Transcription

Step - By - StepAC InstallationGuide

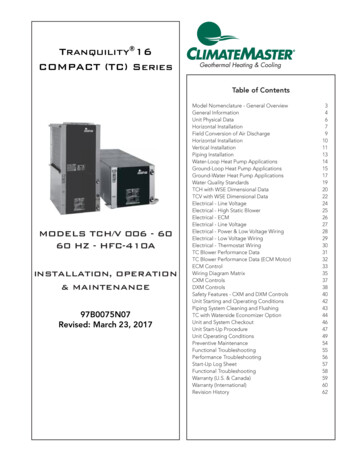

IndexAC Installation Guide - 1Welcome to the Step-By-Step AC Installation Guide .03AC Installation Guide - 2Safety Guidelines When Installing Central Air .04AC Installation Guide - 3What You’ll Need .05AC Installation Guide - 4Find a Spot for Your New AC Unit.06AC Installation Guide - 5Cut a Hole in Wall of Home to Run Wires and Tubing.07AC Installation Guide - 6Install Coil (Uncased).08AC Installation Guide - 1Welcome to the Step-By-Step AC Installation GuideWelcome to Alpine Home Air Products Step-By-Step Central Air ConditioningInstallation Guide. Installing your own air conditioning is easy. Follow along withthis simple guide, complete with photographs and diagrams.You can also view our 12 minute sample online installation video. This video is asample of a full 1 hour AC installation DVD included with your purchase. Click hereto view.AC Installation Guide - 7Install Line Set.20AC Installation Guide - 8Prepare High-Voltage Connections.27AC Installation Guide - 9Hook Up Low Voltage Wiring (24 Volts).42AC Installation Guide - 10Complete the Job.49www.alpinehomeair.com - (800) 865-5931

AC Installation Guide - 2Safety Guidelines When Installing Central AirAC Installation Guide - 3What You’ll Needӹӹ All products must be installed according to manufacturer’s installationinstructions and safety guidelines.ӹӹ All work must be done according to local and national building, electrical andmechanical codes.ӹӹ Wear proper safety equipment when performing your installation.ӹӹ Get local permits if necessary.ӹӹ Do not adjust or handle refrigerant unless you are EPA-Certified.ӹӹ Do not handle high-voltage electrical wiring unless properly trained.ӹӹ Be careful when handling sheet metal - it can be very sharp.ӹӹ Improper installation of products or improperly servicing a furnace can causeserious injury or death.ӹӹ This installation guide is not exhaustive of the subject matter, nor does it replacethe manufacturer’s instructions or requirements.ӹӹ If you do not fully understand how to install your product after reading themanufacturer’s instructions, contact your local heating and air conditioningdealer for help and do not attempt to install it yourself.ӹӹ Alpine Home Air Products, its partners, the product manufacturers or any otherproviders of your purchased items cannot be held responsible for any damages,liability or litigation for any consequences, damages or injury that results fromimproper use or installation.4Go To IndexTools: L-Square Sheet Metal Shears Sheet Metal Benders (optional) Wire Cutters Wrench Screwdriver Tubing Cutter Hole Saws (around 2 inches) Tape Measure Drill Drill BitsSupplies (Contained in the AHA AC Supplies Packages): Prefabricated Sheet Metal ½” Drain Tubing Low-Voltage, 4-Conductor Wire Plastic Tie Wraps Sheet Metal Screws Hex Nut Driver Low Voltage Wire Nuts Evaporator Drain Fitting Copper Fittings Spade Connectors Plastic Hangers for hanging pipeEquipment: Condensing Unit or Heat Pump Line Set Electrical Whips Electrical Safety Shut-Off - Disconnectwww.alpinehomeair.com - (800) 865-59315

