Transcription

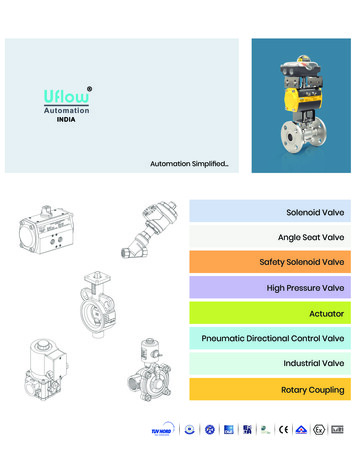

Automation Simplified.Solenoid ValveAngle Seat ValveSafety Solenoid ValveHigh Pressure ValveActuatorPneumatic Directional Control ValveIndustrial ValveRotary CouplingISO 2009:2015

Company ProfileUflow Automation is an engineering organization committed to provide complete solutions to customer's requirements. We are established in the year 2007 andprogressing with a vision of applying finest engineering practices in valve manufacturing industry by our restless and high skilled ENGINEERS, standardorganizational PROCESSES and superior quality PRODUCTS.We are leading in solenoid valve manufacturing company in India, Known as Uflow our range of products include - Pilot Operated Diaphragm Type Valves,Pneumatically Control Valves, Gas Solenoid Valves, High Pressure Valves, Industrial Valve, Pneumatic Directional Control Valve, Rotary Coupling and Actuators. Ourproducts are being sold across INDIA and being exported outside India in various other countries.Our QualityOur CommitmentAbout UsIn-House full scale testing facility.To understand customer's need first before proposingour productIn house R&D, manufacturing and testing facility insingle location at Gujarat, India.To keep providing competitive rates by continuouslyimprovement in process without compromising in quality.Authorized distributor channels in 20 different states inIndia.To provide continuous support to our customers and gobeyond their expectations in terms of delivery and aftersale services.Sales office in the UAE, Germany, Chile, Australia(Expanding).Lean manufacturing practices / six sigma,kaizen, 5S.Certified by : ISO 9001:2015 (Tuv Nord), CE,ERDA, CIMFR, BIS, PESO.We sarted building our products for a specific market segment and over the period of time we progressed to built it for various sectorsthat includes:TextileWater TreatmentEnergy & PowerPackagingPharmaceuticalOil & GasNuclearMarineChemicalFood and BeverageSteel & CementAutomotiveWe stand amongst the pioneers of the industry because of our following competitive advantages:Total quality management allow us to maintain the quality of our products.We follow genuine customer relationship policy and that help us to build trusted relationships.We believe in timely delivery with and consistent quality standards, state of art testing facility to ensure our customers don’t have complains.Innovative products range with and sophisticated and latest technology. Excellent R&D team allow us to develop new product faster.Highly accessible customer service team facilities to interact with our customers. Feel free to ask us for our customer references and product samples.Uflow quality is based on the platform of process control granting the elimination of variances, a computerized integrated system able to guarantee the quality ofproducts, the recording each production step to ensure effective data analysis as well as a complete and efficient traceability of both components and finishedproducts, always maintaining standards of high competitiveness in the marketplace.

