Transcription

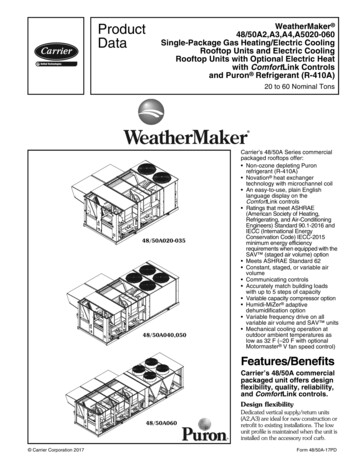

Product DataWeatherMaker Single Package RooftopGas Heat/Electric CoolingVertical Air Flow Unit15, 17.5, 20, 25, 27.5 TonsUnit shown witheconomizer andpower exhaust. 2021 Carrier48TC 17, 20, 24, 28, 30with Puron (R-410A) RefrigerantForm 48TC-17-30-V-06PD Rev. B

Features/BenefitsCarrier’s WeatherMaker 15 to27.5 ton rooftop unit (RTU)was designed by customersfor customers. With “nostrip” screw collars, handledaccess panels, and more,we’ve made your unit reliableand easy to install, maintain,and use.Easy to installThese WeatherMaker units aredesigned for dedicated factory-supplied vertical air flow duct configurations. Designed to fit on pre-installedcurbs by another manufacturer, theseunits also fit on past designed Carrierinstalled curbs with a new certified andauthorized adapter curb. This cabinetdesign also integrates a large controlbox that gives you room to work androom to mount Carrier accessory controls.Easy to maintainEasy access handles by Carrier providequick and easy access to all normallyserviced components. Our “no-strip”screw system has superior holdingpower and guides screws into positionwhile preventing the screw from stripping the unit’s metal. Take accuratepressure readings by reading systempressures with panels in place as compressors are strategically located toeliminate any air bypass.Easy to useThe central terminal board by Carrierputs all your connections and troubleshooting points in one convenientplace, standard. Most low voltage connections are made to the same boardand make it easy to find what you’relooking for and easy to access it.ReliableEach unit comes with precision sizedand tested scroll compressor that isinternally protected from over temperature and pressures. In addition,each refrigerant circuit is further protected with a high-pressure and lowpressure switch as well as containing aliquid line filter drier. Each unit is factory tested prior to shipment to helpensure unit operation once properlyinstalled.Key features 2-stage cooling capability with independent circuits and control. Round tube/plate fin (RTPF) available on all sizes or Novation all aluminum condenser (outdoor) coilsavailable on 17-28 sizes only. Special coil-coating also available forcoastal and industrial environments. Energy efficiency ratios (EERs) up to10.8 IEERs up to 12.0 with single speedindoor fan motor and up to 12.7with 2-speed/VFD indoor fanmotor. Gas heating efficiencies up to 81%thermal efficiency. Dedicated vertical air flow duct configuration models. Utility connections through the sideor bottom. Bottom connections arealso in an enclosed environment tohelp prevent water entry. Field supplied couplings are required. Standardized components and layout. Standardized components andcontrols make service and stockingparts easier. Scroll compressors on all units. Thismakes service, stocking parts,replacement, and troubleshootingeasier.Table of contentsPageFeatures/Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4AHRI Capacity Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Performance Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33Fan Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49Typical Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60Sequence of Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63Application Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 682 Proven Acutrol refrigerant metering system. Easy-adjust, belt-drive motor available. Motor assembly also containsa fan belt break protection systemon all models and reliable pillowblock bearing system that allowslubrication through the front of theunit. Single - point gas / electrical connection. Sloped, composite drain pan shedswater and won’t rust. Standardized controls and controlbox layout. Standardized components and controls make stockingparts and service easier. Clean, large, easy to use controlbox. Color-coded wiring. Large, laminated wiring and powerwiring drawings which are affixed tounit make troubleshooting easy. Single, central terminal board fortest and wiring connections. Fast-access, handled, panels foreasy access on normally accessedservice panels. “No-strip” screw system guidesscrews into the panel and capturesthem tightly without stripping thescrew, the panel, or the unit. Mechanical cooling 115 F to 30 F(46 C to –1 C) standard on all models. Low ambient controller allowsoperation down to –20 F (–29 C). Redundant gas valve for 2-stage gasheating capacity control withinduced-draft flue exhaust design tohelp ensure no flue gas can escapeinto the indoor air stream. Exclusive IGC solid state gas controller for on board diagnostics withLED error code designation, burnercontrol logic and energy savingindoor fan motor delay. 2-in. (51 mm) disposable filters onall units, with 4-in. (102 mm) filtertrack field-installed. Refrigerant filter-drier on each circuit. High and low pressure switches.Added reliability with high-pressureswitch and low-pressure switch. Many factory-installed options ranging from air management economizers, 2-position dampers, manualoutdoor air, plus convenient outlets,disconnect switch and smokedetectors.

