Transcription

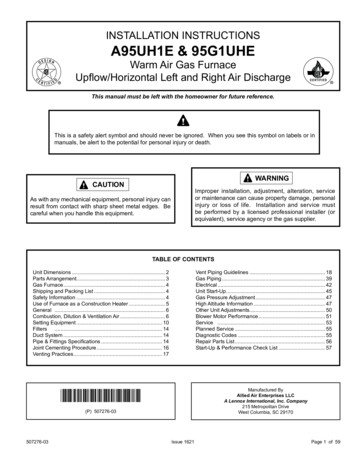

INSTALLATION INSTRUCTIONSA95UH1E & 95G1UHEWarm Air Gas FurnaceUpflow/Horizontal Left and Right Air DischargeThis manual must be left with the homeowner for future reference.This is a safety alert symbol and should never be ignored. When you see this symbol on labels or inmanuals, be alert to the potential for personal injury or death.WARNINGCAUTIONImproper installation, adjustment, alteration, serviceor maintenance can cause property damage, personalinjury or loss of life. Installation and service mustbe performed by a licensed professional installer (orequivalent), service agency or the gas supplier.As with any mechanical equipment, personal injury canresult from contact with sharp sheet metal edges. Becareful when you handle this equipment.TABLE OF CONTENTSVent Piping Guidelines. 18Gas Piping. 39Electrical. 42Unit Start-Up. 45Gas Pressure Adjustment. 47High Altitude Information. 47Other Unit Adjustments. 50Blower Motor Performance. 51Service . 53Planned Service. 55Diagnostic Codes. 55Repair Parts List. 56Start-Up & Performance Check List. 57Unit Dimensions. 2Parts Arrangement. 3Gas Furnace. 4Shipping and Packing List. 4Safety Information. 4Use of Furnace as a Construction Heater. 5General . 6Combustion, Dilution & Ventilation Air. 6Setting Equipment. 10Filters . 14Duct System. 14Pipe & Fittings Specifications. 14Joint Cementing Procedure. 16Venting Practices. 17Manufactured ByAllied Air Enterprises LLCA Lennox International, Inc. Company215 Metropolitan DriveWest Columbia, SC 29170*P507276-03*(P) 507276-03507276-03Issue 1621Page 1 of 59

A95UH1E & 95G1UHE Unit Dimensions - inches (mm)1 NOTE - C20 and D20 (5 Ton) size units installed in upflowapplications that require air volumes of 1800 cfm (850 L/s) orgreater must have one of the following:1. Single side return air with transition, to accommodate20 x 25 x 1 in. (508 x 635 x 25 mm) cleanable air filter.(Required to maintain proper air velocity.)2. Single side return air with optional “RAB” Return AirBase.3. Bottom return air.4. Return air from both sides.5. Bottom and one side return air.See “Blower Performance Tables” for additional information.2 Optional External Side Return Air Filter kit is not for use withoptional Return Air Base.* Consider sizing requirements for optional IAQ equipment beforecutting side return opening.FRONT VIEWModelA95UH1E & 95G1UHEPage 2 of 59SIDE 135-2024-1/262223-3/85942358411-1/8283Issue 1621507276-03

