Transcription

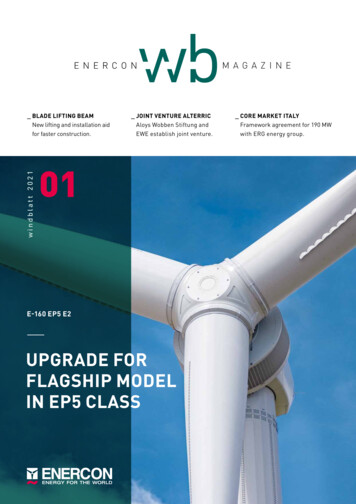

E N E R CO Nwindblatt 2021 BLADE LIFTING BEAMNew lifting and installation aidfor faster construction.J OINT VENTURE ALTERRICAloys Wobben Stiftung andEWE establish joint venture.01E-160 EP5 E2UPGRADE FORFLAGSHIP MODELIN EP5 CLASSM A GA Z I N E CORE MARKET ITALYFramework agreement for 190 MWwith ERG energy group.

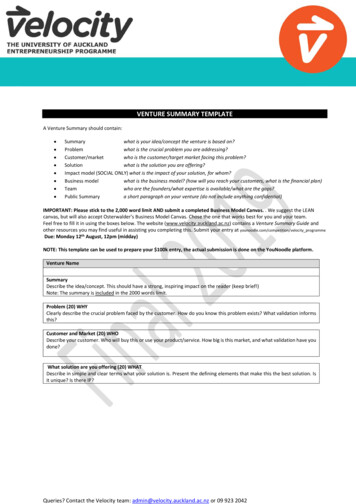

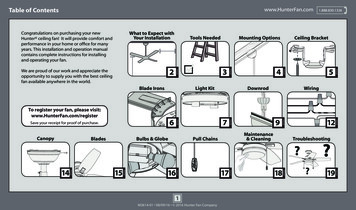

CONTENTEDITORIALSTANDARDSTABLE OF CONTENTS03 EDITORIALTITLE10 EP5 programmeENERCON starts test operation of E-160 EP5 E2at wind energy test site in Wieringermeer.04 VIEW06 ENERCON NEWS14 ADDRESSESTECHNICAL LEXICON15 Ematec blade lifting beamThe new lifting and installation aid makes asignificant contribution to reducing the costsof installation and can be universally used formany types of ENERCON rotor blade.TECHNOLOGY16 First job for Climbing Crane in series projectThe Climbing Crane LCC140 lived up to allexpectations during installation of an E-136 EP5.PRACTICE18 Producer of green energyAloys Wobben Stiftung and EWE establish jointventure Alterric for project management andoperation of onshore wind energy converters.POLITICS NATIONAL20 Climate protection versus nature conservation?About an ongoing conflict that should not beone, because nature conservation of all things isbecoming a roadblock to wind energy expansion.18Dawn of the industrialera of renewables24 Climate neutrality by 2050: what role doeswind energy play?wb interview with Giles Dickson, CEO of theEuropean wind energy association WindEurope,on the European Union climate targets.32POLITICS INTERNATIONAL26 European wind energy growth is too slowThe EU states should decisively tackle theobstacles that stand in the way of wind energyexpansion and take the first step toward rigorously implementing the EU’s RenewableEnergy Directive on schedule.Dear customers, business partners and employees, dear readers,We are currently in a phase where everything is changing. Our society, our economy and ourenergy system are all undergoing a radical transformation, sped up and intensified in someareas by the coronavirus pandemic that continues to rage. The start of the new year wasmarked with changes for ENERCON, too. One of these is the fact that I am addressing you asENERCON’s new CEO in this editorial. In the midst of all the changes we are currently dealingwith, I would like to carry on with the time-tested procedure established by my predecessorHans-Dieter Kettwig, and use this opportunity to inform you of news from the company.INTERNATIONAL28 ENERCON concludes framework agreementfor 190 MW with energy group ERGAs part of the agreement, ENERCON will supplya total of 46 E-138 EP3 E2 and E-115 EP3 E3wind energy converters for five projects in Italyand Great Britain over the next three years.In addition to the management changes regarding myself, the changes mainly include measuresfrom our reorientation programme for the company, which we are driving forward with vigour.At the start of the year we launched the reorganisation of our international operational units,granting more responsibility to our regional teams. At the same time, organisational restructuring of the central divisions in the company got underway. Our programme of measures toreduce the cost of energy also entered a new phase of implementation at the turn of the year.30 E NERCON commissions E-126 EP3 onMagdalen Islands in Canada The ‘Dune du Nord’ wind farm is a major partof the island municipality’s plan to diversifythe energy supply and switch over to renewable energies.All of these changes are being made in pursuit of the objective to turn ENERCON into an agile,powerful and competitive international industrial company operating in the core business