Transcription

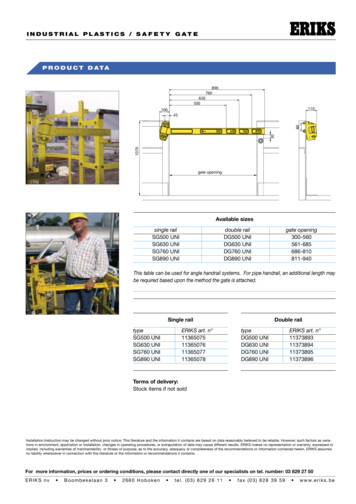

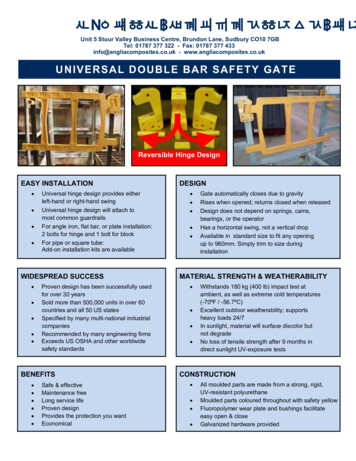

N*/, &20326,7(6 /7'.Unit 5 Stour Valley Business Centre, Brundon Lane, Sudbury CO10 7GBTel: 01787 377 322 - Fax: 01787 377 433info@angliacomposites.co.uk - www.angliacomposites.co.ukUNIVERSAL DOUBLE BAR SAFETY GATEReversible Hinge DesignEASY INSTALLATION Universal hinge design provides eitherleft-hand or right-hand swingUniversal hinge design will attach tomost common guardrailsFor angle iron, flat bar, or plate installation:2 bolts for hinge and 1 bolt for blockFor pipe or square tube:Add-on installation kits are availableWIDESPREAD SUCCESS Proven design has been successfully usedfor over 30 yearsSold more than 500,000 units in over 60countries and all 50 US statesSpecified by many multi-national industrialcompaniesRecommended by many engineering firmsExceeds US OSHA and other worldwidesafety standardsBENEFITS Safe & effectiveMaintenance freeLong service lifeProven designProvides the protection you wantEconomicalDESIGN Gate automatically closes due to gravityRises when opened; returns closed when releasedDesign does not depend on springs, cams,bearings, or the operatorHas a horizontal swing, not a vertical dropAvailable in standard size to fit any openingup to 960mm. Simply trim to size duringinstallationMATERIAL STRENGTH & WEATHERABILITY Withstands 180 kg (400 lb) impact test atambient, as well as extreme cold temperatures(-70ºF / -56.7ºC)Excellent outdoor weatherability; supportsheavy loads 24/7In sunlight, material will surface discolor butnot degradeNo loss of tensile strength after 9 months indirect sunlight UV-exposure testsCONSTRUCTION All moulded parts are made from a strong, rigid,UV-resistant polyurethaneMoulded parts coloured throughout with safety yellowFluoropolymer wear plate and bushings facilitateeasy open & closeGalvanized hardware provided

N*/, &20326,7(6 /7'.Unit 5 Stour Valley Business Centre, Brundon Lane, Sudbury CO10 7GBTel: 01787 377 322 - Fax: 01787 377 433info@angliacomposites.co.uk - www.angliacomposites.co.ukSAFETY GATE DESIGN CONSIDERATIONS--- ATTACHES EASILY TO --ANGLE IRONFLAT BARWELDED PLATEROUND AND SQUARE TUBEINTREPID 950mm MAXIMUM SWING ROTATION, RISE, AND KICK-OUTFully Open 112 degreesDESIGN CONSIDERATIONSWHEN GATE IS IN A TIGHT AREAWhen the Safety Gate is to be mounted in a tightspace, such as a corner or a narrow catwalk area,the designer must be aware of both the rise and thekick-out caused by the swing rotation of the selfclosing gate. This is depicted in these two drawings.INTREPID 950mm MaximumRise 356 mmPlease allow as much room as possible so that thegate can swing fully open. However if space istight, then try to provide at least a 100mm –150mm corner so that the gate can swing open asmuch as 75 – 90 .