AC Installation Guide - 4Find a Spot for Your New AC Unit4. Place the condensing pad in the spotchosen for the condensing unit. Makesure the spot is level. Level ground with ashovel if necessary.5. Center the condensing unit on thecondensing pad.1. Choose a spot for your condensing unit,outdoors. Some locations are better thanothers. Some things to keep in mind: Ground needs to be level and secure. Keep unit out of constant, directsunlight, if possible. It will run moreefficiently in the shade. Unit should not be positioned directlyunder a gutter or where excessive watercould pour down on it. Rain won’t hurtthe unit, but it’s best to keep it fromneedlessly getting wet. Unit should be close to electrical circuitpanel in home for an easier wiring run. Unit should not be placed too closely toplants. The unit needs clearance aroundit for adequate airflow. For cosmetic reasons, the unit should beplaced in an area that is slightly hiddenfrom direct view of home. Unit must be three feet away from a gasor electric meter. See local codes.AC Installation Guide - 5Cut a Hole in Wall of Home to Run Wires andTubing1. Cut hole in a spot near the condensingunit and near the bottom of your home.The hole should allow access to 1) runwires to the main electrical panel; 2) runpipes to furnace or air handler.2. Find something visible both inside andoutside of the home as a point of reference(like a water spigot or electrical hole forphone wires) to ensure you do not drill thehole in the wrong area.2. Make sure there is a ten-to-twelve-inchclearance between the condensing unitand the walls of your home.3. Cut bushes back, if necessary.63. From the outside of the home, use thehole saw to drill hole at marked spot.Go To Indexwww.alpinehomeair.com - (800) 865-59317

AC Installation Guide - 6Install Coil (Uncased)Note: Skip the following steps if 1) you have an air handler, since the coil is already5. Using a marker and your L-Square markthe correct dimensions (the width fromStep 2 and the height from Step 4) on theside of the supply plenum.installed inside it, or 2) you have a cased coil, since it will fit on the top of your furnace(or on the side if it is a horizontal coil).Cut Opening on Supply Plenum to Mount Coil Within ItObjective: Cut opening in side of supply plenum (located on top of your furnace) tomount evaporator coil inside6. Use your drill to cut a hole out in the cornerof the rectangular outline you drew. (Thiswill allow you to use your sheet metalshears to start cutting out the rectangle.)1. Measure the width of the evaporator coilat its widest point.2. Add one half inch to the width. This willbe the measurement for the width of therectangle you cut out of the supply plenum.3. Measure the height of the evaporator coilat its highest point.4. Add one half inch to the height. This willbe the measurement for the length of therectangle you cut out of the supply plenum.87. Using your sheet metal shears, cut alongthe rectangular outline you drew on thesupply plenum. Be careful, because sheetmetal is extremely sharp.Go To Indexwww.alpinehomeair.com - (800) 865-59319

Objective:The shelves should be cutnarrowly enough that the full coil opening isexposed to the air stream beneath it, but notso narrowly that the coil does not have enoughof a base to sit on. This photograph shows thebottom of the coil and how far over the sheetmetal should reach.8. Remove and carefully discard the rectangleyou cut out of the supply plenum.Build Sheet Metal Shelves to HoldEvaporator Coil Inside PlenumObjective:To ensure that water runsforward to the drain hole in the plastic tray onthe bottom of the coil, the back shelf shouldbe positioned 1/2” higher than the front shelf.This will create a 1/2” forward pitch on thecoil and will allow water (which collects aswater condenses on the cold evaporator coil)to drain out of the plastic tray.Objective: Build sheet metal shelves insidesupply plenum so that evaporator coil can sitcentered inside plenum. Four sheet metalshelves are supplied with your suppliespackage. Each is larger than what you willneed and are designed to be cut to size to fityour exact application.Objective: Trim the shelves so that they fitinside the plenum, but do not block airflowinto bottom of coil. This is what the coil willlook like sitting on top of the sheet metalshelves. This will all be mounted inside thesupply plenum.10Go To Indexwww.alpinehomeair.com - (800) 865-593111

