Transcription

Sweep Frequency Response Analysis

Transformer Diagnostics Diagnostics is about collecting reliable information tomake the correct decision Making the correct decisions saves moneySFRAOil analysisFDSWindingResistance

SFRA testing basics Off-line test The transformer is seen as a compleximpedance circuit [Open] (“excitation current”) and[Short] (“short-circuit impedance”)responses are measured over a widefrequency range and the results arepresented as magnitude responsecurves (“filter response”) Changes in the impedance can bedetected and compared over time,between test objects or within testobjects The method is unique in its ability todetect a variety of winding faults, coreissues and other electrical faults in onetest

Detecting Faults with SFRA Winding faults Deformation Displacement Shorts Core related faults Movements Grounding Screens Mechanical faults/changes Clamping structures Connections And more.

Comparative testsTransformer ADesign basedTime basedTransformer ATransformer BType based

SFRA Measurement philosophyNew measurement Reference measurementBack in ServiceNew measurement Reference measurementFurther Diagnostics Required

SFRA Measurements

SFRA test setup

FRAX measurement circuitry

SFRA Analysis

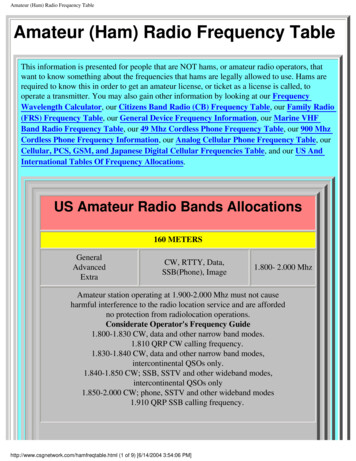

SFRA analysis tools Visual/graphical analysis Starting dB values for–– The expected shape of star and delta configurationsComparison of fingerprints from;––– [Open] (excitation impedance/current)[Short] (short-circuit impedance)The same transformer (symmetry)A sister transformerSymmetric phasesNew/missing resonance frequencies Correlation analysis DL/T 911 2004 standard Customer/transformer specific

Typical response from a healthy transformerHV [short] identicalbetween phasesLV [open] asexpected for a Y txVery low deviationbetween phases forall tests – no windingdefectsHV [open] as expected fora Y tx”Double dip” and midphase response lower12

Transformer with serious issues.Large deviationsbetween phases forLV [open] at lowfrequenciesindicates changes inthe magneticcircuit/core defectsLarge deviationsbetween phases at midand high frequenciesindicates winding faults13

FRAXThe Features And Benefits14

FRAX101 – Frequency Response Analyzer

FRAX101 – Frequency Response AnalyzerPower Input11-16VDC,internal battery(FRAX101)Most feature rich and accurateSFRA unit in the world!USB PortOn all On FRAX101Rugged ExtrudedAluminum CaseActive ProbeConnector on FRAX101All ConnectorsPanel Mounted

News in FRAX 2.3 SW System integrity test (as recommended in GIGRE and otherstandards) added in measurement templates and field test box FTB101 with defined response included as standard accessory Adjustable output voltage (FRAX101 and FRAX150) Extended frequency range 0.1 Hz – 25 MHz Standard (low-high) or reversed (high-low) frequency sweeps New fast and optimized default frequency sweep and detaileddescription of alternative sweep settings IEEE, IEC and VDE standard measurement templates Improved Doble and Omicron import including template data CIGRE standard *.xfra file export and import Standardized CSV export Doble export

FRAX test setupOptional Internal BatteryOver 8h effective run timeIndustrial grade class 1Bluetooth (100m)USB for redundancyEasy to connectshortest braid cables

