Transcription

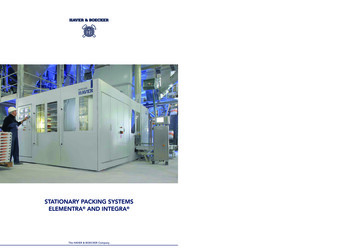

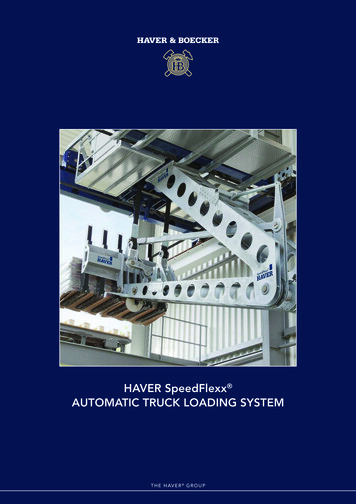

HAVER SpeedFlexx AUTOMATIC TRUCK LOADING SYSTEMT H E H AV E R G R O U P

HAVER SpeedFlexx We view ourselves as a provider of process solutions. Ourwell-known product line is nowextended by a product whichhas not been available up tonow and allows the automaticloading of palletized baggedgoods onto open truck bedsand trailers.The HAVER SpeedFlexx loaderDesign advantagesis an additional product of HAVER &n Portal design for two lanesBOECKER that is characterised byn Robust construction for allspeed, rentability and flexibility.moving partsn Electromechanical moving The name SpeedFlexx unifies allprocesses without pneumaticsthe advantages of this high-perfor-and hydraulicsmance system:n Menu-controlled operating panelSpeed performanceMain areas of applicationThe HAVER SpeedFlexx is a high-n Total speed of 260 t/hrn Cement industryspeed direct truck-loading unit with an Increases packer and palletizern Building materials and operating timeloading speed of up to 260 tonnesminerals industryper hour. The system’s flexibility alson Fully automatic loading cycleallows delivery to stock in the eventn 2 truck lanesof dead truck times. Therefore highn Lane change in 11 secondsn Chemical industrypacking and palletizing plant capacityutilisation is assured even duringFlexx flexibilitytimes of missing trucks. By combiningn All conventional pallets can behandledthe proven components of stationarypalletizing technology with conveying technology, the SpeedFlexx systemoffers unique and reliable operation.n Combination directloading/stocking is possiblen Split loads possibleFilled bags are handled with shipping(simultaneous loading of trucksand in-house pallets, as well asfrom palletizer and from stock)sheets. It is a loading unit that isdesigned for two truck lanes.PACKINGMACHINEHAVERSpeedFlexx LOADER4,500 bags/hrPALLETIZER260 t/hrSTOCKTRUCKTRUCK

TRUCK LOADING SYSTEM FROM HAVER & BOECKERT H E H AV E R G R O U P2 3

BAG HANDLINGThe HAVER SpeedFlexx loaderThe loading cycle begins with a scanMoreover, in the event of bottlenecks,enters new territory when it comesof the truck bed surface. Using opti-it is also possible to reverse thisto performance and scope of appli-cal analysis technology, a three-di-process, i.e. to feed the HAVERcation: 260 tonnes per hour canmensional image is produced and thisSpeedFlexx from a filled stock.be loaded with this truck loadingassures that the truck bed is clearsystem. This is possible through aand ready to be loaded. During thehighly efficient loading cycle andloading process, open trucks on twoby trucks in a second lane, whichtravel lanes are alternately loadedreduces waiting times.with stacks of bags. This is done by afeeding rack installed over the truck.Type of load unitsOnce the loading of the first truck isn Pallets with covers, shrink-wrap,completed, the HAVER SpeedFlexx stretch-film, or slingschanges lanes within a few secondsn With or without palletsand the second truck, which in then Slip sheetmeantime had positioned itself inparallel, is then loaded.The result: continuously high loadingspeeds are achieved during peaktimes.Considering the anti-cyclic demandof the daily profile of a loadingsystem, timeframes with reducedtruck frequency will lead to the fillingof the adjacent pallet stock. Herestocking is handled in the usual manner with forklift trucks. This enablescontinuous use of the packing andpalletizing plant, and thus optimumutilisation of installed capacity.Valve bag typesPaper bagpastedWoven PP bagpastedWoven PP bagpasted (sealable)PE bagpasted (sealable)

4 5Pallet typesIn-house pallet with slip sheetIn-house palletShipping palletIndustrial palletT H E H AV E R G R O U P

