Transcription

Building SuccessfulVibration Fixturesfor ED shakersPresented by:Milt BosThermotron Industriesmbos@thermotron.com

Fixturing for ED ShakersFixturing definedFixturing expectationsDesigning to meet the expectations

Fixturing DefinedFixturing holds unit under test (UUT).Fixturing attaches to shaker.Fixturing provides auxiliary functions suchas cooling, heating, electrical power, fluidflow.Fixturing transmits vibration from shaker toUUT – the most important function andexpectation.

Fixturing Expectations The UUT is held securely and does not rattle or impactthe fixture. The fixture attachment to shaker is secure and do notrattle or impact the shaker. The fixture is flat (.001”/foot) and it does not createstresses in the shaker table or have gaps at attachmentpoints. The fixture is durable, hefty and strong. The fixture has no internal joints that rattle or impact inthe frequency range of test.

A non‐linear fixture exampleHollow structural membersThin platesLong beamsSmall attachmentsSuccessful – low frequency, light UUT

Fixturing Non‐Linear IssuesAny impact creates a non‐linear behavior.Certain modes of vibration can be non‐linear.Rubbing (frictional) contact creates non‐linearbehavior.Fixture material selection and construction have directimpacts on linearity.Linear response means that for every input, apredictable and scalable response is achieved.Non‐linear response results in control that is verydifficult or not achievable.

Fixturing QualityCenter of gravity (CG) of entire vibrating system mustbe on center line of motionComposites and “dead” materials (such as magnesiumor phenolic) are preferredSteel and beryllium are undesirableFixture resonances are linear to shaker input.Joints are eliminated or minimized.Test results and shaker life require quality.

Fixturing ExamplesWelded magnesiumconstruction.Multiple attachment planes.Careful CG calculation.Duplicates actual use andattachment.Collaborative machiningand welding.Extensive design.

Fixturing ConstructionTwo approaches: Top down design Bottom up designTop down design surrounds UUT with solid mass, thenexpands mass downward to meet shaker table.Bottom up design grows from table to product, andadds material everywhere possible to preventundesirable bending modes.Both methods assume mass and volume exist whereverpossible.Mass and volume reduction typically reduces quality.

Fixturing ExamplesMassive product.Massive fixture pillars.Duplication of mounting.Specific repetitive use.PurposelyblurredLack of controlwhen product isincorrectly built.Extreme profile,extreme noise.

Fixture ConstructionJoints are welded and 75‐25 rule is followed (75%of the joint is weld, 25% is flat surface contact)Fixture is machined after welding so that surfacesare true and flat.(5) times as many bolts are required for shear(sliding) transmission as are required forcompression transmission if the frictioncoefficient is 0.2

Fixture MaterialMagnesium, aluminum or steel?For same mass, cross‐section of beam increasesas material density decreases.Cross‐section thickness affects resonancebecause bending modes are inhibited.Same width beam can be made thicker with noincrease in mass with lighter materials.

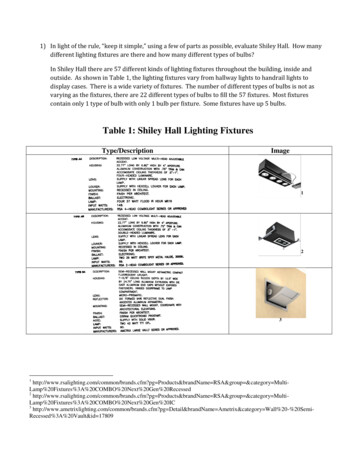

Fixture Cross‐SectionsStart with a 4” square plate – ¼” thicksteel.Make thicker using mass ratio.MassVolumeFirst ResonanceSecond ResonanceThird ResonanceFourth ResonanceFifth ResonanceSixth ResonanceSteel1.1 lbm.34 in520 Hz1246 Hz3135 Hz3965 Hz4473 Hz5216 HzAluminum1.1 lbm.312 in1470 Hz3232 Hz5228 Hz7884 Hz10051 Hz10718 Hz‐ Results of FEA study of platesMagnesium1.1 lbm.317 in2129 Hz4335 Hz5165 Hz10141 Hz12491 Hz13171 Hz

Vertical plate – steel ¼” thick.First resonance.

Vertical plate – alum .714” thick.First resonance.

Vertical plate – mag 1.076” thick.First resonance.

Fastener DilemmaFastener health – thread life.Fixturing is made to be used repeatedly.Fasteners are not made to be usedrepeatedly.Durability of inserts versus durability ofbolts and screws.

Questions or Comments?

For More Information:291 Kollen Park DriveHolland, MI 49423 USAwww.thermotron.cominfo@thermotron.com(ph) 800‐409‐3449(ph) 616.393.4580(fax) 616.392.5643

the fixture. The fixture attachment to shaker is secure and do not rattle or impact the shaker. The fixture is flat (.001"/foot) and it does not create stresses in the shaker table or have gaps at attachment points. The fixture is durable, hefty and strong.