Transcription

HAVER & BOECKERInformationHAVERValve-bagFilling Machines

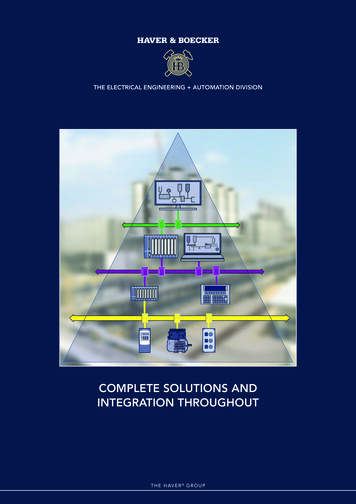

HAVER valve-bag filling machinesCONTENTSOptimum concepts,analysis, testsPage 3Vertical impeller fillingsystemPage 4Horizontal impellerfilling systemPage 6Air entrainment systemPage 7System componentsPage 10Bag chair variantsPage 12Weigher electronicsPage 13Ultrasonic bagclosing systemsPage 14Automatic bag applicatorsPage 16INTEGRA and miniseal Page 17HAVER valve-bag filling machines for all bulk materials2

HAVER optimum concepts, analyses, testsHighly developed technology and continuousimprovements in fillingsystems are amongHAVER & BOECKER’sgreatest specialties.HAVER has optimumsolutions for: every loose,bulk product property every commerciallyavailable valve-bag typeand dimensions all customer requirements, tailored to fulfillocal requirementsSuccessful and completesystem solutions arebased on HAVER &BOECKER’s analyticalapproach and its broadbased expertise and experience from: continuous researchand development its own in-companylaboratories its own, self-developedtest methods detailed sampling fordetermining physicalproduct properties exact air permeabilitytests on empty bagsusing precisioninstruments economically soundconceptsFilling trials and product analysisin HAVER & BOECKER test laboratoriesLaboratory for product analysisTest machine for empty bags3

HAVER filling system with vertical impellerFully automatic HAVER valve-bag filling machine with valve closing and automatic bag applicator4

HAVER vertical filling impellerHAVER valve-bag fillingmachines using the verticalimpeller filling system is ahighly successful technology for filling loose, powder-type, bulk material intovalve-bags according to thegross weight system.Cross-sectional view of a HAVER valve-bag filling machine with the vertical impeller filling system andautomatic, vertical bag dischargeThe advantages production rate of up to350 bags / hour perfilling spout precise weighing duringthe filling process high compaction levels low aeration amountduring filling produceshigh density packaging minimal spillage rapid emptying of thepacking silo and fillingmachine via a second(optional) impeller outlet easy accessibility foreffective maintenanceand cleaning modern drive systemdesign and optimallydesigned wear-partsassure maximum plantoperation time maximum adaptation todifferent productproperties and bagsizes through optionalvariability5

HAVER valve-bag filling machine with horizontal impeller filling systemThrough continuousdevelopment, HAVER’shorizontal impeller filling machine is designedto pack highly flow-resistant, powder-type, loosematerials that are proneto clogging.Features especially adaptable todifferent materials andmaterial flow characteristics large material inletcross section high filling speeds continuous materialfeeding (no clogging,no bridging) high filling speedswhile maintaining tightweight tolerancesHAVER valve-bag filling machinewith the horizontal impeller filling systemHAVER horizontal impeller6Cross-sectional view of a HAVER valve-bag machinefilling with the horizontal impeller filling system

HAVER air entrainment system - variant IThe air entrainment machineaccording to the gross weightfilling system is used for fillingfree flowing materials as well astechnically difficult powder-typeand granular products.The pressure chamber aerationconcept provides optimum productflow with minimal air consumption.Aeration rates depend on theproduct characteristics and areindividually adjustable.Thanks to continuous suctionduring filling, high filling rateswith minimum internal bagpressure are assured.Pressure chamber with inclined bottomAir entrainment packing machine for manual operationOpened pressure chamber allows easy and rapid cleaning7

HAVER air entrainment system - variant IIThe universal air entrainment system has gainedwide acceptance for fillingfine to granular productsinto valve-bags. The idealarea of application is thepacking of products thatconsist of a mixture of fineand coarse particles.Inline filling machines areavailable for manual orfully automatic operationand for integration into existing packing plants withup to four filling spouts.Advantages gentle product handling material components donot become separatedduring the packing process production rates of up to400 bags / hour per fillingspout high weight precision fully aerated pressurechamberHAVER valve-bag filling machine using the air entrainment systemoutfitted with an automatic vertical bag discharger8Cone valve(opened / closed)

homogeneous product/air mixture dust minimization automatic cleaningprogram trouble-free filling ofpaper, PE and PPvalve-bags operator friendlydesign easy accessibility formaintenance and service entire system requiresminimal maintenanceUniversal applicationfor filling many products types, which varyin particle size anddensity, where the airentrainment amountscan be optimallyadjusted independent ofeach other and wherethe air pressure can becentrally regulated.As an option, thisadjustment process maybe automated via thesort-selection of theHAVER weigherelectronics.Cross-sectional view of a HAVER valve-bag filling machine using the air entrainment systemPressure chamber with viewing windowand fill level indicatorPressure chamberwith maintenance doorMaintenance dooron the filling hopper9