Features/Benefits (cont) Factory-installed Humidi-MiZer adaptive dehumidification system.Available on 17-28 sizes withRTPF condenser coil models only. Standard Parts Warranty: 10-yearaluminized heat exchanger, 5-yearcompressor, 3-year Novation condenser coil, 1-year others. Tool-less filter removal and installation. Staged air volume (SAV ) systemutilizes a Variable Frequency Drive(VFD) to automatically adjust theindoor fan motor speed betweencooling stages. Available on 2stage cooling models 17-30 withelectro-mechanical controls orRTU Open Controller. Note thatSAV is required on all units forinstallation in the United States asper Department of Energy (DOE)efficiency standard of 2018.3

Model number nomenclature48TC UNITS MODEL NUMBER NOMENCLATUREPosition:123456789 10 11 12 13 14 15 16 17 18Example:48TCDD24A1A5-0AG3Unit Heat Type48 - Gas Heat Packaged RooftopPackaging0 StandardModel Series - WeatherMaker TC - Standard EfficiencyHeat OptionsD Low Gas HeatE Medium Gas HeatF High Gas HeatS Low Heat w/ Stainless Steel ExchangerR Medium Heat w/ Stainless Steel ExchangerT High Heat w/ Stainless Steel ExchangerRefrig. Systems OptionsD Two stage cooling model with RTPF coilsE Two stage cooling models with Humidi-MiZer (17-28 models with RTPF coils only)Cooling Tons (Vertical Airflow)17 15 tons28 25 tons20 17.5 tons30 27.5 tons24 20 tonsSensor OptionsA NoneB RA Smoke DetectorC SA Smoke DetectorD RA SA Smoke DetectorE CO2F RA Smoke Detector and CO2G SA Smoke Detector and CO2H RA SA Smoke Detector and CO2J Condensate Overflow Switch(electromechanical controls only)K Condensate Overflow Switch and RA Smoke DetectorsL Condensate Overflow Switch and RA SASmoke DetectorsIndoor Fan Options & Air Flow Configuration1 Standard Static/Vertical Supply, Return Air Flow2 Medium Static/Vertical Supply, Return Air Flow3 High Static/Vertical Supply, Return Air FlowB Med Static High Efficiency Motor/Vertical Supply, Return Air FlowC High Static High Efficiency Motor/Vertical Supply, Return Air FlowCoil Options – RTPF (Outdoor – Indoor – Hail Guard)A Al/Cu – Al/CuB Precoat Al/Cu – Al/CuC E-coat Al/Cu – Al/CuD E-coat Al/Cu – E-coat Al/CuE Cu/Cu – Al/CuF Cu/Cu – Cu/CuM Al/Cu – Al/Cu – Louvered Hail GuardN Precoat Al/Cu – Al/Cu – Louvered Hail GuardP E-coat Al/Cu – Al/Cu – Louvered Hail GuardQ E-coat Al/Cu – E-coat Al/Cu – Louvered Hail GuardR Cu/Cu – Al/Cu – Louvered Hail GuardS Cu/Cu – Cu/Cu – Louvered Hail GuardCoil Options – Novation (Outdoor – Indoor – Hail Guard)G Al/Al – Al/CuH Al/Al – Cu/CuJ Al/Al – E-coat Al/CuK E-coat Al/Al – Al/CuL E-coat Al/Al – E-coat Al/CuT Al/Al – Al/Cu – Louvered Hail GuardU Al/Al – Cu/Cu – Louvered Hail GuardV Al/Al – E-coat Al/Cu – Louvered Hail GuardW E-coat Al/Al – Al/Cu – Louvered Hail GuardX E-coat Al/Al – E-coat Al/Cu – Louvered Hail Guard40Electrical OptionsA Non USA models - No (SAV) includedC Non-Fused DisconnectG Standard USA models - (SAV) includedJ 2 Speed Fan Controller (VFD) &Non-Fused DisconnectService Options0 None1 Unpowered Convenience Outlet2 Powered Convenience Outlet3 Hinged Panels4 Hinged Panels andUnpowered Convenience Outlet5 Hinged Panels andPowered Convenience OutletIntake / Exhaust OptionsA NoneB Temperature Economizer w/ Barometric ReliefF Enthalpy Economizer w/ Barometric ReliefK 2-Position DamperU Temp Ultra Low Leak Economizer w/ Baro ReliefV Temp Ultra Low Leak Economizer w/ PE (cert) Vertical Air OnlyW Enthalpy Ultra Low Leak Economizer w/ Baro ReliefX Enthalpy Ultra Low Leak Economizer PE (cert) Vertical Air OnlyBase Unit Controls0 Base Electro-mechanical Controls (can be usedwith W7212 EconoMi er IV)1 PremierLink Controller (for 1-speed motors only)2 RTU Open Multi-Protocol Controller6 Electro-mechanical w/ 2-Speed Fanand W7220 Economizer Controller (can be usedwith W7220 EconoMi er X)Design Revision- Factory Design RevisionVoltage1 575/3/605 208-230/3/606 460/3/60

