Transcription

TECK CABLECATALOGUE

Wire & Cable SpecialistsOur CommitmentOur commitment to our customers is simple we deliver even when others can’t.As one of Canada’s largest wire, cable and datacommunication distributors for over 40 years,Texcan supplies solutions for automotive, powerdistribution, control, industrial automation,commercial, residential, premise wiring andnetworking applications. Our commitment tosuperior customer service is the number onereason customers keep coming back.Our parent company, Sonepar, is a majorglobal electrical distributor, with divisions in 44countries, 5 continents, over 46,000 associatesand 2,800 branches.Dedicated to OurCustomersTexcan understands that business is donebetween people. We consider a job finishedwhen the customer is completely satisfied. Thisapproach highlights our commitment to qualityand our high level of customer service. Thiswinning combination focuses on a personalizedapproach to our customers.Product Expertise andSpecialized ServicesTexcan has five stocking locations in WesternCanada. With over 200 employees, Texcan is ableto provide product application expertise,specialized technical assistance and superiorsales service to meet our customers’ needs.We constantly strive to bring value to ourcustomers. We provide: An extensive range of stock wire products Computerized order processing Regionalized bar coded warehousing Competitive pricing Inventory tracking technology JIT inventoryStrategic PartnershipsTexcan has worked hard to developpartnerships with customers and vendors andcontinues to be committed to developing suchstrategic alliances. These partnerships provideTexcan with a successfuland proven record with some of thelargest customers in the pulp and paper,mining, petrochemical, transportation, andcommunication industries.Thanks to our relationships with key vendorssuch as: Prysmian Group, Southwire, Belden,Nexans, Northern Cables, Deca Cables, MarmonElectrical, CMP, and PTI Cables Inc., Texcan isable to offer its customers a diverse selectionof quality products. We are confident we cancontinue to be your successful partner now andin the future.Over 40 Yearsof ServiceCÂBLESCABLESINC.

Table of ContentsPage No.Teck Cable4Standard Design Features5Armoured Control 600V6Teck Multiconductor 600VTeck Composite 600V- 14 AWG7- 12 AWG8- 10 AWG9- 14 AWG10- 12 AWG10Teck 1C 1000V11Teck 2C 1000V12Teck 3C 1000V13Teck 4C 1000V14Teck UnshieldedTeck Shielded- 1C 5kV15- 3C 5kV16- 1C 100% 5kV17- 3C 100% 5kV18- 1C 133% 5KV (aka 100% 8kV)19- 3C 133% 5KV (aka 100% 8kV)20- 3C 133% 8kV21- 1C 133% 15kV22- 3C 133% 15kV23- 1C 133% 25kV24- 3C 133% 25kV25- 1C 133% 28kV26- 3C 133% 28kV27- 1C 100% 35kV28- 3C 100% 35kV29Teck ConnectorsTechnical Information30-31- Metric Conversions32- Installation Data33To Place an Order - For many of the products in the catalogue, you will find everything that you need to placean order. Should you need any assistance or require special orders, please contact your sales representative. Acomplete list of our sales offices can be found on the back cover of this catalogue.Universal Toll Free Phone: 1.800.665.1025 3