HAVER SpeedFlexx The loading system responds flexiblyFlexibility with the HAVER HAVER & BOECKER now supple-with regard to the provision of bags.SpeedFlexxments the processing chain withAll types of pallets can be handled:n All conventional load securinghighly efficient loading systems!in-house pallets with or without slipn Minimisation of dead times whenchanging truckssheets, industrial, or shipping pallets.n Two truck lanes can be served byone unitThe pallets do not necessarily haveto be loaded onto the truck directlyn Pallet configuration alreadypre-programmed in the softwarefrom the production line. They canalso be sent to stock and then latern Pallet orientation crosswise andlengthwise possiblebrought to the truck by the loadingsystem as needed.Type of shipping unitsn Pallets / no palletsn Slip sheetn CoveredThe HAVER logistics systemCementn IBAU silo facilities with bulkloadingn HAVER ROTO-PACKER withautomatic RADIMAT bagapplicatorsn Stationary HAVER palletizing madeby Newtec Bag Palletizingn HAVER stocking system, block orhigh-rack systemn HAVER SpeedFlexx – automatictruck loader for palletized goods2,400 bags/hrPACKINGMACHINEAutomatic loading system 1TRUCKAutomatic loading system 22,400 bags/hrAutomatic loading system 3TRUCKAutomatic loading system 42,400 bags/hrPACKINGMACHINEPALLETIZERHAVER SpeedFlexx LOADER 1TRUCKPALLETIZERHAVER SpeedFlexx LOADER 2TRUCK2,400 bags/hr

6 7THE HIGHLY EFFICIENT LOADING SYSTEMT H E H AV E R G R O U P

Brasilien / BrazilGroßbritannien / Great BritainUSA / USAHAVER & BOECKER LatinoamericanaMáquinas Ltda.Rod. Campinas à Monte Mor, km 2013190 MONTE MOR S.P.Phone: 55-19-3879-9101Telefax: 55-19-3879-1410E-mail: haverhbl@haverbrasil.com.brInternet: www.haverbrasil.com.brHAVER CONTINENTAL Ltd.Invincible RoadFARNBOROUGH,Hants Gu14 7QUPhone: 44-1252 512122Telefax: 44-1252 549291E-Mail: info@havercontinental.comInternet: www.havercontinental.comHAVER FILLING SYSTEMS, INC.460, Gees Mill Business CourtConyers, GA 30013Phone: 1-770 760-1130Telefax: 1-770 760-1181E-mail: sales@haverusa.comInternet: www.haverusa.comChina / ChinaIndien / IndiaHAVER IBAU SHENZHEN LIMITED1st Floor, L BuildingJingtie Technological & Industrial ZoneNo. 49 Changjiangpu Road, Heao VillageHenggang Town, Longgang DistrictShenzhen 518115Phone: 86-755 2862 5372Telefax: 86-755 2862 5382E-mail: info@haveribau.cnInternet: www.haveribau.cnHAVER IBAU INDIA Pvt. Ltd.KhandiwadaPost AsojDistrict Vadodara – 391 510Phone: 91-2676 30 66 00Telefax: 91-2676 30 69 99E-mail: india@haverboecker.comInternet: www.haveribauindia.comRussland / RussiaFrankreich / FranceHAVER FRANCE S.A.R.L.ZA - 7, rue des Bauches78260 ACHERESPhone: 33-1-39118080Telefax: 33-1-39118089E-mail: contact@haverfrance.frInternet: www.haverfrance.frHAVER & BOECKER, RussiaGostinichny Proezd8 /1, Buero 42127106 MOSCOWPhone/Telefax: 7 495 783 34 48E-mail: m.maslova@haverrussia.ruInternet: www.haverrussia.ruSpanien / SpainDeutschland / GermanyIBAU HAMBURGRödingsmarkt 3520459 HamburgPhone: 49-40-3613090Telefax: 49-40-363983E-mail: info@ibauhamburg.deInternet: www.ibauhamburg.deHAVER & BOECKER IBERICAGran Vía Corts Catalanes, 701 - 3 1a B08013 BARCELONAPhone: 34-93-247 61 90Telefax: 34-93-247 61 91E-mail: hbi@haverboecker.comHAVER & BOECKER OHGCarl-Haver-Platz 3 · 59302 OELDE · GermanyPhone: 49 2522 30-0 · Telefax: 49 2522 30-403E-mail: haver@haverboecker.comInternet: www.haverboecker.comHAVER MIDDLE EAST FZEP.O. Box 34098Ras Al Khaimah / U.A.E.Phone: 971 7 24 34 711Telefax: 971 7 24 34 712E-mail: hme@haverboecker.comInternet: www.havermiddleeast.com and representatives all over the world!PM 315 E 3157 0912 1 FeThe machines and plants shown in this leaflet as well as the stated technical parameters are examples of customer-specific technical solutions. Therefore they are subject to modifications.The designation indicates a registered trademark of HAVER & BOECKER OHG in Germany. Several indicated designations are registered trademarks also in other countries worldwide.VAE / UAE

HAVER & BOECKER, Russia Gostinichny Proezd 8/1,Buero42 127106 MOSCOW Phon e/T l fax: 495 3 E- m ail: .so v@h e ru I n t rw .h v usi Spanien / Spain H AV ER& BO CK I Gran Vía Corts Catalanes, 701 - 3 1a B 08 13B ARCELON Pho e: 4- 92 761 0 T el f x: 3- 76 1 E-mail: hbi@haverboecker.com USA / USA HAVER FILLING SYSTEMS, INC. 460, Gees Mill .