of‘developing, producing, selling and servicing onshore wind energy converters’, which is ourfocus in the course of our turnaround. The situation remains tense for us: we are competingon a global scale, the markets – you, our customers! – dictate the pace, and we deliver.32 Repowering at highest wind farm in France Repowering of the Cham Longe wind farm hasbeen completed. ENERCON replaced 12 windenergy converters with 12 E-82 E4 models for thewind farm owner Boralex, and almost doubledthe total installed capacity of the wind farm indoing so.33 ENERCON surpasses two GW mark in Turkey The completion of the Metafor project in theprovince of Bingöl in eastern Turkey meansENERCON has now installed more than twogigawatts of power in the country.10ID-No. 21101445Impressum2windblattPublisher: ENERCON GmbH, Dreekamp 5, D-26605 Aurich, Phone 49 49 41 927 0, Fax 49 49 41 927 109, www.enercon.deEditorial office: Felix Rehwald, Antje Cznottka Design: smz GmbH, Hamburg Printed by: Druckerei Meyer GmbH, AurichCopyright: All photos, illustrations, texts, images, graphic representations, insofar as this is not expressly stated to the contrary, are the propertyof ENERCON GmbH and may not be reproduced, changed, transmitted or used otherwise without the prior written consent of ENERCON GmbH.Frequency: The windblatt is published four times a year. Subscribe: Phone 49 49 41 927 667 or www.enercon.de.Cover page image: Prototype of E-160 EP5 E2 in WieringermeerPrivacy Protection: Within the framework of your subscription, we will collect and process your personal data to the extent necessary.For more information please visit www.enercon.de/en/privacy-policy.01 2021We will implement our ‘Cost of Energy’ measures consistently in future to help us do just that,and become more efficient, more innovative, and more cost-effective with every year that passes.This may be a process that takes a bit of getting used to, both for the renewables sector asa whole and for us as a company. Institutionalised, company-wide programmes to increaseefficiency have long been standard practice for other industries and other globally operatingindustrial companies. If we want to be successful at an international level in the long term, itwill need to become a reality for us too. Our reorientation cannot just stop. We need to ensurewe are constantly evolving.As CEO of ENERCON, I will continue to push forward the internal changes necessary to helpus achieve this. We will focus on the market even more intently than before in order to respondquickly to new requirements. We will continue to gather speed, and will internalise the cultureof constant change as something that is part of our identity as a competitive global industrialcompany in the renewables sector.Momme JanssenENERCON Managing Directorwindblatt01 20213

VIEWFIRST E-138 EP3 E2SUCCESSFULLY INSTALLEDIN SOUTH KOREAThe first ENERCON E-138 EP3 E2 has been successfully installed at the Jaeun Residentswind farm in South Korea. It’s the first project in Asia to install the E-138 EP3 E2. Despitethe winter conditions at site, and facing the coronavirus pandemic, Dongkuk S&C, a trustedpartner of ENERCON, has showed once more their strong capability by installing the firstturbine within a record time, setting the benchmark for the remaining 100 units which areplanned to be installed in Vietnam and Korea within 2021.4windblatt01 2021windblatt01 20215

