Transcription

Int. J. Mech. Eng. Autom.Volume 3, Number 1, 2016, pp. 1-9Received: December 3, 2015; Published: January 25, 2016International Journal ofMechanical Engineeringand AutomationSolidCAM iMachining (2D): A Simulation Study of a SpurGear Machining and G-code Generation for CNCMachineNazma Sultana, Md. Raihan Quader, Md. Jakaria and Md. Habibur RahmanDepartment of Industrial Engineering and Management, Khulna University of Engineering & Technology (KUET), Khulna 9203,BangladeshCorresponding author: Md. Habibur Rahman (habibur091@gmail.com)Abstract: SolidCAM is a popular add-in of SolidWorks. SolidCAM is the manufacturing suite for easiest, fastest, most efficientCNC (computer numerical control) simulation and programming facility that can be done directly inside SolidWorks. It provides aseamless single window integration and full associativity with the SolidWorks model. SolidCAM iMachining is a real breakthroughin CNC milling tool path technology. The iMachining technology uses intelligent, patented algorithms for specific operations tooptimize the tool path, reduce machining time, tool wear, etc. A great variety of machining operations on different stock objects forproducing various products can be easily defined by using this suite which results in increased flexibility. The simulation processmakes it possible to observe the operations in real time conditions and makes the G-code flawless for physical operation. In thispaper, SolidCAM iMachining is studied and the detailed procedures of the machining process of a spur gear from stock material aredescribed step by step by using SolidCAM 2014 2D iMachining technology. After the steps are defined, the whole process issimulated in various modes. Finally, the G-codes are automatically generated for the practical use in CNC machine. SolidCAM helpsunderstand the concept, operation and importance of using CAM software in modern day manufacturing industries. Moreover, byusing SolidCAM the steps of operation, parameter details can be set in a way to save time, cost, tool lives, etc.Keywords: CAM (computer-aided manufacturing), SolidCAM iMachining, CNC (computer numerical control), simulation, G-code.1. IntroductionCAM (computer-aided manufacturing) is thecomputerized process of manufacturing. This iscurrently applied by most of the heavy and mediumindustries in developed and some developingcountries. CAM can be defined as the use of computersystems or software to plan, manage, and control theoperations of a manufacturing plant through eitherdirect or indirect computer interface with the plant’sproduction resources [1]. An important action ofCAM includes controlling the CNC (computernumerical control) machines for the desiredproduction.CNC can be defined as a form of programmableautomation in which the process is controlled bynumbers, letters and symbols. In CNC, the numbers,symbols form an instruction based program designedfor a particular work or job [2]. These instructions arecalled G-code. Computer numerical control works asthe automated system that transforms the codes intomachine language and gives the machine the ability toperform the task.At present, most of the renowned industries areusing CNC machines and CAM process to producesmall, medium to large complex, intricate shapes. Theprocess of CAM can be done either by writing G-codein the software for the control of particular operations

