Transcription

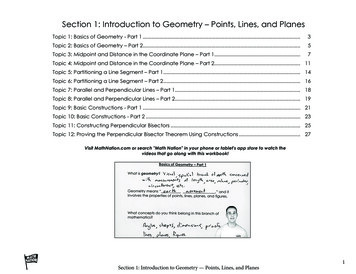

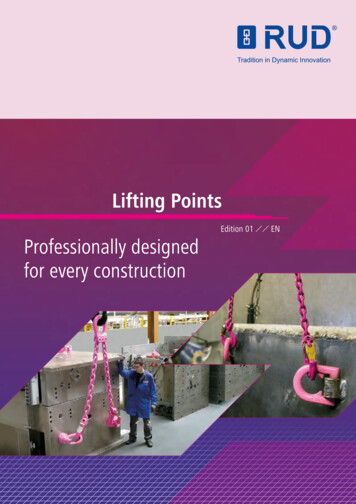

Lifting PointsEdition 01 /Professionally designedfor every construction/EN

Table of ContentsTABLE OF CONTENTSRUD-Group / Introduction / Technical Information / Lifting pointspage03Overview – Lifting pointsTradition in Dynamic Innovation04ICE-Bolt / RUD-ID-System06Bad Points / Good Points08Selection Chart – Product Features10Application Examples / Lifting points – ready for bolting14Working Load Limit / Lifting points – ready for bolting16 LIFTING POINTS – READY FOR BOLTINGICE-LBG-SRVWBG / VWBG-VPP-S / PP-B / PP-VIPICE Load ring for bolting SUPER ROTATION 30VIP Load ring for bolting36PowerPoint -Star VIP Load ring for bolting Vario-Ring connection-VIP chain connection42Hoist ring boltable on plate48VIP Load ring for bolting PLUS / Load ring for bolt. stainless steel50VRSVario eye bolt „STARPOINT“56VRMVario eye nut „STARPOINT“62WBPGVLBG-PLUS / LBG-RSINOX-STARRBG / VRBGT-FRB / B-FRB (FLARIBO)VABH-B / VCGH-GB-ABARS / RM64Stainless steel eye boltLoad ring eye plate-boltableVIP-Load ring eye plate-boltable66Flange load ring top flangeFlange load ring bottom flange68VIP Excavator hook for bolting70Boltable lifting point with full load in all directions72Eye bolt74Eye nutApplication Examples / Lifting points – ready for welding80Workind Load Limit / Lifting points – ready for welding82LIFTING POINTS – READY FOR WELDINGWPP-S / WPP-B / WPP-VIPABAPowerPoint -Star-Ring connection-VIP chain connectionWeldable lifting point with full full load in all directions9094VRBS-FIX / VRBK-FIXVIP Load ring FIX weld.VRBSVIP Load ring weldable100VIP Load ring for welding102VIP Excavator hook for welding106VLBS / VLBS-U-LT / LBS-RSVABH-W / VCGH-SRUD Ketten Rieger & Dietz GmbH u. Co. KGVIP Load ring FIX for 90 -edges weldable96

MADEINGERMANYOVERVIEWLifting – ready for bolting / Lifting – ready for weldingp.30READY FOR BOLTINGRUD lifting points / M6 – M150 / WLL 0.1 t – 250 tPowerPoint FIXVRBK-FIXp.100VRBSp.68B-FRBT-FRBRMPowerPoint READY FOR WELDINGFLARIBOp.74RSRUD lifting points / WLL 0.63 t – 100 0p.94WPP-B WPP-VIPABAp.106p.102VLBSLBS-RSVABH-WOverview – Lifting pointsVCGH-S03

Tradition in Dynamic InnovationTRADITION IN Our guiding principle and what drives usAs a family-owned company, operating internationally, we provide future-oriented solutionswith chain systems and components for a wide range of applications.In lifting technology and load securing, our mountable lifting points attest to our topquality, ergonomics and safety.More than 700 different, tested, threaded and weldable lashing pointmodels in load ranges up to 250 tonnes together with the uniqueapplication variety of our ICE and VIP chain systems meet the highestrequirements in all areas of application.Our constant pursuit of innovative product designs,coupled with the highest standards in productiontechnology and quality management, are benchmarksrecognised worldwide.Our highly skilled employees are always curious about the tasks of ourpresent and future customers - as the desire to create added value is whatdrives all their actions.04RUD Ketten Rieger & Dietz GmbH u. Co. KG

