Transcription

Power Transformers

HYUNDAI,A RELIABLEBUSINESS PARTNERIN THE POWERINDUSTRYCONTENTS06Production Range07Transformer Design08Core Construction10Winding12Core & Coil Assembling14Tank15Cooling System16Testing17Research & Development17Quality Assurance18Worldwide Experiences

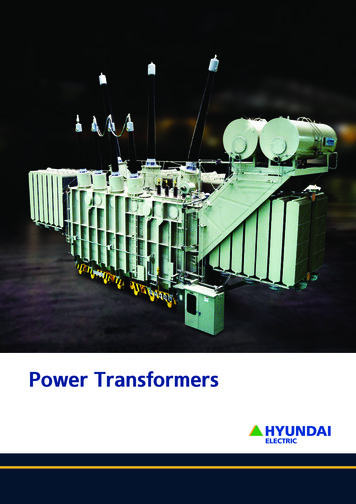

Power TransformersUsing cutting-edge designs, state-of-the-art manufacturingfacilities, and innovative production technology, we manufacturehigh-quality power and distribution transformers with a ratedvoltage of up to 800 kV and a capacity of up to 1,500 MVA.Hyundai transformers are in service around the world and meetinternational standards such as IEC, ANSI, NEMA, CSA, AS, and ES.

ULSAN FACTORY, KOREAALABAMA FACTORYHYUNDAI POWER TRANSFORMERS USA, INC.SOFIA FACTORYHYUNDAI ELECTRIC - BULGARIA

HyundaiTransformersat a GlanceHyundai Electric, being specialized in designand manufacturing of electrical equipment,has been pursuing the business goal ofproviding total solution to the customersaround the world since its establishment.We are offering the complete range ofelectrical equipment for power plants,transmission and distribution, and variousindustrial sectors such as Transformers, SF6Gas Insulated Switchgear, Medium VoltageSwitchgear, Motors, Generators, IntegratedControl & Monitoring Systems, PowerElectronics, etc.Among such wide range of products, HyundaiTransformers, featuring excellent performanceand a high level of reliability proven througha lot of experiences accumulated over a longspan of period, have been delivered to thecustomers and gained good reputation fromthe customers.To best serve our clients with global capacity,we are currently operating Ulsan plant inKorea, Alabama plant in the USA and Sofiaplant in Bulgaria.Hyundai Ulsan factory, equipped with themost advanced manufacturing and testingequipment, and having the annual capacityof 120,000 MVA, is manufacturing the wholerange of transformers from distribution andpower transformers up to 800 kV includingcast resin and various kinds of special purposetransformers such as furnace transformersand gas transformers, etc.Hyundai Power Transformer USA inMontgomery, Alabama is built based onthe invaluable experience and cutting-edgetechnologies gained over 30 years. HyundaiPower Transformer USA strictly follows theprocedures that have been tested and provenfrom Ulsan plant in order to guarantee theproduction of high-quality power transformers.The new plant is fully capable of providingclient-specific power transformers to mostly,but not limited to, North America, SouthAmerica, and African regions. Always strivingto produce innovative and superior powertransformers, Hyundai Power TransformerUSA is confident in achieving worldwidecustomer satisfaction.And Hyundai Sofia factory, with its longexperience of more than 50 years inmanufacturing transformer and tap changers,has been supplying its products to thecustomers for power generation, transmissionand distribution areas.Hyundai, having the competitive edges in price,delivery and quality, has become the worldleading supplier of transformers over the shortspan of period since its establishment. Weare committed to offer the best service for thecustomers including after-sales service.Hyundai has kept total quality system certifiedby ISO 9001 and we are providing qualityproducts and services for the customers inaccordance with their requirements.