ENERCON NEWSENERCON NEWSENERCONimproves 2020ecobalance inEP3 programmeAs in other years, in 2020 the ecobalance of new wind energyconverters was examined in a Life Cycle Assessment (LCA) todetermine environmental impact. The LCAs of the E-92, E-147 EP5and E-138 EP3 E2 were completed by the end of last year.The objectives for reducing ENERCON’s carbon footprint arepursued on the basis of the LCA of the E-138 EP3 E2. With a carbonfootprint of 5.83 g CO2-e/kWh, the value for the CO2 emissions(calculated as CO2 equivalent) for each kilowatt-hour produced issignificantly below the target value of 6.1 g CO2-e/kWh. The energyreturned on energy invested is measured to be 36.5, meaningthe wind energy converter generates 36.5 times more electricalenergy than the energy used for its production. The energypayback time, or the amount of time the wind energy converterneeds to be operated for until the energy used for productionis generated again, is 8.22 months. In 2021 the aim is to reducethe carbon footprint by another three percent in reference to theE-138 EP3 E3. ENERCON can collect valid data on its ownIECRE-certified rotor blade test stationindependently of external test stations.ENERCON rotor blade test stationcertified to IECRE standardsENERCON’s rotor blade test station at the Innovation Centre inAurich has been successfully certified as a test facility accordingto IECRE standards. It was already possible to carry out a varietyof tests and validations on the rotor blade test station before thisdevelopment. However, as of 1 January 2021 these certificationtests according to IEC 61400-23 are only recognised by inspectionbodies like the TÜV if we perform them on test stations certified tothe IECRE standards. The data collected is used among other things forthe certification of prototypes, the validation of model simulations,material testing of fibre-reinforced composites, and validation ofthe rotor blade design in full-scale rotor blade tests. If no certified test station is available in-house, data has to be gathered atexternal test stations in an expensive and time-consuming process.On the whole, a huge amount of time is now saved during testingand certification of the rotor blades. Improvements can be trialled6windblatt01 2021and implemented reliably in a short time frame, which in turn hasa positive effect on risk minimisation for the development of newwind energy converters. The higher availability means it is possibleto complete more tests in a shorter space of time and thus increasethe maturity level of the rotor blades faster. “We still resort tousing external test stations for projects running in parallel, but ourtest station capacities mean we are now much more flexible in ourproject planning and implementation,” says Sören Flemming, whoworks in the System Testing & Optimisation division responsiblefor validation at ENERCON.The current LCA of the E-147 EP5 has provided the first resultsshowing the extent to which using permanent magnets in the EP5platform has an impact on the ecobalance of the new ENERCONWEC generation. In addition to this, it was the first time an MSTtower has been examined.The high yield of the E-147 EP5 and the options to recycle the magnetsafter decommissioning the WEC mean using rare earth elementsin the permanent magnets has a smaller effect on the carbonfootprint than anticipated. Over its entire lifecycle, the E-147 EP5thus has CO2 emissions per produced kilowatt-hour comparable tothe EP3 platform values. The carbon footprint was calculated tobe 6.44 g CO2-e/kWh. The energy returned on energy invested ismeasured at 37.6 with an energy payback time of 6.38 months.For the E-92, the LCA resulted in a carbon footprint of 5.53 g CO2-e/kWhand an energy returned on energy invested measurement of 44.The energy payback time is thus 6.81 months.In addition to this, an improvement in the test costs has also beenrecorded. When using an external test station, additional costsalso have to be budgeted for factors like personnel, transport andsupport. All of these savings contribute to reducing the cost ofenergy for an entire blade series.windblatt01 20217