AHRI capacity ratingsAHRI COOLING RATINGS48TCUNITCOOLINGSTAGESNOM.CAPACITY(TONS)NET COOLINGCAPACITY(MBH)TOTAL 89.89.810.2LEGENDHeating and Refrigeration Institute TestAHRI— Air-Conditioning,StandardSociety of Heating, Refrigerating and Air-ConASHRAE — Americanditioning Engineers.EER— Energy Efficiency RatioIEER— Integrated Energy Efficiency RatioIECC— International Energy Conservation Code*MCHX option is not available on size 30 units.IEER WITHSINGLE SPEEDINDOOR FANMOTOR12.011.710.610.410.4IEER WITH2-SPEEDINDOOR )4,9006,1258,0008,7509,750NOTES:1. Rated and certified under AHRI Standard 340/360, as appropriate.2. Ratings are based on:Cooling Standard: 80 F (27 C) db, 67 F (19 C) wb indoor airtemp and 95 F (35 C) db outdoor air temp.IEER Standard: A measure that expresses cooling part load EERefficiency for commercial unitary air conditioning and heat pumpequipment on the basis of weighted operation at various loadcapacities.3. The 48TC rooftop units meet ASHRAE 90.1-2016, DOE-2018 andIECC1-2015 minimum efficiency requirements when equipped withthe SAV (staged air volume) option.4. 48TC units comply with US Energy Policy Act (2005). To evaluatecode compliance requirements, refer to state and local codes orvisit the following website: http://bcap-energy.org to determine ifcompliance with this standard pertains to your state, territory, ormunicipality.1. IECC is a registered trademark of International Code Council, Inc.HEATING RATING TABLE - NATURAL GAS AND PROPANE48TCMODEL SIZE1720242830HEAT HIGHAL/SS HEAT EXCHANGERINPUT / OUTPUTINPUT / OUTPUTSTAGE 2 (MBH)STAGE 1 (MBH)220 / 178176 / 142310 / 251248 / 200400 / 324320 / 260220 / 178176 / 142310 / 251248 / 200400 / 324320 / 260220 / 178176 / 142310 / 251248 / 200400 / 324320 / 260220 / 178176 / 142310 / 251248 / 200400 / 324320 / 260220 / 178176 / 142310 / 251248 / 200400 / 324320 / 260TEMP RISE( F)THERMALEFFICIENCY (%)20 - 5530 - 6035 - 6515 - 5525 - 6030 - 6515 - 5520 - 6030 - 6510 - 5515 - 6020 - 6510 - 5515 - 6020 - ES:1. Heat ratings are for natural gas heat exchangers operated at orbelow 2000 ft (610 m). For information on Propane or altitudesabove 2000 ft (610 m), see the Application Data section of thisbook. Accessory Propane/High Altitude kits are also available.2. The input rating for altitudes above 2000 ft (610 m) must be derated by 4% for each 1000 ft (305 m) above sea level.5