06 Power TransformersProduction RangeBeing classified by its application, construction and ratings,Production range of Hyundai Transformer fully covers abovetransformers can be divided into Power Transformer,mentioned transformers and services as follows ;Distribution Transformer, Reactor, Cast Resin Transformerand Special Transformer.Transformer PlantScope of Production & ServicesUlsan Factory in Korea- Power Transformer up to 800 kV / 1,500 MVA- Distribution Transformer- Cast Resin Transformer- Dry Type Transformer- Reactor- Special TransformerAlabama Factory in USA- Power Transformer up to 500 kV / 600 MVA- Distribution Transformer- Reactor- Special TransformerSofia Factory in Bulgaria- Power Transformer up to 420 kV / 200 MVA- Distribution Transformer- Instrument Transformer up to 145 kV- Special Transformer- Tap Changers such as On-Load Tap Changer,Off-circuit Tap Changer and SF6 Gas Insulated Tap ChangerServices to be provided bytransformer factory- Supervision of Transformer Installation & Commissioning- Advisory Services of Transformer Specification- Training of Customer Personnel- Inspection & Trouble Shooting Service- Investigation and Assessment of ProblemsPower TransformerReactorCast Resin TransformerTap Changer

Hyundai Electric 07Transformer DesignBy utilizing the most modern and up-to-date designTaking into account of any possible case of short-circuittechnology, Hyundai provides designs which can meet thefault which may be incurred in service, we utilize acustomer's various requirements and international orcomputer program to calculate accurate radial force, axialnational standards of IEC, ANSI, NEMA, CSA, BS, AS, etc.force and spacer of winding.Also Hyundai design team has sufficient experiences andParticularly, Hyundai can perform seismic analysis with theproven records which can meet the customer's variouscomputer program to ensure that the transformer has theneeds of power, voltage, mode of operation, low noisecapability to withstand the seismic condition.level, connection techniques, type of cooling, transport andinstallation.

08 Power TransformersCore ConstructionThe cores for Hyundai transformers are made of highIn the core of large power transformer, suitable insulationquality, cold-rolled, grain-oriented silicon steel coated withpapers are inserted between the laminations for themagnesium-silicate-phosphate.purpose of reducing eddy currents and also to minimizeLaser scribed or plasma treated silicon steel can be usedmagnetic short-circuit.for those require low loss design.And for the effective cooling, cooling ducts are providedThe standard core construction type of Hyundai transformerbetween the core laminations.is ‘core form type’ having three leg core or five leg core ofthree phase and two leg core, three leg core or four legThe leg core where the hard wooden bars are inserted, arecore of single phase according to the customer’s specialtightened with synthetic resin impregnated glass band.requirement.Step Lap Core LaminationStep lap core lamination is used to reduce no load losses and noise level.

Hyundai Electric 09Core Cut-to-length MachineThe oriented silicon steel is cut by computerizedmachine to minimize air gap in the joint duringassembly.Core StackingFive Leg Core stackingCore Erection EquipmentSpecial core erection equipment is used for thelarge core in order to prevent deflection fromstress and strain during upright setting of thecores.

10 Power TransformersWindingThe winding is made of copper conductor covered withseveral layers of insulation paper or enamel coating ofhigh dielectric strength. Rectangular conductor, multipleconductor and transposed conductor are employed in thewinding. The most optimized conductor is selected afterconsidering the voltage and capacity of the transformer.Especially, the transposed conductor is composed ofseveral wires individually covered with enamel and thisContinuously Transposed Conductorentire wire unit is covered with several layers of insulationpaper.The advantage of using transposed conductor is to decreaseAnd during the manufacturing process of windings, theeddy current loss in the windings, improve of the laminationfollowing factors are taken into account ;factor and manufacture windings within a short time span. Short circuitWhen manufacturing large power transformers, the most Ability to withstand impulsessuitable winding method is employed according to the Eddy current losscapacity, voltage and tap range of each transformer. Ability to distribute over-voltageHorizontal Winding MachineVertical Winding Machine

