Transcription

Natatorium Design Guide

Table of ContentsIntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3Comfort, Health and Safety . . . . . . . . . . . . . . . . . . 4Comfort and Health . . . . . . . . . . . . . . . . . . . . . . . 4Humidity Control Calculations . . . . . . . . . . . . . . . .Load Calculation . . . . . . . . . . . . . . . . . . . . . . . . .Pool Evaporation . . . . . . . . . . . . . . . . . . . . . . . . .Occupant Load . . . . . . . . . . . . . . . . . . . . . . . . . .Outdoor Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Load Estimation Software . . . . . . . . . . . . . . . . . .555666Humidity Control Technology . . . . . . . . . . . . . . . . .How to Remove Moisture . . . . . . . . . . . . . . . . . . .Refrigeration Based Dehumidifiers . . . . . . . . . . . .Chilled Water with Reheat Air Handler . . . . . . . . .Outdoor Air Ventilation Systems . . . . . . . . . . . . . .77788Indoor Air Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Pool Water Chemistry . . . . . . . . . . . . . . . . . . . . . 9Chlorine Smell . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Pool Water pH Levels . . . . . . . . . . . . . . . . . . . . . 10Total Dissolved Solids . . . . . . . . . . . . . . . . . . . . . 10Humidity and Corrosion . . . . . . . . . . . . . . . . . . . 10Outdoor Ventilation Air . . . . . . . . . . . . . . . . . . . . 10Exhaust Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Air Change Rate . . . . . . . . . . . . . . . . . . . . . . . . 11Condensation Control . . . . . . . . . . . . . . . . . . . . . .Dew Point Temperature . . . . . . . . . . . . . . . . . . .Vapor Retarder . . . . . . . . . . . . . . . . . . . . . . . . . .Window Design . . . . . . . . . . . . . . . . . . . . . . . . .Air Distribution . . . . . . . . . . . . . . . . . . . . . . . . . .1112121313Energy Consumption Considerations . . . . . . . . .Operating Conditions . . . . . . . . . . . . . . . . . . . . .Pool Water Heating Energy Recovery . . . . . . . . .Space Heating . . . . . . . . . . . . . . . . . . . . . . . . . .Space Cooling . . . . . . . . . . . . . . . . . . . . . . . . . .Outdoor Air, Exhaust Air and Energy Recovery . .1515151616162Natatorium Design ManualFinalizing System Design . . . . . . . . . . . . . . . . . . .Key Design Concerns for Traditional Pools . . . . .Step 1: Operating Conditions . . . . . . . . . . . . . . .Step 2: Supply Air . . . . . . . . . . . . . . . . . . . . . . .Step 3: Outdoor Ventilation Air perStandard 62-2004 . . . . . . . . . . . . . . . . .Step 4: Exhaust Air . . . . . . . . . . . . . . . . . . . . . .Step 5: Load Calculations . . . . . . . . . . . . . . . . .Step 6: Condensation and Vapor Migration . . . .Step 7: Energy & LEEDs Considerations . . . . . .191919191920202020Popular Configurations and System Designs . . . 21Hotel and Residential Market . . . . . . . . . . . . . . . 21Purge – Economizer Layout . . . . . . . . . . . . . . . . 22Dehumidifier Specification . . . . . . . . . . . . . . . . . .Service Vestibule . . . . . . . . . . . . . . . . . . . . . . . .Microprocessor Control . . . . . . . . . . . . . . . . . . .WebSentry . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Refrigerant Pressure Transducers . . . . . . . . . . . .Refrigerant System Charges . . . . . . . . . . . . . . . .Receiver Refrigerant Level Indicators . . . . . . . . .Direct Drive Plenum Fans with VFD . . . . . . . . . .Coated Airside Coils . . . . . . . . . . . . . . . . . . . . . .Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Commissioning . . . . . . . . . . . . . . . . . . . . . . . . .First Year Labor . . . . . . . . . . . . . . . . . . . . . . . . .242424242525252525252525Design Installation Details . . . . . . . . . . . . . . . . . .Access Space . . . . . . . . . . . . . . . . . . . . . . . . . .Pool Water Heating (Option) . . . . . . . . . . . . . . . .Outdoor Air Cooled Dry Cooler andCondenser Installation . . . . . . . . . . . . . . . . . . . .Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . .2626262629Frequently Asked Questions . . . . . . . . . . . . . . . . 30