AHRI capacity ratings (cont)SOUND 22OUTDOOR SOUND (dB) AT 60 HzAAHRI 370WEIGHTED 3.465.465.466.367.367.3LEGENDdB — DecibelNOTES:1. Outdoor sound data is measured in accordance with AHRI standard 370.2. Measurements are expressed in terms of sound power. Do notcompare these values to sound pressure values because soundpressure depends on specific environmental factors which normally do not match individual applications. Sound power valuesare independent of the environment and therefore more accurate.3. A-weighted sound ratings filter out very high and very low frequencies, to better approximate the response of “average” human ear.A-weighted measurements for Carrier units are taken in accordance with AHRI standard 370.MINIMUM - MAXIMUM AIRFLOW RATINGS - NATURAL GAS AND PROPANE48TCMODELSIZE1720242830HEATMINIMUMLEVEL SINGLE SPEEDFAN DHIGHCOOLINGMINIMUMMINIMUM2-SPEED FAN2-SPEED FANMOTORMOTOR(AT HIGH SPEED) (AT LOW NDAL HX — Aluminum Gas Heat ExchangerSS HX — Stainless Steel Gas Heat Exchanger6AL HX HEATINGSS HX 00110001163010000165001550015000165001550015000

Physical dataPHYSICAL DATA (COOLING), 15 AND 17.5 TONS, RTPF — ROUND TUBE/PLATE FIN COIL DESIGNREFRIGERATION SYSTEM# Circuits / # Comp. / TypeR-410A charge A/B (lbs)Metering deviceHigh-press. Trip / Reset (psig)Low-press. Trip / Reset (psig)48TC*D17RTPF2 / 2 / Scroll16.3/17.5AcutrolTM630 / 50554 / 11748TC*E17RTPF2 / 2 / Scroll24.9/25.7TXV630 / 50527 / 4448TC*D20RTPF2 / 2 / Scroll16.3/17.5Acutrol630 / 50554 / 11748TC*E20RTPF2 / 2 Scroll25.9/25.7TXV630 / 50527 / 44Cu / Al3/8-in.4 / 1522.003/4-in.Cu / Al3/8-in.4 / 1522.003/4-in.Cu / Al3/8-in.4 / 1522.003/4-in.Cu / Al3/8-in.4 / 1522.003/4-in.————Cu / Al3/8-in.1 / 1722.00————Cu / Al3/8-in.1 / 1722.001/1/Belt2.9514-6801200562 / Centrifugal15 x 151/1/Belt3.7679-8631200562 / Centrifugal15 x 151/1/Belt4.9826-10091200562 / Centrifugal15 x lt2.9514-6801200562 / Centrifugal15 x 151/1/Belt3.7679-9631200562 / Centrifugal15 x 151/1/Belt4.9826-10091200562 / Centrifugal15 x lt3.7622-8221200562 / Centrifugal15 x lt6.5/ 6.9/ 7.0/ 8.3713-8791200184T2 / Centrifugal15 x 151/1/Belt6.5/ 6.9/ 7.0/ 8.3882-10781200184T2 / Centrifugal15 x 151/1/Belt3.7622-8221200562 / Centrifugal15 x lt6.5/ 6.9/ 7.0/ 8.3713-8791200184T2 / Centrifugal15 x 151/1/Belt6.5/ 6.9/ 7.0/ 8.3882-10781200184T2 / Centrifugal15 x 15EVAP. COILMaterialTube DiameterRows / FPITotal face area (ft2)Condensate drain conn. sizeHUMIDI-MIZER COILMaterialTube DiameterRows / FPITotal face area (ft2)EVAPORATOR FAN AND MOTORMotor Qty / Belt Qty / Driver TypeMax BHPRPM rangeSTANDARDMax Blower/Shaft RPMSTATICMotor frame sizeFan Qty / TypeFan Diameter (in.)Motor Qty / Belt Qty / Driver TypeMax BHPRPM rangeMEDIUMMax Blower/Shaft RPMSTATICMotor frame sizeFan Qty / TypeFan Diameter (in.)Motor Qty / Belt Qty / Driver TypeMax BHPRPM rangeMax Blower/Shaft RPMHIGH STATICMotor frame sizeFan Qty / TypeFan Diameter (in.)Motor Qty / Belt Qty / Driver TypeMax BHP (208/230/460/575v)MEDIUMRPM rangeSTATICMaxBlower/ShaftRPM- HIGHMotor frame sizeEFFICIENCYFan Qty / TypeFan Diameter (in.)Motor Qty / Belt Qty / Driver TypeMax BHP (208/230/460/575v)RPM rangeHIGH STATICMax Blower/Shaft RPM- HIGHEFFICIENCYMotor frame sizeFan Qty / TypeFan Diameter (in.)7