Hyundai Electric 11Layer WindingHelical WindingApplied to low voltage and large current windingsEmployed according to the magnitude of current in case of low voltagewindingDisc WindingInterleaved Layer WindingApplied for high voltage winding and classified into continuous andinterleaved disc windingApplied for tap winding

12 Power TransformersCore & Coil AssemblingFor insulation, all Hyundai transformers have a concentricThe bottom of the windings rest on the supporting systemwinding structure. One or more insulating cylinders areof the lower yoke. And a large wooden press ring calledplaced around the core legs. The number of insulating"pressing wood" is provided at the top of windings.cylinder depends on the voltage stress between the leg andThe windings are pressed by means of the pressing woodthe winding itself.and bolts on the upper clamp device. All leads and busbarare tightly supported to withstand short-circuit force.Vertical spacers are provided to produce an oil duct forthe cooling of windings. Between the low and high voltageAfter the core and coil assembly is completed, it will bewinding a number of insulating cylinders are provided atdried in the vapor phase drying plants under high vacuumfixed distance from each other by using vertical spacers.condition for the purpose of eliminating moisture content.The high voltage winding is wound on the outer cylinder.Transformer under In-tanking ProcessOn completion of the vacuum drying, the core and coil assembly is inserted in the tank.

Hyundai Electric 13Winding InsertingLow voltage winding, high voltage winding and tapwinding are inserted into a leg core.Core and Coil AssemblyCore and coil assembly of the transformer will putthe core, windings clamping device, tap changerand lead together.Vapor Phase Drying PlantVacuum drying with heat in vapor phase dryingplants.

14 Power TransformersTankProtection of the active parts in the transformer is veryHyundai's strict welding procedure and leak test standardimportant, especially in case of high voltage and largeassure 100% leakproof seams and maximum mechanicalcurrent transformer.strength.While achieving the optimized size of transformer to suit theAfter finishing the welding work, it is shot-blasted tosite condition for installation, the main role of the tank isremove all dust and spatters before painting.to protect the active parts and the tank is manufactured tohave sufficient strength to withstand internal and externalfaults that may occur during operation.And the various ancillary devices such as lifting lug, jackpad, pulling eye and skid base are designed and providedon the tank so that the transformer can be moved in anydirection without damage when using rollers, plates orrails.Non-Destructive Test on Transformer TankPainting of TankTransformer TankThe tank is painted with HHI standard painting system which is polyurethane resin in order to prevent the tank from any possible corrosionwhich may appear according to the site condition.The tank is made of high quality mild steel.

Hyundai Electric 15Cooling SystemA transformer in service has losses which are transformedin to heat to be dissipated but causing to a temperature risein the transformer. In order not to allow the temperature torise above the permissible level, a suitable cooling methodshould be considered and adopted.Generally, the suitable cooling method for the transformeris determined by the customer after due considerationof transformer capacity and the circumstances at theinstallation site.Hyundai can design and manufacture transformerwith various types of cooling systems according to thecustomer’s requirement. ONAN: Natural oil cooling (ON), Natural air cooling (AN) ONAF: Natural oil cooling (ON), Forced air cooling (AF) OFAF: Forced oil cooling (OF), Forced air cooling (AF) ODAF: Directed oil cooling (OD), Forced air cooling (AF)Oil to Air Cooler OFWF: Forced oil cooling (OF), Forced water cooling (WF)Panel Type RadiatorOil to Water Cooler

16 Power TransformersTestingHyundai Electric, as one of leading electrical equipmentmanufacturers, has the state-of-the-art testing laboratorywhich is equipped with the most modernized testingfacilities in the world.In this ultra-high voltage testing laboratory, Hyundaitransformers at the system voltage up to 1,000 kVare subjected to the routine and type tests as per thecustomer's requirements and applicable internationalstandards.Control Room of Ultra-High Voltage Test LaboratoryUltra-High Voltage Test LaboratoryEquipped with 4,400 kV impulse generator and 1,200 kV AC generator