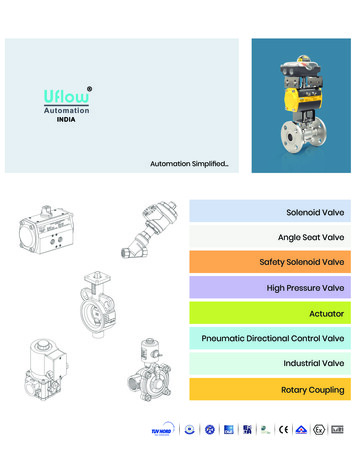

HAVER system componentsRing gap aeration reduces wall frictioninside the fillingchannel using minimalaeration, without airreaching the core of theproduct flow this leads to a clean filling process under ahigh filling pressure thatyields a high densitypacking switching on and off theaeration as a function ofthe filling speedBag sensors for detecting the position of the valve-bag onthe filling spout beforefilling begins for reliable, fully automatic operation sensors operating independently of each otheraccording to varioustechnical principlesassure maximum availability of the HAVERpacking plantsFilling spout individual designs thatmatch specific equipment layouts, productrequirements and bagspecificationsCross-sectional view of the HAVER vertical impeller filling systemVarious HAVER filling spout designs10

Fine flow opening adjustmentFilling shut-off valvesExact flow rate dosing andshort reaction times inchangeovers to coarse flowor to fine flow and closingthe filling channel requireespecially reliable components.HAVER fulfils these requiPinch valverements down to the detail: under the most extremeconditions, independentof the product type orfilling system, pinchvalves have proventhemselves for completely closing the fillingchannel special slide valves minimize wall frictionthrough their compactsize, and are available instandard or in wearresistant designs depending on the material type, the fine flowcross-section of thefilling channel may beregulated manually, ormotorized with a threeposition pneumaticcylinderSlide valve11

HAVER bag chair variants12Bag chairs for manual removal,manually height adjustableBag chairs for automatic,vertical bag discharge - manually adjustableBag chair for automatic verticalbag discharge, motorized,stepless height adjustment viabag-type pre-selectionFor machines with the manualremoval of filled bag, the bag chairmay be adjusted to suit the lengthof the bag using just a few motionsof the hand.When only one bag size is used orwhen bag changeovers are seldom,then the tip-chair for automaticdischarge may be height-adjustedusing standard tools.For different bag lengths and frequent sort changes, the automaticbag chair height adjustment(through a gear reduction motorand spindle) is recommended.Adjustment is done simply by asort-selection key during productor bag changeovers.

HAVER weigher electronicsOnline process monitoring. and documentationMEC III operator terminalProcess data evaluationEvery spout is equippedwith the MEC III electronicweigher controller, whichnot only controls the weigher functions, but the fillingmachine as well.Weigher functions automatic taring andzero-setting dosing time regulation dynamic cut-off pointdetermination tolerance evaluation coarse flow fine flowMachine functions bag breakage detection regulated filling vesselaeration rapid discharge bag chair height adjustment bag discharge controlAdditional features separate IP 65 operating terminal contrast graphic displaywith soft keys forweight, text and status durable film keypadfor dialog operationin selectable languages memory for 99 sorts weight correction viacheck weigher is possible, but not necessary network capable viaEthernet serial interfacesRS 232, RS 485The PTB certificate aswell as domestic approvaland OIML certificate areavailable.The DPS 4.1 data processing system can be hooked up to the MEC III.Details are available in theother brochures.13

HAVER ultrasonic bag closing systemThe optimized bag closingsystem using the HAVERultrasonic process prevents unwanted materialleakage from the bagvalve, assures cleanly filled bags and subsequentlyimproves storage andhandling of filled bags.After filling, the valvebag is moved away in thestanding position. Theultrasonic closing headthen pneumatically swivels downward and weldsthe plastic or plastic coated paper valve shut.Special advantages secure closure, evenwhen the valves areaffected by the materialinside self-cleaning effect ofthe weld zone by theultrasonic system short cycle times - highhourly production rates parallelogram transfersystem for moving thefilled bag away fromthe filling spout all standard valve sizescan be closed heating occurs only inthe weld zone valve position sensorsfor activating the ultrasonic generator reliable, low maintenance technologyHAVER valve-bag filling machinewith ultrasonic closing unitUltrasonic valve-bag closing unit14A securely closed valveCleanliness - the result of tightly closedbag valves