ENERCON NEWSENERCON NEWSE-160 EP5 wins ‘best turbineof the year’ awardENERCON expandscapacities in IndiaENERCON has moved into new officepremises in Bangalore in the southwesternIndian state of Karnataka, marking anexpansion of its branch there. The moveinto the new premises meant the existingBangalore sites could be merged togetherand capacity for up to 180 employees created.Back at the start of 2020, ENERCONopened another site for its research anddevelopment organisation in Bangalore,which it has now adapted to the long-termrequirements of this location.The new branch is an essential componentfor further organisation and networking ofthe company divisions in India. At the sametime, it means ENERCON’s activities canbe coordinated close to the market. As wellas the R&D division, the second importantfocus, Global Procurement, is also locatedthere together with the Supply Qualitydepartment. The Indian R&D division is afully-fledged part of the develoment unit ofHeadqaurters, and handles product and technology projects independently. The key focusof Indian Global Procurement, together withthe Supply Quality division, is on safeguardingthe supply chain and reducing the LCOE of thecompany as a whole.In addition to this, the support functions,Finance, IT and HR are also represented inthe new office complex. Synergy effects havealready been generated during training ofIndian Production employees, who weretaught the specialised knowledge necessaryfor their work in India at the MagdeburgRothensee site. The new ENERCON branch in Indiawas inaugurated with a ceremony.E-160 EP5 winner of ‘Best Onshore Turbine 4.5 MW ’ award.The E-160 EP5 has been given the ‘turbine of the year award 2020’ bythe international specialist journal Windpower Monthly. ENERCON'snew flagship won first place in the ‘large onshore turbine’ category.The key aspects influencing the expert committee's vote were therapid development and the substantial advances in the wind energyconverter technology that ENERCON has achieved in a relativelyshort space of time with its new top model. According to the jury,the team has built on the LP4 platform designed by Lagerwey, whichforms the basis for all of the EP5 models, to develop the E-160 EP5into a high-performance wind energy converter with a new PMGgenerator, one of the biggest rotor diameters on the market anda groundbreaking modular design. The jury added that in doingso, ENERCON has also created the foundations to design otherPMG-based direct drive wind energy converters in the future, withhigher nominal power and more yield potential.8windblatt01 2021It went on to say the E-160 EP5 therefore represents how muchENERCON has achieved in its reorientation in such a short spaceof time. In addition to the enormous effort made by the company,the jury’s award also takes into account the fact that the E-160 EP5prototype was successfully installed and commissioned in 2020despite the negative impacts of the COVID-19 pandemic.D ownload Windpower Monthly’s winner’s videoof the gold medallist E-160 EP5 here.windblatt01 20219

TITLETest operation ofE2 prototype startedENERCON is completing the conversion of an E-160 EP5 E1to the more powerful next evolutionary step at the wind energytest site in Wieringermeer.10windblatt01 2021windblatt01 202111

