Transcription

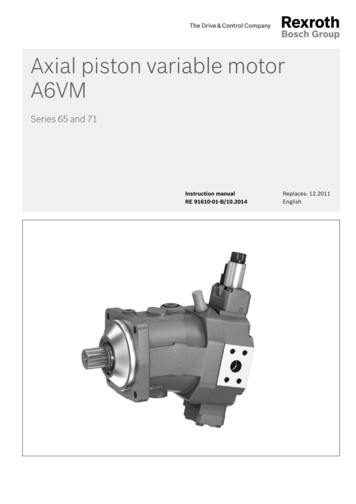

Axial piston variable motorA6VMSeries 65 and 71Instruction manualReplaces: 12.2011RE 91610-01-B/10.2014English

The data specified above only serve todescribe the product. No statement abouta specific characteristic or suitability for acertain application can be derived from thisinformation. Information from the catalogdoes not represent assured properties.The information given does not release theuser from the obligation of own judgment andverification. It must be remembered that ourproducts are subject to a natural process ofwear and aging. This document, as well as the data,specifications and other information setforth in it, are the exclusive property ofBosch Rexroth AG. It may not be reproduced orgiven to third parties without its consent.The cover shows an example application.The product delivered may differ from theimage on the cover.The original instruction manual was createdin German.

Contents3/60Contents1About this documentation51.1Validity of the documentation51.2Required and supplementary documentation51.3Display of information61.3.1 Safety instructions61.3.2 Symbols71.3.3 Designations71.3.4 Abbreviations72Safety instructions82.1About this chapter82.2Intended use82.3Improper use82.4Personnel qualifications92.5General safety instructions2.6Product-specific safety instructions102.7Personal protective equipment133General instructions on damage to property and the product144Scope of delivery175About this product185.1Performance description185.2Product description1895.2.1 Layout of the axial piston unit185.2.2 Functional description195.3Product identification206Transport and storage216.1Transporting the axial piston unit216.1.1 Transporting by hand216.1.2 Transporting with lifting device216.2Storing the axial piston unit237Installation257.1Unpacking257.2Installation conditions257.3Installation position277.3.1 Below-reservoir installation (standard)277.3.2 Above-reservoir installation287.429Installing the axial piston unit7.4.1 Preparation297.4.2 Dimensions297.4.3 General notes297.4.4 Installation with coupling317.4.5 Installation on a gearbox327.4.6 Installation with cardan shaft327.4.7 Completing installation327.4.8 Hydraulically connecting the axial piston unit337.4.9 Electrically connecting the axial piston unit407.541Performing flushing cycleRE 91610-01-B/10.2014, A6VM Series 65 and 71, Bosch Rexroth AG

4/60 Contents8Commissioning428.1Initial commissioning428.1.1 Filling the axial piston unit428.1.2 Testing the hydraulic fluid supply448.1.3 Performing functional test448.2Running-in phase458.3Recommissioning after standstill459Operation4610Maintenance and repair4710.1 Cleaning and care4710.2 Inspection4710.3 Maintenance4810.4 Repair4810.5 Spare parts491150Removal and replacement11.1 Required tools5011.2 Preparing for removal5011.3 Carrying out removal5011.4 Preparing the components for storage or further use5012Disposal5113Extension and conversion5114Troubleshooting5214.1 How to proceed with troubleshooting5214.2 Malfunction table5315Technical data5516Alphabetical index56Bosch Rexroth AG, A6VM Series 65 and 71, RE 91610-01-B/10.2014