Hyundai Electric 17Research & DevelopmentResearch & Development is an essential requirement forimprovement and advance of modern technology.Hyundai Electric commitment to the research anddevelopment has been a motivating factor of the company’svarious technical achievements and will be vital in itsadvance into the 21st century.Hyundai Electric is operating three renowned in-houseresearch institutes: HMRI(Hyundai Maritime ResearchInstitute), HIRI(Hyundai Industrial Research Institute) andHEMRI (Hyundai Electro-Mechanical Institute) as well as anHyundai transformers have been supplied to most of theoverseas institute (HUNELEC) in Budapest, Hungary.countries all over the world and their technology, qualityand reliable performance have been widely acknowledgedThese institutes are fully equipped with state-of-the-artby the customers around the world.R&D devices and our top-notch brains are exploring thefuture of high technology.Quality AssuranceIt is the policy of Hyundai Electric that the products shallHyundai Electric also considers human safety andmeet the customer's specified and implied requirements,environmental protection, the most important in performingindustrial codes and national standards and shall beall related works in its business, and thus acquired ISOproduced and delivered to the customers on schedule.14001 (Environmental Management Certificate) andOHSAS 18001 Certificate (Occupational Health & SafetyWe have been dedicated to supply the best quality productsand services for our customers. And we have developedour own quality assurance program to comply with the ISO9001 as required by the most authoritative InternationalOrganization for Standardization (ISO) in order to assurethat Hyundai products are designed, manufactured,inspected, tested and delivered in the most efficientmanner.Management System Certificate) from DNV.

18 Power TransformersWorldwide ExperiencesHyundai transformers have been supplied to most of the countries all over the world and have achieved a world-widereputation for their quality and performance to the customer’s satisfaction.EUROPEAFRICATHE MIDDLE EASTASIA300 kV 60 MVA TransformerNedre Vinstra Project in Norway220 kV 125 MVA TransformerEgyptian Electricity TransmissionCompany in Egypt380 kV 502 MVA TransformerPrincess Nora Univ. Project inSaudi Arabia235 kV 500 MVA Generator Stepup TransformerBowin Combined Cycle PowerPlant in Thailand500 kV 390 MVA Generator Stepup TransformerTenaska Georgia Power Plantin USA235 kV 205 MVA Generator Stepup TransformerSempra Energy in USA66 kV 20 MVA TransformerTokyo Electric Power Companyin Japan765 kV 204 MVA Generator Stepup TransformerDangjin Thermal Power Plantin KoreaNORTH AMERICA500 kV 750 MVA TPRS(Tank Pressure Relief System)Transformer / Hydro One inCanadaGlobal aDubaiYangzhongShanghaiRiyadhAnantapurBangkok

Hyundai Electric 19EUROPEAFRICATHE MIDDLE EASTASIAOCEANIASOUTH GYPTKENYALIBYANIGERIASOUTH AFRICASUDANBAHRAINIRANIRAQJORDANLEBANONOMANSAUDI NEPALPAKISTANPHILIPPINESSINGAPORESRI LANKATAIWANTHAILANDVIETNAMAUSTRALIANEW ZEALANDPAPUA NEW TH AMERICACANADAMEXICOUSACENTRAL AMERICAGUATEMALANICARAGUAPANAMACARIBBEANCUBAPUERTO RICOTRINIDAD AND TOBAGOAlabamaAtlantaOverseas SubsidiariesOverseas Branch OfficeR&D Center

