Transcription

TELEDYNE BATTERY PRODUCTSDRY-CHARGED LEAD-ACIDAIRCRAFT BATTERY SERVICE MANUALPROPOSITION 65 WARNINGBATTERY POSTS, TERMINALS AND RELATED ACCESSORIES CONTAIN LEAD AND LEAD COMPOUNDS,CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER AND REPRODUCTIVE HARM.WASH HANDS AFTER HANDLING.

Receipt and use of this technical document by any receiving party is subject to compliance with all decrees, statutes, rules and regulations ofthe United States Government and of the Governments of the countries in which Teledyne Battery Products and the receiving party are doingbusiness at the time of receipt by the receiving party in effect, or which may be in effect hereafter, which govern exports or otherwisepertains to export controls, including without limitation, the Export Administration Regulations and the International Traffic in ArmsRegulations.WARNINGTHE SAFETY INSTRUCTIONS/PRECAUTIONS POSTED IN VARIOUS SECTIONS WITHIN THIS MANUALMUST BE STRICTLY FOLLOWED.ALWAYS WEAR SAFETY GLASSES AND ACID-RESISTANT GLOVES WHENEVER HANDLING BATTERIESELECTROLYTE CONTAINS SULFURIC ACID, WHICH CAN PERMANENTLY DAMAGE EYES AND CAUSESEVERE BURNS TO EXPOSED SKIN.FOR LIMITATIONS, PROCEDURES AND PERFORMANCE INFORMATION NOT CONTAINED IN THIS SUPPLEMENT CONSULT THEBASIC PILOTS OPERATING HANDBOOK, AIRPLANE FLIGHT MANUAL, THE SPECIFIC STC OR THE BATTERY CONTINUOUSAIRWORTHINESS INSTRUCTIONS FOR THE APPLICATION.THIS SERVICE MANUAL SHOULD NOT BE CONSTRUED AS THE FINAL AUTHORITY IN MAINTAINING YOUR SPECIFIC BATTERY.PLEASE CONSULT WITH TELEDYNE TECHNICAL SUPPORT FOR FURTHER INFORMATION.Document Number: Q01-1120iiRevision K 12-5-16

Gill DRY CHARGE SERVICE MANUALSectionCONTENTSPage1REVISION PAGE .2SCOPE.23INTRODUCTION .34DRY-CHARGED LEAD-ACID tion Definitions4.3Temperature Effects4.41.4.5Life Expectancy .6PREPARING DRY-CHARGED BATTERIES FOR USE.8.85.1Tools Needed5.2Filling (or Activation)INSTALLATION.8.146.1Battery Installation Pre-Verification .146.2Battery Ventilation.146.3Sump Jar Treatment.156.4Ventilation System RequirementsSERVICING.15.167.1Service Requirements.167.2Connector/Wiring Inspection .167.3Electrolyte Levels.177.4Sump Jar Maintenance .197.5Managing Periods of Non-Use.197.6Shelf Life and Storage Conditions.197.7Continued Airworthiness Determination7.8Charging.21.227.8.7 Constant-Current (CI).237.8.8 Constant-Voltage (CV).247.9Recharging Deeply Discharged Batteries7.10Battery SafetyRevision K12-16.25.26iiiTeledyne Battery Products

Gill DRY CHARGE SERVICE MANUALSectionPage7.118Jump Starting an EngineRECYCLING.28.298.1Material Safety Data Sheets.298.2Recycler Locations .298.3International Recycling Resources.30.319FAQ’S10GLOSSARY11TROUBLE SHOOTING12APPENDIX ABattery Specifications13APPENDIX BUsing a Hydrometer14APPENDIX CActivation and Service Instructions forGill Dry-Charged Lead-Acid Aircraft.Batteries (TBP 1560)Q01-1120Revision K12-16iv3435.39.5962 .Teledyne Battery Products