About this documentation5/601 About this documentation1.1 Validity of the documentationThis documentation is valid for the following product: Axial piston variable motor A6VM series 65 Axial piston variable motor A6VM series 71This documentation is intended for machine/system manufacturers, fitters andservice technicians.This documentation contains important information on the safe and appropriatetransport, installation, commissioning, operation, maintenance, removal and simpletroubleshooting of the axial piston unit. Read this documentation completely and in particular the chapter 2 “Safetyinstructions” on page 8 and chapter 3 “General instructions on damage toproperty and the product” on page 14 before you start work with the axialpiston unit.1.2 Required and supplementary documentation Only commission the axial piston unit if the documentation marked with the booksymbolis available to you and you have understood and observed it.Table 1: Required and supplementary documentationTitleDocument numberDocument typeOrder confirmationContains the order-related technical data for your A6VM axial piston variablemotor.–Order confirmationInstallation drawingContains the outer dimensions, all connections and the hydraulic circuit diagramfor your axial piston variable motor A6VM.Please requestthe installationdrawing via yourcontact person atBosch Rexroth.Installation drawingAxial piston variable motor A6VM series 65Axial piston variable motor A6VM series 71Contains the permissible technical data.9160791610Data sheetMineral-oil based hydraulic fluids and related hydrocarbons90220Describes the requirements for a mineral-oil based hydraulic fluid and relatedhydrocarbons for operation with Rexroth hydraulic components, and assists you inselecting a hydraulic fluid for your hydraulic system.Data sheetEnvironmentally acceptable hydraulic fluidsDescribes the requirements on an environmentally acceptable hydraulic fluidfor operation with Rexroth hydraulic components and assists you in selecting ahydraulic fluid for your hydraulic system.90221Data sheetFire-resistant, water-free hydraulic fluids (HFDU/HFDR)Describes the requirements on fire-resistant, water-free hydraulic fluids foroperation with Rexroth hydraulic components and assists you in selecting ahydraulic fluid for your hydraulic system.90222Data sheetAxial piston units for operation with HF hydraulic fluidsContains additional information on the use of Rexroth axial piston units with HFhydraulic fluids.90223Data sheetInformation for the use of hydrostatic drives at low temperaturesContains additional information on the use of Rexroth axial piston units at lowtemperatures.90300-03-BManualStorage and preservation of axial piston unitsContains additional information on storage and preservation.90312Data sheetRE 91610-01-B/10.2014, A6VM Series 65 and 71, Bosch Rexroth AG

6/60About this documentation1.3 Display of informationStandardized safety instructions, symbols, terms and abbreviations are usedthroughout this documentation so that you can work quickly and safely with yourproduct. To give you a better understanding, these are explained in the sections below.1.3.1 Safety instructionsThis manual includes safety instructions in chapter 2.6 “Product-specific safetyinstructions” on page 10 and in chapter 3 “General instructions on damage toproperty and the product” on page 14 and before a sequence of actions or aninstruction involving a risk of personal injury or damage to equipment.The measures described to avert danger must be observed.Safety instructions are set out as follows:Signal wordType and source of dangerConsequences of non-compliance Measures to avert danger Warning sign: draws attention to the danger Signal word: identifies the degree of danger Type and source of the danger: identifies the type and source of the danger Consequences: describes what will happen if the safety instructions are notcomplied with Precautions: states how the danger can be avoidedTable 2: Hazard classes as defined in ANSI Z535.6-2006Warning sign, signal wordMeaningDANGERIdentifies a dangerous situation that will result in death orserious injuries if it is not avoided.WARNINGIdentifies a dangerous situation that may result in death orserious injuries if it is not avoided.CAUTIONNOTICEBosch Rexroth AG, A6VM Series 65 and 71, RE 91610-01-B/10.2014Identifies a dangerous situation that may result in minor tomoderate injuries if it is not avoided.Property damage: The product or the environment may bedamaged.

About this documentation7/601.3.2 SymbolsThe following symbols indicate information that is not directly relevant to safety butincreases understanding of the manual.Table 3: Meaning of the symbolsSymbolMeaningIf this information is disregarded, the product cannot be used or operatedto its optimum potential. Single, independent step1.Numbered instruction:The numbers indicate that the steps must be completed one after theother.2.3.1.3.3 DesignationsThis documentation uses the following designations:Table 4: DesignationsDesignationMeaningA6VMAxial piston variable motor, open and closed circuitsThreaded plugMetal screw, pressure-resistantProtective plugMade out of plastic, not pressure-resistant, only for transportationAs a generic term for the “A6VM axial piston variable motor” the designation “axialpiston unit” is used in the following.1.3.4 AbbreviationsThis manual uses the following abbreviations:Table 5: AbbreviationsAbbreviationMeaningATEXEU directive on explosion protection (Atmosphère explosible)DINDeutsche Industrie Norm (German Institute for Standardization)EPProportional control electricEZTwo point control electricHAAutomatic control, high-pressure relatedHPProportional control hydraulicHZTwo-point control, hydraulicISOInternational Organization for Standardization(Internationale Normierungsorganisation)JISJapan Industrial StandardRERexroth document in the English languageVDI 2230Directive for the systematic calculation of high duty bolted joints andjoints with one cylindrical bolt from the VDI (Verein Deutscher Ingenieure Association of German Engineers)RE 91610-01-B/10.2014, A6VM Series 65 and 71, Bosch Rexroth AG