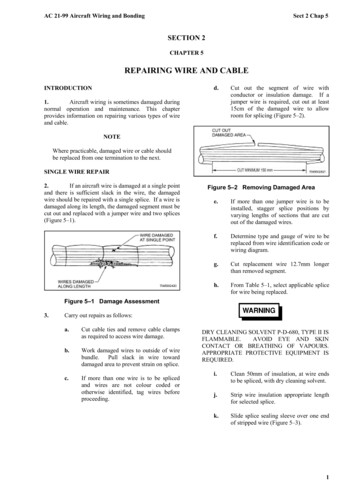

Teck CableIntroductionTeck cable, a flexible armoured cable originallydesigned for use in Canadian mines, has becomea key component for the distribution of electricitythrough a broad range of industrial, commercialand manufacturing facilities.Teck cable’s combination of interlocking flexible armourwith two layers of PVC jacket provide a rugged, compactand flexible cable that is resistant to corrosion, waterand mechanical abuse. It is designed for use in wet ordry locations with a maximum conductor temperatureof 90 C and a low temperature rating of -40 C.ApplicationsSpecificationsTeck cable is used extensively by the pulp and paper,chemical, mining, petrochemical and manufacturingindustries in a broad range of applications, especiallywhere cable may be subjected to mechanical damageand corrosive chemicals. Commercial applications forTeck cable include apartment buildings and commercialcomplexes. Teck cable is also an economical alternative asthe need for conduits or ducts and pull boxes is eliminated. CSA FT1 & FT4 CSA C22.2 No. 131 for Teck cables rated up to and including 5kV CSA C68.10 for shielded Teck cables rated 5kV and above(C68.10 pending) CSA C22.2 No. 0.3 Clause 4.11.4 FT4 flame test C SA C22.2 No. 174 for use in the following hazardous locations (HL):- Class 1 Group A, B, C, D. Division 1 & 2- Class II Group E, F, G. Division 1 & 2- Class III ICEA S-66-524 / NEMA WC7 for Teck cables rated above 5kV IEEE 383 &1202 (70,000 BTU/hr) flame test ICEA T-29-520 (210,000 BTU/hr) Vertical Cable Tray Flame Test ICEA T-30-520 (70,000 BTU/hr) Vertical Cable Tray Flame TestTeck cable is approved for use; in wet and dry locations,indoor and outdoor, in exposed and concealed wiring,in ventilated, non-ventilated and ladder type cabletrays, for direct earth burial and for service entranceinstallations, above and below ground. It is ‘HL’ rated foruse in all hazardous locations when used with optional‘HL’ approved connectors.*Refer to CE Code for detailsCAUTION NOTICEIn case of fire, well maintained early warning smoke detectors will give an alarm long before non-metallic coverings become combustible.However, the Electrical and Electronic Manufacturers Association of Canada has suggested that all purchasers of PVC insulated / jacketedproducts be advised of the following: Non-metallic coverings of electrical cables can burn and may transmit fire when ignited. Burning non-metallic coverings may emit acid gases which are toxic and may generate dense smoke. Emission of acid gases may corrode metal in the vicinity e.g. sensitive instruments and reinforcing rods in cement.The installer and/or user assumes all liability for the consequences of the installation and/or use of any of the products in violation of anyapplicable law, regulation, or code.4 Universal Toll Free Phone: 1.800.665.1025

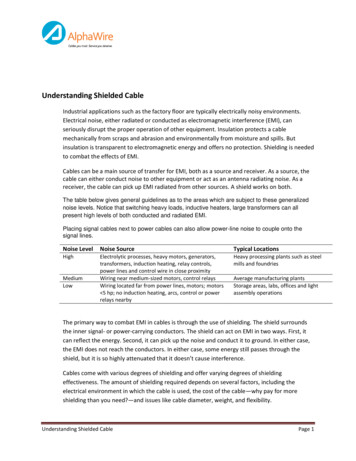

Standard Design FeaturesConductors – Class B compact or compressed concentricOUTER JACKETINSULATIONINNER JACKETstranded soft drawn bare copper per ASTM, conforming to CSA C68.3.TAPEFILLERSBONDCONDUCTORConductor Shielding – A thermoset semi-conductingshield is extruded over the conductor on all cables rated over 1kV.Minimum thickness in accordance with CSA C68.3, Table 2.Insulation – Cross-linked polyethylene (XLPE), meeting therequirements of CSA RW90 for cables rated up to and including1kV. For cables rated 5kV and above, the TR-XLPE insulation meetsthe requirements of CSA Standard C68.3 M92.COPPERTAPEARMOURMetallic Shield – A 15% gapped copper tape ing the requirements of CSA C68.3 is helically applied to theinsulated conductors in three conductor shielded cables rated5kV and above. In single conductor cables, the concentric groundserves as the metallic shield and bonding conductor.Bonding (Ground) Conductor – Class B strandedsoft bare copper conductor, in accordance with CSA C68.3and CSA C22.2 No. 131, is included in the assembled cable formulticonductor cables. In single conductor cables, the concentricground serves as the metallic shield and bonding conductor.Fillers and Core Binder Tape – Where required,suitable fillers to make round and core binders may be used.Inner Jacket – Flame-retardant and moisture resistantPVC Jacket is applied over the core in accordance withCSA C22.2 No. 131.Armour – An interlocking aluminum armour is appliedover the inner jacket meeting the requirements of CSA C22.2No. 131, Clause 5.11.Outer Jacket – A low temperature (-40 C), flame-retardant,moisture and sunlight resistant PVC jacket is applied over thearmour in accordance with CSA C22.2 No. 131. Minimum thicknessin accordance with CSA 68.3, Table 21. Complete cable FT4 rated.Accessories Non-hazardous Teck connectors Explosion proof (hazardous location) cable connectors High voltage termination and splice kits Compression lugs and sleevesColour CodeTECK 90 CABLES: 2 conductor cables are colour coded black and white 3 conductor cables are colour coded black, red and blue 4 conductor cables are colour coded black, red, blue and white 5 or more conductor cables are black and alpha numeric codedARMOURED CONTROL: Conductor #1 is white, the remaining conductors are blackand numberedOptions Aluminum phase conductor and bonding conductor Ethylene-propylene rubber (EPR) insulation for shielded Teckcables rated 5kV and above Overlapping copper tape shield Sequential marking on outer jacket Special ground wire requirements: 50% of phase conductor ormore than one ground conductor Fully filled core for multiconductor Teck cables rated 5kV and above Galvanized steel interlocked armour (GSIA) for multiconductorTeck cables Coloured outer jacket Vertical riser Teck Variable frequency drive (VFD) Other constructions available upon requestUniversal Toll Free Phone: 1.800.665.1025 5