5. Cut the front and back sheet metal shelvesto same length as the width of the plenum.Set the front shelf aside.6. Position the back shelf so that the flappoints downwards and against the plenumwall. Place it 1/2” higher than where youwill locate the front shelf.7. Drill screws into the sheet metal flap tosecure the shelf to the plenum wall.8. Cut the side shelves the same length as thedepth of the plenum.9. Position the shelves so that the flaps of thesheet metal point downward against theplenum wall on both sides.10. Drill screws into the flaps to secure bothsheet metal shelves.The dimensions in the diagram are for example purposes ONLY. Your measurementswill be different.1. Cut sheet metal shelves the appropriate width.2. Width of Front and Back Shelves (Depth of Plenum - Length of Coi)/2 1(23”- 20”)/2 1 2.5”3. Width of Side Shelves (Width of Plenum - Width of Coil)/2 1(19” - 13”)/2 1 4”4. Cut the shelves on the sides opposite the 90-degree bend.12Go To Index11. Position the front shelf 1/2” lower than theback shelf with the flap pointing downwardagainst the plenum wall.www.alpinehomeair.com - (800) 865-593113

16. Screw the sheet metal cover into place,making sure not to put any screws throughthe white plastic condensate tray onbottom of coil. You are ready to installyour line set. Skip the following steps.12. Drill enough screws into corners of shelvesto secure all four.Create a Raised Sheet Metal Cover13. Slide coil into plenum on top of shelves,with refrigerant lines pointing outwardIf the coil sticks out beyond the plenumopening (excluding the refrigerant lines) youwill need to build a raised sheet metal cover.1. To do this, first measure the numberof inches the coil sticks out beyond theplenum opening.14. Place sheet metal cover (found in suppliespackage) over plenum opening, fitting therefrigerant lines and the drain connectorsthrough the designated holes.15. If the sheet metal cover fits flush over theplenum opening, use your marker to markthe back of the cover where it meets theedges of the plenum. Go to Step 16. If thecoil protrudes from the opening and thecover is not flush with the plenum, skipStep 16 and see instructions to “Create aRaised Sheet Metal Cover” below.142. Measure from the center of the suctionline (this is the refrigerant line near topof coil that sticks out the furthest) to theplenum opening, on all four sides. Writethese measurements down.Go To Indexwww.alpinehomeair.com - (800) 865-593115

The dimensions on the sheet metal cover in the picture are for example purposesONLY. Your measurements will be different.3. Using your L-Square and marker,mark the measurements taken instep 2 on the sheet metal cover.Make sure all measurements startat the center of the top (suctionline) hole. (Note: You can makethe markings on the back side ofthe cover for cosmetic purposes,as well. Just make sure to flip thehorizontal measurements.)4. Draw a box properly distancedfrom the suction line hole on allsides, using the L-Square.5. Measure the width and height ofthe box you drew.The dimensions on the sheet metalcover in the picture are for examplepurposes ONLY. Your measurementswill be different.7. Draw a third rectangle around thefirst two, 1/2” larger on all sides.The dimensions on the sheet metalcover in the picture are for examplepurposes ONLY. Your measurementswill be different.6. Draw another rectangle around thefirst adding the number of inchesthat the coil sticks out beyond theplenum opening (determined inStep 1).For example, if the coil sticksout one inch beyond the plenumopening, add one inch to thewidth of the first rectangle (inthis example 17” 1” 18”) andadd one inch to the length (in thisexample 19” 1” 20”).168. Cut around the edges of the outerrectangle with sheet metal sheers.Go To Indexwww.alpinehomeair.com - (800) 865-593117

