Transcription

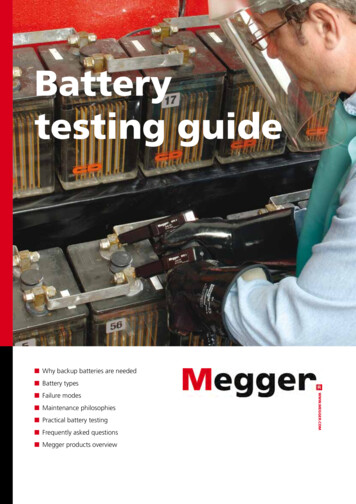

Batterytesting guideWWW.MEGGER.COM Why backup batteries are needed Battery types Failure modes Maintenance philosophies Practical battery testing Frequently asked questions Megger products overview

ContentsWhy backup batteries are needed. 4Ripple current. 16Why test battery systems. 4Temperature. 16Why batteries fail. 4Lead-acid overview. 5Data analysis. 17Locating ground faults on DC systems withoutsectionalizing. 18Overview. 18Nickel-Cadmium Overview. 5Current test methods. 18Battery construction and nomenclature. 6Configurations. 6A better test method. 18Battery types. 5Single post batteries. 6Multiple post batteries. 6Failure modes. 7Lead-acid (flooded) failure modes. 7Lead-acid (VRLA) failure modes. 7Nickel-Cadmium failure modes. 8Frequently asked questions. 19Battery technology summary. 19Megger products overview. 20Impedance test equipment. 20BITE 3. 20BITE 2 and BITE 2P. 21ProActiv battery database management software. 21Maintenance philosophies. 9BITE accessories. 21How to maintain the battery. 9Standards and common practices. 9Capacity testing. 23TORKEL 820/840/860. 23IEEE 450. 9TORKEL accessories. 23Inspections. 9Capacity test (discharge test) should be done. 9Ground fault tracing equipment. 24Battery Ground Fault Tracer (BGFT). 24IEEE 1188. 10Battery Ground-fault Locator (BGL). 24Inspections. 10Capacity test (capacity test) should be done. 10Battery replacement criteria. 10IEEE 1106. 10Inspections. 10Digital Low Resistance Ohmmeters (DLRO ) andMicrohmmeters (MOM). 26DLRO200 and DLRO600. 26DLRO 247000 series. 26Capacity test (discharge test) should be done. 10MJÖLNER 200 and MJÖLNER 600. 27Summary best way to test and evaluate yourbattery. 10MOM200A and MOM600A. 27Test intervals. 10Multimeters. 28MMC850 Multi-conductor AC DigitalClampmeter. 28Practical battery testing. 11Capacity test. 11Battery testing matrix – IEEE recommendedpractices. 11Procedure for capacity test of vented lead acidbattery. 12MOM690. 27Multimeters. 28Insulation Resistance Test Equipment. 29MIT400 series insulation resistance testers. 29Impedance test. 13Impedance theory. 13Intercell connection resistance. 14Testing and electrical paths. 15Voltage. 15Specific gravity . 15Float current. 16battery TESTING GUIDE3

Why backupbatteries areneededBatteries are used to ensure that critical electrical equipmentis always on. There are so many places where batteries areused – it is nearly impossible to list them all. Some of theapplications for batteries include: Electric generating stations and substations for protectionand control of switches and relays Telephone systems to support phone service, especiallyemergency services Industrial applications for protection and control Back up of computers, especially financial dataand information “Less critical” business information systemsWithout battery back-up hospitals would have to close theirdoors until power is restored. But even so, there are patientson life support systems that require absolute 100% electricpower. For those patients, as it was once said, “failure is notan option.”Just look around to see how much electricity we use andthen to see how important batteries have become in our everyday lives. The many blackouts of 2003 around the worldshow how critical electrical systems have become to sustainour basic needs. Batteries are used extensively and withoutthem many of the services that we take for granted wouldfail and cause innumerable problems.Why test battery systemsThere are three main reasons to test battery systems: To insure the supported equipment is adequately backedup To prevent unexpected failures by tracking the battery’shealth To forewarn/predict deathAnd, there are three basic questions that battery users ask: What is the capacity and the condition of the batterynow? When will it need to be replaced? What can be done to improve / not reduce its life?Batteries are complex chemical mechanisms. They havenumerous components from grids, active material, posts,jar and cover, etc. – any one of which can fail. As with allmanufacturing processes, no matter how well they are made,there is still some amount of black art to batteries (and allchemical processes).A battery is two dissimilar metallic materials in an electrolyte. In fact, you can put a penny and a nickel in halfof a grapefruit and you now have a battery. Obviously, anindustrial battery is more sophisticated than a grapefruit4battery TESTING GUIDEbattery. Nonetheless, a battery, to work the way it is supposed to work must be maintained properly. A good batterymaintenance program may prevent, or at least, reduce thecosts and damage to critical equipment due to an AC mainsoutage.Even thought there are many applications for batteries,standby batteries are installed for only two reasons: To protect and support critical equipment duringan AC outage To protect revenue streams due to the loss of serviceThe following discussion about failure modes focuses onthe mechanisms and types of failure and how it is possibleto find weak cells. Below is a section containing a moredetailed discussion about testing methods and their prosand cons.Why batteries failIn order for us to understand why batteries fail, unfortunately a little bit of chemistry is needed. There are two mainbattery chemistries used today – lead-acid and nickel-cadmium. Other chemistries are coming, like lithium, which isprevalent in portable battery systems, but not stationary, yet.Volta invented the primary (non-rechargeable) battery in1800. Planté invented the lead-acid battery in 1859 andin 1881 Faure first pasted lead-acid plates. With refinements over the decades, it has become a critically importantback-up power source. The refinements include improvedalloys, grid designs, jar and cover materials and improvedjar-to-cover and post seals. Arguably, the most revolutionarydevelopment was the valve-regulated development. Manysimilar improvements in nickel-cadmium chemistry havebeen developed over the years.

