Transcription

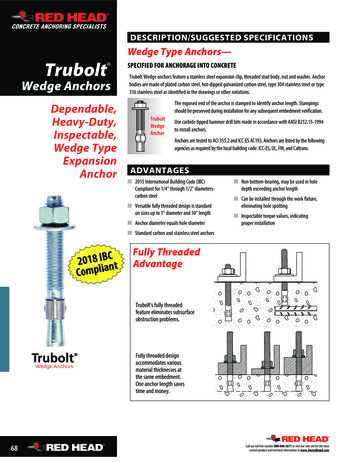

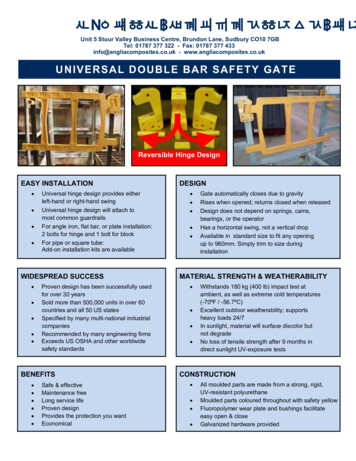

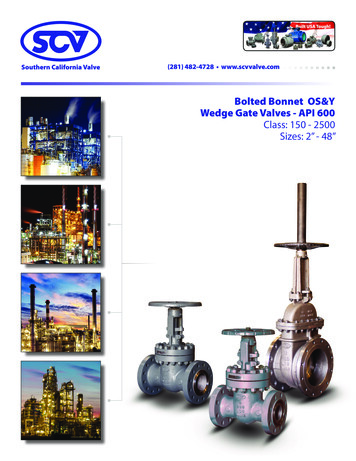

(281) 482-4728 www.scvvalve.comBolted Bonnet OS&YWedge Gate Valves - API 600Class: 150 - 2500Sizes: 2” - 48”

SOUTHERN CALIFORNIA VALVE manufactures superior cast body,bolted bonnet globe valves in a variety of materials, trims, packingtypes, sizes (2” thru 48”) and pressure classes (150 thru 2500). Themechanical characteristics (moveable disc and stationary seat ring)make the SCV globe valve ideal for repeatable pipeline unidirectionalthrottling applications and frequent operation.The valve design conforms to API 598 and B16.34. Face-to-face andend-to-end dimensions conform to ANSI B16.5 and B16.25.Innovative valve solutions.

Bolted Bonnet OS&Y Wedge Gate Valves - API 600[ Product Preview ]For more information call us @ (281) 482-4728 or visit our website @ www.scvvalve.comBolted Bonnet Globe Valves - API 600Basic Design: API 600 & ANSI/ASME B 16.34Wall Thickness: ASME B 16.34Face-to-Face Dimensions: ANSI/ASME B16.10Flange End Dimensions: ANSI/ASME B16.5 (2” to 24”) MSS SP-44 (26” & up)Butt-Weld End Dimensions: ANSI/ASME 16.34Pressure/Temperature Rating I/A/W: ANSI/ASME B16.34Inspection & Testing: API 598Note: SCV reserves the right to change any technical design anddimensional data without prior notice. Please contact SCV toconfirm all Dimensions and Data offered in this catalog.