9. Cut out four corners on the sheet metal, thesame dimensions as the number of inchesthe coil sticks out beyond the plenum plusa 1/2”. Or simply cut squares out using theL-Square and inner-most rectangle as acorner.16. Place the raised cover over the plenumopening, allowing the drain connectorsand refrigerant lines to fit throughdesignated holes.17. Drill screws into cover’s 1/2” lip on allsides to secure it to the plenum. (Note:Make sure not to put any screws into whiteplastic condensate tray on bottom of coilas this may cause it to leak).10. To create a 1/2” lip on the sheet metal, laythe cover on a flat surface front side up.11. Place the L-Square on the edge of themiddle rectangle.12. Bend the sheet metal upwards, so that theouter edge of the cover forms a 90-degreeangle with the middle rectangle.(You can also use sheet metal benders, if youhave them.)13. Flip the cover over.14. Place the L-Square on the edge of the firstrectangle you drew.15. Bend the sheet metal upwards at the edgeto form a 90-degree angle.18Go To Indexwww.alpinehomeair.com - (800) 865-593119

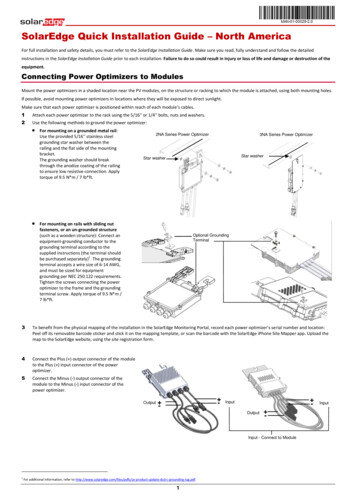

AC Installation Guide - 7Install Line SetObjective: The line set consists of two refrigerant lines that connect the condensing4. Run suction line along the ceiling towardsthe evaporator coil.unit to the evaporator coil. To complete this part of the installation, connect the lineset to the condensing unit and run it inside along the ceiling toward the evaporatorcoil. Your EPA-certified contractor will complete the installation.1. Roll out suction line (the larger, insulatedline) holding one end down with yourfoot.5. Secure suction line to ceiling using lineset mounting brackets. Use two screwson each side of bracket to hold in place.Use as many brackets as needed to firmlysecure suction line.2. Peel back a few feet of insulation on oneend of line and cut off with knife. (Theamount you peel back should be about thesame length as the distance between thehole in your house and the condensingunit.) Set insulation aside.6. Outside, the suction line may need to beredirected towards the condensing unit.To redirect the line, it must be cut and thenfitted back together with 45-degree and/or 90-degree copper fittings (whicheverbest fits your application - you may needto use both). The suction line is slightlymalleable, but sharply bending the line toredirect may cause it to kink.3. Push enough of the suction line through thehole in the house to reach the condensingunit. If you push too much through, youcan cut the line later.20Go To Indexwww.alpinehomeair.com - (800) 865-593121

7. Using a tube cutter, cut the suction linenear the hole in your house. Make surethat the length of the suction line you cutoff is long enough to reach the condensingunit.Continued from Step 8.9. Reattach the piece of piping cut off fromthe end.Continued from Step 7.10. As in this example, both a 90-degreeand 45-degree copper fitting are used toredirect the suction line to the condensingunit. You may need to cut the pipe twiceand use two fittings.8. Attach either a 90-degree or 45-degreecopper fitting to the end of the suction linewhere it protrudes from hole in house.(Use whichever fitting is necessary toredirect the line appropriately.)22Go To Indexwww.alpinehomeair.com - (800) 865-593123

14. Run the liquid line along the suction lineand through the same line set mountingbrackets already secured in place.11. Redirect the pipe to the condensing unit.12. Press the suction line into the suction linesurface valve on the condensing unit.15. Outside, use slight pressure to bendthe liquid line and run it towards thecondensing unit. Copper fittings are notnecessary to bend the liquid line.Tip: Keep suction and liquid lines cleaninside. These are sensitive environmentswhen the air conditioning runs. Cleanlinessand dryness are important for proper airconditioning operation.Tip: When bending copper, be careful notto crimp or kink it. If you do accidentallycrimp or kink it, the pipe is not unsalvageable.Straighten out the piping, splice it with thetube cutter and rejoin the cut ends with acopper coupling.16. Attach the liquid line to the liquid linesurface valve on the condensing unit bypressing it into place.13. Back inside home, run the smaller liquidline (smaller of the two lines in line set)out through hole in house. Push enoughof the line through to reach the condensingunit.24Go To Indexwww.alpinehomeair.com - (800) 865-593125