Section 1COMPONENT MAINTENANCE MANUALRevisionDateCompletely RevisedJMR7-15-03AAdded new load testerJMR8-31-04BCorrected manual numberJMR6-30-05CRevised load test FRevised Activation and ServiceInstructions; added other graphicsRevisedRevised references to Appendixes,Troubleshooting SectionRevised 7.5.2JMR9-8-14HRevised 7.7.1JMR12-3-14JCorrected service instruction languageJMR7-8-15KRevised Section 7.7JMR12-5-16www.gillbatteries.comGTELEDYNE BATTERY PRODUCTSApproved ByNCDescription of ChangePremium Aircraft BatteriesREVISIONS800.456.0070Q01-1120Revision K 12-5-16Page 1 of 62Teledyne Battery Products

Section 2COMPONENT MAINTENANCE MANUALThis manual provides Maintenance Procedures for Gill Dry-Charged Lead Acid AircraftBatteries manufactured under FAA Parts Manufacturer Approvals (PMA).This manual has been written for the purpose of guidance only; consult Teledyne BatteryProducts Technical Support for further information.The latest list of our PMA’s can be obtained on our website at: www.gillbatteries.com or bycalling our Customer Support at (800) 456 0070.Premium Aircraft BatteriesSCOPETELEDYNE BATTERY evision K 12-5-16Page 2 of 62Teledyne Battery Products

Section 3COMPONENT MAINTENANCE MANUALTeledyne Battery Products of today had a modest beginning in the early 1920’s under theStewardship of Mr. Lawrence Gill. Since inception, Gill has been producing first rate batteriesprimarily for the aircraft industry. In the 1960’s, Gill Electric was sold to Teledyne, acquiringthe new name of Teledyne Battery Products.Gill has introduced most of the innovations in the industry, including 24 volt batteries for lightaircraft and low impedance, high power batteries for the turbine fleet. Meeting the stringentweight requirements, it was a Gill battery that powered the Voyager’s electrical systems andGiven our demonstrated ability of building batteries that have predictable characteristics tonarrow specifications, we are chosen as original equipment by most airframe manufacturersand are the popular choice for replacement. Many design innovations contribute to the valueof a Gill aircraft battery, such as: Through-the-partition intercell welding.Enveloped plates.Improved case-cover seal.Heavy-duty internal post.Redesigned cell construction to provide better power delivery and charge acceptance.Whether cranking a piston engine, spooling a demanding jet turbine or high-outputapplications in business jets, turboprops and helicopters, Teledyne Battery Products has theTELEDYNE BATTERY PRODUCTSavionics on its record-breaking non-stop around-the-world flight.Premium Aircraft BatteriesINTRODUCTIONright power source for the job!group of companies to continue providing unsurpassed product integration enablingcustomers’ ease of use and reliability.www.gillbatteries.comTeledyne Battery Products is committed to utilizing/developing synergies within the Teledyne800.456.0070Q01-1120Revision K 12-5-16Page 3 of 62Teledyne Battery Products

Section 4COMPONENT MAINTENANCE MANUAL4.1DESCRIPTION4.1.1These batteries are assembled with electrodes (plates) that have been fullycharged and dried. The dried plates are quite stable over time, allowing thebatteries to be stored indefinitely.4.1.2Each cell is tightly sealed prior to shipment. These seals must not be tamperedwith during storage and should only be removed just prior to activation with4.1.3It is recommended that these batteries be stored in cool, dry areas, as highhumidity and temperature will only serve to discharge the negative plates,requiring considerable conditioning if the oxidation is severe.4.2SPECIFICATION DEFINITIONSGill aircraft batteries are defined by a series of specifications:4.2.1The One-Hour RateThis is the rate of discharge a battery can endure for one hour with the batteryvoltage at or above 1.67 volts per cell, or 20 volts for a 24 volt lead-acidbattery, or 10 volts for a 12 volt lead-acid battery.the discharge rate and time (in hours) to the specified end voltage.4.2.2The Emergency RateThis is the rate of discharge a battery can endure for thirty minutes with thebattery voltage at or above 1.67 volts per cell, or 20 volts for a 24 volt lead-acid battery, or 10 volts for a 12 volt lead-acid battery.to support the essential bus for thirty minutes.Q01-1120Revision K 12-5-16Page 4 of 62Teledyne Battery Products800.456.0070The Emergency Rate is the total essential load, measured in amperes, requiredwww.gillbatteries.comThe One-Hour Capacity, measured in Ampere Hours or Ah, is the product ofTELEDYNE BATTERY PRODUCTSelectrolyte. Battery life begins when the electrolyte is added.Premium Aircraft BatteriesDRY-CHARGED LEAD-ACID BATTERIES