EXPANDED VIEWFigure 1507276-03Issue 1621Page 3 of 59

A95UH1E & 95G1UHE Gas FurnaceThe A95UH1E and 95G1UHE Category IV gas furnace isshipped ready for installation in the upflow or horizontalposition. The furnace is shipped with the bottom panel inplace. The bottom panel must be removed if the unit is tobe installed in horizontal or upflow applications with bottomreturn air.The A95UH1E and 95G1UHE can be installed as either aDirect Vent or a Non-Direct Vent gas central furnaceThe furnace is equipped for installation in natural gasapplications. A conversion kit (ordered separately) isrequired for use in propane/LP gas applications.NOTE: In Direct Vent installations, combustion air is takenfrom outdoors and flue gases are discharged outdoors. InNon-Direct Vent installations, combustion air is taken fromindoors or ventilated attic or crawlspace and flue gases aredischarged outdoors. See Figures 2 and 3 for applicationsinvolving roof termination.Shipping and Packing List1 - Assembled Gas Furnace1 - Bag assembly containing the following:1 - Snap bushing1 - Snap Plug1 - Wire tie1 - Condensate trap1 - Condensate trap cap1 - Condensate trap clamp1 - 2” diameter debris screen1 - 3/4” Threaded street elbowCheck equipment for shipping damage. If you find anydamage, immediately contact the last carrier.Please refer to specification sheets for available accessories.Safety InformationWARNINGImproper installation, adjustment, alteration, serviceor maintenance can cause property damage, personalinjury or loss of life. Installation and service mustbe performed by a licensed professional installer (orequivalent), service agency or the gas supplier.CAUTIONAs with any mechanical equipment, personal injury canresult from contact with sharp sheet metal edges. Becareful when you handle this equipment.DANGERDANGER OF EXPLOSION!Figure 2There are circumstances in which odorant used withLP/Propane gas can lose its scent. In case of a leak,LP/Propane gas will settle close to the floor and may bedifficult to smell. An LP/Propane leak detector shouldbe installed in all LP applications.Use only the type of gas approved for use with this furnace.Refer to unit nameplate.A95UH1E & 95G1UHE units are CSA International certifiedto ANSI Z21.47 and CSA 2.3 standards.Figure 3Page 4 of 59Building CodesIn the USA, installation of gas furnaces must conform withlocal building codes. In the absence of local codes, unitsmust be installed according to the current National FuelGas Code (ANSI Z223.1/NFPA 54). The National Fuel GasCode is available from the American National StandardsInstitute,Inc., 11 West 42nd Street, New York, NY 10036.Issue 1621507276-03

In Canada, installation must conform with current NationalStandard of Canada CSA-B149 Natural Gas and PropaneInstallation Codes, local plumbing or waste water codes andother applicable local codes.In Canada, all electrical wiring and grounding for the unitmust be installed according to the current regulations ofthe Canadian Electrical Code Part I (CSA Standard C22.1)and/or local codes.In order to ensure proper unit operation in non-direct ventapplications, combustion and ventilation air supply must beprovided according to the current National Fuel Gas Codeor CSA-B149 standard.Heating Unit Installed Parallet to Air Handler UnitInstallation LocationsThis furnace is CSA International certified for installationclearances to combustible material as listed on the unitnameplate and in the table in Figure 13 and 18. Accessibilityand service clearances must take precedence over fireprotection clearances.NOTE: For installation on combustible floors, the furnaceshall not be installed directly on carpeting, tile, or othercombustible material other than wood flooring.For installation in a residential garage, the furnace must beinstalled so that the burner(s) and the ignition source arelocated no less than 18 inches (457 mm) above the floor.The furnace must be located or protected to avoid physicaldamage by vehicles. When a furnace is installed in a publicgarage, hangar, or other building that has a hazardousatmosphere, the furnace must be installed according torecommended good practice requirements and currentNational Fuel Gas Code or CSA B149 standards.NOTE: Furnace must be adjusted to obtain a temperaturerise within the range specified on the unit nameplate. Failureto do so may cause erratic limit operation and prematureheat exchanger failure.This furnace must be installed so that its electricalcomponents are protected from water.Installed in Combination with a Cooling CoilWhen this furnace is used with cooling units (Figure 4),it shall be installed in parallel with, or on the upstreamside of, cooling units to avoid condensation in the heatingcompartment. With a parallel flow arrangement, a damper(or other means to control the flow of air) must adequatelyprevent chilled air from entering the furnace. If the damper ismanually operated, it must be equipped to prevent operationof either the heating or the cooling unit, unless it is in thefull HEAT or COOL setting.When installed, this furnace must be electrically groundedaccording to local codes. In addition, in the United States,installation must conform with the current National ElectricCode, ANSI/NFPA No. 70. The National Electric Code(ANSI/NFPA No. 70) is available from the following address:National Fire Protection Association1 Battery March ParkQuincy, MA 02269507276-03Figure 4NOTE: This furnace is designed for a minimum continuousreturn air temperature of 60 F (16 C) or an intermittentoperation down to 55 F (13 C) dry bulb for cases where anight setback thermostat is used. Return air temperaturemust not exceed 85 F (29 C) dry bulb.This furnace may be installed in alcoves, closets, attics,basements, garages, and utility rooms in the upflow orhorizontal position.This furnace design has not been CSA certified for installationin mobile homes, recreational vehicles, or outdoors.Use of Furnace as a Construction HeaterThese units are not recommended for use as a constructionheater during any phase of construction. Very low return airtemperature, harmful vapors and operation of the unit withclogged or misplaced filters will damage the unit.These units may be used for heating of buildings orstructures under construction, if the following conditionsare met: The vent system must be permanently installed perthese installation instructions. A room thermostat must control the furnace. The useof fixed jumpers that will provide continuous heating isnot allowed. The return air duct must be provided and sealed to thefurnace. Return air temperature range between 60 F (16 C) and80 F (27 C) must be maintained. Air filters must be installed in the system and must bemaintained during construction. Air filters must be replaced upon construction completion.Issue 1621Page 5 of 59