Natatorium Design – IntroductionThe natatorium experience for a patron should be no different to any otherroom in a building. It should be comfortable, healthy and have good airquality. When designing a natatorium the relative humidity, air temperature,pool water temperature, pool activity levels, air distribution, outdoor air,exhaust air and pool water treatment are all key aspects that must beaddressed to provide a good environment.While 50-60% relative humidity levels are ideal for bather comfort and healththey can lead to condensation problems and serious damage to the buildingstructure. If the building structure itself has not been properly designed for thishigher humidity application catastrophic results may occur.IntroDuction3

Comfort, Health and SafetyA natatorium is one of the most notoriously difficultcodes require. More is not better in this case as itcauses the RH levels can plummet to as low as 20%,facilities to design because there are so many criticalcosting the operator in dearly in increased air andconsiderations that, if overlooked, can develop intopool water heating costs.problems with the building structure or into complaintsfrom the occupants. The designer must take a complete Swimmers leaving the water feel chilly at lower relativehumidity levels due to evaporation off their bodies.system approach, from basic engineering issues to themore subtle details in the air distribution. Experience anda complete understanding of the designFigure 1 – Relative Humidity Impacts Occupant Healthissues help the designer satisfy: Comfort and healthHumidity controlIndoor air qualityCondensation controlRelative Humidity Impacts Occupant HealthDecrease in bar width indicatesdecrease in effectBacteriaVirusesComfort and HealthTemperature and relative humidity playa critical role in human comfort levels.It is essential that both are controlledand stable. While temperature controlis generally well understood andmastered by designers, it is importantto recognize the temperature levelsnatatorium patrons expect. The spacetemperatures in a natatorium are uniqueto each project and assumptions mustnever be made.Optimum ZoneFungiMitesRespiratory Infections 1Allergic Rhinitis and AsthmaChemical InteractionOzone Production201Insufficient data above 50% R.H.4060% Relative Humidity80Study by Theodore Sterling Ltd., A. Arundel Research Associates and Simon Fraser University.Proper control of relative humidity levelsare also a concern because of the direct effect onhuman comfort and health. Figure 1 shows that relativehumidity levels outside the optimum zone 40%-60%range can result in human vulnerability to disease.These diseases include bacteria, viruses, fungi, mitesand other contaminants that lower air quality and willpotentially lead to respiratory issues.The type of facility being designed will typically dictatethe space temperature. Table 1 helps target sometypical conditions. It is critical to understand who will beusing the facility in order to deliver the conditions mostlikely to satisfy them.Table 1 – Natatorium Design ConditionsWhile 40% is certainly an acceptableindoor relative humidity level, mostindoor pools do not operate at lowerthan 50% RH due to significantlyincreased operating costs. At lower RH levels, the poolevaporation rate increasesdramatically. This increases both thedehumidification load and the poolwater heating requirement. In cold climate applications it isimportant to ensure no more outdoorair be introduced than what the4Natatorium Design ManualTypical Natatorium Design ConditionsPool TypeAirTemperature ( F)WaterTemperature ( F)Competition75 to 8576 to 82Diving80 to 8584 to 88Elderly Swimmers84 to 8585 to 90Hotel82 to 8582 to 86Physical Therapy80 to 8590 to 95Recreational82 to 8580 to 85Whirlpool/spa80 to 85102 to 104