8/60Safety instructions2 Safety instructions2.1 About this chapterThe axial piston unit has been manufactured according to the generally acceptedrules of current technology. There is, however, still a danger of personal injuryor damage to equipment if this chapter and the safety instructions in thisdocumentation are not complied with. Read this documentation completely and thoroughly before working with theaxial piston unit. Keep this documentation in a location where it is accessible to all users at alltimes. Always include the required documentation when you pass the axial pistonunit on to third parties.2.2 Intended useAxial piston units are hydraulic components, meaning that in their application theyare classified neither as complete nor as incomplete machines in the sense of theEU machine directive 2006/42/EC. A component is exclusively intended to form anincomplete or a complete machine together with other components. The componentmay only be commissioned after it has been installed in the machine/system forwhich it is intended and the safety of the entire system has been established inaccordance with the machine directive.The product is intended for the following use:The axial piston unit is only approved as a hydraulic motor in hydrostatic drive systems. Observe the technical data, application and operating conditions andperformance limits as specified in data sheet 91607 and 91610 and in the orderconfirmation. Information about approved hydraulic fluids can be found in datasheet 91607 and 91610.The axial piston unit is only intended for professional use and not for private use.Intended use also includes having read and understood the documentation in full,especially the chapter 2 “Safety instructions” on page 8.2.3 Improper useAny use other than that described as intended use shall be considered as improperand is therefore impermissible.Bosch Rexroth AG shall accept no liability whatsoever for damages resulting fromimproper use. The user shall bear all risks arising from improper use.The following foreseeable forms of misuse shall also be considered to be improper(this list does not claim to be exhaustive): Use outside the operating parameters approved in the data sheet or in the orderconfirmation (unless customer-specific approval has been granted and confirmedin writing) Use of non-approved fluids, e.g. water or polyurethane components Modification of the factory settings by non-authorized personnel Use of add-on parts (e.g. control unit, valves) not in combination with specifiedRexroth componentsBosch Rexroth AG, A6VM Series 65 and 71, RE 91610-01-B/10.2014

Safety instructions9/60 Using the axial piston unit under water at a depth of more than 10 meters withoutnecessary additional measures, e.g., pressure equalization Using the axial piston unit when the ambient pressure is greater than the interiorpressure (case pressure) Using the axial piston unit in explosive environments unless the component ormachine/system has been certified as compliant with the ATEX directive 94/9/EC Use of the axial piston unit in an aggressive atmosphere Use of the axial piston unit in aircraft or space craft2.4 Personnel qualificationsThe activities described in this documentation require basic mechanical, electricaland hydraulics expertise, as well as knowledge of the associated technical terms.For transporting and handling the product, additional knowledge is necessary withregard to working with lifting gear and the corresponding attachment equipment.In order to ensure safe use, these activities may therefore only be performed byan appropriately qualified person or an instructed person under the direction andsupervision of a qualified person.Qualified personnel are those who can recognize possible hazards and institutethe appropriate safety measures due to their professional training, knowledge, andexperience, as well as their understanding of the relevant conditions pertaining tothe work to be done. Qualified personnel must observe the rules relevant to thespecialist field and have the necessary hydraulics expertise.Hydraulic expertise includes: Reading and fully understanding hydraulic diagrams, Specifically, fully understanding the relationships with regard to safety devices, and Understanding how hydraulic components work and are put togetherBosch Rexroth offers training support for specialist fields. An overview of thetraining contents can be found on the Internet at:www.boschrexroth.com/training.2.5 General safety instructions Observe the applicable accident prevention and environmental protectionregulations. Observe the safety regulations and provisions of the country in which the productis used/operated. Use Rexroth products only when they are in good technical order and condition. Observe all notes on the product. Persons who install, operate, remove or maintain Rexroth products must notconsume any alcohol, drugs or pharmaceuticals that may affect their ability torespond. Only use genuine Rexroth accessories and spare parts to ensure there is no risk topersonnel from unsuitable spare parts. Adhere to the technical data and ambient conditions specified in the productdocumentation.RE 91610-01-B/10.2014, A6VM Series 65 and 71, Bosch Rexroth AG