17. Back inside, trim liquid line with a tubecutter several inches longer than necessaryto reach the evaporator coil.20. Leave refrigerant lines hanging forcontractor to solder connectionsAC Installation Guide - 8Prepare High-Voltage ConnectionsA central air conditioner runs on 220 volts of electricity. A connection must be madebetween the main electrical circuit panel in your home and the condensing unit inorder for the air conditioning to run. You can prepare the wiring for hook-up, butonly a skilled contractor should complete the high-voltage wiring. Inexperience cancause electrical shock or damage to your equipment or property.18. Using a knife, cut the insulation off theend of the suction line.You will need to select the correct thickness of wire and corresponding breaker basedon your condensing unit. Wires are rated by gauge. The higher the gauge number,the thinner the wire. Most residential AC units use 8 or 10-gauge wire. See themanufacturer’s spec sheets for more information.The first step to preparing your high-voltage connections is to install the disconnect.Electrical codes require a disconnect/safety switch to be located near the condensingunit. Check your local electrical codes for specifics.19. Trim suction line with tube cutter severalinches longer than needed to attach toevaporator coil.26The disconnect will have two electrical whips running in and out of it: one runs fromthe condensing unit to the disconnect and the other runs from the home’s electricalcircuit panel to the disconnect.Go To Indexwww.alpinehomeair.com - (800) 865-593127

Install Disconnect Box andElectrical Whips5. Mount the box to the wall with screws anddrill.1. Select a spot on wall to mount disconnectbox. Locate it near the hole in the house andclose to condensing unit. Place it high enough up to keep it out ofsnow or water on ground. See electrical codes for specifics onwhere to locate the disconnect.2. Pull cover off of disconnect box to seeinside. You will find spots to attach wiresand small holes to mount the box withscrews.3. Remove the On-Off switch.6. Slide whips through holes in box andtighten nuts. (See Step 6 for more details.)4. Punch out one pre-stamped hole on eachside (or bottom) of disconnect box. Punchout the holes that are properly-sized forthe electrical whips. One electrical whipwill be inserted on each side.7. One whip has a 90-degree bend and onehas a straight end. Use the whip on eachside that best fits your application.28Go To Indexwww.alpinehomeair.com - (800) 865-593129

Hook wires up inside the disconnect box. Thegreen wires are the ground wires.8. Cut the two green wires to size and stripback 1/2” of insulation.9. Hook up both wires, each one under eitherlug in center of disconnect and tightendown with screwdriver. Make a good solidconnection.13. On the other whip, cut the red andblack wires to size and strip back 1/2” ofinsulation.14. Hook up the red wire to the terminalclosest to the red wire just installed.Tighten down with screwdriver.For the whip closest to condensing unit,hook up the red and black wires inside boxat the “load” terminals (in center, near top ofdisconnect).10. Cut the red and black wires to size andstrip off 1/2” of insulation.11. Hook up each wire under either lug.15. Hook up the remaining black wire to theterminal closest to the black wire justinstalled. Tighten down with screwdriver.16. Slide the electrical whip closest to hole inhouse, through the hole.12. Tighten lugs down with screwdriver. Highvoltage needs a good, solid connection.30Go To Indexwww.alpinehomeair.com - (800) 865-593131