ANGLIA COMPOSITES LTDUnit 5 Stour Valley Business Centre, Brundon Lane, Sudbury CO10 7GB Tel:01787 377 322 - Fax: 01787 377 433info@angliacomposites.co.uk - www.angliacomposites.co.ukSAFETY GATE TYPICAL INSTALLATIONMOUNT HINGEMOUNT BLOCKMount the block so that it is positioned at least 25mmBELOW the closed bar.Mount hinge as close as possible to the top of guardrail.Ideally the top bolt hole should be located 25mm downfrom top rail, but this may need to be adjusted dependingupon the guardrail members. Typical dims shown below.Position one 13mm hole for mounting the block with theM12 x 100mm carriage bolt.Position two 13mm holes on 159mm centers for two M12carriage bolts (100mm top and 125mm bottom). Holesshould be positioned to allow clearance for tighteningnuts.Block should not interfere with the opening or closing of thegate. It is intended to provide vertical support in anemergency. The block should be located at least 125mmbelow where the top of the hinge is positioned.REMEMBER –– YOU MUST MAKE SURE:¾ Safety Gate is no more than1100mm above the platformsurface to avoid too large of anopening below the gate¾ Double bar gate is longenough to contact, andextend past, opposite sideguardrail post by 25mm min.¾ The block is provided to resist verticaldeflection. The block SHOULD NOT MAKECONTACTWITHTHEGATEORINTERFERE WITH IT SWINGING CLOSED

ANGLIA COMPOSITES LTDUnit 5 Stour Valley Business Centre, Brundon Lane, Sudbury CO10 7GBTel: 01787 377 322 - Fax: 01787 377 433info@angliacomposites.co.uk - www.angliacomposites.co.ukSAFETY GATE ADD-ON INSTALLATION KITSPipe or Square Tube Guardrail AttachmentThese add-on kits allow for easy installation onto both pipe and square tubeThe pipe kit attaches to either 38mm, 50mm or 60mm pipe. The square tube kit canattach to square tube 38mm, 50mm or 60mm. Both are great alternatives to weldingplate. Instructions below are for the pipe kit.INSTALLATION INSTRUCTIONSSUPPORT BLOCK INSTALLATIONHINGE INSTALLATIONPosition top of the metal hinge angle plate 25mmbelow top of the guardrailAttach plate by putting the two carriage bolts throughthe plate and tighten nuts.Install assembly onto guardrail using 2 No M8 roundor square U bolts. Loosely install M8 nuts. Once incorrect position tighten all nuts.Install the block and plate assembly onto the oppositeguardrail post, using round or square M8 U bolt. Bolt thesupport block to the plate using one M12 x 100 bolt (supplied).Loosely install two M8 nuts to the U bolts. Once the block ispositioned approximately 25mm below the bar of the gate,tighten the nuts.NOTE: The bar of the gate should not rest on the block.Likewise, the block should not interfere with the openingor closing of the gate. It is intended to provide verticalsupport in an emergency.HoldTight Magnet Closure KitThe add-on HoldTight Magnet Closure Kit provides a way to hold the Safety Gate securely in a closedposition. All parts of the kit have been designed and tested for outdoor use and exposure. In fact, it hassuccessfully held the Intrepid Safety Gate closed on an offshore rig along the Canadian-Atlanticcoastline where the winds are around 30 knots with gusts of 70-80 knots!INSTALLATION INSTRUCTIONSDetermine where the Safety Gate contacts the vertical guardrailpost. Mark and drill a 6mm hole through the top bar of SafetyGate. Since the bar has both recessed and solid areas along itslength, use the shorter machine screw for the recessed areas andthe longer machine screw for the solid sections.Two nuts are used to secure the magnetic disk. In this way, themagnet can “float” or “wobble”, and still make good, flat contactwith the metal guardrail post.Once the screw, nuts, and magnet are together, use the washer,(plus additional nuts, if required) and the cap nut to secure theunit to the gate.

Blade of gate is long enoughto contact, and extend past,opposite side guardrail postby 30mm or more fromcenter line of support blockposition.1085950830705MIN. 30HINGE2 x M12 BOLTSSUPPORT BLOCK1 x M12 BOLT610114Opening Between Angle Guardrail88Min. 4510015935 typ.Standard Size to fit maximum960mm opening from centreof hinge as shown aboveSupport block is mountedbelow the top rail of gate toprevent vertical deflection.IT SHOULD NOT MAKECONTACT WITH THE GATEOR INTERFERE WITH ITSWINGING CLOSED.Field installations: simplymount the block at least45mm BELOW the closedbar.Use plastic washer tocompensate angle thickness.Safety GateEditionSheet21/1

Min. 505310125 - 30972610489All steel parts are galvanized54321ITEM31111QTYU-bolt M8Bracket, support blockBracket, gateSupport block, Safety GateSafety GateDESCRIPTIONPARTS LIST109876ITEM32166QTYHex Nut M12Carriage bolt M12 x 100mmCarriage bolt M12 x 125mmHex Nut M8Washer M8DESCRIPTIONPARTS LISTRound Tube KitEditionSheet61/1

successfully held the Intrepid Safety Gate closed on an offshore rig along the Canadian-Atlantic coastline where the winds are around 30 knots with gusts of 70-80 knots! INSTALLATION INSTRUCTIONS Determine where the Safety Gate contacts the vertical guardrail post. Mark and drill a 6mm hole through the top bar of Safety Gate. Since the bar has both recessed and solid areas along its