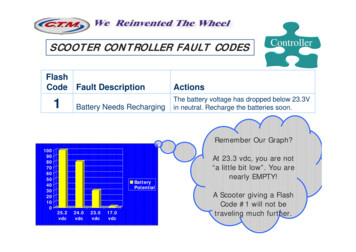

Gill DRY-CHARGE MAINTENANCE MANUAL4.2.3State of Chargevoltage measurements should be used as a guide only. Note Figure 1, whichindicates the relationship between Open-Circuit Voltage (No-Load Voltage,OCV) and % State-of-Charge (SOC) for Dry-Charged Products.Please note that state-of-charge is not the same as available capacity (seeGLOSSARY).Figure 1TELEDYNE BATTERY PRODUCTSBattery Open Circuit Voltage Vs Approximate % State of Charge24 Volt Dry-Charged Lead-Acid Batteries26.5Battery Open Circuit Voltage26.025.525.024.524.020%40%60%80%100%% State of Charge4.3TEMPERATURE EFFECTS4.3.1External temperatures will alter electrolyte viscosity – in turn affecting theQ01-1120The freezing point of electrolyte is quite low. However, a discharged battery,with lower specific gravity electrolyte, will tend to freeze at higherRevision K 12-5-16Page 5 of 62Teledyne Battery Products800.456.0070current developing characteristics of the battery. Lower temperatures willgenerally result in reduced power m Aircraft BatteriesState of Charge is a quick reference to the state of health of a battery. These

Gill DRY-CHARGE MAINTENANCE MANUALtemperatures. Note Table 1 for electrolyte freezing points with varying4.3.3Charge acceptance at low temperatures (less than 300F) is generally low. It ispreferred to charge batteries at higher temperatures (300F to 900F).Table 1FREEZING POINT OF ELECTROLYTEFreezing PointSpecific -271.175-4-191.150 5-151.125 13-101.100 18-7.7LIFE EXPECTANCY4.4.1Typical battery failure mode should be complete non-reversible utilization ofactive material. A battery that is operated and maintained per manufacturersguidelines should deliver several years of useful service.4.4.2Charging variations4.4.2.1Improper voltage settings Note recommended voltage settings in Table 2. Make sure that thevoltage regulators are correctly adjusted.4.4.2.2OverchargingOvercharging could result from leaving a battery on charge toolong at voltages higher than recommended. This will result indeterioration of the active material and accelerated grid corrosion.Revision K 12-5-16Page 6 of 62Teledyne Battery Products800.456.0070 Q01-1120www.gillbatteries.comHowever, actual service life varies due to several factors:TELEDYNE BATTERY PRODUCTS4.40FPremium Aircraft Batterieselectrolyte strength (sulfuric acid concentration).

Gill DRY-CHARGE MAINTENANCE MANUAL4.4.2.3UnderchargingChronic undercharging will lead to extensive sulfation andunderperformance. These batteries will be difficult to recharge.4.4.3High/Very Low temperature operations4.4.3.1Higher temperatures (above 1200F) will lead to quicker grid andactive material deterioration.4.4.3.24.4.4Very low temperature (below -100F) operations could lead tochronically undercharged batteriesImproper electrolyte level adjustmentsAdding contaminated water/other liquids Electrolyte must be free from organics, chlorides and metals.These impurities will affect performance significantly.4.4.4.2Using a battery with low levels of electrolyte A battery operated with low levels of electrolyte will only use thesubmerged portions of the battery plates, causing irreversibledamage to the exposed portion of the plates.4.4.4.3Adding too much water in some cells These cells will have electrolyte that could be considerably diluted,affecting the essential chemical balance in the cell, causingdecrease in performance.Table 2RECOMMENDED VOLTAGE REGULATOR SETTINGS(0F)12 Volt BatteryMinimumNominal24 Volt .2514.4528.128.528.83014.114.514.728.629.029.3 014.3514.7514.9529.129.529.8Q01-1120Revision K 12-5-16Page 7 of 62Teledyne Battery Products800.456.0070CONTINUOUS OPERATION ABOVE 1200F IS NOT reTELEDYNE BATTERY PRODUCTS4.4.4.1Premium Aircraft Batteries