10/60Safety instructions If unsuitable products are installed or used in applications that are relevant forsafety, unexpected operating conditions may occur in the application, which couldresult in injury to personnel or damage to equipment. For this reason, only usethe product in a safety-related application if this use is expressly specified andpermitted in the product documentation, for example in explosion protectionapplications or in safety-related parts of a control system (functional safety). You may only commission the product if it has been determined that the endproduct (e.g., machinery or system) in which the Rexroth products are installedcomplies with the country-specific provisions, safety regulations and standards forthe application.2.6 Product-specific safety instructionsThe following safety instructions apply for chapters 6 to 14.WARNINGDanger from excessively high pressure!Danger to life or risk of injury, damage to equipment.An inappropriate change in the factory pressure settings can result in a pressureincrease beyond the permissible maximum pressure.Operating the unit above the permissible maximum pressure can causecomponents to burst and hydraulic fluid to escape under high pressure. Changes to the factory settings must only be made by Bosch Rexroth specialistpersonnel. In addition, a pressure relief valve is needed as back-up in the hydraulic system.If the axial piston unit is equipped with a pressure cut-off and/or a pressurecontrol, this is not an adequate back-up against pressure overload.Danger from suspended loads!Danger to life or risk of injury, damage to equipment.Improper transportation may cause the axial piston unit to fall down and lead toinjuries e.g. crushing or broken bones or damage to the product. Make sure that the load capacity of the lifting gear is sufficient to safely bear theweight of the axial piston unit. Never step or reach under a suspended load. Ensure a stable position during transportation. Use your personal protective equipment (e.g., safety glasses, safety gloves,suitable working clothes, safety shoes). Use suitable lifting gear for transportation. Observe the prescribed position of the lifting strap. Observe the national laws and regulations on work and health protection andtransportation.Bosch Rexroth AG, A6VM Series 65 and 71, RE 91610-01-B/10.2014

Safety instructions11/60WARNINGPressurized machine/system!Danger to life or risk of injury, serious injuries when working on machines/systemsnot shut down. Damage to equipment. Switch off the entire system and secure it against reconnection according toinformation provided by the machine/system manufacturer. Make sure that all relevant components of the hydraulic system aredepressurized. Follow the machine/system manufacturer’s specifications. Note that the hydraulic system may still may be under pressure even after theseparation of the actual pressure supply. Do not disconnect any line connections, ports and components while thehydraulic system is pressurized.Escaping oil mist!Risk of explosion, fire, health hazard, environmental pollution. Depressurize the machine/system and repair the leak. Only perform welding work then the machine/system is depressurized. Keep open flames and ignition sources away from the axial piston unit. If axial piston units are to be situated in the vicinity of ignition sources orpowerful thermal radiators, a shield must be erected to ensure that any escapedhydraulic fluid can not ignite, and to protect hose lines from premature aging.Electrical voltage!Risk of injury due to electric shock or damage to equipment. Always set up the relevant part of the machine/system so that it is free ofelectrical voltage before you install the product or when connecting anddisconnecting plugs. Protect the machine/system against being energized.Overloading of the axial piston motor!Risk of injury or damage to equipment!When using the axial piston motor in winch drives it can, when extremelyoverloaded (e.g. if the maximum permissible rotational speeds are exceededduring weighing of the anchor while the ship is in motion) cause damage to therotary group and in the worst case, the axial piston motor may burst. Ensure that the technical limits are not exceeded in any operating conditions. Check whether any additional measures are needed for your machine/system(up to an encapsulation) in order to avoid injury to persons. If necessary, makesure that these are properly implemented. For safety reasons, axial piston variable motors with beginning of control at Vg min(e.g., HA) are not permissible for winch drives (e.g. anchor winches).RE 91610-01-B/10.2014, A6VM Series 65 and 71, Bosch Rexroth AG

12/60Safety instructionsWARNINGLimitation of the control function!Risk of injury or damage to equipment!Moving parts in control equipment (e.g. valve pistons) can, under certaincircumstances get blocked in position as a result of contamination (e.g. impurehydraulic fluid, abrasion, or residual dirt from components). As a result, the flow ofhydraulic fluid and the build-up of momentum in the axial piston unit can no longermeet the operator's specifications. Even the use of various filter elements (externalor internal flow filtering) cannot rule out errors, but can only help minimize risks. Check whether remedial measures for your application are needed on yourmachine in order to put the driven consumer in a safe state (e.g. safe stop). If necessary, make sure that these are properly implemented.Bosch Rexroth AG, A6VM Series 65 and 71, RE 91610-01-B/10.2014