Physical data (cont)PHYSICAL DATA (COOLING), 20, 25, AND 27.5 TONS, RTPF — ROUND TUBE/PLATE FIN COIL DESIGN48TC*D2448TC*E24REFRIGERATION SYSTEMRTPFRTPF# Circuits / # Comp. / Type2 / 2 / Scroll2 / 2 / ScrollR-410A charge A/B (lbs)20.6/14.727.9/20.5Metering deviceAcutrolTXVHigh-press. Trip / Reset (psig)630 / 505630 / 505Low-press. Trip / Reset (psig)54 / 11727 / 44EVAP. COILCu / AlCu / AlMaterialTube Diameter3/8-in.3/8-in.Rows / FPI4 / 154 / 1522.0022.00Total face area (ft2)Condensate drain conn. size3/4-in.3/4-in.HUMIDI-MIZER COILMaterial—Cu / AlTube Diameter—3/8-in.Rows / FPI—1 / 17—22.00Total face area (ft2)EVAPORATOR FAN AND MOTORMotor Qty / Belt Qty / Driver Type1/1/Belt1/1/BeltMax BHP4.94.9RPM range690-863690-863STANDARDMax Blower/Shaft RPM12001200STATICMotor frame size5656Fan Qty / Type 2 / Centrifugal2 / CentrifugalFan Diameter (in.)15 x 1515 x 15——Motor Qty / Belt Qty / Driver TypeMax BHP——STANDARDRPM range——STATIC Max Blower/Shaft RPM——HIGHMotor frame size——EFFICIENCYFan Qty / Type——Fan Diameter (in.)——Motor Qty / Belt Qty / Driver Type1/1/Belt1/1/BeltMax BHP 6.5/ 6.9/ 7.0/ 8.3 6.5/ 6.9/ 7.0/ 8.3MEDIUMRPM range ShaftRPM12001200- HIGHMotor frame size184T184TEFFICIENCYFan Qty / Type 2 / Centrifugal2 / CentrifugalFan Diameter (in.)15 x 1515 x 15Motor Qty / Belt Qty / Driver Type1/1/Belt1/1/BeltMax BHP (208/230/460/575v) 10.5/11.9/11.9/11 10.5/11.9/11.9/11HIGHRPM range941-1176941-1176STATICMax Blower/Shaft RPM12001200- HIGHMotor frame size213T213TEFFICIENCYFan Qty / Type 2 / Centrifugal2 / CentrifugalFan Diameter (in.)15 x 1515 x 15848TC*D28RTPF2 / 2 / Scroll19.8/20.4Acutrol630 / 50554 / 11748TC*E28RTPF2 / 2 Scroll27.9/28.9TXV630 / 50527 / 4448TC*D30RTPF2 / 2 Scroll27.0/28.5Acutrol630 / 50554 / 117Cu / Al3/8-in.4 / 1523.113/4-in.Cu / Al3/8-in.4 / 1523.113/4-in.Cu / Al3/8-in.4 / 15263/4-in.————Cu / Al3/8-in.1 / 1723.11————1/1/Belt4.9717-9111200562 / Centrifugal15 x 15———————1/1/Belt6.5/ 6.9/ 7.0/ 8.3913-11161200184T2 / Centrifugal15 x 151/1/Belt10.5/11.9/11.9/11941-11761200213T2 / Centrifugal15 x 151/1/Belt—4.9—717-911—1200—56—2 / Centrifugal—15 x 15——1/1/Belt—6.5/ 6.9/ 7.0/ 8.3—751-954—1300—56—2 / Centrifugal—15 x 151/1/Belt1/1/Belt6.5/ 6.9/ 7.0/ 4T2 / Centrifugal2 / Centrifugal15 x 1515 x 151/1/Belt1/2/Belt10.5/11.9/11.9/11 3T2 / Centrifugal2 / Centrifugal15 x 1515 x 15

Physical data (cont)PHYSICAL DATA (COOLING), 15-27.5 TONS, RTPF — ROUND TUBE/PLATE FIN COIL DESIGN48TC*D17CONDENSER COIL(CIRCUIT A)Coil TypeRTPFCoil length (in.)70Coil height (in.)44Rows / FPI2/1721.4Total face area (ft2)CONDENSER COIL(CIRCUIT B)RTPFCoil TypeCoil length (in.)70Coil height (in.)44Rows / FPI2/1721.4Total face area (ft2)CONDENSERFAN/MOTORQty/Motor drive type 3 / directMotor HP / RPM 1/4 / 1100Fan diameter (in.)22FILTERS6/RA filter #/ size (in.)20 x 25 x 24/OA inlet screen #/size (in.) 16 x 25 x 727.1RTPF95522/1734.33 / direct1/4 / 1100223 / direct1/4 / 1100223 / direct1/4 / 1100224 / direct1/4 / 1100224 / direct1/4 / 1100224 / direct1/4 / 1100224 / direct1/4 / 1100226 / direct1/4 / 1100226/20 x 25 x 24/16 x 25 x 16/20 x 25 x 24/16 x 25 x 16/20 x 25 x 24/16 x 25 x 16/20 x 25 x 24/16 x 25 x 16/20 x 25 x 24/16 x 25 x 19/16 x 25 x 24/16 x 25 x 19/16 x 25 x 24/16 x 25 x 19/16 x 25 x 24/16 x 25 x 19