CON T R OLA RMOURE D CON TROLArmoured ControlOUTER JACKETINNER JACKETBONDCONDUCTORFILLERSArmoured Control 16 AWG 600VXLPE/PVC/AIA/PVCTAPEINSULATIONSPECIFIC ATIONSCONSTRUC TION CSA FT4Conductor: Bare copper Class B compressed stranded CSA C22.2 No. 239Insulation: Cross-Linked Polyethylene (XLPE) Type RW90 CSA C22.2 No. 174Ground (Bonding) Conductor: Uninsulated stranded bare copper conductor CSA C22.2 No. 38Inner Jacket: Flame-retardant and moisture resistant Polyvinyl Chloride (PVC)*Refer to CE Code for detailsCONDUCTORARMOURArmour: Aluminum Interlocked Armour (AIA)Outer Jacket: Low-temperature and moisture resistant Polyvinyl Chloride (PVC), blueOptions: Galvanized Steel Interlocked Armour (GSIA)Other coloured outer jacket and constructions available upon requestHL16 AWGApproximateDiameter (Over)AWG SizePart NumberNo. ofConductorsNet Weightw/ ArmourCond.Bond WireInner Jacket (in.)Armour (in.)Outer 11697Note: A ll dimensions are nominal and are subject to normal manufacturingtolerance. Specifications are subject to change without prior notice.6 Universal Toll Free Phone: 1.800.665.1025* See pages 30 & 31 for corresponding connector.

Teck 90 Armoured PowerOUTER JACKETINNER JACKETBONDCONDUCTORFILLERSMulticonductor 14 AWG 600VXLPE/PVC/AIA/PVCTAPEARMOURCONDUCTORCONSTRUC TION CSA FT1 & FT4Conductor: Bare copper Class B compressed stranded CSA C22.2 No. 131 & 174Insulation: Cross-Linked Polyethylene (XLPE) Type RW90 IEEE 383 & 1202 (70,000BTU/hr) Flame TestGround (Bonding) Conductor: Uninsulated stranded bare copper conductor ICEA T-30-520 (70,000BTU/hr) Vertical Flame TestArmour: Aluminum Interlocked Armour (AIA)Inner Jacket: Flame-retardant and moisture resistant Polyvinyl Chloride (PVC)Outer Jacket: Low-temperature, moisture and sunlight resistant Polyvinyl Chloride (PVC), black*Refer to CE Code for detailsOptions: G alvanized Steel Interlocked Armour (GSIA)Other coloured outer jacket and constructions available upon requestHL14 AWGAWG SizePartNumberNo. ofConductorsCond.Bond WireInsulationThickness(in.)ApproximateDiameter (Over)CopperContentNet Weightw/ ArmourInsul.(in.)Inner Jacket(in.)Armour(in.)OuterJacket : A ll dimensions are nominal and are subject to normal manufacturingtolerance. Specifications are subject to change without prior notice.* See pages 30 & 31 for corresponding connector.Universal Toll Free Phone: 1.800.665.1025 7CON T R OLSPECIFIC ATIONS6 0 0 V M ULTIINSULATION

Teck 90 Armoured PowerOUTER JACKETINNER JACKETBONDCONDUCTORFILLERSMulticonductor 12 AWG 600VXLPE/PVC/AIA/PVCCON T R OL6 0 0 V M ULTITAPEARMOURCONDUCTORINSULATIONSPECIFIC ATIONSCONSTRUC TION CSA FT1 & FT4Conductor: Bare copper Class B compressed stranded CSA C22.2 No. 131 & 174Insulation: Cross-Linked Polyethylene (XLPE) Type RW90 IEEE 383 & 1202 (70,000BTU/hr) Flame TestGround (Bonding) Conductor: Uninsulated stranded bare copper conductor ICEA T-30-520 (70,000BTU/hr) Vertical Flame TestArmour: Aluminum Interlocked Armour (AIA)Inner Jacket: Flame-retardant and moisture resistant Polyvinyl Chloride (PVC)Outer Jacket: Low-temperature, moisture and sunlight resistant Polyvinyl Chloride (PVC), black*Refer to CE Code for detailsOptions: G alvanized Steel Interlocked Armour (GSIA)Other coloured outer jacket and constructions available upon requestHL12 AWGAWG SizePartNumberNo. ofConductorsCond.Bond WireInsulationThickness(in.)ApproximateDiameter (Over)CopperContentNet Weightw/ ArmourInsul.(in.)Inner Jacket(in.)Armour(in.)OuterJacket .1500.4000.6200.70055822283400500

AWG Size Approximate Net Weight Diameter (Over) w/ Armour Cond. Bond Wire Inner Jacket (in.) Armour (in.) Outer Jacket (in.) LB/MFT KG/KM Armoured Control 6 Universal Toll Free Phone: 1.800.665.1025 CONTROLARMOURED CONTROL