01Pneumatic Valve SeriesMODEL INFORMATIONTypeCOIL INFORMATIONSolenoid Operated, Lever Operated, Pilot Air Operated,Push Pull (3X2, 5X2, 5X3 & NC / NO)DesignSpool with Cartridge TypeMediaCompressed Air (Filtered & Lubricated)Working Pressure Range2 - 10 barAmbient/MediumTemperature5 C - 60 CMaterials of ConstructionAluminium, Nitrile, Brass, PolymerCoil Width26 mmCoil Bore10 mmVoltage (V) 10%AC (50Hz, 60Hz) - 24V, 110V, 230VDC 12V, 24V, 36V, 48V, 110VPower ConsumptionAC-6W, DC-6WDuty CycleContinuousClass of InsulationClass HType of Coil ProtectionIP65FEATURESCartridge Type design for Long LifeLow Power ConsumptionCompact DesignLubrication not essentialStandard NAMUR Mounting10 Lacs Cycle testedManual OverrideWide range of coil voltage3X2, 5X2 SINGLE SOLENOID VALVE WITH SPRING RETURN1 - Input,2/4 - Output,FlowPort SizeIN OUT EXHFunctionSSA1BN23CT060V01200 LPM¼” ¼” ¼”at 6 BarSPRINGRETURN (NC)STA1BN23CT060V01200 LPM¼” ¼” ¼”at 6 BarSPRINGRETURN (NO)1200 LPMSFA1BN23CT060V0¼” ¼” ⅛”at 6 BarSPRINGRETURN3500 LPMSSA2BN23CT120V0½” ½” ½”at 6 BarSPRINGRETURN (NC)3500 LPM½” ½” ½”at 6 BarSPRINGRETURN (NO)STA2BN23CT120V0SFA2BN23CT120V0 3500 LPM ½” ½” ½”at 6 BarSPRINGRETURNSymbol21 321 34 251 32SYMBOLPRODUCT IMAGEModel3/5 - Exhaust1 321 34 251 33X2, 5X2 DOUBLE SOLENOID VALVE1 - Input,2/4 - Output,FlowPort SizeIN OUT EXHFunction1200 LPM¼” ¼” ¼”at 6 BarDOUBLESOLENOID1200 LPMSDA1BN23CT060V0¼” ¼” ⅛”at 6 BarDOUBLESOLENOID3500 LPM½” ½” ½”at 6 BarDOUBLESOLENOID3500 LPMSDA2BN23CT120V0½” ½” ½”at 6 bol21 34 25132SYMBOLPRODUCT IMAGEModel3/5 - Exhaust1 34 25133X2, 5X2 SINGLE SOLENOID NAMUR VALVE WITH SPRING RETURN2/4 - Output,ModelSSA1RN23CT060V0SFA1RN23CT060V0Flow3/5 - ExhaustPort SizeIN OUT EXHFunction1200 LPM¼” ¼” ¼”at 6 Bar3X2 SPRINGRETURN1200 LPM¼” ¼” ¼”at 6 Bar5X2 SPRINGRETURNSymbol21 34251 3SYMBOLPRODUCT IMAGE1 - Input,

02Pneumatic Valve SeriesModelSVA1RN23CT060V0SDA1RN23CT060V0FlowPort SizeIN OUT EXHFunction1200 LPM¼” ¼” ¼”at 6 Bar3X2 DOUBLESOLENOID1200 LPM¼” ¼” ¼”at 6 Bar5X2 DOUBLESOLENOIDSymbol21 3SYMBOLPRODUCT IMAGE3X2, 5X2 DOUBLE SOLENOID NAMUR VALVE425135X3 DOUBLE SOLENOID VALVE WITH SPRING CENTER1 - Input,2/4 - Output,FlowPort SizeIN OUT EXHFunctionSBA1BN23CT060V01200 LPM¼” ¼” ⅛”at 6 BarCENTEREDBLOCKEDSEA1BN23CT060V01200 LPM¼” ¼” ⅛”at 6 BarCENTEREDEXHAUSTED1200 LPMSPA1BN23CT060V0¼” ¼” ⅛”at 6 BarCENTEREDPRESSURISED3500 LPMSBA2BN23CT120V0½” ½” ½”at 6 BarCENTEREDBLOCKEDSEA2BN23CT120V03500 LPM½” ½” ½”at 6 BarCENTEREDEXHAUSTEDSPA2BN23CT120V03500 LPM½” ½” ½”at 6 BarCENTEREDPRESSURISEDSymbol425 134 2SYMBOLPRODUCT IMAGEModel3/5 - Exhaust5 134 25 134 25 134 25 134 25 133X2 HAND LEVER VALVE MANUAL AND SPRING RETURN1 - Input,2/4 - Output,FlowPort SizeIN OUT EXHFunctionLSA1BN04V01200 LPM¼” ¼” ¼”at 6 BarSPRINGRETURN (NC)LTA1BN04V01200 LPM¼” ¼” ¼”at 6 BarSPRINGRETURN (NO)LVA1BN04V01200 LPM¼” ¼” ¼”at 6 BarMANUALRETURNLSA2BN04V03500 LPM½” ½” ½”at 6 BarSPRINGRETURN (NC)LTA2BN04V03500 LPM½” ½” ½”at 6 BarSPRINGRETURN (NO)LVA2BN04V03500 LPM½” ½” ½”at 6 BarMANUALRETURNSymbol21 321 321 32SYMBOLPRODUCT IMAGEModel3/5 - Exhaust1 321 321 35X2 HAND LEVER VALVE MANUAL AND SPRING RETURN1 - Input,2/4 - Output,Flow3/5 - ExhaustPort SizeIN OUT EXHFunctionLFA1BN04V01200 LPM¼” ¼” ¼”at 6 BarSPRINGRETURNLDA1BN04V01200 LPM¼” ¼” ¼”at 6 BarMANUALRETURNLFA2BN04V03500 LPM½” ½” ½”at 6 BarSPRINGRETURNLDA2BN04V03500 LPM½” ½” ½”at 6 BarMANUALRETURNSymbol425134 25134 25134 2513SYMBOLPRODUCT IMAGEModel