Southern California Valve’s product lines include commodity valves as well as specialty valves in all Sizes, Pressure Classes &Metallurgy; including Carbon Steel, Stainless Steel & Exotic Alloys. The valve types include Gate, Globe, Swing Check - BoltedBonnet & Pressure Seal Bonnet, Ball - floating, trunnion, rising stem, Thru-Conduit Gate - slab and expanding, Swing Check - Fulland Regular Port, Lubricated Plugs, Dual Plate Checks - wafer and lug. Southern California Valve’s High Quality Standards demand100% pressure testing of every valve to insure its reliability and full customer satisfaction.At Southern California Valve, we pride ourselves with high quality products in the commodity and specialty valve lines, as well as,timely deliveries, and competitive prices.Company HistorySouthern California Valve was established in 1972. The primary focus of the Company was to provide full inline field service forvalve maintenance as well as in house valve modifications. While serving the Power Industry, Paper & Pulp, Oil & Gas, and thePetro Chemical Industry; through years of dedication and commitment to quality and service, Southern California Valve hasbecome one of the largest West Coast full range, field service companies, with a reputation for superior quality.In the mid 1970s, Southern California Valve entered the valve manufacturing industry, primarily serving the Power Industry.Since that time, Southern California Valve has expanded their products to cover a broad range of valves. Southern CaliforniaValve holds the API 6A & API 6D Monogram, API Q1 Quality Management System, and ASME “R” stamp. The Corporate office andmanufacturing facility is located in Santa Fe Springs, California. The Sales and Projects office is located in Santa Fe, Texas.Mission StatementSouthern California Valve is committed to consistently providing products that meet or exceed customer and regulatoryspecifications. SCV aims to enhance customer satisfaction through implementing the highest levels of quality standards whileassuring full conformity to those requirements.

Table of ContentsPageTable of Contents.1Complete Product Line.2Certifcations.3 American Petroleum Institute (API) ISO 9001:2008 Canadian Registration Numbers CE PEDFigure Number Chart. 4 & 5Valve ID Tag & Valve Markings Identification.6BOLTED BONNET OS&Y WEDGE GATE VALVES - API 600.7 THRU 14Expanded View.8 Class 150 - Bolted Bonnet OS&Y Wedge Gate Valves - 2” thru 48”.9 Class 300 - Bolted Bonnet OS&Y Wedge Gate Valves - 2” thru 48. 10 Class 600 - Bolted Bonnet OS&Y Wedge Gate Valves - 2” thru 42”. 11 Class 900 - Bolted Bonnet OS&Y Wedge Gate Valves - 2” thru 24”. 12 Class 1500 - Bolted Bonnet OS&Y Wedge Gate Valves - 2” thru 24”. 13 Class 2500 - Bolted Bonnet OS&Y Wedge Gate Valves - 2” thru 12”. 14Pressure Temperature Ratings.15, 16, & 17Flange Dimensions. 18 & 19Industry Standards for Valve Manufacturing. 22Terms and Conditions. 231

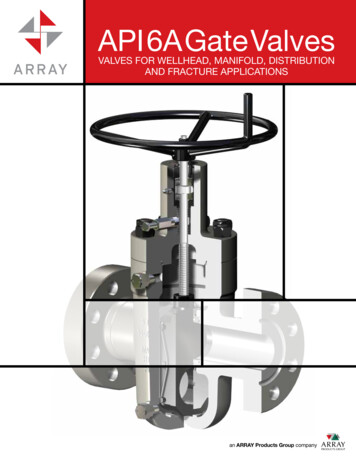

Complete Product LineCall SCV today @ (281) 482-4728 for all your valve needs or visit us on the web @ www.scvvalve.com.BOLTED BONNET OS&YWEDGE GATESCarbon & StainlessSizes: 2” - 48”Class: 150 - 2500Design: API 600THRU CONDUIT - SLAB &EXPANDING GATESCarbon SteelSizes: 2” - 36”Class: 150 - 1500Design: API 6DPRESSURE SEAL GATESCarbon & StainlessSizes: 2” - 24”Class: 600 - 2500Design: API 600B16.34BOLTED BONNET GLOBESCarbon & StainlessSizes: 2” - 24”Class: 150 - 2500Design: BS1873B16.34PRESSURE SEAL GLOBESCarbon & StainlessSizes: 2” - 16”Class: 600 - 2500Design: API623B16.34PRESSURE SEAL CHECKSCarbon & StainlessSizes: 2” - 24”Class: 600 - 2500Design: API 594B16.34FLOATING BALL VALVES1-PIECE REDUCED PORT2-PIECE FULL PORTCarbon & StainlessSizes: 1/2” - 12”Class: 150 - 1500Design: B16.34BOLTED COVER FULL PORT SWING CHECKSCarbon & StainlessSizes: 2” - 36”Class: 150 - 2500Design: API 6D3-PIECE TRUNNION BALLSCarbon & StainlessSizes: 2-1/16” - 13-5/8”Pressure: 2000, 3000 & 5000Design: API 6ACOVER PISTON CHECKSCarbon Steel BoltedSizes: 2” - 24”Class: 150 - 2500Design: API 6D3-PIECE TRUNNION BALLSBOLTED & WELDED BODYCarbon & StainlessSizes: 2” - 42”Class: 150 - 2500Design: API 6DDUAL PLATE CHECKS WAFER & LUGCarbon & StainlessWafer Sizes: 1.5” - 36”Wafer Class: 150 - 2500Lug Sizes: 2” - 36”Lug Class: 150 - 900Design: API 5943-PIECE FULL PORT BALLSCarbon & StainlessSizes: 1/4” - 3”Class: 3705 W.O.G.Design: B16.34LUBRICATED PLUGSCarbon SteelSizes: 2” - 36”Class: 150 - 2500Design: API 6D2