17. Replace On/Off Switch in disconnect box.18. Turn switch to Off until contractor startsunit.21. Punch out appropriately-sized holes onboth sides of junction box.Mount Whip To Ceiling, ConnectFlexible Wire and Run to Home’sElectrical PanelBack inside home, the whip needs to bemounted to the ceiling, wires connected to itand the wires run to home’s electrical circuitpanel.22. Run whip into junction box on side closestto hole in house.19. Find a spot on the ceiling to mount thewhip and wires. See local electricaland building codes for more allowableplacement23. Run flexible wire from junction box tohome’s electrical panel. Use the correctwire gauge (based on your condensingunit). Flexible wire such as Romex maybe used if building/electrical codes permit.Some building/electrical codes require theuse of solid, conduit pipe to pass wiresthrough.20. Use a standard 4x4 junction box (availableat any hardware store) to mount whip andwires. Screw box into place.32Go To Indexwww.alpinehomeair.com - (800) 865-593133

24. Strip about one foot of insulation fromwire.27. Tighten down top screw on box connectoruntil it holds insulated wire securely. Don’t pinch the wires by tightening thescrews down too tightly. The connector itself is not screwed intoanything, yet.28. Tighten down bottom screw on boxconnector.25. Slide wires into box connector (availableat any hardware store).26. Slide box connector down the wires towhere the insulation begins.3429. Remove nut on end of box connector.Go To Indexwww.alpinehomeair.com - (800) 865-593135

33. Match wires by color inside junction box.Attach wires from whips to correspondingRomex wires. Green (ground) matches copper. Red matches red or white. Black matches black.34. Trim wires and cut back 1/2” of insullation.Use wire nuts to make connections.30. Slide wires through hole in side of junctionbox.31. Replace nut.35. Replace cover on junction box once youhave matched all wires.32. Hand-tighten nut to secure wires.36. Secure flexible wire to ceiling with nails,wire staples and hammer.36Go To Indexwww.alpinehomeair.com - (800) 865-593137

37. Run flexible wire over to main electricalcircuit panel in home.40. Remove access panel.41. Remove nut from electrical whip hangingfrom disconnect box.42. 42. Run whip up through the high-voltageelectrical hole that protrudes from cornerof condensing unit.38. Spool wire up for contractor to completehigh voltage wiring on panel.Hook Up High Voltage Wiring toCondensing Unit43. Slide nut over wires.39. Outside, remove screws from access panelon front of condensing unit.38Go To Indexwww.alpinehomeair.com - (800) 865-593139

44. Tighten nut down on washers.Use spade connectors to make an easyconnection.45. Trim ground (green) wire and strip back1/2”.46. Place ground wire under lug located onside.47. Tighten down with screwdriver.48. Slip spade connectors over end of red andblack wires.The remaining black and red wire from whipwill be connected to either side of contactor.4049. Crimp end of spade connectors with spadecrimpers or pliers.Go To Indexwww.alpinehomeair.com - (800) 865-593141

50. Press red and black wires with spadeconnectors up into contactors, one oneach side.3. Run wires up through low-voltageelectrical hole in front of condensing unit.AC Installation Guide - 9Hook Up Low Voltage Wiring (24 Volts)Hook up Low Voltage Wires toCondensing Unit4. Strip 1/2” of insulation from end of bothwires.Hook up Two-Conductor, 18-Gauge wire(found in Supplies Package) to condensingunit.1. Run wires out hole in side of house.5. Use two blue wire nuts to connect the twoincoming 24-volt wires with the 24-voltwires already attached to the condensingunit.2. Outside, pull wires through hole and runtowards condensing unit.42Go To Indexwww.alpinehomeair.com - (800) 865-593143

(After your contractor solders your line setconnections, replace the foam insulation thatyou had previously removed from suctionline. Use tie wraps to secure it.)6. Make sure all four wires are stripped 1/2”.(Run 24-Volt wire along same line and securewith additional tie wraps. Wait to do this untilyou can replace the insulation.)7. Secure wire nuts by squeezing on ends ofwires.Run Low Voltage Wiring AlongCeiling to Furnace or Air Handler8. Replace access panel on condensing unit.441. Inside, run the 24-Volt wire alongside theline set and secure with plastic tie wraps.Go To Indexwww.alpinehomeair.com - (800) 865-593145