03Pneumatic Valve Series5X3 HAND LEVER VALVE MANUAL RETURN1 - Input,2/4 - Output,FlowPort SizeIN OUT EXHSymbolFunctionLBA1BN04V01200 LPM¼” ¼” ⅛”at 6 BarCENTEREDBLOCKEDLEA1BN04V01200 LPM¼” ¼” ⅛”at 6 BarCENTEREDEXHAUSTEDLPA1BN04V01200 LPM¼” ¼” ⅛”at 6 BarCENTEREDPRESSURISEDLBA2BN04V03500 LPM½” ½” ½”at 6 BarCENTEREDBLOCKEDLEA2BN04V03500 LPM½” ½” ½”at 6 BarCENTEREDEXHAUSTEDLPA2BN04V03500 LPM½” ½” ½”at 6 BarCENTEREDPRESSURISED425 134 2SYMBOLPRODUCT IMAGEModel3/5 - Exhaust5 134 25 134 25 134 25 134 25 135X3 HAND LEVER VALVE WITH SPRING CENTER1 - Input,2/4 - Output,FlowPort SizeIN OUT EXHSymbolFunctionLKA1BN04V01200 LPM¼” ¼” ⅛”at 6 BarCENTEREDBLOCKEDLHA1BN04V01200 LPM¼” ¼” ⅛”at 6 BarCENTEREDEXHAUSTEDLRA1BN04V01200 LPM¼” ¼” ⅛”at 6 BarCENTEREDPRESSURISEDLKA2BN04V03500 LPM½” ½” ½”at 6 BarCENTEREDBLOCKEDLHA2BN04V03500 LPM½” ½” ½”at 6 BarCENTEREDEXHAUSTEDLRA2BN04V03500 LPM½” ½” ½”at 6 BarCENTEREDPRESSURISED425 134 2SYMBOLPRODUCT IMAGEModel3/5 - Exhaust5 134 25 134 25 134 25 134 25 133X2 EXTERNAL PILOT OPERATED VALVE1 - Input,2/4 - Output,FlowPort SizeIN OUT EXH10/12 - External PilotSymbolFunction2ASA1BN04V01200 LPM¼” ¼” ¼”at 6 BarSPRINGRETURN (NC)10ATA1BN04V01200 LPM¼” ¼” ¼”at 6 BarSPRINGRETURN (NO)10AVA1BN04V01200 LPM¼” ¼” ¼”at 6 BarDOUBLEEXTERNAL10ASA2BN04V03500 LPM½” ½” ½”at 6 BarSPRINGRETURN (NC)10ATA2BN04V03500 LPM½” ½” ½”at 6 BarSPRINGRETURN (NO)10AVA2BN04V03500 LPM½” ½” ½”at 6 BarDOUBLEEXTERNAL101 321 32121 32SYMBOLPRODUCT IMAGEModel3/5 - Exhaust,1 321 32121 35X2 EXTERNAL PILOT OPERATED VALVE1 - Input,2/4 - Output,FlowPort SizeIN OUT EXH10/12 - External PilotSymbolFunction4AFA1BN04V01200 LPM¼” ¼” ⅛”at 6 BarSPRINGRETURN10ADA1BN04V01200 LPM¼” ¼” ⅛”at 6 BarDOUBLEEXTERNAL10AFA2BN04V03500 LPM½” ½” ½”at 6 BarSPRINGRETURN10ADA2BN04V03500 LPM½” ½” ½”at 6 BarDOUBLEEXTERNAL1025134 2125134 25134 212513SYMBOLPRODUCT IMAGEModel3/5 - Exhaust,