MADEINGERMANYDYNAMIC INNOVATIONProduction Units(with sales activity)Sales Units(with manufacturing activity)It is extremely important for us to beclose to our customers. That’s whyour sales team works on expandingour global sales and service networkon a daily basis. Global consultingand product availability is ensured bya large number of RUD subsidiaries,associated companies and RUDspecialist distributors.There are highly satisfied users ofRUD’s top-quality products for liftingand lashing in almost all industrialsectors. Numerous market leadersand global corporations have beenworking with our products fordecades and have, in many cases,also made them part of their internalworks standards.and transportation tasks more easily.And if there are tasks that you feelcannot be solved with the productsin this catalogue, then please get intouch with us. We are curious, afterall.!This new and unique catalogue isintended to help you, as a currentor future user of our products, findthe ideal solution for your liftingTradition in Dynamic Innovation05

ICE-BOLT / RUD-ID-SystemICE-BOLTThe new grade for bolts in lifting pointsThe fastening bolts of modern boltable lifting points have to withstand extreme daily loads –in any direction.These extreme forces on bending loads has safely to be accepted in terms of staticsand dynamics – even under lowest temperatures and maximum heat. Thepatented material of the ICE chains has been predestinated for this safetyrelevant challenge.The ICE-Bolt was developed and will in future replace allcommon bolts.That means for the user: increased WLL or thinnerbolt diameters, uncritical use with low temperatures upto -60 C, increased toughness and thus increased bendingstrength as well as less wear.Briefly summarized: maximum safety with Grade 120!Breaking force increase due to ICE-Bolt 45 % 39 % 19 %VLBGM16Current breaking force06VWBG-VM16ICE-Bolt breaking forceRUD Ketten Rieger & Dietz GmbH u. Co. KGVRSM12tensile test with bolts

MADEINGERMANYTHE THREE PILLARSRUD-ID-Point proportionsThe components have been equippedwith the RUD-ID-Point (RFID-Chip)and can be clearly identified by thedistinctive chip number.RUD-ID-READERThe robust RUD-ID-READER (readingdevices) captures the identificationnumber of the RUD-ID-Point andtransmits it to the RUD-ID-NET application (online software) oroptionally to your PC applications (e.g.MS Word, Excel, WordPad, SAP), etc.RUD-ID-NET The expandable RUD-ID-NET online application supports you withthe administration & documentationof your components.Advantages of the RUD-ID-Systems general.for inspectors./ fullfills legal requirements/ Avoiding possible errors/ unique and long-lasting/ Easy search functionidentification/ Process safety (avoiding errors)/ Reduction of inspectioncosts / time/ Clearly defined inspection planning/ Automatic generation oftest reports and filingfor IT./ No software implementation /installation/ Data privacy/ No separate data saving required/ No Hosting/ reminder function/ No software support/ Various filter possibilities/ No costly user administration/ Overview and planning of/ Immediate call-off possibility of/ Interface (SOA – Service/ Expandable for various working/ Intuitive, self-explanatory/ Maintenance and administration ofproduct data / documentsyour inspectionsmeans subject to inspectionsinspection historyOriented Architecture)user guidanceICE-BOLT / RUD-ID-System07

Bad Points / Good PointsBAD POINTS!Examples for insufficient lifting pointsDON‘T ALifting points with the design principle as shown abovedo not always automatically adjust in pulling direction.Actual pictures taken of incorrect usage: load shallbe used with four lifting points and two cranes.A Hooking in the lifting points below.BB Turning process at about 45 . Lifting points have notadjusted in the permissible force directionC Turning process at 90 . Lifting points have not adjusted.With full load and exterior use of hook, the bolt mightbreak.State-of-the-art and approved liftingpoints increase the working safety!08RUD Ketten Rieger & Dietz GmbH u. Co. KGC

MADEINGERMANYGOOD POINTSRUD advantagesMD2006/42/ECMachinery Directive 2006/42/EC4:14:1 min. safety factor for liftingAll load-bearing components are 100 %crack tested resp. proof loaded.ICE-Pink overheat indicatorVIP-Pink overheat indicatordesign programsstandard feature: RFIDICE-LBG-SR SUPER ROTATION VRBK-FIXVRS STARPOINTABABad Points / Good Points09