Certifications & RegistrationsAmerican Petroleum Institute (API)Texas Facility: API 6A CertificationCalifornia Facility: API 6A CertificationTexas Facility: API 6D CertificationCalifornia Facility: API 6D CertificationISO 9001:2008 CertificateCE PED CertificateCanadian Registration Number Alberta- 0C07063.2 New Brunswick- 0C07063.27 New Foundland & Laborador- 0C07063.20 Northwest Territory- 0C07063.25 Novascotia- 0C07063.27 Nunavut- 0C07063.2N Manitoba- 0C07063.24 Ontario- 0C07063.25 Prince Edward island- 0C07063.29 Yukon- 0C07063.23

SCV Figure Number ChartNote: SCV Figure Chart is subject to change without notice.1234Valve TypeBore SizePressure ClassBody/BonnetBAL BallDBV Double Ball ValveDCK Dual Wafer CheckDSP Dual Seal PlugFCK Full Port CheckGAT GateGLB GlobePCK Piston CheckPLG PlugRSB Rising Stem BallSCK Swing CheckTCG Thru Conduit GateTCK Tilting Disc CheckWCK Wafer Check.50 1/2”.07 9/16”.08 13/16”.75 3/4”01 1”1.2 1-1/16”1.3 1-1/8”1.4 1-1/4”1.5 1-1/2”1.8 1-13/16”02 2”2.2 2-1/16”2.3 2-1/8”2.5 2-1/2”2.7 2-9/16”03 3”3.3 3-16”04 4”4.2 4-1/16”05 05”06 06”08 08”10 10”12 12”14 14”16 16”18 18”20 20”22 22”24 24”26 26”30 30”32 32”36 36”40 40”42 42”.5 50.7 7512 12501 15002 20003 30004 40006 60008 80009 90011 100015 150017 17520 200025 250030 300037 370545 450050 500060 600010 1000005 15000B BoltedH Bar StockL LugN NRS BoltedP Pressure SealR Threaded BodyS Seal WeldT Top EntryU UnionW WaferY Y-Pattern456Body Material01 Cast Iron02 A352/LCC03 A352/LC204 CF805 Ductile06 CF8M08 A216 WCC09 WC9/F2210 A216 WCB11 A352 LCB12 A350 LF213 A10514 LC3/LF315 A217 C516 WC6/F1117 17-4 PH18 A10819 LF420 Alloy 2021 LF622 F-2224 254 SMO25 F526 F9127 C12A28 Sanicro 2829 C12/F930 AISI 413031 32132 321L33 304L34 30435 316L36 31637 317L38 31740 AISI 414041 410/F6a44 F44 Duplex47 34748 347L49 Carpenter50 Monel51 F51 Duplex52 Nickel Alloy53 F53 Duplex54 ASTM A51655 F55 Duplex56 ASTM A3657 ASTM A53760 Duplex61 Super Duplex62 Inconel 62563 Inconel 60065 F6569 Naval Brass70 Bronze71 Aluminum78 Inconel 71880 Alu Bronze81 Ni Alu/Brz82 Inconel 82583 Hastelloy B84 Hastelloy C86 AISI 802687 48788 A890-4A89 A890-5A90 Titanium91 Tantalum96 ZirconiumTrim Material10 CR1311 CR13/HF12 CR13 HF/HF13 A105/ENP14 Steel/Chrome15 LF2/ENP16 41617 17 4-PH18 LF3 ENP20 Alloy 2021 Alloy 20/HF22 F-2225 Inconel Overlay28 Sanicro 2830 413031 32132 316L33 304/HF34 30435 316/HF36 31637 317/HF38 31739 104041 410/F6a42 Full Teflon44 F44 Duplex47 34748 347/HF49 Carpenter50 Monel51 F51 Duplex52 Nickel Alloy53 F53 Duplex54 A516/ENP55 F55 Duplex56 A36/ENP57 A537/ENP60 Duplex61 Super Duplex62 Inconel 62563 Inconel 60069 Naval Brass70 Bronze71 Aluminum78 Inconel 71880 Alu/Brz81 Ni Alu/Brz82 Inconel 82583 Hastelloy86 802687 48788 A890-4A89 A890-5A90 Titanium91 Tantalum92 Inconel 92593 Tungsten Carbide96 Zirconium97 Nickel Boron