The input rate and temperature rise must be set per thefurnace rating plate.One hundred percent (100%) outdoor air must be providedfor combustion air requirements during construction.Temporary ducting may supply outdoor air to the furnace.Do not connect duct directly to the furnace. Size thetemporary duct following the instructions in section forCombustion, Dilution and Ventilation Air in a confinedspace with air from outside.The furnace heat exchanger, components, duct system,air filters and evaporator coils must be thoroughlycleaned following final construction cleanup.All furnace operating conditions (including ignition, inputrate, temperature rise and venting) must be verifiedaccording to these installation instructions.GeneralThese instructions are intended as a general guide and donot supersede local codes in any way. Consult authoritieshaving jurisdiction before installation.In addition to the requirements outlined previously, thefollowing general recommendations must be consideredwhen installing one of these furnaces: WARNINGThe State of California has determined that this productmay contain or produce a chemical or chemicals, invery low doses, which may cause serious illness ordeath. It may also cause cancer, birth defects or otherreproductive harm.Combustion, Dilution & Ventilation AirIf this unit is installed as a Non-Direct Vent Furnace,follow the guidelines in this section.NOTE: In Non-Direct Vent Installations, combustion air istaken from indoors and flue gases are discharged outdoors.WARNINGInsufficient combustion air can cause headaches,nausea, dizziness or asphyxiation. It will also causeexcess water in the heat exchanger resulting in rustingand premature heat exchanger failure. Excessiveexposure to contaminated combustion air will resultin safety and performance related problems. Avoidexposure to the following substances in the combustionair supply:Place the furnace as close to the center of the airdistribution system as possible. The furnace shouldalso be located close to the vent termination point.When the furnace is installed in non-direct ventapplications, do not install the furnace where draftsmight blow directly into it. This could cause impropercombustion and unsafe operation.When the furnace is installed in non-direct ventapplications, do not block the furnace combustion airopening with clothing, boxes, doors, etc. Air is neededfor proper combustion and safe unit operation.When the furnace is installed in an attic or otherinsulated space, keep insulation away from the furnace.When the furnace is installed in an unconditioned space,consider provisions required to prevent freezing ofcondensate drain system.Permanent wave solutionsChlorinated waxes and cleanersChlorine base swimming pool chemicalsWater softening chemicalsDe-icing salts or chemicalsCarbon tetrachlorideHalogen type refrigerantsCleaning solvents (such as perchloroethylene)Printing inks, paint removers, varnishes, etc.Hydrochloric acidCements and gluesAntistatic fabric softeners for clothes dryersMasonry acid washing materialsNOTE: The Commonwealth of Massachusetts stipulatesthese additional requirements: Gas furnaces shall be installed by a licensed plumberor fitter only.The gas cock must be “T handle” type.When a furnace is installed in an attic, the passagewayto and service area surrounding the equipment shall befloored.CAUTIONThese units should not be installed in areas normallysubject to freezing temperatures.Page 6 of 59In the past, there was no problem in bringing in sufficientoutdoor air for combustion. Infiltration provided all the airthat was needed. In today’s homes, tight constructionpractices make it necessary to bring in air from outside forcombustion. Take into account that exhaust fans, appliancevents, chimneys, and fireplaces force additional air thatcould be used for combustion out of the house. Unlessoutsideair is brought into the house for combustion, negativepressure (outside pressure is greater than inside pressure)will build to the point that a down draft can occur in thefurnace vent pipe or chimney. As a result, combustionIssue 1621507276-03