2SolidCAM iMachining (2D): A Simulation Study of a Spur Gear Machiningand G-code Generation for CNC Machinein CNC or by using CAM software to design theoutput product with stock material and define themachining steps and then generate G-codeautomatically. Writing the G-code is very muchdifficult as it requires very deep machine knowledgeand time to learn. Written codes may have faultswhich without performing the operations is verydifficult to find. Trial and error method is needed toidentify the problems and make a successful product.Prototypes are built in this purpose. Modern CAMsoftware is very much user friendly. By using a CAMsuite the previous problems can be easily solved as iteliminates the necessity of learning G-code. It alsosimulates the operation in real like conditions whichhelps the users to find any kind of problems andeliminate those. As a result, trial and error method,prototypes are not needed.There are many CAM suites available in the marketto fulfill the purposes. SolidCAM is in a leadingposition in this field. It provides intelligent machiningoptions, optimum tool path, multi-axis machining,simulation, G-code facilities and many more. Anattempt is made to study about SolidCAM iMachiningsoftware and to define the steps to machine a spur gearalong with G-code generation as an example.2. Literature ReviewSethi, et al. [3] elaborately discussed the variouskinds of flexibility in manufacturing with the purposes,means and measurements in details. The primaryflexibility considerations included machine, materialhandling and operation. The secondary considerationswere product, process, volume and program flexibility.The use of CAM and CNC machines can improve allthe above flexibilities greatly.Boogert, et al. [4] developed a module to automaticallycalculate tool paths and cutting conditions for metalcutting operations in which the necessary algorithmshad been designed to generate reliable numericallycontrolled programs. The developed module is anexample of CAM based CNC simulation system.Barbosa, et al. [5] used CNC parametricprogramming to get higher flexibility of themanufacturing process by simulating the operation inSiemens NX7R. The ball-end milling process wassimulated and verified in a virtual model of themachine tool created in Siemens NX7R. After that, thereal process was carried out on the shop floor tomachine the test surface. The output showed that thevirtual machine tools are an effective resource tosimulate and verify the performance of machiningprocesses controlled by CNC programs. The processof accurately simulating the CNC program reduces therisk of its implementation.Ficko, et al. [6] researched about the automaticprogramming of CNC machine tools. They exploredthe various ways of programming in CNC machinesand made differences among those. The necessity andbenefits of automated programming for producing thecomplex shapes was elaborately discussed. The rolesof CAM and CNC programmers were made clear tomake the best use.Uzun [7] manufactured a concave-convex spur gearin vertical-spindle CNC milling machine andcompared the resulting values against conventionalmanufacturing values to differentiate between the twomethods. The output products expressed that the useof CNC machines significantly improve the quality.At first, the researchers explored how to improvethe flexibility of manufacturing. After that, algorithmswere used to generate NC programs to calculate toolpaths and cutting conditions. Later, some attemptswere made to simulate the process before actualoperation was done in CAM software to ensure higherflexibility. The importance of automatic programmingin CAM was established by then. It was found that useof CAM suites can drastically increase the productquality which was absent before. Though all theprevious works tried to explore the variousdimensions of how the CAM process can be improvedthose are yet to use the intelligent machining systemslike SolidCAM iMachining. It integrates the various

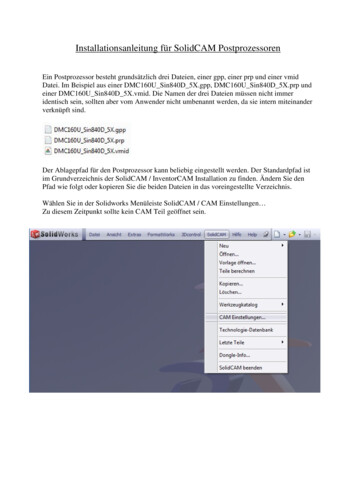

SolidCAM iMachining (2D): A Simulation Study of a Spur Gear Machiningand G-code Generation for CNC Machinefactors and conditions of CNC machines and toolstogether and finds the optimum selection of processes,tools, tool paths and reduces total cost, machiningtime, increases tool life and output quality. The mainscope of this study is to know about SolidCAMiMachining in detail and perform a simulation usingiMachining 2D.3. SolidCAM iMachiningTM: The Leaders inIntegrated CAMSolidCAM iMachining is the de-facto Works. It provides seamless, single-windowintegration and full associativity to the SolidWorksdesign model. All machining operations are defined,calculated and verified, without leaving theSolidWorks window.This is widely used in the mechanicalmanufacturing, electronics, medical, consumerproducts, machine design, automotive and aerospaceindustries, as well as in mold die and rapidprototyping shops. SolidCAM supports the completerange of major manufacturing applications in Milling,Turning, Mill-Turn and Wire cut EDM (electrodischarge machining) [8]. And with its powerfuliMachining technology, SolidCAM is revolutionizingthe CAM industry. The successful manufacturingcompanies of today (Yamaha, Honda, Aircraft Phillip,Intel, HP, etc.) are using integrated CAD/CAMsystems to get their products to market faster andreduce costs [9].iMachining uses advanced, patented algorithms togenerate smooth tangent tool paths, coupled withmatching conditions, that together keep themechanical and thermal load on the tool constant,whilst cutting thin chips at high cutting speeds anddeeper than standard cuts (up to 4 times diameter).The patented iMachining is completely unique in itstool path that increases the cutting speed and devourshard material, even with the smallest cutting tools, andalso increases tool life dramatically. The exclusive3iMachining technology wizard provides automatic,optimal feed and speed values for different materialsand CNC machines to ensure “first-cut” success [10].4. SolidCAM 2D iMachining MethodologyFor the purpose of study and simulation, SolidCAM2014 trial version is used. This section describes thesteps required to virtually machine a spur gearpreviously designed in SolidWorks 2014 in detailswith the help of figures and necessary directions. Theradius of the stock material is 50 mm and height is 38mm. The general procedure of 2D iMachining isdemonstrated in Fig. 1.4.1 Setting SolidCAM and Entering PreliminaryMilling DataAfter opening SolidWorks, SolidCAM settings areaccessed from SolidCAM tab, kept the unit in metric,made gMilling Haas SS 3x the default millingCNC-controller, selected the CAM-part as external, allboxes are unchecked from automatic CAM-Partdefinition submenu and the settings are applied. OpenSolidCAM tab- New- Milling- Ok. A new windowhas appeared at the left side of the screen where theCNC-machine, coordinate system, stock and targetmodel dialog boxes are shown. CNC-machine is set tothe default one. In order to set the coordinate systemdefine is clicked, then the top face of the stock model isFig. 1The overall steps involved for defining 2DiMachining milling operations.