Section 5Gill DRY-CHARGE MAINTENANCE MANUALPREPARING DRY-CHARGED BATTERIES FOR USETOOLS NEEDEDa) Hydrometer (To read 1.110 to 1.300), with zero at 800F.b) 800F Correction Thermometer; a thermometer capable of reading up to 1500F mayalso be used.c) Constant-Current Charger.d) Wax-coated funnel (provided); a plastic (non-nylon) funnel may also be used.5.2FILLING (OR ACTIVATION)Always use the electrolyte that is supplied with the batteries. For designperformance, do not use electrolyte with specific gravities other than thosespecified.5.2.2Please refer to Activation and Service Instructions for Gill Dry-Charged Lead-5.2.3If electrolyte is not available, refer to Appendix C for preparation of electrolyteAcid Aircraft Batteries, TBP 1560, latest revision provided with your battery.from concentrated acid.WARNINGElectrolyte contains sulfuric acid which is highly corrosive and can cause severe burns toexposed skin and permanent damage to eyes. Avoid spilling or splashing. Wear rubberTELEDYNE BATTERY PRODUCTS5.2.1Premium Aircraft Batteries5.1gloves and safety goggles whenever you are handling electrolyte or examining batteries5.2.4The activation process:a) Inspect the battery for any shipping damage prior to filling.b) Permanently mark the activation date (Month and Year) on the battery,www.gillbatteries.comduring charging.making sure that the battery is not damaged while doing so.d) Make sure you have enough electrolyte – refer to Table 3.Q01-1120Revision K 12-5-16Page 8 of 62Teledyne Battery Products800.456.0070c) Remove storage caps.

Gill DRY-CHARGE MAINTENANCE MANUALe) Gently shake the electrolyte bottles before removing the cap to ensureCAUTIONWhen adding electrolyte to dry charged batteries, ensure cleanliness at all times. Electrolytecontains about 40% sulfuric acid and is very corrosive. Metals, chlorides or organic impuritiesin electrolyte will definitely impair performance. Avoid contaminating the electrolyte. Anyplastic container except nylon may be used to contain the electrolyte.f)Carefully add electrolyte through the wax-coated funnel (provided) or aof the separatorsWARNINGWear safety goggles when looking into the cells and acid resistant gloves when handlingbatteries. Electrolyte contains sulfuric acid, which is highly corrosive and can cause severeburns to exposed skin and permanent damage to eyes.g) Install the vent caps with a quarter turn and let the battery sit forapproximately 30 minutes (soak time) – gently rock the battery a few timesto allow the entrapped air to escape.h) The battery may heat up due to the reactions going on in the cells,occasionally causing the electrolyte to react vigorously. Please ensure ventTELEDYNE BATTERY PRODUCTSplastic (non-nylon) funnel – to prevent spillage, filling each cell to the topPremium Aircraft Batterieselectrolyte is thoroughly mixed.caps are placed on correctly. Use external cooling (fan) if needed.After the soak time, check each cell for electrolyte levels. Add electrolyte toj)Connect the charging cables and begin charging using our recommendedthe top of the separators. DO NOT ADD ANY WATER AT THIS TIME.methods (Refer to Initial Charging Rates in Table 4).www.gillbatteries.comi)k) After the first hour of charge, check the electrolyte level in each cell. Makel)Q01-1120Replace vent caps finger tight, to ensure electrolyte does not leak.Revision K 12-5-16Page 9 of 62Teledyne Battery Products800.456.0070sure that the level is just to the bottom of the split ring. USE ELECTROLYTEONLY.