Bag filling positionBag closing position15

HAVER automatic bag applicatorsThe COMPACT automatic,linear bag applicator byHAVER is a flexible andsimple solution for fillingmachines with one or twofilling spouts.The advantages speeds of up to 700 bagsper hour compact design low maintenance drivesystem simple and quick changeover to other bagtypes or sizes integrated bundle magazine cart with a storagecapacity of up to 300bags as needed, other emptybag magazine designsmay be usedThe HAVER COMPACT automatic bag applicatorThe HAVER linear bagapplicator was especiallydesigned for multiplespout, inline packingmachines.Special features speeds of up to 1500bags per hour the HAVER valve-bagapplicator system ismodularly integrated long machine operationtimes, economical in allapplication areas universally applicablewith respect to bagmaterial and empty bagdelivery condition highly reliable processsteps and rationalizedcontrol systemsFor further details, see ourseparate system brochures.The HAVER FRONT LINE automatic bag applicator16

The HAVER -“Plug and Pack“ concept INTEGRA and minisealHAVER minseal With the development ofthe HAVER miniseal , anew trend in filling smallpackages has emerged.For the first time it ispossible to fill powderlike material in valvebags with a volume of2 to 3 liters. When compared to conventionalpackaging these valvebags, the smallest worldwide, make for an impressive product presentationon the market. In additionthe bag is equipped with acarrying handle and pourer opening, making it anespecially consumerfriendly product.Filling machine, bag closure, bag applicator - acomplete system inside adust-proof enclosure - acompact, turnkey production system!HAVER miniseal HAVER INTEGRAHAVER INTEGRAThe INTEGRA is a complete, fully assembled filling system for loose,bulk materials inside adust-proof enclosure consisting of the followingcomponents: filling machine valve closing system bag applicator control system operating terminal discharge conveyorIt’s a complete, factoryassembled, turnkey unitthat is quickly installedon site and put into operation. Only the productfeeding system andpower supply need to beprovided on site.Additional INTEGRAand miniseal systemfeatures: compactness minimum space requirements enclosure (reducednoise and dust emissions) higher operationalreliability easy installation andassembly, easy to reposition or to readjust ifnecessary highest possible flexibility, quick changeoversfor other material typesand bag formats large maintenancedoors allow easy accessibility to all components window panels made ofscratch-resistant safetyglass that allow viewing operator terminal operator instructions indialog (text display)17

The HAVER -“Plug and Pack“ concept INTEGRA and minisealSuspended transportTransport using a forkliftAll doors for accessing theHAVER INTEGRA system areequipped with safety switches toeliminate an inadvertent entryduring operation.Large area windows made ofscratch-resistant, anti-static safetyglass allow the machine operatorto view all functional areas whilereducing noise emissions.The control cabinet is integratedinto the support frame via telescoping tracks, making it easy to pullout from the support frame formaintenance purposes.If hazardous materials are to befilled, then it is highly recommendable to include a de-dustingsystem with the INTEGRA to generate a negative pressure from outside to inside to achieve dust-freefilling.HAVER INTEGRA placed at its operational site18

The HAVER -“Plug and Pack“ concept INTEGRA and minisealThe valve-bag, in itsvarious shape formatsand for different products, is a highly flexiblepackaging system thatallows loose, bulk materials to be packed economically. And due tosound valve-closing technology and virtual elimination of spillage, awhole new range ofapplications has resulted.Spillage cart under the filling impellerOpened maintenance doorAir entrainment systemNew techniques for airescape from bags nowallow practically airtightbags to be filled. Thebest filling system isdetermined by considering the properties of theproduct to be filled, thedesign of the bag andespecially its air permeability characteristics.Horizontal impeller filling systemVertical impeller filling system19

HAVER & BOECKERHAVER ROTOSEAL -PACKERHAVER semi-bulk filling stationHAVER Form-Fill-Seal DELTA automatic machinesHAVER & BOECKERP.O. Box 33 20 D-59282 OELDE , Germany Phone: 49-25 22-30 0 Telefax: 49-25 22-30 4 03E-mail: mf@haverboecker.com Internet: http://www.haverboecker.comAffiliated Company USA: HAVER FILLING SYSTEMS, INC.Phone: 1-770 760-11 30 Telefax: 1-770 760-11 81E-mail: sales@haverusa.com Internet: http://www.haverusa.comAffiliated Company Brazil: HAVER & BOECKER Latinoamericana Màqs. Ltda.Phone: 55-19-3879-91 00 Telefax: 55-19-3879-14 10E-mail: haverhbl@haverbrasil.com.br Internet: http://www.haverbrasil.com.brAffiliated Company France: HAVER FRANCE S.A.R.L.Phone: 33-1-39 11 80 80 Telefax: 33-1-39 11 80 89E-mail: contact@haverfrance.fr Internet: http://www.haverfrance.frPM 212 E 2804 0606 1 FeHAVER sand processing plantThe machines and plants shown in this leaflet as well as the stated technical parameters are examples of customer-specific technical solutions. Therefore they are subject to modifications.Innovation and Qualityfor the 21st Century

HAVER vertical filling impeller HAVER valve-bag filling machines using the vertical impeller filling system is a highly successful technolo-gy for filling loose, pow-der-type, bulk material into valve-bags according to the gross weight system. The advantages production rate of up to 350 bags / hour per filling spout precise weighing during