYPE BUSE SCREW 128-284AT 1/4" GLASS#12 X 1-1/2 FL HD TYPE ABAT CORNERS AND SPLAYS RETAINERS SHOULD BEMADE FROM A GOOD QUALITY HARDWOOD. THESERETAINERS ARE NOT SUPPLIED BY KAWNEER.AT EACH HORIZONTAL AND VERTICAL PRESSURE PLATEINSTALL TWO SCREWS PART WAY, THEN INSTALL THE THIRDSCREW ALL THE WAY, AND THEN TIGHTEN THE FIRST TWOSCREWS. THIS ELIMINATES LATERAL WALKING OF THEPRESSURE PLATE POSITION.TORQUE ALL SCREWS TO 95 TO 100 INCH POUNDS. DURINGCOLD WEATHER, TORQUE SCREWS TO 50 INCH POUNDSUNTIL ALL 4 SIDES HAVE BEEN CLAMPED. THEN TORQUESCREWS TO 95 TO 100 INCH POUNDS.B-BTOOL EXCESSSEALANT95449-6910/20/071600 SYSTEMDRAWING:2INSTALLATION INSTRUCTIONSPART NUMBER162-971 9 OF 12ORDER:SHT:

162-971 10 OF 12STEP - 17 INSTALL EXTERIORPRESSURE PLATESINSTALL HORIZONTAL PRESSURE PLATESINSTALL HORIZONTAL PRESSURE PLATESREFERENCE INSTRUCTIONS 162-983FOR EXTERIOR FRAME PERIMETERSAT CAPTURED VERTICALSAT SSG VERTICALSCENTER HORIZONTAL PRESSURE PLATESSO END GAPS ARE EQUAL.INSTALL VERTICAL PRESSURE PLATESAT CAPTURED VERTICALSINTERMEDIATEHORIZONTALVISION OVERSPANDRELAVERTICAL EXPANSION JOINTSSEAL BETWEEN PRESSUREPLATE AND HEAD/SILL ENDCAP AS SHOWN.HEAD HORIZONTALSILL SAMEDNOTE - THE TORQUE LIMIT TOOL WAS DESIGNEDTO BE USED WITH A HAND DRIVEN DEVICE.THE TOOL CAN BE ADAPTED TO A DRILL MOTORIF USED AT A MAXIMUM SPEED OF APPROX.300 RPM. HIGHER SPEEDS CAN CAUSEOVERHEATING AND AFFECT THE ACCURACY. AFTERAPPROX. 1 HOUR OF TOOL USAGE CHECKTORQUE SETTINGS WITH A TORQUE WRENCH.ABDETOP OF VERTICALMULLION TO TOPOF PRESSURE PLATEIS 1-1/2"SEAL JOINTS ASSHOWN. TOOLSEALANT.THIS SEAL IS TOJOIN AND ADHERETO THE JOINTPLUG SEALS.BGASKET027-850CLEAN JOINTPER SEALANTMANUFACTURER'SRECOMMENDATIONSA-ADO NOT LET THE SEALINTERFERE WITH THE COVER SNAP.AT TOP PRESSURE PLATELOCATE SCREW CLOSE TOTHE MULLION JOINT BUTNOT BELOW THE JOINT.VISIONCECD-DVERTICAL GASKETSTOPS 1/2"SHORT OF END.SEAL JOINTS ASSHOWN. TOOLSEALANT.THIS SEAL IS TOJOIN AND ADHERETO THE JOINTPLUG SEALS.GASKET027-857PERIMETER FILLERJUST BEFORE APPLYING PRESSURE PLATEAPPLY A GENEROUS AMOUNT OFSEALANT TO THE JOINT PLUG FACE.CLEAN JOINT PER SEALANTMANUFACTURER'S RECOMMENDATIONSE-ESPANDRELGASKET027-850HEAD HORIZONTALSILL SAMESPANDRELDO NOT LET THE SEALINTERFERE WITH THE COVER SNAP.B-BFACE VIEWSPANDRELCLEAN JOINTPER LEAN JOINTPER 7-850GASKET027-850SPANDRELFACE VIEWDO NOT LET THE SEALINTERFERE WITH THE COVER SNAP.VISIONDVISIONC-CDGASKET027-850ECOMPLETELY SEAL JOINT.DO NOT LET SEALANTINTERFERE WITH COVER SNAPOVERLAP PRESSURE PLATE FACECREATING A BAND-AID SEAL95449-6910/20/07CECSEAL JOINTS ASSHOWN. TOOL SEALANT.THIS SEAL IS TO JOINAND ADHERE TO THEJOINT PLUG SEALS.1600 SYSTEMDRAWING:2INSTALLATION INSTRUCTIONSPART NUMBER162-971 10 OF 12ORDER:SHT:

162-971 11 OF 12STEP - 17 INSTALL EXTERIORPRESSURE PLATESINSTALL HORIZONTAL PRESSURE PLATESINSTALL HORIZONTAL PRESSURE PLATESAT SSG VERTICALSAT SSG VERTICALSINSTALL HORIZONTAL PRESSURE PLATESSTEP - 18 INSTALL PERIMETERSEALSGASKET027-857AT SSG NS162-983 FOREXTERIOR -850PERIMETER FILLERHEAD HORIZONTALSILL SAMEVISIONPERIMETER WEATHER SEALS ARE INSTALLED AT THEPRESSURE PLATE LOCATION AS DETAILED BELOW.(THIS SEAL SHOULD BE INSTALLED BEFORE COVERSARE APPLIED WHEN COVERS DEEPER THAN 3/4" AREUSED) EXTERIOR COSMETIC SEALS AT THE COVERMAY BE APPLIED AT THE HEAD AND JAMBS ONLY.SILL COVERS MUST REMAIN OPEN TO ALLOW WATERDRAINAGE TO THE AD HORIZONTALSILL DO NOTSEAL OVERWEEP HOLESBSPANDRELSPANDRELASILLCONDITIONBSPANDRELWEEP AREAPERIMETER FILLERVISIONHEAD HORIZONTALSILL SAMEREQUIREDWEATHERSEALHEAD HORIZONTALSILL SAMEBBBBJAMBCONDITIONASPANDRELACOMPLETELY SEAL HORIZONTALPRESSURE PLATE JOINT.DO NOT LET SEALANT INTERFEREWITH COVER SNAPCLEAN JOINT PER SEALANTMANUFACTURER'S PLETELY SEAL HORIZONTALPRESSURE PLATE JOINT.DO NOT LET SEALANT INTERFEREWITH COVER SNAPCOMPLETELY SEAL HORIZONTALPRESSURE PLATE JOINT.DO NOT LET SEALANT INTERFEREWITH COVER SNAPCLEAN JOINT PER SEALANTMANUFACTURER'S RECOMMENDATIONSCLEAN JOINT PER SEALANTMANUFACTURER'S RSEAL95449-8702/17/1221600 SYSTEMINSTALLATION INSTRUCTIONSPART NO.162-971 11 OF 12DRAWING:ORDER:SHT:

h - follow kawneer installation and coat of zinc chromate or bituminous incompatible materials with a heavy directly in contact with the masonry or paint. . head similar 1600 system 2 95449-69 10/20/07. 162-971 5 of 12 part no. #12 x 7/8" flat head type ab 128-405 screws step - 8 install head/sill