04Pneumatic Valve Series5X3 DOUBLE EXTERNAL PILOT OPERATED VALVE WITH SPRING CENTER1 - Input,2/4 - V0ARA2BN04V03/5 - Exhaust,Port SizeIN OUT EXH10/12 - External PilotSymbolFunction1200 LPM¼” ¼” ⅛”at 6 BarCENTEREDBLOCKED1200 LPM¼” ¼” ⅛”at 6 BarCENTEREDEXHAUSTED1200 LPM¼” ¼” ⅛”at 6 BarCENTEREDPRESSURISED3500 LPM½” ½” ½”at 6 BarCENTEREDBLOCKED3500 LPM½” ½” ½”at 6 BarCENTEREDEXHAUSTED3500 LPM½” ½” ½”at 6 BarCENTEREDPRESSURISED4210125 134 210125 134 210125 134 210SYMBOLPRODUCT IMAGEABA1BN04V0Flow125 134 210125 134 210125 133X2 PUSH PULL VALVE MANUAL AND SPRING RETURN1 - Input,2/4 - Output,Flow3/5 - ExhaustPort SizeIN OUT EXHFunctionPSA1BN04V01200 LPM¼” ¼” ¼”at 6 BarSPRINGRETURN (NC)PTA1BN04V01200 LPM¼” ¼” ¼”at 6 BarSPRINGRETURN (NO)PVA1BN04V01200 LPM¼” ¼” ¼”at 6 BarMANUALRETURNPSA2BN04V03500 LPM½” ½” ½”at 6 BarSPRINGRETURN (NC)PTA2BN04V03500 LPM½” ½” ½”at 6 BarSPRINGRETURN (NO)PVA2BN04V03500 LPM½” ½” ½”at 6 BarMANUALRETURNSymbol21 321 321 32SYMBOLPRODUCT IMAGEModel1 321 321 35X2 PUSH PULL VALVE MANUAL AND SPRING RETURN1 - Input,2/4 - Output,NOTE: DOWNLOAD OUR PNEUMATIC SERIES CATLOGEFlowPort SizeIN OUT EXHFunctionPFA1BN04V01200 LPM¼” ¼” ⅛”at 6 BarSPRINGRETURNPDA1BN04V01200 LPM¼” ¼” ⅛”at 6 BarMANUALRETURNPFA2BN04V03500 LPM½” ½” ½”at 6 BarSPRINGRETURNPDA2BN04V03500 LPM½” ½” ½”at 6 BarMANUALRETURNSymbol425134 25134 25134 2513SYMBOLPRODUCT IMAGEModel3/5 - Exhaust

0553Proportional Flow Control Solenoid Valve - MAXØ5x2 NosØ3.1x2 Nos8.4OUTLETINLET111617.6FEATURESSPECIFICATIONSLow power consumption generates less heatModel Code:IBVM35150V0Proven performance tested to 100 million life cyclesUses either DC current or pulse width modulation with closed loopfeedback to deliver optimal system performance.Valve Type:2 Way Normally ClosedPort:Manifold MountingBody Material:BrassSeal:NBR Optional FKMMedia:Air, Oxygen, Nitrous Oxide, Carbon Dioxide,Heliox & Other Medical GasesInsufflatorsLPM:150LPM @ 35PSI Differential PressurePressure and Flow ControlOperating Environment:32 F to 132 F (0 C to 55 C)Storage Temperature:-40 F to 158 F (-40 C to 70 C)Dimensions:L-17.6mm, W-16mm, H-53mmWeight:56gPower:12V DC (2.5 Watts)Operating Pressure:0 to 60 PSIElectric Termination:15” Lead WireOrifice Sizes:5mmStem Base:430FR Stainless steelHysteresis:7% of full scale current (Typical), 15% of full scalecurrent (Max)All Others:NBR/FKM, 430FR Stainless Steel, Stainless Steel,Aluminium(Manifold)Response time:10ms TypicalReliability:100 Million Cycles, 0.95 Reliability Factor,95% Confidence IntervalAPPLICATIONSVentilatorsAnesthesia Delivery & MonitorsPERFORMANCE CHARACTERISTICSLeak Rate:The leakage shall not exceed the following values:Internal: 5.0 sccm of Air up to 101 psi (7 bar)External: 0.5 sccm of Air up to 101 psi (7 bar)Ø7.5 0.1 51.75 - 0.2G1/8 x 8Ø7.5 0.1 15.75 - 0.2G1/8 x 8M3 x 82 NosØ6x2 Nos 11 MANIFOLD DIMENSIONS (MM)NOTE: Contact factory for customized configurtions: eg custom calibration and electrical connections. 8.4 q 1934 0.1NOTE: In order to provide the best possible solution for your application, please provide the following requirements when contacting Applications Engineering:Media, Inlet & Outlet PressuresSystem Supply Voltage Minimum Required Flow RateMedia & Ambient Temperature Range