General Notes: Facilities with warmer water temperatures tend tohave warmer space temperatures. Physical Therapy facilities will often cater to therapistcomfort rather than the patient. The patient isgenerally not in the space for more than an hour,whereas the therapist is there all day. The designershould consult local codes. Some States require a fullpurge of the clinic room air with 100% outdoor air forevery hour of occupancy. Elderly swimmers tend to prefer much warmer air andwater temperatures. Maintain Relative Humidity between 50% & 60% RH.Do not go below 50%.Humidity Control CalculationsAs mentioned previously, 50-60% relative humiditylevels are ideal for bather comfort but they can leadto condensation problems and serious damage to thebuilding structure. If the building structure itself hasnot been properly designed for this higher humidityapplication catastrophic results may occur. The Architectshould design and protect the building enveloped basedon an indoor dew point design condition.Controlling humidity to provide this stable dew pointcondition year round requires that a total moisture loadbe accurately calculated. This moisture load must beremoved from the space at the same rate it is generatedin order to maintain stable space conditions.calculate the baseline (unoccupied) evaporation ratein the natatorium.The Activity Factor is the fifth variable. It is a wateragitation factor. The Activity Factor is used to evaluatehow much water agitation and splashing is expectedwhen the pool is in use and how that increasesthe evaporation from the baseline value. Chapter 4of ASHRAE’s 2011 HVAC Applications Handbookpublishes an Activity Factor table (Table 2) based onyears of empirical field and test data.Table 2 – Activity FactorsLoad CalculationEvery building’s moisture (latent) load is calculated in thesame way. There are generally three sources of moisturethat are considered: Internal load (pool evaporation) Occupants Outdoor air loadPool EvaporationThe internal load in a natatorium is the evaporation fromthe pool water and wet deck surfaces. In a natatoriumthis represents the majority of the total dehumidificationload. Consequently, it is essential to accurately predictthe pool evaporation.Type of PoolActivity FactorElderly swim0.65Fitness club – Aquafit0.65Hotel0.8Institutional - School0.8 – 1.0Physical Therapy0.65Public / YMCA1.0Residential0.5Swim Meet0.65Wave Pool1.5 – 2.0Whirlpool1.0Evaporation Rate Equation:There are 5 variables used to calculate theevaporation rate:Equation #2 in chapter 4 of ASHRAE’s 2011 HVACApplications Handbook calculates the evaporation ratein pounds of water per hour (lb/h) for air velocity overwater @ 10-30 fpm. The Vapor Pressure values can befound in steam tables. ERERAAFPwPool water surface areaPool water temperatureRoom air temperatureRoom air relative humidityPool water agitation and Activity FactorThe first four variables are straightforward andshould be dictated by the owner. They are used to 0.1 x A x AF (Pw – Pdp) evaporation Rate of water, lb/h area of pool water surface, ft2 Activity Factor (see Table 2) saturation vapor pressure at watersurface, in. HgPdp partial vapor pressure at roomdew point, in. HgHUmidity Control Calculations5

It can be seen from the equation that the followingfactors increase the evaporation rate: Increasing water temperatureLowering air temperatureLowering air relative humidityHigh activity/agitationOnce equipment has been selected and installed, anychange of the variables that increases the evaporationrate can result in equipment no longer being suitable forthe new larger load.Occupant LoadSwimmers are not usually considered occupants as theyare submerged in the water. Swimmers and their wateragitation are included in the Activity Factor. Spectators,especially in facilities that host swim meets can totalseveral thousand, and add a significant moisture load,(see Table 3).It is important to understand that when a facility ishosting a swim meet the Activity Factor of the wateris considerably reduced. Typically there is only oneswimmer per lane and while they agitate the waterconsiderably, the overall agitation is much less than adensely occupied pool during a public swim.Table 3 – Occupants Latent LoadActivity LevelLb/h perSpectatorQuietly Seated0.155Moderate Activity0.205Enthusiastic0.250Highly Enthusiastic0.530To evaluate the dehumidification load during swimmeets an Activity Factor of 0.65 is used to calculate theevaporation rate. The total number of spectators andcompetitors on the pool deck must also include in theload. Codes also generally require that each spectatorbe provided with 7.5 CFM of outdoor air. The loadimpact of the outdoor air must also be calculated.Seresco recommends that facilities hosting swimmeets size equipment based on the larger of the twomain operating modes, normal operation load or swimmeet load.6Natatorium Design ManualOutdoor AirThe introduction of outdoor air is essential to maintaininggood air quality in any facility. The impact of this outdoorair ventilation on a natatorium changes with the weatherand the geographic location of the facility. Introducingoutdoor air during the summer generally adds moistureto the space and in the winter removes moisture from thespace. For maximum dehumidification load calculationsthe Summer Design conditions are considered.Construction codes generally require that outdoorair be introduced into a commercial building duringoccupied hours. ASHRAE Standard 62-2004 Table6.1 recommends the introduction of outdoor air into anatatorium at the following rates: 0.48 CFM/ft2 of pool and (wet) deck area as base line 7.5 CFM per spectator added to the base line duringswim meetsASHRAE interprets the wet deck area as no more thansix foot perimeter around the pool. The purpose ofthis outdoor air is to help dilute chemicals off-gassedfrom water. A predictably dry portion of the deck willnot factor into the IAQ issues. Additionally, outdoor airrequires considerable heating in the winter.More is not better. Exceeding code requirements is notrecommended. In winter it will significantly increase theoperating expenses and in summer may increase thedehumidification load.Load Estimation SoftwareSeresco has developed software that calculates allmoisture loads in a matter of minutes. Figure 2 gives asnapshot of the basic data that would generally need tobe entered to calculate a load.Figure 2 – Sample of Seresco’s Load Estimating Software