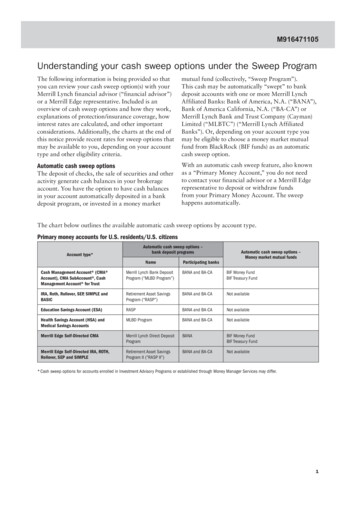

Import formats

Fast testingLess points where it takestime to test and where highfrequency resolution is not neededMore points wherehigher frequencyresolution is usefulTraditional testabout 2 minvs.FRAX fast test 40 seconds

Unlimited analysis Unlimited graph control Lots of availablemodels/graphs e.g.magnitude, impedance,admittance, etc Ability to create customcalculation models using anymathematic formula and themeasured data from allchannels

FRAX99Same As FRAX101 except: No internal battery optionNo BluetoothDynamic range 115 dBFixed output voltage9 m cable setNo active probes

FRAX150 (Q1 2010)Same As FRAX101 except: Internal PC/stand-aloneNo internal battery optionNo active probesNo Bluetooth

FRAX product summary Light weightRuggedBattery operatedWireless communicationAccuracy & Dynamic Range/Noise floorCable practiceEasy-to-use softwareExport & import of dataComplies with all SFRA standards and recommendOnly unit that is compatible with all other SFRAinstruments

Sweep Frequency Response AnalysisApplication Examples

Time Based Comparison - Example 1-phase generator transformer 400 kV SFRA measurements before and afterscheduled maintenance Transformer supposed to be in good conditionand ready to be put in service

Time Based Comparison - Example”Obvious distorsion” as by DL/T911-2004 standard (missing core ground)

Time Based Comparison – After repair”Normal” as by DL/T911-2004 standard (core grounding fixed)

Type Based Comparisons (twin-units)Some parameters for identifying twin-units: ManufacturerFactory of productionOriginal customer/technical specificationsNo refurbishments or repairSame year of production or /-1 year for large unitsRe-order not later than 5 years after reference orderUnit is part of a series order (follow-up of ID numbers)For multi-unit projects with new design: “reference” transformer shouldpreferably not be one of the first units produced

Type Based Comparison - Example Three 159 MVA, 144 KV single-phase transformersmanufactured 1960 Put out of service for maintenance/repair after DGAindication of high temperatures “Identical” units SFRA testing and comparing the two transformerscame out OK indicating that there are noelectromechanical changes/problems in thetransformers Short tests indicated high resistance in one unit(confirmed by WRM)

Type Based Comparison – 3x HV [open]

Type Based Comparison – 3x HV [short]

Type Based Comparison – 3x LV [open]

Design Based Comparisons Power transformers are frequently designed in multi-limbassembly. This kind of design can lead to symmetricelectrical circuits Mechanical defects in transformer windings usuallygenerate non-symmetric displacements Comparing FRA results of separately tested limbs can bean appropriate method for mechanical conditionassessment Pending transformer type and size, the frequency rangefor design-based comparisons is typically limited to about1 MHz

Design Based Comparison - Example40 MVA, 114/15 kV, manufactured 2006Taken out of service to be used as spareNo known faultsNo reference FRA measurements from factorySFRA testing, comparing symmetrical phasescame out OK The results can be used as fingerprints forfuture diagnostic tests

Designed Based Comparison – HV [open]

Designed Based Comparison – HV [short]

Designed Based Comparison – LV [open]

Design Based Comparison– After Suspected Fault Power transformer, 25MVA, 55/23kV, manufactured1985 By mistake, the transformer was energized withgrounded low voltage side After this the transformer was energized again resultingin tripped CB (Transformer protection worked!) Decision was taken to do diagnostic test

Design Based Comparison– After Suspected Fault101001000100001000000-10R esponse (dBs)-20-30-40-50-60-70-80Frequency (Hz) HV-0, LV open A and C phase OK, large deviation on B-phase (shorted turn?)1000000

Design Based Comparison– After Suspected Fault101001000100000Response (dBs)-10-20-30-40-50-60Frequency (Hz) HV-0 (LV shorted) A and C phase OK, deviation on B-phase1000001000000

And how did the mid-leg look like ?Core limbInsulation cylinderLV winding

Considerations when performing SFRA TestsorHow do I maximize my investmentin time and money whenperforming SFRA measurements?