Safety instructions13/60CAUTIONHigh noise levels during operation!Danger of hearing damage, deafness.The noise emission of axial piston units depends on, among other factors,rotational speed, operating pressure and installation conditions. The soundpressure level may rise above 70 dB (A) during normal application conditions. Always wear hearing protection when in the vicinity of the operating axialpiston unit.Hot surfaces on the axial piston unit!Risk of burns! Allow the axial piston unit to cool down sufficiently before touching it. Wear heat-resistant protective clothing, e.g. gloves.Improper routing of cables and lines!Tripping danger and damage to equipment! Lay cables and lines so that they can not be damaged and nobody can tripover them.Contact with hydraulic fluid!Health hazard / risk of health impairment, e.g., eye injuries, skin damage, poisoningon inhalation. Avoid contact with hydraulic fluids. When working with hydraulic fluids, strictly observe the safety instructionsprovided by the lubricant manufacturer. Use your personal protective equipment (e.g., safety glasses, safety gloves,suitable working clothes, safety shoes). If hydraulic fluid should, nevertheless, come into contact with your eyes, get intoyour bloodstream or be swallowed, consult a doctor immediately.Escaping hydraulic fluid due to machine/system leakage!Risk of burns and risk of injury due to escaping oil jet. Depressurize the machine/system and repair the leak. Never attempt to block or seal the leak or oil jet with a cloth.2.7 Personal protective equipmentThe personal protective equipment is the responsibility of the user of the axialpiston unit. Observe the safety regulations and provisions in your country.All components of the personal protective equipment must be intact.RE 91610-01-B/10.2014, A6VM Series 65 and 71, Bosch Rexroth AG

14/60General instructions on damage to property and the product3 General instructions on damage toproperty and the productThe following instructions apply for chapters 6 to 14.NOTICEDanger from improper handling.Product can be damaged! Do not expose the product to a non-permitted mechanical load. Never use the product as a handle or step. Do not place/lay any objects on the product. Do not strike the drive shaft of the axial piston unit. Do not set/place the axial piston unit on the drive shaft or fittings. Do not strike fittings (e.g., sensors or valves). Do not strike sealing surfaces (e.g. working line ports). Leave the protective covers on the axial piston unit until shortly before the linesare connected. Disconnect all electrical connectors before performing electro-welding orpainting operations. Make certain that the electronic components (e.g., sensors) do not becomeelectrostatically charged (e.g., during painting operations).Damage to equipment due to improper lubrication!Product can be damaged or destroyed. Never operate the axial piston unit with insufficient hydraulic fluid. In particular,make sure that the rotary group has sufficient lubrication. When commissioning a machine/system, make sure that the case interior andthe working lines of the axial piston unit are filled with hydraulic fluid and remainfilled during operation. Air inclusions in the forward drive shaft bearing are to beprevented, especially with the installation position “drive shaft upwards”. With the installation position “drive shaft upwards” additional air bleeding is tobe provided via the flushing port U. Check the hydraulic fluid level in the motor housing regularly; if necessary,recommission. With above-reservoir installation, the motor housing may drainvia the drain line after longer standstill periods (air enters via the shaft seal)or via the working line (gap leakage). When switched on, the bearings are thusinsufficiently lubricated.Mixing of hydraulic fluids.Product can be damaged! Before installation, remove all fluids from the axial piston unit to prevent mixingwith the hydraulic fluid used in the machine/system. Any mixing of hydraulic fluids from different manufacturers or different typesfrom the same manufacturer is not generally permitted.Bosch Rexroth AG, A6VM Series 65 and 71, RE 91610-01-B/10.2014