Gill DRY-CHARGE MAINTENANCE MANUALm) Make sure that battery temperature does not exceed 1150F. Reduce then) Completion of charge is indicated by a stable specific gravity reading of1.275 to 1.295 (temperature compensated as described in Appendix B)taken in three readings over three hours, as described in paragraph 5.2.5,Initial Charging Instructions. Use recommended hydrometer.A stable on-charge voltage reading may also be used. The battery shouldtypically be charged in about 8-12 hours using a constant current charger.p) After the battery is fully charged, adjust the level of the electrolyte to thebottom of the split ring (bottom of vent well) with the charger still on.Figure 2TELEDYNE BATTERY PRODUCTSo) At the end of charge, all cells should be gassing (bubbling) uniformly.Premium Aircraft Batteriescharge rate or use external cooling if it sion K 12-5-16Page 10 of 62Teledyne Battery Products

Gill DRY-CHARGE MAINTENANCE MANUALELECTROLYTE VOLUMESGill PartNumberFormer PartNumberFillGill PartVolumeNumber(Quarts)Former 640EBB640/T-E3G-246PS12-24P114G-641G-414Note: These are approximate volumes.5.2.5INITIAL CHARGING INSTRUCTIONSa) Replace vent caps tightly and start charging per recommendations for yourbattery type. Note Table 4 for Initial Charge Rates.TELEDYNE BATTERY PRODUCTSG-25Premium Aircraft BatteriesTable 3b) Do not allow the battery to stand for more than 8 hours, after thec) After the first hour of charge, check the electrolyte levels in each cell. Makesure that the level is just to the bottom of the split ring. Use hydrometer toremove excess. If the electrolyte levels are low, ADD ELECTROLYTE ONLY.DO NOT ADD WATER AT THIS STAGE.www.gillbatteries.comelectrolyte has been added and before you begin to charge.WARNINGWear safety goggles when looking into the cells and acid resistant gloves when handlingto exposed skin and permanent damage to eyes.Q01-1120Revision K 12-5-16Page 11 of 62Teledyne Battery Products800.456.0070batteries. Electrolyte contains sulfuric acid, which is highly corrosive and can cause severe burns

Gill DRY-CHARGE MAINTENANCE MANUALd) Replace the vent caps tightly then clean up any spilled electrolyte.reduce the charging rates and increase the charge time proportionally.Note: The charge time can be adjusted proportionally to compensate forchargers that may not be capable of delivering the recommended rate.f)It may take 8 to 12 hours to fully charge the battery using a constantcurrent charger.g) The best indicator of full charge is a stable specific gravity reading. Usingthe recommended hydrometer, take three readings at approximately equaltime intervals over three hours. When fully charged, the specific gravitytemperature compensated as described in Appendix B.Appendix B has appropriate measurement techniques using a hydrometer.Please call Teledyne Battery Products if there are any further questions.h) If it is not possible to measure specific gravity, battery voltage may be usedas an indicator. ON-CHARGE battery voltages will stabilize around 32 voltswhen charging at constant current for 24 volt batteries or around 16 voltsfor 12 volt batteries.i)At the end of charge, all cells will be gassing freely and the battery voltagewill stabilize and start to drop slightly. At this point, the current rate mustbe switched to the "Final Charge Current" - as indicated in Table 4.WARNINGTELEDYNE BATTERY PRODUCTSshould be around 1.275 to 1.295. Make sure that the readings arePremium Aircraft Batteriese) Maintain temperature of the battery around 750F to 1100F. If it gets hotter,Electrolyte contains sulfuric acid which is highly corrosive and can cause severe burns togloves and safety goggles whenever you are handling electrolyte or examining batteriesduring charging.j)Once the battery has been charged and all cables disconnected, cleanresidual electrolyte on the battery as follows: Make sure the vent caps areon tight – otherwise the solution of baking soda will enter the cells andwww.gillbatteries.comexposed skin and permanent damage to eyes. Avoid spilling or splashing. Wear rubberpartly neutralize the electrolyte – then clean the battery with water andQ01-1120Revision K 12-5-16Page 12 of 62800.456.0070baking soda. Wipe dry before installation.Teledyne Battery Products