TITLEwhich has been announced for the end of theyear and which will include a new E-nacellewith built-in electrical systems, the E2 stillcomes with converters located in the towerbase, ENERCON’s standard so far. In addition to these changes, ENERCON has addedother optimisation features to the E2 with theprimary goal of achieving a further rigorousreduction of the Cost of Energy (CoE).protection concept. Another changeshortens the installation time for the MSTtowers. A new type of coating provideshigher friction coefficients on the contactsurfaces of the steel plates, and this reducesthe number of bolt connections required.“Every bolt that does not need to be insertedand tightened by a technician at the construction site saves time, materials, andinstallation costs,” says Sascha Exner.Optimisations thatreduce the CoEA similar effect is achieved by a new installation aid that ENERCON acquired for theinstallation of the EP5 rotor blades. The conversion of the prototype in Wieringermeerwas the first time this aid was used on anE-160 EP5. The new blade lifting beam madeby Ematec is a hydraulic grabbing andlifting device that allows the crane to hoistthe EP5 blades at different angles; it can alsobe used to turn the rotor head of the WEC(see Technical Lexicon, p. 15).The E2 prototype already includes a modifiedhub that does not require a front hub coveror spoilers between the rotor blades. Theseguide plates were supposed to help with theair flow towards the exterior cooling finsof the stator. The E1 trials, however, foundthat they did not significantly impact thecooling effect for the generator. Omittingthese components, on the other hand, savesmaterial costs and installation time, whichhas a positive effect on the Cost of Energy. The new blade lifting beam from the manufacturer Ematec, a hydraulic grabbingand lifting device, was used for the first time in Wieringermeer.Springtime in the Netherlands is reallynot a great time to install wind energyconverters: frequent rain, cold temperatures and strong winds on many days –these weather conditions can easily causeinstallation delays. The team tasked with theinstallation of the E-160 EP5 E2 prototypehad to struggle with such adversities, too.The site is located in the wind energy testfacility in Wieringermeer in the province ofNorth Holland, about 80 kilometres north ofAmsterdam and not far from the North Seacoast. For this project, though, ENERCONhad chosen an approach able to compensatefor most weather-related delays: the first E2installation consists in the conversion of anE-160 EP5 E1 previously built at the test site.Conversion shortensinstallation phase“This is the fastest way for us to start thereal-life testing of the next evolutionarystage of our EP5 platform," explains12windblatt01 2021Sascha Exner, EP5 platform manager atWRD, ENERCON’s research and development organisation. “The foundation, towerand machine house of the existing WECremain untouched; we will only replacethe generator and the hub and make somechanges to the E-module. This shortens theinstallation phase and in particular reducesthe number of required crane hoists significantly. That means we need fewer windwindows for installation. In the Netherlands,a prototype can be realised more quickly andwith less red tape than at our alternativesites in Germany.“For the developers, the E2 test phase is animportant milestone of the EP5 programme.“Being able to gain real-life experiencewith operating the E2 and to start collectingmeasurement data ahead of the first largescale projects is very important to us,” saysSascha Exner. In 2021, ENERCON will shipthe first E-160 EP5 E2 WECs for internationallarge-scale projects, including in Vietnam –a major focus for the company in the currentbusiness year. “Another benefit for us is thatthe wind energy converter at the test siteis already equipped with measuring instruments. After the conversion is complete, wecan start the trial operation right away.”Next evolutionary stageof the E-160 EP5More optimisations will be added in themedium term. Starting with the first majorE2 series projects, ENERCON will use thetried-and-tested standard ENERCON lightning protection for the EP5. This meansthat all ENERCON WECs will follow a single“The new blade lifting beam is an enormous help for the installation team,” agreesDaniel Wolken, ENERCON project managerfor the E2 conversion in Wieringermeer.