General instructions on damage to property and the product15/60NOTICEContamination of the hydraulic fluid!The cleanliness of the hydraulic fluid has a considerable impact on the cleanlinessand service life of the hydraulic system. Contamination of the hydraulic fluid couldcause premature wear and malfunctions. Make sure that the working environment at the installation site is fully freeof dust and foreign substances in order to prevent foreign particles, such aswelding beads or metal cuttings, from getting into the hydraulic lines andcausing product wear or malfunctions. The axial piston unit must be installed ina clean condition. Use only clean connections, hydraulic lines and attachments (e.g. measuringequipment). No contaminants may enter the ports when they are sealed. Before commissioning, make sure that all hydraulic connections are tight andthat all of the connection seals and plugs are installed correctly to ensure thatthey are leak proof and fluids and contaminants are prevented from penetratingthe product. Use a suitable filter system to filter hydraulic fluid during filling to minimize solidimpurities and water in the hydraulic system.Improper cleaning!Product can be damaged. Plug all openings with the appropriate protection equipment in order to preventcleaning agents from entering the hydraulic system. Never use solvents or aggressive cleaning agents. Use only water and,if necessary, a mild cleaning agent to clean the axial piston unit. Do not point the high-pressure cleaner at sensitive components, e.g., shaft seal,electrical connections and components. Use lint-free cloths for cleaning.Environmental pollution due to incorrect disposal!Careless disposal of the axial piston unit and its fittings, the hydraulic fluid and thepackaging material can lead to pollution of the environment! Dispose of the axial piston unit, hydraulic fluid and packaging in accordancewith the national regulations in your country. Dispose of the hydraulic fluid in accordance with the applicable safety datasheet for the hydraulic fluid.Escaping or spilling hydraulic fluid!Environmental pollution and contamination of groundwater. Always place a drip tray under the axial piston unit when filling and draining thehydraulic fluid. Use an oil binding agent if hydraulic fluid is spilt. Observe the information in the safety data sheet for the hydraulic fluid and thespecifications provided by the system manufacturer.RE 91610-01-B/10.2014, A6VM Series 65 and 71, Bosch Rexroth AG

16/60General instructions on damage to property and the productThe warranty only applies to the delivered configuration.The warranty entitlement is rendered void if the product is incorrectly installed,commissioned or operated, as well as in cases of improper use and/or handling.Bosch Rexroth AG, A6VM Series 65 and 71, RE 91610-01-B/10.2014

Scope of delivery17/604 Scope of delivery111122Fig. 1: Axial piston unitIncluded in the scope of delivery are: Axial piston unit as per order confirmationThe following parts are also fitted prior to delivery: Protective covers (1) Protective plug/threaded plug (2)RE 91610-01-B/10.2014, A6VM Series 65 and 71, Bosch Rexroth AG

18/60About this product5 About this product5.1 Performance descriptionA Axial piston variable motor converts hydrostatic flow into mechanical rotationand controls or regulates this. The A6VM is designed for mobile and stationaryapplications.Refer to data sheets 91607 and 91610 and to the order confirmation for thetechnical data, operating conditions and operating limits of the axial piston unit.5.2 Product descriptionThe A6VM is a variable motor with axial piston rotary group of bent-axis design, forhydrostatic drives in open and closed circuits. For axial piston units with bent-axisdesign, the pistons (7) are arranged at an angle to the drive shaft (1). The pistonsrest directly on the drive shaft where they generate torque depending on thepressure and swivel angle. The specific torque and displacement can be changed byadjusting the bent axis.Open circuitIn the open circuit, the hydraulic fluid flows from the reservoir to the hydraulic pumpfrom where it is transported to the hydraulic motor. From the hydraulic motor, thehydraulic fluid flows directly back to the reservoir. The output direction of rotation ofthe hydraulic motor can be changed, e.g. by a directional valve.Closed circuitIn the closed circuit, the hydraulic fluid flows from the hydraulic pump to thehydraulic motor and from there directly back to the hydraulic pump. The outputdirection of rotation of the hydraulic motor is changed, e.g. by reversing the flowdirection in the hydraulic pump.5.2.1 Layout of the axial piston unit2173654Fig. 2: Layout of the A6VM1 Drive shaft4 Port plate2 Control piston5 Lens plate3 Stroke piston6 CylinderBosch Rexroth AG, A6VM Series 65 and 71, RE 91610-01-B/10.20147 Piston

About this product19/605.2.2 Functional descriptionMotor functionA hydraulic motor converts hydrostatic energy into mechanical energy. Hydraulic fluidis directed via the port plate (4) and the lens plate (5) to the cylinder bores.The pistons (7) in the cylinder bores execute a stroke that is converted into rotarymovement by the piston on the drive shaft flange. During this process, the pistonsmove the cylinder (6) and generate an output torque at the drive shaft. The outputtorque increases with the pressure difference between the high- and low-pressuresides and increasing displacement. The output speed i

Contains additional information on the use of Rexroth axial piston units with HF hydraulic fluids. 90223 Data sheet Information for the use of hydrostatic drives at low temperatures Contains additional information on the use of Rexroth axial piston units at low temperatures. 90300-03-B Manual Storage and preservation of axial piston units