Test results – always comparisonsCore NOT groundedCore groundedRepeatability is of utmost importance!

Example of repeatability 105 MVA, Single phase Generator Step-up (GSU)transformer SFRA measurements with FRAX101 before andafter a severe short-circuit in the generator Two different test units Tests performed by two different persons Test performed at different dates

Before (2007-05-23) and after fault (2007-08-29)LV windingHV winding

Potential compromising factors Connection quality Shield grounding practice Instrument dynamic range/internal noisefloor Understanding core property influence inlower frequencies in “open” - circuit SFRAmeasurements

Bad connection Bad connection can affect the curve at higher frequencies

Good connection After proper connections were made

FRAX C-Clamp C-Clamp ensures goodcontact quality Penetrates non conductivelayers Solid connection to round orflat busbars Provides strain relief for cable Separate connector for singleor multible ground braids

Proper ground connection ensuresrepeatability at high frequenciesCIGRE grounding practice;use shortest braid from cableshield to bushing flange.Poor grounding practice

Shield grounding influenceC. Homagk et al, ”Circuit design for reproducible on-site measurements oftransfer function on large power transformers using the SFRA method”, ISH2007

FRAX cable set and groundingAlways the same ground-loopinductance on a given bushing

Instrument performance Transformers have high impedance/largeattenuation at first resonance Internal instrument noise is often the main limitingsource, not substation noise Test your instruments internal noise by running asweep with “open cables” (Clamps not connected totransformer)

Internal noise level – ”Noise floor””Open”/internal noise measurementsRed Other brandGreen FRAX101

Example of internal noise problemH1 – H2 (open & short) measurementsBlack Other brandRed FRAX101

Why you need at least -100 dB.Westinghouse 40 MVA, Dyn1, 115/14 kV, HV [open]

Influence of core Try to minimize the effect, however, somedifferences are still to be expected and must beaccepted. Preferably: perform SFRA measurements prior to windingresistance measurements (or demagnetize thecore prior to SFRA measurements) Use the same measurement voltage in all SFRAmeasurements

Run winding resistance test after SFRA!After winding resistance testAfterdemagnetization

Measurement voltage 0.1 – 10VGrey 0.1 VLight Blue 0.5 VBlue 1 VBrown 2 VBlack 5 VGreen 10 V60

Effect of applied measurement voltage2.8 VOmicron10 VFRAX, Doble and others61

FRAX has adjustable output voltage!Omicron (2.8 V)FRAX (2.8 V)62

Field Verification UnitField verification unit with knownfrequency response isrecommended in CIGRE andother standards to verifyinstrument and cables beforestarting the test

Summary – Measurement accuracy andrepeatability The basis of SFRA measurements is comparison andrepeatability is mandatory To ensure high repeatability the following is important Use of a high quality, high accuracy instrument with inputs andoutput impedance matched to the coaxial cables (e.g. 50 Ohm) Use same applied voltage in all SFRA measurements Make sure to get good connection and connect the shields ofcoaxial cables to flange of bushing using shortest braid technique. Make good documentation, e.g. make photographs ofconnections. Follow the standard recommended in CIGRE report 3422008!

SFRA – Summary and conclusions SFRA is an established methodology for detectingelectromechanical changes in power transformers Collecting reference curves on all mission criticaltransformers is an investment! Ensure repeatability by selecting good instrumentsand using standardized measurement practices Select FRAX from Megger, the ultimate FrequencyResponse Analyzer!

Transformer Diagnostics Diagnostics is about collecting reliable information to make the correct decision Making the correct decisions saves money Oil analysis SFRA FDS Winding Resistance. SFRA testing basics Off-line test The transformer is seen as a complex impedance circuit [Open] (“excitation current”