“It really reduces the number of crane hoists,it is easy to operate and ready to use withoutany lengthy set-up. It has proven its practicalworth in our project, and it will greatlysimplify and speed up the installation of theseries projects, too.”E-160 EP5 E2Nominal power: 5.5 MWAnnual yield at 7.5 m/s averagewind speed at hub height: 21,534 MWhHub heights: 120 m, 166 mGenerator: direct-drive permanentmagnet generator (PMG) uring the conversion, only the generatorDand hub were replaced and modificationswere made to the E-module. This made itpossible to shorten the installation phase.The E2 is the next evolutionary stage ofthe E-160 EP5 with a marked performanceincrease: its nominal power is 5.5 MW, andat sites with annual average wind speeds of7.5 m/s at hub height, it will produce morethan 21,534 megawatt-hours (MWh) ofannual energy yield. This is an increaseof about 9 percentage points compared tothe E1, which yields about 19,615 MWh peryear at the same site.The engineering changes compared to theE1 concern mainly the generator, whichhas a higher nominal power. Accordingly,modified converters need to be installedin the E-module. Unlike the E-160 EP5 E3,windblatt01 202113

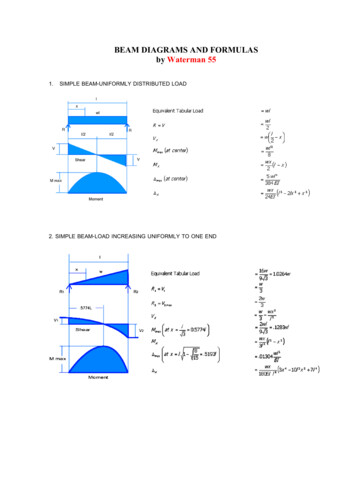

ADDRESSESTECHNICAL LEXICONFinlandENERCON Services Finland OyTekniikantie 14 (Building Innopoli II)FI-02150 EspooPhone 358 400 990 764E-mail: sales.finland@enercon.deAsia-PacificENERCON GmbHDreekamp 5 · 26605 Aurich, GermanyPhone 49 4941 927 0Fax 49 4941 927 669E-mail: Sales-Asia@enercon.de (Asia),Sales-Pacific@enercon.de(New Zealand, Australia, Pacific States)FranceENERCON GmbH330, rue de Port Salut · 60126 Longueil-Sainte-MariePhone 33 344 836 720Fax 33 344 836 729E-mail: info-france@enercon.deAustraliaENERCON Australia Pty Ltd10/F, Tower 4 · World Trade Center611 Flinders StreetMelbourne VIC 3005Phone 61 428 225 104E-mail: sales-pacific@enercon.deAustriaENERCON GmbH Austrian branchResselstraße 16 · 2120 WolkersdorfPhone 43 22 45 82 828Fax 43 22 45 82 838E-mail: office@enercon.atBelgium / LuxemburgENERCON GmbH Branch BelgiumHeldenplein 7A · 3945 HamPhone 32 11 340 170Fax 32 11 340 179E-mail: sales.be@enercon.deBrazilWobben Windpower Ltda.Av. Fernando Stecca nº 100Distrito · Industrial CEP18087450 Sorocaba · São PauloPhone 55 15 21 011 700Fax 55 15 21 011 701E-mail: vendas@wobben.com.brCanadaENERCON Canada Inc.700, rue de La Gauchetière ouest · Bureau 1200H3B 5M2 Montréal, QuébecPhone 1 514 363 72 66 · 1 87 77 082 101 (toll free)E-mail: info.canada@enercon.deChileENERCON Chile SpAAndres Bello 2299 · oficina 703Providencia Santiago · ChileE-mail: chile@enercon.deGermanyENERCON GmbHDreekamp 5 · 26605 AurichPhone 49 49 41 927 0Fax 49 49 41 927 669E-mail: vertrieb@enercon.deGreeceENERCON GmbH Office Athens49A Doukissis Plakentias Ave152 34 Chalandri AthensPhone 30 210 68 38 490Fax 30 210 68 38 489E-mail: sales.hellas@enercon.deIndiaENERCON WindEnergy Pvt. Ltd.N-204, 2nd Floor, World Trade CenterBrigade Gateway Campus · 26/1 Dr. Rajkumar RoadMalleswaran-RajajinagarBangalore - 560 055IrelandENERCON GmbH IrelandUnit 14, Northwood House, NorthwoodBusiness Campus · Santry, County DublinPhone 353 1 89 34 020Fax 353 1 86 24 151E-mail: sales.ireland@enercon.deItalyENERCON GmbH ItaliaVia Carlo Veneziani, 58 · 00148 RomePhone 39 06 91 97 71 23Fax 39 06 91 97 71 99E-mail: sales.italy@enercon.deJapanENERCON Services Japan Co., Ltd.8F Nihonbashi North Place1-7, Nihonbashi-OodenmachoChuo-ku, Tokyo ·103-0011 JapanPhone 81 3 5826 8951E-mail: sales-asia@enercon.deColombiaENERCON Colombia SASCarrera 14 No. 93-86110221, Bogotá D.C.E-mail: sales.colombia@enercon.deLatin AmericaENERCON GmbHDreekamp 5 · 26605 AurichPhone 49 49 