Physical data (cont)PHYSICAL DATA (COOLING), 15-27.5 TONS, NOVATION — ALL ALUMINUM COIL DESIGNREFRIGERATION SYSTEM# Circuits / # Comp. / TypeR-410A charge A/B (lbs)Metering deviceHigh-press. Trip / Reset (psig)Low-press. Trip / Reset (psig)EVAP. COILMaterialTube DiameterRows / FPItotal face area (ft2)Condensate drain conn. sizeEVAPORATOR FAN AND MOTORMotor Qty / Belt Qty / Driver TypeMax BHPRPM rangeSTANDARDMax Blower/Shaft RPMSTATICmotor frame sizeFan Qty / TypeFan Diameter (in.)Motor Qty / Belt Qty / Driver TypeMax BHPRPM rangeMEDIUMMax Blower/Shaft RPMSTATICmotor frame sizeFan Qty / TypeFan Diameter (in.)Motor Qty / Belt Qty / Driver TypeMax BHPRPM rangeHIGHMax Blower/Shaft RPMSTATICmotor frame sizeFan Qty / TypeFan Diameter (in.)Motor Qty / Belt Qty / Driver TypeMax BHPMEDIUMRPM rangeSTATIC Max Blower/Shaft RPMHIGHmotor frame sizeEFFICIENCYFan Qty / TypeFan Diameter (in.)Motor Qty / Belt Qty / Driver TypeMax BHPHIGHRPM rangeSTATICMax Blower/Shaft RPM- HIGHmotor frame sizeEFFICIENCYFan Qty / TypeFan Diameter (in.)1048TC*D17MCHX2 / 2 / Scroll9.5/12.0Acutrol630 / 50554 / 11748TC*D20MCHX2 / 2 / Scroll9.5/12.0Acutrol630 / 50554 / 11748TC*D24MCHX2 / 2 / Scroll14.4/12.5Acutrol630 / 50554 / 11748TC*D28MCHX2 / 2 Scroll12.5/13.0Acutrol630 / 50554 / 117Cu / Al3/8-in.4 / 1519.563/4-in.Cu / Al3/8-in.4 / 1519.563/4-in.Cu / Al3/8-in.4 / 1522.003/4-in.Cu / Al3/8-in.4 / 1523.113/4-in.1/1/Belt2.9514-6801200562 / Centrifugal15 x 151/1/Belt3.7679-863679-863562 / Centrifugal15 x 151/1/Belt4.9826-10091200562 / Centrifugal15 x lt3.7622-8221200562 / Centrifugal15 x lt6.5/6.9/7.0/8.3713-8791200184T2 / Centrifugal15 x 151/1/Belt6.5/6.9/7.0/8.3882-10781200184T2 / Centrifugal15 x 151/1/Belt4.9690-8631200562 / Centrifugal15 x lt6.5/6.9/7.0/8.3835-10211200184T2 / Centrifugal15 x 151/1/Belt10.5/11.9/11.9/11941-11761200213T2 / Centrifugal15 x 151/1/Belt4.9717-9111200562 / Centrifugal15 x lt6.5/6.9/7.0/8.3913-11161200184T2 / Centrifugal15 x 151/1/Belt10.5/11.9/11.9/11941-11761200213T2 / Centrifugal15 x 15