gases enter the living space creating a potentially dangeroussituation.In the absence of local codes concerning air for combustionand ventilation, use the guidelines and procedures in thissection to install these furnaces to ensure efficient and safeoperation. You must consider combustion air needs andrequirements for exhaust vents and gas piping. A portionof this information has been reprinted with permission fromthe National Fuel Gas Code (ANSI-Z223.1/NFPA 54). Thisreprinted material is not the complete and official positionof ANSI on the referenced subject, which is representedonly by the standard in its entirely.In Canada, refer to the CSA B149 Installation codes.All gas-fired appliances require air for the combustionprocess. If sufficient combustion air is not available, thefurnace or other appliance will operate inefficiently andunsafely. Enough air must be provided to meet the needs ofCAUTIONDo not install the furnace in a corrosive or contaminatedatmosphere. Meet all combustion and ventilation airrequirements, as well as all local codes.all fuel-burning appliances and appliances such as exhaustfans which force air out of the house. When fireplaces,exhaust fans, or clothes dryers are used at the same timeas the furnace, much more air is required to ensure propercombustion and to prevent a down draft. Insufficient aircauses incomplete combustion which can result in carbonmonoxide.In addition to providing combustion air, fresh outdoor airdilutes contaminants in the indoor air. These contaminantsmay include bleaches, adhesives, detergents, solvents andother contaminants which can corrode furnace components.infiltration. If the furnace is located in a building of tightconstruction with weather stripping and caulking aroundthe windows and doors, follow the procedures in the “Airfrom Outside” section.Confined SpaceA confined space is an area with a volume less than 50cubic feet (1.42 m³) per 1,000 Btu (.29 kW) per hour ofthe combined input rating of all appliances installed in thatspace. This definition includes furnace closets or smallequipment rooms.When the furnace is installed so that supply ducts carryair circulated by the furnace to areas outside the spacecontaining the furnace, the return air must be handled byducts which are sealed to the furnace casing and whichterminate outside the space containing the furnace. Thisis especially important when the furnace is mounted ona platform in a confined space such as a closet or smallequipment room. Even a small leak around the base of theunit at the platform or at the return air duct connection cancause a potentially dangerous negative pressure condition.Air for combustion and ventilation can be brought into theconfined space either from inside the building or fromoutside.Air from InsideIf the confined space that houses the furnace adjoins aspace categorized as unconfined, air can be brought in byproviding two permanent openings between the two spaces.Each opening must have a minimum free area of 1 squareinch (645 mm²) per 1,000 Btu (.29 kW) per hour of totalinput rating of all gas-fired equipment in the confined space.Each opening must be at least 100 square inches (64516mm²). One opening shall be within 12 inches (305 mm) ofthe top of the enclosure and one opening within 12 inches(305 mm) of the bottom. See Figure 5.The requirements for providing air for combustion andventilation depend largely on whether the furnace is installedin an unconfined or a confined space.Unconfined SpaceAn unconfined space is an area such as a basement or largeequipment room with a volume greater than 50 cubic feet(1.42 m³) per 1,000 Btu (.29 kW) per hour of the combinedinput rating of all appliances installed in that space. Thisspace also includes adjacent rooms which are not separatedby a door. Though an area may appear to be unconfined,it might be necessary to bring in outdoor air for combustionif the structure does not provide enough air by infiltration.If the furnace is located in a building of tight constructionwith weather stripping and caulking around the windowsand doors, follow the procedures in the “Air from Outside”section.one 90o elbow. The minimum length certified for use withthis furnace is 5’ and one elbow, not including the vent andair intake terminals.507276-03Issue 1621Equipment in Confined Space - All Air From InsideFigure 5Page 7 of 59