41 927 684Fax 49 49 41 927 669E-mail: sales.international@enercon.deCosta RicaENERCON Service Costa RicaEdificio Latitud Norte · 400mts norte Construplaza10203 Guachipelín, Escazú · San JoséPhone 506 40 33 14 10E-mail: Sales.CentralAmerica@enercon.deMexicoENERCON Wind Mexico Srl de CVPaseo de la Reforma 250 · 9th Floor · Suite 06600Mexico CityPhone 52 55 3600 7375E-mail: sales.mexico@enercon.deEastern Europe / Baltic StatesENERCON GmbHAugust-Bebel-Damm 24-30 · 39126 MagdeburgPhone 49 391 24 460 230Fax 49 391 24 460 231E-mail: sales.international@enercon.dePolandENERCON Polandul. Polska 30 · PL 60-595 PoznanPhone 48 618 45 37 30Fax 48 618 45 37 39E-mail: sales.poland@enercon.dePortugalENERCON GmbH Sales PortugalParque Empresarial de LanhesesLugar de Segadas4925 424 Lanheses · Viana do CasteloPhone 351 258 803 500Fax 351 258 803 509E-mail: sales.portugal@enercon.deSpainENERCON GmbH Sucursal en EspañaRonda de Auguste y Louis Lumière 23Edificio 21 A Parque Tecnológico46980 Paterna (Valencia)Phone 34 961 824 556Fax 34 961 828 143E-mail: enercon.spain@enercon.deSouth AfricaWind Energy ENERCON South Africa1st Floor, 18 Cavendish StreetClaremont 7708 · Cape TownPhone: 27 21 831 97 00E-mail: sales.southafrica@enercon.dewindblatt01 2021The new lifting and installation aid makes a significant contribution to reducingthe costs of installation. It also carries another advantage: it can be universallyused for many types of ENERCON rotor blade.South KoreaENERCON Korea Inc.#703. · Shinwon Plaza 85 · Dokseodang-ro04419 Seoul · Republic of KoreaPhone: 82 (0) 10 3255 4698E-mail: sales-asia@enercon.deSwedenENERCON GmbH – SwedenArlövsvägen 9 · 211 24 MalmöPhone 46 40 143 580Fax 46 40 222 420E-mail: scandinavia@enercon.deTaiwanENERCON Taiwan Ltd.15F., No.2, Ln. 150, Sec. 5, Xinyi Rd., Xinyi Dist.11059 Taipei CityPhone 886 2 87 26 37 26E-mail: sales-asia@enercon.deThe NetherlandsENERCON GmbH – Dutch BranchVoltastraat 19 · 8013 PM ZwollePhone 31 38 46 96 010Fax 31 38 42 28 010E-mail: info-netherlands@enercon.deTurkeyENERCON Rüzgar Enerji SantraliKurulum Hizmetleri Ltd. Sti · Ulugöl PlazaKüçükbakkalköy Mah. Vedat GünyolCad. No: 20 Kat: 2TR-34750 Atasehir · IstanbulPhone: 90 216 569 7417Fax: 90 216 569 7427E-mail: sales.turkey@enercon.deUnited KingdomENERCON GmbH24 St. John’s Road · EH12 6 NZ EdinburghPhone 44 131 31 40 150Fax 44 131 31 40 152E-mail: sales.uk@enercon.deVietnamENERCON Vietnam Company LTDCentec Tower Bldg. / Floor 04Ngyuen Thi Minh Khai Street 72-74Ho Chi Minh District 3Phone: 84 9 4567 34 98E-mail: Hung.Albert@enercon.deNote on ENERCON events: Events are currently being rescheduled as a result of the coronavirus pandemic.New dates will be published on the intranet on enercon.de as soon as they are definite.14Faster EP5 installationwith new blade lifting beamPhoto: EmatecArgentinaENERCON Argentina SRLAv. del Libertador 6680, piso 13, oficina 1301C1428ARW Buenos AiresPhone / Fax 54 11 47 888 686E-mail: fernando.petrucci@enercon.deFrom now on ENERCON will be using a new blade lifting beam toinstall wind energy converters in the EP5 platform. The liftingand installation aid supplied by the manufacturer Ematecreduces the productive duration of the blade installation processfrom 4.5 days to 1.5 days. This move has allowed ENERCON tosuccessfully reduce the cost of installing its EP5 platform machinesby a mid-five figure sum, an effect that has a direct impact on theCoE values of the EP5 models.The Ematec lifting beam replaces the installation aids used for EP5blade installation to date: the blade hoisting device for rotor bladeinstallation, where the support device is attached to the crane hooktogether with the fixed rotor blade; and the hub rotating toolspecially adapted to the EP5 type for turning the rotor head duringblade installation. The