Physical data (cont)PHYSICAL DATA (COOLING), 15-27.5 TONS, NOVATION — ALL ALUMINUM COIL DESIGNCONDENSER COIL (CIRCUIT A)Coil TypeCoil length (in.)Coil height (in.)Rows / FPITotal face area (ft2)CONDENSER COIL (CIRCUIT B)Coil TypeCoil length (in.)Coil height (in.)Rows / FPITotal face area (ft2)CONDENSER FAN/MOTORQty/Motor drive typeMotor HP / RPMFan diameter (in.)FILTERSRA filter #/ size (in.)OA inlet screen #/ size (in.)48TC*D1748TC*D2048TC*D2448TC*D28Novation70441 / 20.321.4Novation70441 / 20.321.4Novation82441 / 20.325.1Novation75521 / 20.327.1Novation70441 / 20.321.4Novation70441 / 20.321.4Novation57441 / 20.317.4Novation75521 / 20.327.13 / direct1/4 / 1100223 / direct1/4 / 1100224 / direct1/4 / 1100224 / direct1/4 / 1100226/20 x 25 x 24/16 x 25 x 16/20 x 25 x 24/16 x 25 x 16/20 x 25 x 24/16 x 25 x 19/16 x 25 x 24/16 x 25 x 111

Physical data (cont)PHYSICAL DATA (HEATING), 15-27.5 TONS48TC*1748TC*2048TC*2448TC*2848TC*30GAS CONNECTION# of Gas Valves11111Natural gas supply line press (in. wg) / (PSIG) 5-13 / 0.18-0.47 5-13 / 0.18-0.47 5-13 / 0.18-0.47 5-13 / 0.18-0.47 5-13 / 0.18-0.47LP supply line pressure (in. wg) / (PSIG) 11-13 / 0.40-0.47 11-13 / 0.40-0.47 11-13 / 0.40-0.47 11-13 / 0.40-0.47 11-13 / 0.40-0.47HEAT ANTICIPATOR SETTING (AMPS)First stage0.140.140.140.140.14Second stage0.140.140.140.140.14NATURAL GAS HEAT# of stages / # of burners (total)2/52/52/52/52/5Connection size3/4-in. NPT3/4-in. NPT3/4-in. NPT3/4-in. NPT3/4-in. NPTLOWRollout switch opens / closes ( F)195 / 115195 / 115195 / 115195 / 115195 / 115Temperature Rise ( F)25-5525-5525-5525-5525-55# of stages / # of burners (total)2/72/72/72/72/7Connection size3/4-in. NPT3/4-in. NPT3/4-in. NPT3/4-in. NPT3/4-in. NPTMED195 / 115195 / 115195 / 115195 / 115195 / 115Rollout switch opens / closes ( F)Temperature Rise ( F)30-6030-6030-6030-6030-60# of stages / # of burners (total)2 / 102 / 102 / 102 / 102 / 10Connection size3/4-in. NPT3/4-in. NPT3/4-in. NPT3/4-in. NPT3/4-in. NPTHIGHRollout switch opens / closes ( F)195 / 115195 / 115195 / 115195 / 115195 / 115Temperature Rise ( F)35-6535-6535-6535-6535-65LIQUID PROPANE HEAT# of stages / # of burners (total)2/52/52/52/52/5Connection size3/4-in. NPT3/4-in. NPT3/4-in. NPT3/4-in. NPT3/4-in. NPTLOW195 / 115195 / 115195 / 115195 / 115195 / 115Rollout switch opens / closes ( F)Temperature Rise ( F)25-5525-5525-5525-5525-55# of stages / # of burners (total)2/72/72/72/72/7Connection size3/4-in. NPT3/4-in. NPT3/4-in. NPT3/4-in. NPT3/4-in. NPTMEDRollout switch opens / closes ( F)195 / 115196 / 115197 / 115198 / 115198 / 115Temperature Rise ( F)30-6030-6030-6030-6030-60# of stages / # of burners (total)2 / 102 / 102 / 102 / 102 / 10Connection size3/4-in. NPT3/4-in. NPT3/4-in. NPT3/4-in. NPT3/4-in. NPTHIGH195 / 115195 / 115195 / 115195 / 115195 / 115Rollout switch opens / closes ( F)Temperature Rise ( F)35-6535-6535-6535-6535-6512