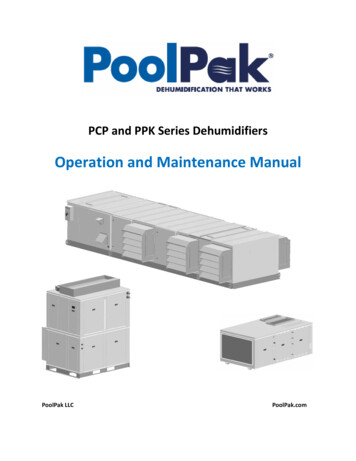

Humidity Control TechnologyHow to Remove MoistureEngineers typically consider one of three approaches toventilate a natatorium. It is important to understand thecapabilities and limitations of each approach in orderto select the best system for the application. Serescomanufactures all three styles of unit and will help youevaluate what is right for your application. Energyconsumption, geographic location, budget and desiredcontrol of space conditions are among some of the keydecision making criteria. Refrigeration based dehumidifiers Chilled water with reheat air handler Outdoor air ventilation (usually with heat recovery)Refrigeration Based DehumidifiersRefrigeration based dehumidifiers are by far the mostcommon and popular method of removing moisturefrom the space. These are the NE Series style unit builtby Seresco. The units are designed and developedspecifically for dehumidifying indoor pools. They offer yearround humidity control at the lowest operating costs.A major benefit of this approach is year round humiditycontrol with low operating costs. These systems useboth sides of the refrigeration cycle (evaporator andcondenser) simultaneously. Contrast this to traditionalair conditioning units that use only the evaporator anddump condenser heat outdoors. These units use theevaporator to dehumidify (and cool when needed)but also put heat back into the pool and/or backinto the process air. This approach is unique to theThe Energy CycleDry Airnatatorium industry. The system can be simultaneouslydehumidifying (cooling) the air and then reheating it (and/or the pool water) to deliver dehumidified and reheatedair to the space, and warm water to the pool. Not asingle BTU on either side of the refrigeration cycle iswasted. COPs are close to 8 and EERs greater than 25!Figures 3 and 4 illustrate schematically how warm humidair passes through the dehumidifying coil and is cooledto below its dew point. Once air is cooled below its dewpoint, moisture condenses out of the air. Depending onthe space temperature requirements the hot gas fromthe compressor can be used to reheat the air or berejected to an outdoor condenser. Compressor hot gascan also be used to heat the pool water. Figure 4 showsan example of these components in a vertical unit.Figure 3 – Packaged Mechanical Refrigeration SystemsOutdoor CondenserHot gasPoolWaterHeaterCool gasWater topoolWater frompoolDryAirPlug FanCompressorHot gasReheat Coil(Condenser)Dehumidifier(Evaporator)DryAirHumid AirHumid AirRecycledHeatEnergyLiquidThermostaticExpansion ValveHumidity Control Technology7

have 100% outdoor air modes for milder weather. It isimportant to note that the space conditions may not bemaintained in summer as the outdoor air may not bedry enough.Figure 4 – Vertical DehumidifierOUTDOORAIRSUPPLYAIRThe outdoor ventilation style units have several attractivefeatures if your facility is located in a suitable geographicarea. They have a lower first cost than a refrigerantbased approach and are also considerably simplerunits. With heat recovery between the exhaust air andoutdoor air streams and controls that properly sequencethe outdoor air, this can be a very attractive means toventilate a natatorium.Electrical PanelReceiver withSight GlassBlower MotorBlowerCompressorRETURNAIRPool Water HeaterAir FiltersEvaporatorReheat coilDrain PanChilled Water with Reheat Air HandlerThese units are not very common and generally onlyfound on applications that have abundant chilled wateryear round and installing a refrigerant based systemproves problematic. The dehumidification processof these systems is essentially the same as withcompressorized systems. The chilled water supplytemperature must be low enough to cool the air belowits dew point at the chilled water coil and condensemoisture out of the air. Reheat is required for most ofthe year. Systems that cannot use captured condenserheat for reheating air require the operation of a heatingcoil while the chilled water coil is in use. If reclaimed heatis not available for reheat, this approach does not meetmost energy codes. This approach is not recommendedif chilled water is not available year round.Outdoor AirVentilation SystemsWhile not technically a dehumidifier, becauseonly outdoor air is used, this approachis considered in areas that are dry and/or cool outdoors year round. Solutionscan be a very basic, from a single pass ofoutdoor air that is introduced at one end ofthe space and exhausted at the other to amore sophisticated system that has variableoutdoor air and heat recovery. The singlepass system is rare due to the prohibitiveoperating costs.A more typical approach is the Seresco NVseries style ventilation unit. These units provideventilation air, heat recovery, heating and also8Natatorium Design ManualThere is a misconception that because these systemsprovide more outdoor air than a refrigeration basedunit that the spaces as a result will have much betterair quality. This is not correct. The airside designrequirements are the same for a Natatorium regardlessof which solution is chosen. Supply air CFM, minimumoutdoor air CFM and minimum exhaust air CFMrequirements are identical for all systems.Some manufacturers promote more outdoor air thancodes require in order to ensure good IAQ. Seresco doesnot recommended this approach because it increasesbuilding operating costs and still may not have any suchimpact on the space if the air distribution is not donecorrectly. A better solution is to stick with the ASHRAEguidelines and ensure the air distribution is correct.System comparisons and features are highlighted intable 4. Note: The table assumes all units are designedwith the same airside characteristics.Table 4 – System ComparisonRefrigerationChilledWaterOutdoor AirVentilationOperating CostLowestHIghestMediumFirst CostHighestMediumLowestYear round humidity controlYesYesWeatherdependantMeets/exceeds EnergyStandard 90.1YesNoNoDehumidification energy recoveryYesNoNoHeat recovery on Exhaustand Outdoor airOptionOptionOptionFree summertime ACYesYesNoFree summertime poolwater heatingYesNoNo

