Transcription

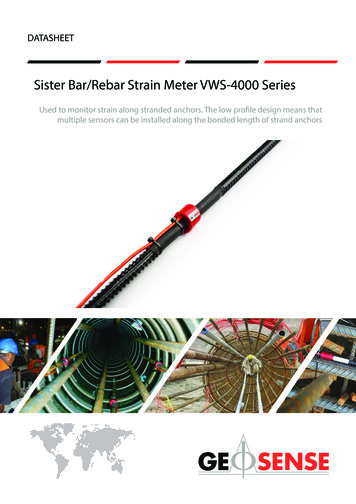

DATASHEETSister Bar/Rebar Strain Meter VWS-4000 SeriesUsed to monitor strain along stranded anchors. The low profile design means thatmultiple sensors can be installed along the bonded length of strand anchors

Sister Bar/Rebar Strain Meter VWS-4000 SeriesOverviewAPPLICATIONSPile Load TestingConcrete PilesTunnel LiningsMass concrete structuresDiaphragm walls and barrettesFEATURESBuilt-in thermistorReliable long-term performanceRugged, suitable for demanding environmentsHigh accuracyInsensitive to long cable lengthsGeosense VWS-4000 series vibrating wire Sister Barsand Rebar Strain Meters are designed to be embeddedin concrete to measure strains due to imposed loads.Direct concrete embedmentSISTER BARThe VWS-4000 Sister Bar is installed by tying it alongsidean existing length of rebar within the cage. Available intwo diameters: 12 and 16mm.REBAR STRAIN METERThe VWS-4001 Rebar Strain Meter is installed by weldingit into the existing rebar cage at a location within thestructure where loads can be accurately passed fromthe concrete into the gauge. Available in various sizesto match the size of the rebar cage into which it is to bewelded.VWwww.geosense.co.uk

Sister Bar/Rebar Strain Meter VWS-4000 hermistor3k ohms at 25 C3k ohms at 25 COver-range 20% 20%Resolution0.6 με0.6 μεAccuracy 0.25%FS 0.25%FSNon-linearity 0.75%FS 0.75%FS2500 με2500 με2 pair PUR outer sheath2 pair PUR outer sheathOperating rangeCableCable TypeInstallationType 900 - VW Sensor with Foil Screen & Drain WireDirect EmbedmentDirect Embedment50mm (nominal)50mm (nominal)25kN25kNDe-bonded Length175mm175mmOverall Length1.39m*1.39mStandard Diameter12, 16mm14, 16, 20, 25, 28, 32mmCoefficient of thermal expansion12ppm/ºC12ppm/ºCEffective Gauge LengthMax Load*Other lengths available on requestOPTIONS & ACCESSORIESIn-house calibrationReadout unitsTerminal unitsORDERING INFORMATIONSister Bar or Rebar Strain MeterCable lengthRebar sizeLightning protectionwww.geosense.co.uk

Sister Bar/Rebar Strain Meter VWS-4000 SeriesFurther InformationREBAR STRAIN METERSThey are normally installed in pairs within thestructure on either side of the neutral axis to separatebending moments from axial loads.They comprise two lengths of ribbed rebar weldedto a central gauge section. The central gaugesection has a miniature stainless steel, fitted alongthe longitudinal axis of the gauge. The strain gaugeoperates on the principle that a tensioned wire,when plucked, vibrates at its resonant frequency. Thesquare of this frequency is proportional to the strainin the wire.The gauge consists of two end blocks with atensioned steel wire between them. Around the wireis a magnetic coil which when pulsed by a vibratingreadout or data logger interface plucks the wireand measures the resultant resonant frequency ofvibration. As the steel or concrete surface undergoesstrain the end blocks will move relative to each other.The tension in the wire between the blocks willchange accordingly thus altering the resonantfrequency of the wire.The coil units and cable connection are encapsulatedwith a proprietary rigid epoxy resin to keep the gaugede-bonded from the concrete.www.geosense.co.uk

Geosense Ltd, Nova House, Rougham Industrial Estate, Rougham, Bury St Edmunds, Suffolk IP30 9ND, Englandwww.geosense.co.uk e sales@geosense.co.uk t 44(0)1359 270457Specifications may change without prior noticeV1.7 09/2017

The central gauge section has a miniature stainless steel, fitted along the longitudinal axis of the gauge. The strain gauge operates on the principle that a tensioned wire, when plucked, vibrates at its resonant frequency. The square of this frequency is proportional to the strain in the wire. The gauge consists of two end blocks with a