Options and accessoriesFACTORY-INSTALLED AND FIELD-INSTALLED ACCESSORIESCATEGORYITEMCABINETHinged access panelsCu/Cu outdoor & indoor coilsCOIL OPTIONSE-coated outdoor & indoor coilsPre-coated outdoor coilsHUMIDITY CONTROLHumidi-MiZer Adaptive Dehumidification System (17-28 RTPF)CONDENSER PROTECTION Condenser coil hail guard (louvered design)Thermostats, temperature sensors, and subbasesPremierLink DDC communicating controller 9RTU Open protocol controllerSmoke detector (supply and/or return air)CONTROLSHorn/strobe annunciator 8Time Guard II compressor delay control circuitPhase monitorEconoMi er IV for electro-mechanical controls Non FDD(Low air leak damper models) 6, 9EconoMi er2 for DDC controls, complies with FDD(Low Leak and Ultra Low Leak air damper models) 6, 7EconoMi erX for electro-mechanical controls, complies with FDD.ECONOMIZERS6& OUTDOOR AIR DAMPERS (Low Leak and Ultra Low Leak air damper models)9Motorized 2 position outdoor-air damperManual outdoor-air damper (25%) 9Barometric relief 1Power exhaust–centrifugal blowerSingle dry bulb temperature sensors 2Differential dry bulb temperature sensors 2Single enthalpy sensors 2ECONOMIZER SENSORSDifferential enthalpy sensors 2& IAQ DEVICESWall or duct mounted CO2 sensor 2Unit mounted CO2 sensor 24-in filter track assemblyPropane conversion kitStainless steel heat exchangerGAS HEATHigh altitude conversion kitFlue discharge deflectorMultiple motor and drive packagesAir Vol (SAV ) system w/VFD controllerStagedINDOOR MOTOR & DRIVE(2-stage cool only with electrical mechanical and RTU Open controls)Display Kit for SAV system with VFDWinter start kit 3LOW AMBIENT CONTROLMotormaster head pressure controller to -20 F (-29 C) 3Convenience outlet (powered)Convenience outlet (unpowered): 15 amp factory-installed,POWER OPTIONS20 amp field-installedNon-fused disconnect 4Roof curb 14-in. (356 mm)ROOF CURBSRoof curb 24-in. (610 mm)Adapter curb (Adapts to models: DP/DR/HJ/TM/TJ) 5NOTES:1. Included with economizer.2. Sensors used to optimize economizer performance.3. See application data for assistance.4. Non-fused disconnect switch cannot be used when unit FLA ratingexceeds 200 amps on 208/230 volt and 100 amps on 460/575 voltunits. Carrier Packaged RTUBuilder selects this automatically.5. Not for 48TCE024-028 models using 48DP900041, 48DP900051or 48DP900061 roof XXXXXX6. FDD (Fault Detection and Diagnostic) capability per CaliforniaTitle 24 Section 120.2i, ASHRAE 90.1-2016 and IECC-2015 FaultDetection and Diagnostic (FDD) requirements.7. Models with RTU Open DDC controls comply with CaliforniaTitle 24 Section 120.2i, ASHRAE 90.1-2016 and IECC-2015 FaultDetection and Diagnostic (FDD) requirements. PremierLink controller is non FDD.8. Requires a field-supplied 24V transformer for each application.See price pages for details.9. Not available on units with SAV.13

Options and accessories (cont)Factory-installed optionsEconomizer (dry-bulb or enthalpy)Economizers can reduce operating costs. They bring infresh, outside air for ventilation; and provide cool outsideair to cool your building. This also is the preferred methodof low ambient cooling. When coupled to CO2 sensors,economizers can limit the ventilation air to only thatamount required.Economizers are available, installed and tested by the factory, with either enthalpy or temperature dry-bulb inputs.There are also models for electro-mechanical, direct digitalcontrollers and single speed fan or 2-speed indoor fanmotors. Additional sensors are available as accessories tooptimize the economizer.Economizers include gravity controlled barometric reliefthat helps equalize building pressure and ambient air pressures. This can be a cost effective solution to prevent building pressurization. Economizers are available in ultra lowleak and low leak versions.CO2 sensorThe CO2 sensor works with the economizer to intake onlythe correct amount of outside air for ventilation. As occupants fill your building, the CO2 sensor detects their presence through increasing CO2 levels, and opens theeconomizer appropriately.When the occupants leave, the CO2 levels decrease, andthe sensor appropriately closes the economizer. This intelligent control of the ventilation air, called Demand Controlled Ventilation (DCV), reduces the overall load on therooftop, saving money.Smoke detectorsTrust the experts. Smoke detectors make your applicationsafer and your job easier. Carrier smoke detectors immediately shut down the rooftop

Carrier's WeatherMaker . Model Series - WeatherMaker TC - Standard Efficiency Unit Heat Type 48 - Gas Heat Packaged Rooftop Cooling Tons (Vertical Airflow) 17 15 tons 28 25 tons 20 17.5 tons 30 27.5 tons . B Med Static High Efficiency Motor/Vertical Supply, Return Air Flow .