Indoor Air QualityGood indoor air quality can be a challenge in an indoorpool. However, designers that follow ASHRAE guidelinesas well as those addressed in this manual shouldhave every expectation of a great space conditionand pleasant overall experience for the patrons of thefacility. There are steps a design engineer must takein their design to minimize the chances that a patronexperiences a foul smelling pool odor and stingingeyes. There are many factors that impact the IAQ in anatatorium: pool water chemistry problems, inadequateoutdoor air, air stagnation, poor air distribution, highhumidity, mold, mildew, condensation and corrosion.Four of the five key factors having the mostdirect impact on Indoor Air Quality (IAQ) areunder the control of the design engineer. Pool water chemistryPoor air distribution: No Airflow in the Breathing Zone.Outdoor air ventilationExhaust airAir change rateChemical off gassing from the pool water isthe pollutant that causes all the IAQ issuesin a natatorium. A successful HVAC designwill adequately remove these chemicals andprovide good IAQ by properly addressing thefour key airside design requirements.Pool Water Chemistry is the key variable thatimpacts IAQ and is not under the responsibilityof the design engineer.Poor water chemistry is the single biggestsource of indoor air pollution and corrosionproblems in a Natatorium.Ultraviolet light (UV) treatment of poolwater has shown to have a very positiveChlorine smellWhen you walk into an indoor pool and smell a strongchlorine odor, you naturally think it’s caused by toomuch chlorine in the water. The odor is actually causedby chloramines (combined chlorines) off gassing fromthe pool water surface. Chloramines are formed in thepool water when there is insufficient free chlorine in thepool to address the nitrogen-containing compoundsbrought into the pool water by the swimmers. Thesenitrogen compounds are naturally-occurring andcontained in sweat, urine, body oils and other proteinsthat get released into the pool water. If the introductionof these nitrogen compounds outpaces the introductionof free chlorine the chlorine becomes combined with thenitrogen compounds rather than fully oxidizing them.The chloramine (combined chlorine) levels increase inthe water, resulting in an increase in chloramine offgassing, which creates the odor of chlorine in the room.There are three different types of chloramines that canform: monochloramine, dichloramine and trichloramine.Trichloramine is the most volatile and will off-gasmost quickly.The powerful chlorine smell that is often associatedwith indoor pools is NOT the result of too much freechlorine in the water; it is TOO LITTLE free chlorine thatis the culprit!Pool Water ChemistryGood pool water chemistry by the buildingoperator is critical in order to achieve levelsof human comfort and health. Also bymaintaining optimal pool water conditionsyou will have the best possible indoor airquality and ensure optimal performancefrom the mechanical system.impact on the water chemistry and can help reduce,if not totally eliminate chloramines. This approach toenhance water treatment is gaining popularity and aspositive data continues to come should become moreand more common.To avoid chloramines it is imperative to maintain properfree chlorine and pH levels as outlined in table 5.Table 5 – National Spa and Pool Institute Recommended Levels forWater QualityPool Water Chemistry Parameters Recommended by NSPIPoolsWhirlpoolsDesirable RangeDesirable RangepH7.4 – 7.67.4 – 7.6Alkalinity80 – 100 PPM80 – 100 PPMFree Chlorine2.0 – 3.0 PPM3.0 – 4.0 PPMCombinedChlorine0 PPM0 PPMDissolved Soli ds100 – 300 PPM100 – 300 PPMTotal Hardness225 – 250 PPM175 – 275 PPMIndoor Air Quality9