Gill DRY-CHARGE MAINTENANCE MANUALINITIAL CONSTANT CURRENT CHARGE RATESGill PartFormer PartNumberNumberInitialChargeCurrent (A)Final ChargeCurrent 31.5G-641G-4131.5Note: The Final Charge Current is initiated once the cells start gassing.www.gillbatteries.comPS6-9TELEDYNE BATTERY PRODUCTSG-25Premium Aircraft BatteriesTable 4800.456.0070Q01-1120Revision K 12-5-16Page 13 of 62Teledyne Battery Products

Section 6Gill DRY-CHARGE MAINTENANCE MANUALINSTALLATIONWhen installing or removing a battery, take special care to ensure that no sparks are createdby tools, and that the terminals are not shorted out by tools or loose jewelry. ALWAYSREMOVE THE GROUND CABLE FIRST AND INSTALL IT LAST. IF POSSIBLE, ATTACH THEGROUND CABLE TO THE FRAME OF THE BATTERY COMPARTMENT. Do not lift the battery bytheir vent tubes, receptacles or terminals.6.1BATTERY INSTALLATION PRE-VERIFICATIONIf the original equipment battery is of another type or manufacture, the Teledyne GillType Certificated installation kit.WARNINGThe battery compartment must be coated with an acid resistant material to preventcorrosion due to accidental spills of electrolyte. If possible, the spilled electrolyte must bedrained away from or contained such that it does not come into contact with the aircraftsystems or structure.WARNINGBATTERIES MUST NOT BE LOCATED IN ENGINE COMPARTMENTS UNLESS ADEQUATEMEASURES ARE TAKEN TO GUARD AGAINST POSSIBLE FIRE HAZARDS, DELETERIOUS EFFECTSTELEDYNE BATTERY PRODUCTSreplacement should be accomplished with the proper FAA Approved SupplementalPremium Aircraft BatteriesWARNINGOF HIGH TEMPERATURE ON BATTERIES AND PROVISION FOR ADEQUATE VENTILATIONWARNINGAircraft must be equipped with a leak proof battery ventilation system. The system providesfor the removal of gases and acid fumes from the airplane in order to reduce fire hazard andto eliminate corrosion of metal parts due to acid.6.2www.gillbatteries.comAROUND THE BATTERY.BATTERY VENTILATIONso air can flow over the top of the battery and through a sump jar, where the fumesare neutralized by a sodium bicarbonate solution or dry sodium bicarbonate.Q01-1120Revision K 12-5-16Page 14 of 62Teledyne Battery Products800.456.0070Some Teledyne Gill batteries are designed with cover manifold vents (single or double)

Gill DRY-CHARGE MAINTENANCE MANUAL6.3SUMP JAR TREATMENTTeledyne Gill battery distributor. The jar should contain a ½” thick pad saturated with a5% solution of sodium bicarbonate in water or about ³ ₈” of dry sodium bicarbonate.The tube carrying fumes to the sump extends into the jar about 1” from the lid. SeeFigure 3 for basic ventilation outline.6.4VENTILATION SYSTEM REQUIREMENTSAn overboard discharge tube leads from the top of the jar to a point outside theaircraft. The tube is designed so there is air flow from the inlet venting out of theplane (with negative pressure at inlet) whenever the aircraft is in flight. This helps tooutside the aircraft. See FAA AC 43.13-1B, Chapter 11, Section 2, Battery VentilatingSystems.Figure 3Battery Ventilation SystemTELEDYNE BATTERY PRODUCTSensure a continuous flow of air across the top of the battery, through the sump andPremium Aircraft BatteriesThe sump jar has a capacity of approximately one pint and is available through ion K 12-5-16Page 15 of 62Teledyne Battery Products