0645Proportional Flow Control Solenoid Valve - MINIØ3.18X2 NOSIN7.14Ø4.37OUT17.61/8" BARB7.9216FEATURESSPECIFICATIONSLow power consumption generates less heatModel Code:IBVB30005V0Proven performance tested to 100 million life cyclesValve Type:2 Way Normally ClosedPort:1/8” BARB, Manifold MountingUses either DC current or pulse width modulation with closed loopfeedback to deliver optimal system performance.Body Material:BrassSeal:NBR Optional FKM, VitonMedia:Air, Oxygen, Nitrous Oxide, Carbon Dioxide,Heliox & Other Medical GasesLPM:6LPM @ 10PSI Differential PressureOperating Environment:32 F to 132 F (0 C to 55 C)Storage Temperature:-40 F to 158 F (-40 C to 70 C)Dimensions:L-17.6mm, W-16mm, H-45mmLeak Rate: 0.2 sccm of helium (bubble tight)Weight:58gOperating Pressure:0 to 30 psiPower:9V DC (2 Watts)Orifice Sizes:0.8mmElectric Termination:15” Lead WireHysteresis:Stem Base:430FR Stainless steel7% of full scale current (Typical), 15% of full scalecurrent (Max)All Others:NBR/FKM, 430FR Stainless Steel, Stainless Steel,Aluminium(Manifold)Response time:10ms TypicalReliability:100 Million Cycles, 0.95 Reliability Factor, 95%Confidence IntervalAPPLICATIONSVentilatorsAnesthesia Delivery & MonitorsInsufflatorsPressure and Flow ControlPERFORMANCE CHARACTERISTICSNOTE: Contact factory for customized configurtions: eg custom calibration and electrical connections.

07Rotary Quarter Turn Pneumatic ActuatorCHJCN1ON X O1‘P1 Dee’ PC pNXDON ‘PO Deep’ PCDI-90 GBM5X4FKLJKCIGCHN1 XON ‘P O1 Dee1’ PC pNXDON ‘PO Deep’ PCDA-90 BM5X4MM5X8DeepD45 F45 KKL8M5eXpDeDLMADiagram No. 8.1Diagram No. 8.2Uflow has successfully developed Compact, Patented Aluminium FreeRack & Pinion Pneumatic Rotary Actuator, Consuming Low Volume of Air.Wear proof aluminium free Rack & Pinion design.Low air consumption with maximum torque due to compact design.Providing a hard-anodized body for high corrosion resistance.Smooth travelling stroke for extending the life of ball valve sheet.Finer teeth module for smoother operation, and jerk-free sliding.Maintenance-free design.Aluminium Extruded, Hard Anodized Body.NBR-20oC to 80oC 5o Over travelling possible for openingViton-20 C to 125 C-5o Under travelling can be adjustedFlourosilicone-60 C to 110 CoooSINGLE ACTINGEND STROKE (0 - 90 )TEMPERATURE RANGEoWORKING PRESSURESECTION VIEWDOUBLE ACTINGFEATURESMaximum working pressure 8 barTORQUE CHART (DOUBLE ACTING)Model No.DiagramNo.AD32ANBV0AD50ANBV0TORQUE Nm (10Nm 1 Kgm)7 Bar8 Bar7.60910.5012402732.50384313740506070804505 Bar4.6061621.5020303 Bar8.138.110.80AD63ANBV08.1Piston OutwardStroke, ml/bar6 Bar4 Bar2 190254317.50381444.505081810AIR CONSUMPTION COMPARISON WITH OTHER REPUTED BRANDModelPiston Inward Strokeml / barPiston Outward Strokeml / bar(Uflow) AD50128137Other Brand Y260110Other Brand X200180TECHNICAL DATAModel No.DiagramNo.Double / SingleABCDFGIJKLMNOPAD32ANBV0 / AD32ANBV08.1 / 8.292 / 115N1O1P1CH 90 ISO V0 / AS50ANB02V08.1 / 8.2 131 / 16277207230801341612¼”M61250M5103611F03 / F05AD63ANBV0 / AS63ANB02V08.1 / 8.2 147 / 20387208630801541612¼”M81270M6105014F05 / F07AD80ANBV0 / AS80ANB201V0 8.1 / 8.2 170 / 233982010330801841612¼”M81270M6105017F05 / F07AD100ANBV0 / AS100ANB6UV0 8.1 / 8.2 221 / 3241292012630802641612¼”M1015102M8147022F07 / F10AD125ANBV0 / AS125ANB6UV0 8.1 / 8.2 389 / 3891612015030803041612¼”M1220125M101410222F10 / F12