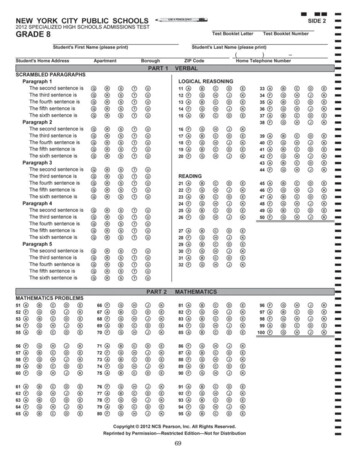

Selection Chart – product featuresLifting points – ready for boltingSELECTION CHARTproduct featuresWLLICE-LBG-SRVWBG-VVWBGPP-S /-B /-VIPWBPGVLBG-PLUSLBG-RS0.6 t – 6.7 t0.63 t – 5 t6 t – 40 t0.63 t – 8 t85 t – 250 t0.63 t – 20 t1t / 2t––––Ideal for rotating and turningBall bearing typeSRSafety factor4:14:14:14:14:14:14:1RUD-ID-System RUDIDRUDIDRUDIDRUDIDRUDIDRUDIDRUDID–Full working load in all –DGUVTest–Range of rotation360 360 360 360 360 360 360 Pivoting range suspension link180 230 230 180 180 180 Mpossible threadsMetricMM8–M30MM8–M48–MFM12 1.5–M30 2–UNC –13UNC1 1/2"-–UNC3/8"16UNC– 2"4.5UNC–MM8–M30MM33–M150M12 1.5–M30 1.5MFM33 2–M160 4MF M12 1.5–1 1/2"6UNC– 5"Metric fine thread–MFUNC inch thread–UNC –18UNCUNC1 1/4"-5/16"7UNCM12–M42M42 3MM42–M481/2"-6UNCMM16 /M208-UN-inch thread––8UN––8UN–UNF inch thread––UNF––––BSW – BritishStandard Whitworth––BSW––––G – pipe thread (nach ISO O–––––1 1/2"–5"further thread types on requestVariable thread lengthSpring10Maximum operation temperaturerange WITHOUT reduction of WLL-40 –100 C-40 –100 C-40 –200 C-40 –200 C-10 –100 C-40 –100 C-60 –100 CMaximum operation temperatureWITH reduction of WLL300 Cmax.350 Cmax.400 Cmax.400 Cmax.100 Cmax.350 Cmax.400 Cmax.RUD Ketten Rieger & Dietz GmbH u. Co. KG

MADEINGERMANYLIFTINGLifting points – ready for boltingVRSVRMINOX-STARRBG / VRBGFLARIBOVABH-BVCGH-GB-ABARSRM0.1 t – 12 t0.1 t – 4.5 t0.5 t – 2.5 t3 t – 50 t18 t – 31.5 t1.5 t – 6.7 t10 t – 20 t1.6 t – 31.5 t0.1 t – 8 t0.1 t – 8 DGUVTest––––––DGUVTest––360 360 360 ––––––––––180 ––––––MM6–M48MFM8 1–M36 3UNC1/4"20UNC– 0–M30––MM6–M48MFM10 1–M48 3MF M14 1.5–UNC1/4"20UNC– 2"4.5UNC1 1/4"8-UN –1 3/4"8-UN3/8"24UNF– 1"12UNFUNC –16UNC1 1/4"-MM6–M48M48 BSW1/2"–1 ��–––-40 –100 C-40 –100 C-40 –280 C-20 –100 C-40 –100 C-40 –100 C-20 –200 C-40 –100 C-40 –200 C-40 –200 C350 Cmax.100 Cmax.280 Cmax.350 Cmax.350 Cmax.350 Cmax.350 Cmax.350 Cmax.400 Cmax.400 Cmax.G1/4"–3"Selection Chart – product featuresLifting points – ready for bolting8UN1 3/4"8-UN–11

