Transcription

IN VERTICAL CENTRIFUGAL CASTING PROCESSA PERMANENT MOLD IS ROTATED ABOUT ITS VERTICAL AXISTHE MOLD IS SPUN AT HIGH SPEEDS ( USUALLY 50 TO 100 TIMESGRAVITY FORCE)AS THE MOLTEN METAL IS POURED, THE MOLTEN METAL ISCENTRIFUGALLY THROWN TOWARDS THE INSIDE MOLD WALLTHE OUTSIDE OF THE MOLD IS COOLED BY WATER , THUSPROVIDING “DIRECTIONAL SOLIDIFICATION” FROM OUTSIDE TOINSIDE.

CoresCopeSTATIC (SAND CASTING)A pattern, metal delivery system (gatesand risers) is constructed out ofhardwood.Sand containing bonding material ispacked around the patternMolten metal is poured into the cavityand the metal solidifies. The sand isremoved though a shakeout process.VERTICAL CENTRIFUGAL CASTING A permanent mold is rotated about itsVertical axis The Mold is spun at high speeds ( Usually50 TO 100 times GRAVITY FORCE) the molten metal is poured. Themolten metal is centrifugally throwntowards the inside mold wall, THE OUTSIDE OF THE MOLD IS WATER COOLED .

copeODDRAGSTATIC (SAND) CASTINGMETAL START TO SOLIDIFYFROM THE MOLD TOP ANDBOTTOMLEADNG TO CENTERLINESHRINKAGE IN THE CASTINGCENTRIFUGAL CASTINGSOLIDIFICATION STARTS AS A THIN LAYERAT THE OUTSIDE DIAM.BUILDS LAYER BY LAYER TOWARDS THEHOLLOW BOREDUE TO DIRECTIONAL SOLIDIFICATION,SHRINKAGE VOIDS MOVE TO THE BORE

CENTRIFUGAL CASTING AS METAL SOLIDIFY, THE SOLIDIFICATION IS FED BY A HUGE SURFACEAREA OF HIGH PRESSURE MOLTEN METAL .RESULT SHRINKAGE VOIDS AND GAS ENTRAPMENT MOVE TOWARDS BOREAND ARE ELIMINATED IN CENTRIFUGALLY CAST ROLLSSAND CASTING AS METAL SOLIDITY, MOLTEN METAL IS FED THROUGH A COMPLEXNETWORK OF NARROW GATES AND RISERS.RESULTo POTENTIAL FOR SHRINKAGE VOIDS AND GAS HOLES IN THE CASTING

GRAIN SIZE DIFFERENCE : CENTRIFUGAL CASTING Vs SAND CASTING CENTRIFUGAL CASTINGSINCE CENTRIFUGAL CASTING MOLD IS STEEL OR GRAPHITE, THEY PROVIDE HIGHERHEAT EXTRACTION ( DUE TO HIGHER CONDUCTIVITY) THAN SAND THE MOLD IS WATER COOLED, PROVIDING ADDITIONAL COOLING (CHILL) TO THEOUTSIDE DIAMETER ( WORKING SURFACE OF THE ROLL) RESULT: MUCH FINER GRAIN STRUCTURESTATIC CASTINGTHE SAND AND OTHER BINDER MATERIAL USED ARE POOR CONDUCTOR OF HEAT.DUE TO GATING AND RISER NETWORK, A HIGHER POUR TEMP IS REQUIRED RESULT: COARSE GRAIN STRUCTURE

WHAT IS G- FORCE JUST AS THE AMUSEMENT PARK RIDE FORCES RIDERS UP ITSWALLS, IN CENTRIFUGAL CASTING MACHINE , THE METAL ISPUSHED OUTWARD UNDER FORCES MANY TIMES THAT OFGRAVITY, CALLED “G- FORCE” THE HIGH G-FORCES ( 50- 100 TIMES THE GRAVITY) APPLIEDTO THE MOLTEN METAL IN THE SPINNING ALLOWS, LESS DENSEMATERIALS LIKE SLAG, IMPURITIES, GAS TO “FLOAT” TO THEI.D. WHERE IT IS SUBSEQUENTLY REMOVED BY MACHINING. METAL SOLIDIFY UNDER PRESSURE, FROM THE O.D. TO THEI.D., LEAVING A DEFECT-FREE STRUCTURE WITHOUT CAVITIESOR GAS POCKETS