08Rotary Quarter Turn Pneumatic ActuatorTORQUE CHART (SINGLE ACTING)Size32506380100125Model No.Spring SetAS32ANB21V0TORQUE Nm (10Nm 1 Kgm)Spring Torque3 bar4 bar5 bar6 bar0 (Min)90 (Max)90 (Min)0 (Max)90 (Min)0 (Max)90 (Min)0 (Max)90 (Min)0 B13UV013U129205--49125113189176252Note: For Any Other Spring Combination Contact Uflow* Specifications are subject to change without noticePiston OutwardStroke, ml/bar4013728045010401810

09Micro Limit SwitchMODEL NO.GWP11AMVOGWP12AMV0FEATURESWeatherproof limit switch.Compact & Light weight designOpen / Close indication show in any direction.No extra attachment require for indicator dome inbuilt with transparent cover.Every adjustable serrated cam for fast & Fine switch adjustment & Also helpfulfor fine adjusting of feedback setting.Cable entries with various connection availability M20 & 1/2” NPT.Additional mounting available as the UNC series.A stainless steel bracket is available as an option.Temperature range -20 C to 80 C35.4WIRING DIAGRAM91C1NO1NONC1NCVALVE OPENCOMC250.5NONC2NC94.4VALVE CLOSECOMRed CamTop SwitchSV SV SV-SVSolenoid ValveSolenoid ControlSignal19.9INDICATORThe two piece unique indicator, ensures a life long visibility4Ø123.93.270.5111Standard Indicator Color Red & Yellow27.197.6DIMENSION DRAWING40.5NO2Yellow CamBottom Switch

103 Piece Flange Ball ValveCHDEDiagram No. 11.1SPECIFICATIONSIAØJ x K NOSØG (PCD)BØHØFISOFLANGEFEATURES3PC design twinseal ball valve.End Connection :Flange end, Butt weldFace to Face :ASME B 16.10 (Flange end)Pressure Class :150#Design Standard :ASME B16.10, ASME B16.25, ASME B16.34,ASME B16.5, API 598, BS EN ISO 17292, ISO 5211Body Material :CF8 / CF8M / WCB / CF3MTail Piece Material :CF8 / CF8M / WCB / CF3MBall Material :CF8 / CF8MBody Seal Material :PTFE / RPTFE / CFT / GFT / PEEKSeat Ring Material :PTFE / RPTFE / CFT / GFT / PEEKFastener Material :SS304 / SS316Stem Seal Material :PTFE / RPTFE / CFT / GFT / PEEKStem Material :SS304 / SS316 / SS410Gland Bush Material :SS304 / SS316 / SS410Gland Material :SS304 / SS316 / SS410Full port ball valve.Blow out proof stem.Floating ball design.Hand Lever / Gear / Actuator Operated.Balls are precision machined and mirror finished for bubble-tight shutoff with less operating torque.Face to Face:- ASME B16.10.End Connection:- Flanged (ASME B16.5), Buttweld (ASME B16.25).ISO 5211 top mounting pad available for easy Uflow make actuatormounting.SECTION VIEWDIMENSIONModel No.DiagramNo.BCPC2AFFBV0BCPC3AFFBV0Pipe SO 257.50

11Screwed / Socket Weld Ball ValveCHDISOFLANGBCEADiagram No. 12.1SPECIFICATIONSEnd Connection:FEATURES3PC design twinseal ball valve.Screwed end, Socket WeldSize :DN15 - DN80Face to Face :MFG. StandardPressure Class :150#Full port ball valve.Blow out proof stem.Floating ball design.Design Standard :ASME B16.11, ASME B16.34, API 598, BS EN ISO 17292, ISO 5211Body Material :CF8 / CF8M / WCB / CF3MPipe End Material :CF8 / CF8M / WCB / CF3MHand lever / Gear / Actuator operated.Balls are precision machined and mirror finished for bubble-tight shutoff with less operating torque.Face to Face:- MFG Standard.End Connection:- Screwed / Socket weld (ASME B16.11).Ball Material :CF8 / CF8MBody Seal Material :PTFE / RPTFE / CFT / GFT / PEEKSeat Ring Material :PTFE / RPTFE / CFT / GFT / PEEKFastener Material :SS304 / SS316PTFE / RPTFE / CFT / GFT / PEEKSS304 / SS316 / SS410Gland Bush Material :SS304 / SS316 / SS410Gland Material :SS304 / SS316 / SS410SECTION VIEWStem Seal Material :Stem Material :ISO 5211 top mounting pad available for easy Uflow make actuatormounting.DIMENSIONModel No.Diagram No.BCPC2ABFBV0BCPC3ABFBV0Pipe (Inch)ABCCHDISO 01720.50F07