Air from OutsideIf air from outside is brought in for combustion andventilation, the confined space shall be provided with twopermanent openings. One opening shall be within 12” (305mm) of the top of the enclosure and one within 12” (305mm) of the bottom. These openings must communicatedirectly or by ducts with the outdoors or spaces (crawl orattic) that freely communicate with the outdoors or indirectlythrough vertical ducts. Each opening shall have a minimumfree area of 1 square inch per 4,000 Btu (645 mm² per .59kW) per hour of the total input rating of all equipment in theenclosure (See Figures 6 and 7). It is also permissible tobring in air for combustion from a ventilated attic (Figure 9)or ventilated crawl space (Figure 10).Equipment in Confined Space - All Air from Outside(All Air through Ventilated Attic)Equipment in Confined Space - All Air from Outside(Inlet Air from Crawl Space and Outlet Air to Ventilated Attic)Figure 7Equipment in Confined Space - All Air from OutsideROOF TERMINATEDEXHAUST PIPEFigure 6OUTLET AIRWhen communicating with the outdoors through horizontalducts, each opening shall have a minimum free area of 1square inch (645 mm²) per 2,000 Btu (.56 kW) per hour ofthe total input rating of all equipment in the enclosure. SeeFigure 8.When ducts are used, they shall be of the same crosssectional area as the free area of the openings to which theyconnect. The minimum dimension of rectangular air ductsshall be no less than 3 inches (75 mm). In calculating freearea, the blocking effect of louvers, grilles, or screens mustbe considered. If the design and free area of protectivecovering is not known for calculating the size openingrequired, it may be assumed that wood louvers will have 20to 25 percent free area and metal louvers and grilles willhave 60 to 75 percent free area. Louvers and grilles must befixed in the open position or interlocked with the equipmentso that they are opened automatically during equipmentoperation.Page 8 of 59Issue 1621SIDE WALLTERMINATEDEXHAUST PIPE(ALTERNATELOCATION)FURNACEINLET AIRNOTE Each air duct opening shall have a free area of at least onesquare inch per 2,000 Btu (645mm 2 per .59kW) per hour of the totalinput rating of all equipment in the enclosure. If the equipment roomis located against an outside wall and the air openings communicate directly with the outdoors, each opening shall have a free areaof at least 1 square inch per 4,000 Btu (645mm 2 per 1.17kW) perhour of the total input rating of all other equipment in the enclosure.Figure 8507276-03

Equipment in Confined Space(Inlet Air from Ventilated Attic and Outlet Air to Outside)Shipping Bolt RemovalUnits with 1/2 hp & 3/4 hp blower motor are equipped withthree flexible legs and one rigid leg. The rigid leg is equippedwith a shipping bolt and a flat white plastic washer (ratherthan the rubber mounting grommet used with a flexiblemounting leg). See Figure 11. The bolt and washer mustbe removed before the furnace is placed into operation.After the bolt and washer have been removed, the rigid legwill not touch the blower housing.Units with 1/2 HP & 3/4 HPBlower MotorFigure 9Figure 11INSTALLATIONSetting EquipmentEquipment in Confined Space(Inlet Air from Ventilated Crawlspace and Outlet Air to Outside)WARNINGDo not connect the return air ducts to the back of thefurnace. Doing so will adversely affect the operation ofthe safety control devices, which could result in personalinjury or death.WARNINGBlower access panel must be securely in place whenblower and burners are operating. Gas fumes, whichcould contain carbon monoxide, can be drawn into livingspace resulting in personal injury or death.Figure 10Upflow ApplicationsThe gas furnaces can be installed as shipped in the upflowposition. Refer to Figure 13 for clearances. Select a locationthat allows for the required clearances that are listed onthe unit nameplate. Also consider gas supply connections,electrical supply, vent connection, condensate trap anddrain connections, and installation and service clearances[24 inches (610 mm) at unit front]. The unit must be levelfrom side to side. Tilt the unit slightly (maximum 1/2in. from level) from back to front to aid in the drainingof the heat exchanger. See Figure 12.Allow for clearances to combustible materials as indicatedon the unit nameplate.507276-03Issue 1621Page 9 of 59

Setting EquipmentUnit must be level side-to-side in all applications.Tilt the unit slightly (Max. 1/2”) from back to front to aid in the draining ofthe heat exchanger.Figure 12Page 10 of 59Issue 1621507276-03

WARNINGImproper installation of the furnace can result inpersonal injury or death. Combustion and flue productsmust never be allowed to enter the return air systemor air in the living space. Use sheet metal screws andjoint tape to seal return air system to furnace.In platform installations with furnace return, the furnaceshould be sealed airtight to the return air plenum. Adoor must never be used as a portion of the return airduct system. The base must provide a stable supportand an airtight seal to the furnace. Allow absolutely nosagging, cracks, gaps, etc.For no reason should return and supply air duct systemsever be connected to or from other heating devices suchas a fireplace or stove, etc. Fire, explosion, carbonmonoxide poisoning, personal injury and/or propertydamage could result.Return Air GuidlinesReturn air can be brought in through the bottom or eitherside of the furnace installed in an upflow application. If thefurnace is installed on a platform with bottom return, makean airtight seal between the bottom of the furnace and theplatform to ensure that the furnace operates properly andsafely. The furnace is equipped with a removable bottompanel to facilitate installation.Markings are provided on both sides of the furnace cabinetfor installations that require side return air. Cut the furnacecabinet at the maximum dimensions shown on page 2.Furnace applications which include side return air and acondensate trap installed on the same side of the cabinet(trap can be installed remotely within 5 ft.) require either areturn air base or field-fabricated transition to accommodatean optional IAQ accessory taller than 14.5”. See Figure 14.Side Return Air(with Transition and Filter)Installation ClearancesTopLeft SideRight SideBottom (Floor)Top/Plenum1 in. (25 mm)*Front0Back0Sides0†Vent0Floor0‡Figure 14*Front clearance in alcove installation must be 24 in. (610 mm).Maintain a minimum of 24 in. (610 mm) for front service access.†Allow proper clearances to accommodate condensate trap.‡For installations on a combustible floor, do not install the furnace directlyon carpeting, tile or other combustible materials other than woodflooring.Figure 13507276-03Issue 1621Page 11 of 59