Off-gassed chloramines also have a strong attraction tothe airborne humidity which will combine with moisturein the air. Consequently, any condensation of the spacehumidity will become corrosive. An example of this cansometimes be seen at pools with chloramines problemswhere the ladder rails outside the water corrode whilethe portion under water does not.The proper balance of outdoor air and room exhaustair along with air movement at the water surface is alsocrucial to ensuring chemical concentration levels aremaintained within acceptable levels.Pool Water pH LevelsHigh pH levels (alkaline range) encourage scaleformation, which reduces pool water heater efficiency.With low pH levels the water is acidic and corrosive. Thismay damage the metal parts in pumps, water heatersand piping. Maintaining pH levels between 7.2 and 7.6will ensure the longest life for the pool equipment.Total Dissolved SolidsIt is imperative that pool water filters are routinely backwashed and that total dissolved solids monitored. Highquantities of total dissolved solids will overrun the freechlorine levels and form chloramines.A proper pool water test kit should monitor theparameters seen in table 5.Humidity and CorrosionAs previously mentioned, off-gassed chloramineshave a strong attraction to the airborne humidity andwill combine with moisture in the air. Consequentlyany condensation of the space humidity will becomecorrosive. It is critical that the space humidity levels becontrolled such that condensation is prevented as it willdamage the building and mechanical system. Serescounits are built for a pool environment. All electrical andrefrigeration components are out of the pool air andin a protective service vestibule. The components incontact with the pool air stream are protected with thebest possible corrosion resistant paints, coatings andmaterials. Seresco units are built to last!By design, indoor pool environments arewarmer and have higher moisture levelscompared to traditional spaces.Engineers and architects must understand theconsequences of this and pay special attention to thespecial requirements on the entire HVAC system andbuilding envelope.10Natatorium Design ManualOutdoor Ventilation AirThe amount of outdoor air to be introduced to the facilityis determined by construction codes. Most codes adoptASHRAE Standard 62. Outdoor air is critical towardsdiluting airborne chemicals and maintaining good indoorair quality.Facilities that introduce outdoor air per ASHRAEStandard 62 and have proper air distribution have thebest IAQ. More outdoor air than required by ASHRAE Standard62 is not recommended (except water parks) Outdoor air requires a significant amount of heatingenergy in the winter and must be included in heatload calculations. Heat recovery should be considered between theexhaust air and outdoor air streams. Exceeding code amounts is not recommended,as it creates extremely high operating expenses.Engineers must ensure condensation is avoided.Wintertime outdoor air is cold and in summerit can be very humid. Both scenarios can leadto condensation. Introduce the outdoor air at the factory providedintakes on the air handlers Locate outdoor air intakes away from sources ofairborne contamination such as exhaust fans orplumbing vents. The outdoor air must be preheated to 65 F – If morethan 20% of the total airflow is outdoor air or if thewinter design temperature is below 10 F A certified air-balancing contractor must balance thesystem airflow.All Seresco units are equipped with an outdoor airconnection, filter and balancing damper. Motorizeddampers and time clocks are also available.Exhaust AirASHRAE recommends the room be maintainedat 0.05-0.15” WC negative pressure relative tosurrounding spaces.Ten percent more exhaust air than outdoor air is a goodrule of thumb.More exhaust air than recommended by ASHRAE willnot reduce or stop moisture migration through thebuilding envelope to outdoors in cold weather. Vapormigrates based on vapor pressure differential. Thereis effectively a 10” WC pressure differential betweenindoors and outdoors on cold winter days. There is noamount of negative airside pressure you can put into aspace to stop vapor migration. The building envelope

must be designed by the architectto adequately deal with this byplacing vapor retarders in appropriatelocations in the entire buildingenvelope.Figure 5 illustrates how the strategiclocation of the exhaust grille can alsosignificantly impr

water heating requirement . in cold climate applications it is important to ensure no more outdoor air be introduced than what the codes require . more is not better in this case as it causes the rH levels can plummet to as low as 20%, costing the operator in dearly in increased air and pool water heating costs .