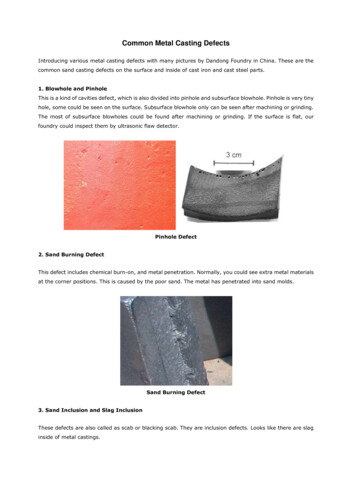

Metal solidified beforefilling the mold cavityTwo Portions of metal flowTogether from differentdirections, but there is lackFusionInternal void caused bySolidification shrinkageCENTRIFUGALLY CAST ROLLS WILL HAVE NO SUCH DEFECTS

Metal Penetrated inSand mold or coreGas holes slightly belowthe surface of thecastingA step in the casting at the parting line dueto shifted cope and dragCENTRIFUGALLY CAST ROLLS WILL HAVE NONE OF THESE DEFECTS

HIGHER MECHANICAL PROPERTIES DUE TO FINE GRAIN STRUCTURESBUILDING A METAL COMPONENT IN THE CENTRIFUGAL METHOD IS LIKEBUILDING A HOUSE; YOU START WITH THE FOUNDATION AND GO UP.OF COURSE, THE FOUNDATION OF A HOUSE IS BUILT NOT WITHIRREGULARLY SHAPED STONES BUT VARIOUS IDENTICALLY SHAPEDBLOCKS. THE GRAIN STRUCTURE OF A CENTRIFUGAL COMPONENT HASTHE SAME TRAITS.SINCE METAL SOLIDIFIES UNDER PRESSURE, A DENSE METAL STRUCTUREIS PRODUCEDFREE OF IMPURITES AND GAS HOLES DUE TO HIGH G- FORCE DURINGCASTINGFREE OF SHRINKAGE VOIDS DUE TO DIRECTIONAL SOLIDIFICATIONSINCE NO SAND, GATES OR RISERS ARE REQUIRED, DEFECTS UNIQUE TOSTATIC SAND CASTING ( SUCH AS MISRUN, COLD SHUT, SURFACE PINHOLES, SAND DEFECTS, ETC) IS VIRTUALLY ELEMINATED.

ABIMETALLIC SLEEVE HAS A HARDER SHELL ( OUTER)MATERIAL AND A SOFTER CORE ( INNER) MATERIAL. REASON STEEL MILL ROLLS NEED TO BE “ HIGH WEAR RESISTANT” ANDAT THE SAME TIME NEED BE IMPACT RESISTANT TO AVOIDBREAKAGE THIS IS POSSIBLE WITH BIMETALLIC SLEEVES BY CASTINGOUTER LAYER WITH HIGH WEAR RESISTANT ALLOY AND INNERLAYER RELATIVELY HIGH IMPACT RESISTANT ALLOY

ACOMPOSTE BIMETALLIC SLEEVE ROLL HAS A “BIMETALLICSLEEVE” SHRINK FITTED ON TO AN ARBOR.

Conventional solidroll

“ WEAR RESISTANCE AND BREAKAGE RESISTANCE ARECONFLICTING REQUIREMENTS” WITH COMPOSITE BIMETALLIC SLEEVE ROLLS, IT IS POSSIBLE TOIMPROVE BOTH WEAR AND BREAKAGE RESISTANCE BY CHOOSING A CENTRIFUGALLY CAST BIMETALLIC SLEEVE WITHHIGHER SHELL HARDNESS AND LOWER CORE HARDNESS ANDCHOOSING HIGH TOUGHNESS ARBOR . CENTRIFUALLY CAST BIMETALLIC SLEEVES PROVIDE FINE GRAIN,METALLURGICALLY SUPERIOR MECHANICAL PROPERTIES THEREFORE CENTRIFUGALLY CAST BIMETALLIC SLEEVE/FORGEDARBOR COMBINATION PROVIDE SUPERIOR WEAR RESISTANCE WITHLESS CHANCES FOR BREAKAGE.

Molten metal is poured into the cavity and the metal solidifies. The sand is removed though a shakeout process. A permanent mold is rotated about its Vertical axis The Mold is spun at high speeds ( Usually 50 TO 100 times GRAVITY FORCE) the molten metal is poured. The molten metal is centrifugally thrown