12Angle Seat Valve with Steel Operator (Normally Closed / Open)1/4"BSPBCEADDiagram No. 13.1NCNODIMENSION (NC)SPECIFICATIONSAll dimensions are in 0890-10 C to 180 CYCP605BNV01½”13.112420017220890Steam, Air, Water, Chemical, Gases, Oil, Diesel, Hot WaterYCP803BNV02”13.115022519123490Port :Refer below technical data sheet (Available BSP / NPT)End Connection :Screwed / Flange / Tri-ClampBody Material :SS ASTM A351 Grade CF8 / CF8MSeal :TEFLON / VITON / EPDM / SILICONCircumstance Temp :-10 C to 70 CMedia Temp:Media :Model No.ACTUATOR TYPESS304Plate :Aluminum Die-CastWorking Pressure :3.5 to 7 bar air (Not recommended actuator pressure above 7 bar)Life :More than ten million cycleOther Technical Data :Available on RequestSECTION VIEWCover :NOTE: Use of filter in the inlet port is recommended.TECHNICAL DATAModel No.BodyMaterialPipe (Inch)Orifice (mm)Min. OperatingPressure Kg/cm²Max. OperatingPressure Kg/cm²Seal & ‘O’ RingMaterialFlow FactorKv m³ / hrYCP205BNV0CF8 / CF8M½”14.50016PTFE / VITON /EPDM6YCP305BNV0CF8 / CF8M¾”20016PTFE / VITON /EPDM10.90YCP405BNV0CF8 / CF8M1”25016PTFE / VITON /EPDM21YCP505BNV0CF8 / CF8M1¼”32016PTFE / VITON /EPDM35YCP605BNV0CF8 / CF8M1½”40016PTFE / VITON /EPDM49YCP803BNV0CF8 / CF8M2”50007PTFE / VITON /EPDM68

13Angle Seat Valve with Plastic Operator (Normally Close / Open / Double Acting)Angle seat valves are 2/2 way pneumatically actuated piston valves. The piston actuator provides a linearmotion to lift the seal off its seat. Because the seat is positioned under an angle, the flow is minimallyimpeded in the open position, resulting in an excellent flow rate and a low pressure loss. They are used toregulate the flow of liquids, gases, steam, vacuum and even aggressive fluids. They can also operate with hightemperatures and high viscosity media, even under zero differential pressures. The robust design makesUFLOW angle seat valves a popular choice for harsh applications and they have very high cycle lives.Therefore, they are excellent long-life alternatives to ball valves. These valves are also suitable alternatives forsolenoid valves, especially with contaminated, viscous media where typical solenoid valves would fail. Theymay be operated using a single acting or double acting configuration, which has an influence on its pressurerating.11222211NC Below PlugNO Below Plug211/212Double Above Plug1/2NO Above Plug2/1NO Bi-DirectionalSPECIFICATIONSNC Above Plug2/1NC Bi-Directional2/11/2Double Below PlugDouble Bi-DirectionalFEATURESPort :Refer below technical data sheet (Available BSP / NPT)End Connection :Screwed / Flange / Tri-ClampBody & Sleeve Material :SS ASTM A351 Grade CF8 / CF8M / CF3MSeal :TEFLON / PEEK / VITONShaft :SS304 / SS316Circumstance Temp :-10 C to 70 CMedia Temp :-10 C to 180 CConvertible from single Acting to Double Acting.Multiple Function with the same operator - NC / NO / Bi-Directional.Rotatable Operator - 360 .Transparent dome for visual valve open indication.Lubricated air not essential.Flow direction below or above the seat.Media: Steam, Air, Water, Chemical, Gases, Oil, Diesel, Hot Water.Application: Steam, Autoclave and Sterilizer, Ink and Paint dispensing, Industrialcompressor bottling and dispensing equipment, textile dying and drying andpharmaceutical.NOTE: Use of filter in the inlet port is recommendedACTUATOR TYPENylon Glass-Filled (Corrosion resistive) with SS LinerSeal :NBR / VITONWorking Pressure :Refer Below Pressure Chart TableLife :Three Million Cycle TestedOther Technical Data :Available on RequestDIMENSION WITH SCREWED ENDSECTION VIEWCover :All dimensions are in M5Ix4HGx2ADDIAGRAM NO. 14.1ACP3055BNV0ØEFActuatorCDiagramNo.BModel No.PortSize