Section 7Gill DRY-CHARGE MAINTENANCE MANUALSERVICINGSERVICE REQUIREMENTS7.1.1Proper maintenance is essential if the battery is to achieve maximum life andperformance. To assure these goals, periodic inspection in the aircraft isnecessary. Please review the latest revision of Activation and ServiceInstructions for Gill Dry-Charged Lead-Acid Aircraft Batteries, TBP 1560.7.1.2To ensure continued airworthiness, remove the battery from the aircraft andperform capacity test (5.1.4) initially at 800 /- 50 flight hours or 11 /- 1capacity test at 400 /- 50 flight hours or 6 /- 1 calendar month(s)whichever comes first.7.1.3For continuing limited (less than one hour) flying, the battery should beremoved from the aircraft at least once a month for top-off charging. TheConstant Voltage charging method described in the Activation and ServiceInstructions must be used.7.1.47.2The use of separate lead-acid and nickel-cadmium battery storage facilities arerecommended to prevent electrolyte contamination.CONNECTOR/WIRING INSPECTIONIf the aircraft is equipped with a battery quick disconnect, the mechanicalintegrity of the plug(s) must be checked for fit on the attaching screw toreceptacle bayonet pins. The resiliency of the female mating surfaces to thebattery receptacle terminals must also be checked.7.2.2Early discovery of defective connectors as well as battery receptacles isextremely important to prevent failure or possible fire hazard.www.gillbatteries.com7.2.1TELEDYNE BATTERY PRODUCTScalendar month(s) whichever comes first. After the initial check perform thePremium Aircraft Batteries7.1Check for the following:b) Pitted or corroded mating surfaces.c) Burn marks caused when battery is disconnected under load.Q01-1120Revision K 12-5-16Page 16 of 62Teledyne Battery Products800.456.0070a) Excessively loose handle and locking assembly.

Gill DRY-CHARGE MAINTENANCE MANUALd) To test for the resiliency of the mating surfaces to an oversized pin, insertNOGO Gauge), into each helix or sleeve to maximum depth. The fit shouldbe snug and require a removal force greater than one pound.e) To be assured that the contact is adequate for a worn battery pin, insert thesmall diameter end of the tool. This must also provide a snug fit, with anominal removal force greater than one pound.Replace the connector if it shows excessive wear or fails to meet the fit test.f)Battery contact pin must be inspected for corrosion, pitting or burn marks.If any of these defects exist, the surfaces should be cleaned.must be replaced.7.2.3In addition to inspecting the connector, condition and type of wiring must beexamined. Excessive corrosion and use of aluminum wire can be detrimental tosafe operation. Please clean/replace wiring. Replacement wiring kits areavailable from the aircraft manufacturer.7.3ELECTROLYTE LEVELS7.3.1Electrolyte levels must be maintained just over the plates at all times. Lowerlevels will damage the battery. Replenish electrolyte with clean water(preferably distilled), and NOT electrolyte, unless electrolyte has beenTELEDYNE BATTERY PRODUCTSg) If the cleaning process reduces the pin diameter below 0.370”, the batteryPremium Aircraft Batteriesthe larger diameter probe of the tool, TBP 3600-51 Rev A, or newer (GO-inadvertently spilled from the battery. See Figure 2 for levels.www.gillbatteries.comThe frequency of water additions will depend on:a) Battery duty cycleb) Battery operating temperaturec) Generator voltage regulator settingd) Flight hours7.3.2Charge the battery when water is added. This will mix the electrolyte and waterspecific gravity readings are constant over three readings taken over threehours at approximately equal intervals.Q01-1120Revision K 12-5-16Page 17 of 62Teledyne Battery Products800.456.0070to provide a homogeneous electrolyte. Continue charging until the voltage and

Gill DRY-CHARGE MAINTENANCE MANUALElectrolyte contains sulfuric acid which is highly corrosive and can cause severe burns toexposed skin and permanent damage to eyes. Avoid spilling or splashing. Wear rubber glovesand safety goggles whenever you are handling electrolyte or examining batteries duringcharging.7.3.3Adjust electrolyte level (just below the vent well) at the end of the charge, withthe use of a hydrometer. Remember, the electrolyte will heat-up and expand asthe battery is being charged.Check the battery electrolyte level and the sump jar on a routine basis (every7.3.5Formation of whitish-green deposits around terminals indicates a leakage of100 flight hours). Do not allow the cells to run dry or be

basic pilots operating handbook, airplane flight manual , the specific stc or the battery continuous airworthiness instructions for the application. this service manual should not be construed as the final authority in maintaining your specific battery. please consult with te