4SolidCAM iMachining (2D): A Simulation Study of a Spur Gear Machiningand G-code Generation for CNC Machineclicked and applied. After that stock and target modelshould be defined. By clicking on the stock button andselecting 3D model from “defined by” option, thestock model is selected by marking the 3D stockmaterial from which the final product could bemachined. Then in order to select the target modeltarget button is clicked and the final shape of theproduct is selected. If we notice at the bottom of themilling data manager, iMachining data needs to beentered. In machine database Haas SS, in materialdatabase Aluminium 100BHN 60HRB, machininglevel 3 are selected and the window is closed properlyby clicking the right icon. In this way the CAM-Part iscompletely defined [11]. The above mentioned stepsare shown in Figs. 2-6, consecutively.Fig. 4Coordinate system selection.Fig. 5Stock model selection.Fig. 6Target model selection.4.2 Defining the OperationsFig. 2Top half of the milling data manager.From SolidCAM manager on the left side of thewindow, right click operations- Add millingoperation- 2D iMachining. A new window namediMachining operation appeared. After selecting theiRough option from technology box from the top ofthe window, first the geometry then the tool areselected. After that the level of cutting should beselected. In the upper level option the upper face ofthe stock is selected and in the pocket depth the depthto which the cutting should take place. The otheroptions will remain unchanged. When these are done,the work is saved by clicking save and calculate whichis located at the bottom of the window and clicksimulate [12]. The procedures of geometry, tool andlevel selection are illustrated in Fig. 7-12.4.3 Simulating the Operations and Applying iFinishTechnologyFig. 3Bottom half of the milling data manager.After clicking simulate new window appeared thatis called simulation. In this window, there are various

SolidCAM iMachining (2D): A Simulation Study of a Spur Gear Machiningand G-code Generation for CNC MachineFig. 7Geometry selection of 2D iMachining window.Fig. 8Tool selection window.Fig. 9Selecting tool from the tool database and setting the parameters of the tool architecture.5

6Fig. 10Fig. 11SolidCAM iMachining (2D): A Simulation Study of a Spur Gear Machiningand G-code Generation for CNC MachineMilling level selection.Selection of upper level.reality. Single step mode and operation step modefacilitates to notice the machining by single step orsingle operation. Different modes of simulation arevery useful to notice how the work will be carried outin practical. At the end of the simulation, the windowis closed and, saved and copied from the bottom of theiMachining window and iFinish from the technologytab is selected. Again save and calculate and simulateto apply a finishing operation [11]. The simulationwindow, SolidVerify for 3D mode, machinesimulation mode and machine statistics aredemonstrated in Figs. 13-16.4.4 Generating the G-codeAt the end, remaining work is the generation ofFig. 12Selection of pocket depth.modes of simulation such as Host CAD, SolidVerify,SolidVerify for 3D, Machine Simulation, etc. There isa slider in the window that controls the simulationspeed. It can be adjusted as per requirements’. Thereare options such as “show tool path”, “show trail”,“show tool 3D”, “show stock”,

Received: December 3, 2015; Published: January 25, 2016 International Journal of Mechanical Engineering and Automation SolidCAM iMachining (2D): A Simulation Study of a Spur Gear Machining and G-code Generation for CNC Machine Nazma Sultana, Md. Raihan Quader, Md. Jakaria and Md. Habibur Rahman Department of Industrial Engineering and Management, Khulna University of