HE-TE-B04-19, 2018.11 Designed by designwatKOREAHeadquarter(Financial)Hyundai Bldg, 75, Yulgok-ro, Jongno-gu, Seoul, KoreaTel: 82-2-746-7646 / Fax: 82-2-746-7441Sales & Marketing(Seongnam)5th Floor 55, Bundang-ro, Bundang-gu, Seongnam-si, Gyeonggi-do, KoreaTel: 82-31-8006-6698, 6756 / Fax: 82-31-8006-6835Main Factory(Ulsan)700, Bangeojinsunhwan-doro, Dong-gu, Ulsan, KoreaTel: 82-52-202-8114 / Fax: 82-52-202-8010Seonam Factory(Ulsan)223, Sapyong-ro, Nam-gu, Ulsan, KoreaTel: 82-52-202-8114R&D Center(Yongin)17-10, 240-gil, Mabuk-ro, Giheung-gu, Yongin-si, KoreaTel: 82-31-289-5114 / Fax: 82-31-289-5040OVERSEASBranch OfficesU.S.A(Atlanta)6100 Atlantic Boulevard, 2nd FL., Norcross, GA30071, U.S.ATel: 1-678-823-7839 / Fax: 1-678-823-7553Japan(Osaka)5th Floor Nagahori Plaza Bldg. 2-4-8 Minami Senba, Chuo-ku, Osaka 542-0081, JapanTel: 81-6-6261-5766 7 / Fax: 81-6-6261-5818Saudi Arabia(Riyadh)Office number 404, 4th floor,Akaria-3 building, Olaya street, P.O Box 8072, Riyadh, 11482, Kindom of Saudi ArabiaTel: 966-11-464-4696, 9366 / Fax: 966-11-462-2352Russia(Moscow)World Trade Center, Ent.3, #703, Krasnopresnenskaya Nab.12, Moscow, 123610, RussiaTel: 7-495-258-1381U.A.E(Dubai)Unit 205, Emaar Square Building No.4 Sheikh Zayed Road, Dubai 252458, U.A.ETel: 971-4-425-7995 / Fax: 971-4-425-7996Germany(Frankfurt)Mendelssohn strabe 55-59 Frankfurt 60325, GermanyTel: 49-69-4699-4988Thailand(Bangkok)19th Floor, Unit 1908, Sathorn Square Office Tower, 98 North Sathorn Road, Silom, Bangrak, Bangkok 10500, ThailandTel: 66-02-115-7920 / Fax: 66-2-115-7898SubsidiariesU.S.A(Alabama)215 Folmar Parkway, Montgomery, AL 36105, U.S.A.Tel: 1-334-481-2000 / Fax: 1-334-481-2098Bulgaria(Sofia)41, Rojen Blvd., 1271 Sofia, BulgariaTel: 359-2-803-3200, 3210, 3220 / Fax: 359-2-803-3203, 3242China(Yangzhong)No.9, Xiandai Road, Xinba Scientific and Technologic Zone, Yangzhong, Jiangsu, P.R.C. Zip:212212, ChinaTel: 86-511-8842-0666, 0500 / Fax: 86-511-8842-0668, 0231India(Anantapur)5-289-4, Near Aimuktheeshwara Temple, Penukonda Mandal, Penukonda, Anantapur Dist, Andhrapradesh-515110, IndiaTel: 91-93982-5137R&D CentersHungary(Budapest)Hyundai Technologies Center Hungary ltd., 1146, Budapest, Hermina ut 22, HungaryTel: 36-1-273-3733 / Fax: 36-1-220-6708China(Shanghai)Room 10102, Building 10, No.498, Guoshoujing Road, Pudong, Shanghai, ChinaTel: 86-21-5013-3393 #108 / Fax: 86-21-5013-3393 #105Switzerland(Zurich)Hardturmstrasse 135, CH-8005, Zurich, SwitzerlandTel: 41-44-527-0-56www.hyundai-electric.com

Power Transformer Reactor Cast Resin Transformer Tap Changer Transformer Plant Scope of Production & Services Ulsan Factory in Korea - Power Transformer up to 800 kV / 1,500 MVA - Distribution Transformer - Cast Resin Transformer - Dry Type Transformer - Reactor - Special Transformer Alabama Factory in USA -