4. Trim the two 24-Volt wires so that they arelong enough to reach the terminals.5. Strip both wires back 1/2”.6. Hook up either of the two wires to terminalC and tighten down with a screwdriver.7. Hook up the other wire to terminal Y andtighten down with a screwdriver.(Some furnaces require you to makeconnections with wire nuts. In this case, youwill connect the 24-Volt wires to the bluefurnace wire and the yellow thermostat wireusing wire nuts. For more information onwiring for these, see our wiring diagrams.)2. Make sure that the power to the furnace/air handler is turned OFF.3. Remove the access panel on the front ofthe furnace/air handler.Next, you will hook up the thermostat to thecondensing unit so that it can turn the airconditioning on and off.You need a total of four wires to run fromthe thermostat to the furnace/air handlerto make the air conditioning run. The wirehooked to the R and W terminals should befour-conductor wire (meaning that two extrawires will be available to hook to two moreterminals for air conditioning). The two extrawires should be protruding from the wirecasing. If there are not two extra wires, youonly have two-conductor wire and it must bereplaced with four-conductor wire.For a standard gas furnace, the control wiringarea displays five or six terminals. Terminalsare labeled C, Y, Gc, Gh, R and W or C, Y, G,R and W. Notice that two wires from yourthermostat are already hooked up to the Rand W terminals.46Go To Indexwww.alpinehomeair.com - (800) 865-593147

11. Inside the thermostat, hook up the whitewire to terminal W, the green wire toterminal G, the yellow wire to terminalY, and the red wire to terminal R (if thereare two R terminals, be sure to install ajumper).8. Hook the extra green wire to the G or Gcterminal and the extra yellow wire to theY terminal.If this is not the lettering configuration in yourthermostat, simply leave the wires hanging forfinal installation by your contractor.9. Replace access panel on furnace or airhandler.12. Replace your thermostat cover.AC Installation Guide - 10Complete the JobRun Wires from Furnace/Air Handler and Hook up toThermostatInstall Drain Tubing1. Use the white barb drain connectorto hook up your drain tubing to theevaporator coil. This will allow waterthat condenses on the coil to empty into afloor drain.10. Remove the cover from your thermostat.Make sure your thermostat has bothheating and cooling capability. Install anew thermostat if necessary.48Go To Indexwww.alpinehomeair.com - (800) 865-593149

If you do not have a floor drain, a CondensateDrain Pump can be used. When installed,this device allows water to be pumped up ordown into an area that allows drainage.The contractor will solder your copperrefrigerant line connections.2. Screw the connector into the drain holealready cut on your sheet metal cover.The contractor will pull a vacuum on therefrigerant line with a vacuum pump.3. Fit the 1/2” drain tubing up into theconnector. Make sure the tubing fitssnugly.Hire a ContractorInstalling central air conditioning consists of two primary parts: what you can doon your own (about 90 percent of the job) and what you need to hire a contractorto complete. Due to federal laws pertaining to the handling of refrigerant, as well asspecial tools required, the completion of the job needs to be handled by an airconditioning professional. Federal law requires that the individual be EPA-certifiedto handle refrigerant. The completion of the project usually costs about 100 300, depending on local labor costs and the extent of the work to be completed.50Go To IndexThe contractor will release refrigerant fromcondenser into system, start system up andbalance pressures.www.alpinehomeair.com - (800) 865-593151

The contractor will connect high voltagewiring to home’s main electrical circuit panel.2. Use tie wraps to secure low-voltage wiringto line set.The contractor will inspect your entireinstallation.3. Use caulking or thumb gum to seal hole inside of houseFinal Details1. Replace insulation on outside portion ofcopper line set.52Go To Indexwww.alpinehomeair.com - (800) 865-593153

Step - By - StepAC InstallationGuidewww.alpinehomeair.com - (800)865-5931

AC Installation Guide - 1 Welcome to the Step-By-Step AC Installation Guide Welcome to Alpine Home Air Products Step-By-Step Central Air Conditioning Installation Guide. Installi