Optional Return Air Base(Upflow Applications Only)Figure 15Removing the Bottom PanelRemoving the Bottom PanelRemove the two screws that secure the bottom cap to thefurnace. Pivot the bottom cap down to release the bottompanel. Once the bottom panel has been removed, reinstallthe bottom cap. See Figure 16.Horizontal ApplicationsWARNINGDo not install the furnace on its front or its back. SeeFigure 17.Figure 16Figure 17Page 12 of 59Issue 1621507276-03

Typical Horizontal ApplicationHorizontal ApplicationInstallation ClearancesRight Hand DischargeL e ft E n dR ight E ndAirFlowAirFlowBottom (Floor)**Left Hand DischargeTopL e ft E n dR ight E ndFigure 19AirFlowAirFlowBottom (Floor)**Top0Front*0Back0Ends0Vent0Floor0‡NOTE: Heavy-gauge sheet metal straps may be used tosuspend the unit from roof rafters or ceiling joists. Whenstraps are used to suspend the unit in this way, supportmust be provided for both the ends. The straps must notinterfere with the plenum or exhaust piping installation.Cooling coils and supply and return air plenums mustbe supported separately.* Front clearance in alcove installation must be 24 in. (610 mm).Maintain a minimum of 24 in. (610 mm) for front service access.**An 8" service clearance must be maintained below the unit to providefor servicing of the condensate trap.‡For installations on a combustible floor, do not install the furnace directlyon carpeting, tile or other combustible materials other than woodflooring.NOTE: When the furnace is installed on a platform or withthe horizontal suspension kit in a crawl space, it must beelevated enough to avoid water damage, accommodatedrain trap and to allow the evaporator coil to drain.Figure 18This furnace can be installed in horizontal applications witheither right or left hand air discharge.Refer to Figure 18 for clearances in horizontal applications.Suspended Installation of Horizontal UnitThis furnace may be installed in either an attic or a crawlspace. Either suspend the furnace from roof rafters or floorjoists, as shown in Figure 19, or install the furnace on aplatform, as shown in Figure 20. A horizontal suspensionkit (51W10) may be ordered from your distributor or useequivalent.507276-03Platform Installation of Horizontal Unit1. Select location for unit keeping in mind service and othernecessary clearances. See Figure 18.2. Construct a raised wooden frame and cover frame with aplywood sheet. If unit is installed above finished space,fabricate an auxiliary drain pan to be installed under unit.Set unit in drain pan as shown in Figure 20. Leave 8inches for service clearance below unit for condensatetrap.3. Provide a service platform in front of unit. Wheninstalling the unit in a crawl space, a proper supportplatform may be created using cement blocks.4. Route auxiliary drain line so that water draining fromthis outlet will be easily noticed by the homeowner.5. If necessary, run the condensate line into a condensatepump to meet drain line slope requirements. The pumpmust be rated for use with condensing furnaces. Protectthe condensate discharge line from the pump to theoutside to avoid freezing.6. Continue with exhaust, condensate and intake pipinginstallation according to instructions.Issue 1621Page 13 of 59

Duct SystemUse industry approved standards to size and install thesupply and return air duct system. This will result in a quietand low-static system that has uniform air distribution.NOTE: This furnace is not certified for operation in heatingmode (indoor blower operating at selected heating speed)with an external static pressure which exceeds 0.5 inchesw.c. Operation at these conditions may result in improperlimit operation.Supply Air PlenumIf the furnace is installed wit

Installation Locations This furnace is CSA International certified for installation clearances to combustible material as listed on the unit nameplate and in the table in Figure 13 and 18. Accessibility and service clearances must take precedence over fire protection clearances. NOTE: For installation on combustible floors, the furnace