78EndsOperationA RF x BWB RTJ x BWC ClampD RF x RTJF FlatH HubJ RTJN NipplesM SW x THO ODDR RFS SWT THW WE109ConfigurationB Bare StemD Dual ActingE ElectricG GearH HandwheelL LeverO Oil/GasS S/ReturnY Hydraulic11Seal Material32 3 Way 2 Port3F 3 Way Floater3T 3 Way Trunnion43 4 Way 3 Port4F 4 Way Floater4T 4 Way TrunnionEX ExpandingFF Full FloaterFT Full TrunnionRF Red, FloaterRT Red, TrunnionSJ Steam Jacket12Seat Material4 304 Ring6 316 RingA Aflas O-RingB BunaE EPDMF FluorosiliconeG GrafoilH HNBRK KalrezL Lip SealN NeopreneP PolyuerethaneR NBRS SiliconeT TeflonU FloursintV VitonD DevlonG GraphiteK PCTFEM Metal SeatedN NylonO NovaP PEEKR RPTFET TeflonSpecialBy PassCadium CoatCryogenicEpoxy PaintLip SealMetal HardfaceMetal Tungsten CarbideNitrideOutside WTQPQ InturnalSlam RetardStancoatSub SeaTeflon LinedTop ExtensionZinc BaseFigure Number Profile123456789101112BAL 02 01 B 13 13 R L FT - H D XNo.Figure Number Code1Valve TypeIdentifies the valve body design (gate, globe, ball, plug, etc.)Description2Bore SizeIdentifies nominal port size (1/4” to 78”)3Pressure ClassIdentifies pressure classes ranging from 50 to 15,0004Body/BonnetIdentifies body and bonnet material configuration (bolted bonnet, pressure seal, top entry, etc.)5Body MaterialIdentifies body material composition (A105, WCB, Stainless Steel, F51, etc.)6Trim MaterialIdentifies trim material composition (ENP, 316, F6, Cr13, HF, etc.)7Ends8Operation9Configuration(ball & expanding gate only)Identifies end connection configuration (weld end, RTJ, socket weld, hub, etc.)Identifies valve operation mechanism (electric, gear, hydraulic, lever, etc.)Identifies valve configuration (floater, trunnion, etc.)10Seal MaterialIdentifies seal material composition (Buna, EPDM, Grafoil, HNBR, Neoprene, Teflon, etc.)11Seat MaterialIdentifies seat material composition (Devlon, Graphite, PCTFE, Nylon, PEEK, Teflon, etc.)12SpecialIdentifies special treatments or configurations (when applicable)Sample Figure Numbers & DescriptionsVal

The valve types include Gate, Globe, Swing Check - Bolted Bonnet & Pressure Seal Bonnet, Ball - floating, trunnion, rising stem, Thru-Conduit Gate - slab and expanding, Swing Check - Full and Regular Port, Lubricated Plugs, Dual Plate Checks - wafer and lug. Southern California Valve’s High Quality Standards demand 100% pressure testing of every valve to insure its reliability and full .