new blade lifting beam is a hydraulic grabbing and lifting device for both work steps, measuring 13 metres x3 metres x 3 metres.The lifting beam grabs and pulls up the rotor blade to be installedsuspended on the crane hook. The holding angle can be changedduring the lifting process. In the new installation procedure designedfor the lifting beam, the rotor blades are installed at the 3 o’clock,8 o’clock and 2 o’clock positions. Once the rotor blade has beenbolted and the hub lock has been released, the hub can be turned tothe installation position required for the next blade hoisting operationby raising or lowering the blade. Separate hoisting operations toattach or set down the hub rotating tool or to install or remove aballast arm are no longer necessary.This method saves a great deal of time on the construction site. It alsohas further positive effects on the logistics, since the 25-tonnes liftingequipment can be transported in one standard truck. At least twotrucks were needed to transport the two pieces of lifting equipmentused for the EP5 blade installation procedure to date. What’s more, thelifting beam is ready for use at the construction site after just 15 minutes.While ENERCON is already utilising these benefits in the current EP5programme, there will be other advantages to make use of in mediumto long-term planning: the new lifting beam can be universally usedfor many types of ENERCON rotor blade. It is easy to operate andextremely user-friendly, meaning even inexperienced installationteams can be quickly trained in its use without any issues.windblatt01 202115

TECHNOLOGYClimbing Crane LCC140 installsE-136 EP5 on a first assignment in EemshavenIn this first assignment in a serial project, the Climbing CraneLCC140 proved that it has a lot of advantages compared to theconventional large cranes usually used for the installation ofwind energy converters. These are especially evident in the area oflogistics. Up to 100 truckloads are required to deliver a large craneto a construction site. Thanks to its transport-optimised size andrelatively low weight of 270 tonnes, the LCC140 requires only11 truckloads. Within one day, the Climbing Crane is assembledand ready for use. These aspects provide significant cost savingsin the installation process.“The installation of the pre-assembled segments of the modular steeltower was completed after two days,” reports Erwin Maas, ENERCONConstruction Manager. The project team had designed a detailedconcept of how to position the tower segments close to the tower sothat the Climbing Crane could easily pick them up. The ClimbingCrane is remote-controlled. Cameras installed on the Climbing Cranealso ensure safe guidance. “The operation of the LCC140 workedwithout any problems. The meticulous testing phase has paid off,”says Erwin Maas.The crane hardstand in Eemshaven was created for a large crane. Inthe future all the spare space on the construction site will no longerbe needed when working with the LCC140.The crane hardstand necessary for installation works with theClimbing Crane can also be significantly smaller in the futurecompared to that for a large crane. This is because the ClimbingCrane can be used both for installation and for subsequentmaintenance and service work. A crane hardstand sized fora large crane is therefore not required in the long term. Thisnot only generates further cost savings, but also preservessurrounding natural and usable areas for industry, forestry oragriculture. In addition, this creates new options for locations

ENERCON MAGAZINE UPGRADE FOR FLAGSHIP MODEL IN EP5 CLASS _ CORE MARKET ITALY Framework agreement for 190 MW with ERG energy group. _ JOINT VENTURE ALTERRIC Aloys Wobben Stiftung and EWE establish joint venture. _ BLADE LIFTING BEAM