Lifting points – ready for welding / Lashing Points / PSASelection Chart – product featuresSELECTION CHARTproduct featuresWPP-S/-B/-VIP WPPH /-B /-VIPABAVRBS-FIXVRBK-FIXVRBSVLBSLBS-RSVABH-W0.63 t – 8 t0.8 t – 31.5 t4 t – 100 t4 t – 50 t4 t – 50 t1.5 t – 16 t1.5 t – 6.7 t1.5 t – 10 tIdeal for rotating andturning––––––––Ball bearing type––––––––4:14:14:1–––WLL / LC [daN]Safety factorRUD-ID-System 0.63 t – 8 t4:1 4:1–Full working load in alldirections12–4:1–4:1 4:1 VTestDGUVTestDGUVTest–DGUVTest––Range of rotation360 ––––––––Pivoting rangesuspension link230 230 –180 270 180 180 180 –Metric–––––––––UNC inch �–Maximum operationtemperature rangeWITHOUT reduction of WLLMaximum operationtemperature WITHreduction of WLL-40 –200 C-40 –200 C-40 –200 C-40 –200 C-40 –200 C-40 –200 C-20 –200 C-40 –200 C-40 –200 C400 Cmax.400 Cmax.400 Cmax.400 Cmax.400 Cmax.400 Cmax.400 Cmax.400 C350 Cmax.350 Cmax.RUD Ketten Rieger & Dietz GmbH u. Co. KG–

MADEINGERMANYLIFTING / LASHING / PSALifting points – ready for bolting / Lashing Points / Fall Protection ILEY BiSMILEYPSA-VRSPSA-INOX-STAR10 t – 20 t10,000 daN3,000 daN –32,000 daN8,000 daN –32,000 daN8,000 daN –20,000 daN16,000 daN3,200 daN –20,000 daN3t /3,000 daN6,000 VTestDGUVTest–––––360 –––360 360 –225 180 180 270 180 ��M3 M12 50M3 M12 50MM12M16M20MM12M16M201/2"-––––UNC 13UNC– 3/4"-–––––––10UNC––-40 –200 C–––––––350 Cmax.–––––––Selection Chart – product featuresYou can find theproducts markedin grey underwww.rud.com––Lifting points – ready for welding / Lashing Points / PSA13

Lifting points – ready for bolting14RUD Ketten Rieger & Dietz GmbH u. Co. KGApplication Examples

MADEINGERMANYLifting Pointsready for boltingLifting points – ready for boltingApplication Examples15

Working Load LimitLifting points – ready for boltingWORKING LOAD LIMITMaximum transport weight “G” in [t] with different lifting pointsThread sizesM8 – M30further thread typesand special lengthson request.ICE-LBG-SRsee p.30type0.6 t0.9 t1.35 t2.5 t3.5 t4.5 t6.7 tthread sizeM8M10M12M16M20M24M30number of legsβ10 0.60.91.352.53.54.56.720 1.21.82.757913.4190 0.60.91.352.53.54.56.7290 1.21.82.757913.420-45 0.81.21.93.54.96.39.4245-60 .54.56.73 4 0-45 1.21.92.85.37.49.514.23 4 45-60 ICE Load ring for bolting Super Rotation3 4unsymmetricalRUD Ketten Rieger & Dietz GmbH u. Co. KG

MADEINGERMANYLIFTINGLifting points – ready for boltingWorking Load LimitLifting Points – ready for bolting17

Lifting points – ready for boltingWorking Load LimitWORKING LOAD LIMITMaximum transport weight “G” in [t] with different lifting pointsThread sizesM8 – M305/16" – 1 ¼"further thread typesand special lengthson request.VWBG-VVIP Load ring for bolting -Variosee p.36type0.3 t(0.4 t)0.45 t(0.6 t)0.6 t(0.75 t)1t(1.25 t)1.3 t(1.5 t)1.8 t(2 t)2t(2.5 t)3.5 t(4 t)5t(6 t)thread sizeM8M10M12M14M16M18M20M22M24M27M30number of legsβ5/16"3/8"1/2"–5/8"–3/4"1"1 1/4"10 0.60.91.222.63.6471020 1.21.82.445.27.281420190 .5)3.5(4)5(6)290 10(12)20-45 52(2.8)2.8(3.5)4.9(5.6)7(8.4)245-60 75)1(1.25)1.3(1.5)1.8(2)2(2.5)3.5(4)5(6)3 4 0-45 .78(4.2)4.2(5.25)7.35(8.4)10.5(12.6)3 4 45-60 1.25)1.3(1.5)1.8(2)2(2.5)3.5(4)5(6)GGGGGGGG3 4unsymmetricalHigher WLL () due to optimised attachmen

Lifting points with the design principle as shown above do not always automatically adjust in pulling direction. Actual pictures taken of incorrect usage: load shall be used with four lifting points and two cranes. Hooking in the lifting points below. Turning process at about 45 . Lifting points have not adjusted in the permissible force direction