14Angle Seat Valve with Plastic Operator (Normally Close / Open / Bi-Directional)DIMENSION WITH FLANGE (ASME 16.5 2M5DIMENSION WITH TRI-CLAMPModel 7.9DIAGRAM NO. 14.350IGx x42HAll dimensions are in mmAACP2055TNV0FIx4Gx2CActuator Port DiagramSizeNo.ØEDDIAGRAM NO. 14.2ACP2054FNV0CABModel No.All dimensions are in mmBActuator Port DiagramSizeNo.ATECHNICAL DATAPipe (Inch)BodyMaterialOrifice (mm)Seal & ‘O’ RingMaterialFlow FactorKv m³ / hr½”CF8 / CF8M14.50PTFE / PEEK / VITON6¾”CF8 / CF8M20PTFE / PEEK / VITON10.91”CF8 / CF8M25PTFE / PEEK / VITON211¼”CF8 / CF8M32PTFE / PEEK / VITON351½”CF8 / CF8M40PTFE / PEEK / VITON492”CF8 / CF8M50PTFE / PEEK / VITON682½”CF8 / CF8M65PTFE / PEEK / VITON120

15Angle Seat Valve with Plastic Operator (Normally Close / Open / Bi-Directional)PRESSURE CHARTNCPipe ”2”2½”4050636363909090Below PlugDouble ActingAbove PlugBelow PlugAbove PlugBelow PRESSURE ABOVE PLUGINNOAbove PlugPRESSURE BELOW PLUGIN

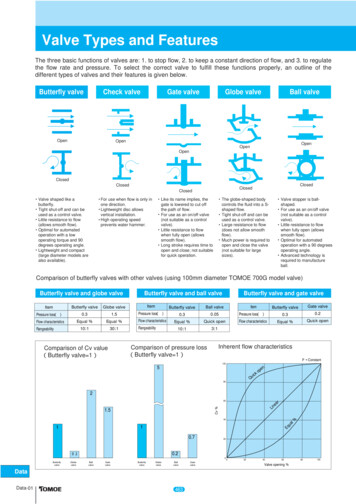

16Butterfly ValveSPECIFICATIONSFEATURESBi-directional zero leakage butterfly valve.End Connection :Wafer - API 609 (CAT - A)Range :Dn40 - DN300Suitable to :ASMI B16.5 150#Pressure Range :Pn10, PN16Accurate dual stem sealing prevents leakage.Leakage Class :100% Tightness at fully differential pressureButterfly valve can be mounted between flanges as per ASME.Standard :API 609, BS 5155, ISO 5211, API 598, ASME B16.5100% tested under Water and Pneumatic.Body Material :Cast Iron, WCB, CF8, CF8MDesign Standard : ISO 5211, API 609, ASME B16.5 150#.Disc Material :SGI, CF8, CF8MFace to Face Dimension : API 609 (CAT A).Stem Material :SS 410, SS 304, SS 316Body Liner / Seat Material :NBR, EPDMShaft Bearing Material :PTFEISO Pad for mounting, Gear Operator / ActuatorExtremely small play between the stem and disc due to ‘Double D’ drive.Operator mounting flange : As per ISO 5211.Operator : Hand Lever / Gear / Actuator.Leakage Class : 100% tightness at full differential Pressure.HAND LEVER OPERATED VALVEHØCA(approx)JEGØKØLØIB(approx)ØDF/F( 2)TECHNICAL DATASizeABØCØDEF/FGHØIJØKØLMOUNTINGFLANGE40 .0--F0550 .4120.7125.0F0565 .0139.7145.0F0580 .0152.4160.0F05100 4190.5180.0F07125 0215.9210.0F07150 0241.3240.0F07200 5295.0F07/10250 0350.0F10300 8400.0F10

17Butterfly ValvePNEUMATIC OPERATED VALVEONA(approx)MØKØLØIB(approx)ØDF/F( 2)TECHNICAL DATA - BUTTERFLY WITH DOUBLE ACTING ACTUATORSizeActuatorSize40 mm50 0091.0065 mm50107.20063.6065.046.0096.8080 mm50127.95072.8

Solenoid Valve Angle Seat Valve Safety Solenoid Valve High Pressure Valve Actuator Pneumatic Directional Control Valve Industrial Valve Rotary Coupling ISO 2009:2015. Company Profile Uflow Automation is an engineering organization committed to provide complete solutions to customer's requirements. We are established in the year 2007 and