Battery typesThere are several main types of battery technologies withsubtypes: Lead-acid Flooded (wet): lead-calcium, lead-antimony Valve Regulated Lead-acid, VRLA (sealed): lead-calcium,lead-antimony-selenium Absorbed Glass Matte (AGM) Gel Flat plate Tubular plateNickel-Cadmium OverviewNickel-Cadmium chemistry is similar in some respectsto lead-acid in that there are two dissimilar metals in anelectrolyte. The basic reaction in a potassium hydroxide(alkaline) electrolyte is:2 NiOOH Cd 2 H2ONi(OH)2 Cd(OH)2However, in NiCd batteries the potassium hydroxide (KOH) doesnot enter the reaction like sulphuric acid does in lead-acid batteries.The construction is similar to lead-acid in that there are alternating positive and negative plates submerged in an electrolyte. Rarelyseen, but available, are sealed NiCd batteries. Nickel-cadmium Flooded Sealed Pocket plate Flat plateLead-acid overviewThe basic lead-acid chemical reaction in a sulphuric acidelectrolyte, where the sulphate of the acid is part of thereaction, is:PbO2 Pb 2H2SO42PbSO4 2H2 1 2 O2The acid is depleted upon discharge and regenerated uponrecharge. Hydrogen and oxygen form during discharge andfloat charging (because float charging is counteracting selfdischarge). In flooded batteries, they escape and water mustbe periodically added. In valve-regulated, lead-acid (sealed)batteries, the hydrogen and oxygen gases recombine to formwater. Additionally, in VRLA batteries, the acid is immobilized by an absorbed glass matte (AGM) or in a gel. Thematte is much like the fibre-glass insulation used in houses.It traps the hydrogen and oxygen formed during dischargeand allows them to migrate so that they react back to formwater. This is why VRLA never need water added comparedto flooded (wet, vented) lead-acid batteries.A battery has alternating positive and negative plates separated bymicro-porous rubber in flooded lead-acid, absorbed glass mattein VRLA, gelled acid in VRLA gel batteries or plastic sheeting inNiCd. All of the like-polarity plates are welded together and to theappropriate post. In the case of VRLA cells, some compression ofthe plate-matte-plate sandwich is exerted to maintain good contactbetween them. There is also a self-resealing, pressure relief valve(PRV) to vent gases when over-pressurization occurs.battery TESTING GUIDE5

Battery construction andnomenclatureNow that we know everything there is to know about batterychemistry, except for Tafel curves, ion diffusion, Randlesequivalent cells, etc., let’s move on to battery construction. Abattery must have several components to work properly: a jarto hold everything and a cover, electrolyte (sulphuric acid orpotassium hydroxide solution), negative and positive plates,top connections welding all like-polarity plates together andthen posts that are also connected to the top connections ofthe like-polarity plates.All batteries have one more negative plate than positive plate.That is because the positive plate is the working plate and ifthere isn’t a negative plate on the outside of the last positiveplate, the whole outer side of last positive plate will not haveanything with which to react and create electricity. Hence,there is always an odd number of plates in a battery, e.g., a100A33 battery is comprised of 33 plates with 16 positiveplates and 17 negative plates. In this example, each positiveplate is rated at 100 Ah. Multiply 16 by 100 and the capacityat the 8-hour rate is found, namely, 1600 Ah. Europe uses alittle different calculation than the US standards.In batteries that have higher capacities, there are frequentlyfour or six posts. This is to avoid overheating of the current-carrying components of the battery during high currentdraws or lengthy discharges. A lead-acid battery is a series ofplates connected to top lead connected to posts. If the toplead, posts and intercell connectors are not sufficiently largeenough to safely carry the electrons, then overheating may oc-Figure 1 Battery construction diagram6battery TESTING GUIDEcur (i2R heating) and damage the battery or in the worst cases,damage installed electronics due to smoke or fire.To prevent plates from touching each other and shortingthe battery, there is a separator between each of the plates.Figure 1 is a diagram of a four-post battery from the toplooking through the cover. It does not show the separators.ConfigurationsBatteries come in various configurations themselves. Add tothat the many ways that they can be arranged, the numberof possible configurations is endless. Of course, voltageplays the biggest part in a battery configuration. Batterieshave multiple posts for higher current draws. The more current needed from a battery, the bigger the connections mustbe. That includes posts, intercell connectors and buss barsand cables.Single po

Battery teStING GUIDe 5 Battery types There are several main types of battery technologies with subtypes: Lead-acid Flooded (wet): lead-calcium, lead-antimony Valve regulated Lead-acid, VrLa (sealed): lead-calcium, lead-antimony-selenium