Transcription

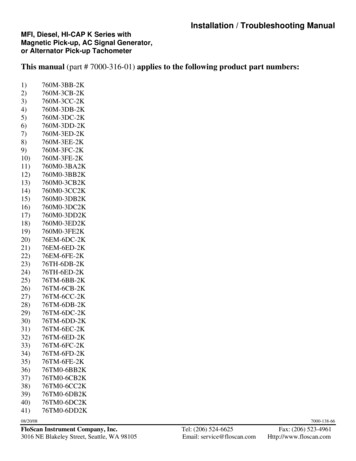

Service Manual9. Troubleshooting9.1 Malfunction IndicatorThe error code will be displayed on the wired controller and the main board of the outdoor unit.The meaning of each error, as shown in table 13.Name of malfunctionYellow lightThe indicator displayRed lightGreen lightIndoor displayCompressor runsFlash onceDefrostFlash twiceH1Anti-freezing protectionFlash 3 timesE2IPM protectionFlash 4 timesH5AC over-current protectionFlash 5 timesE5Over-burden protectionFlash 6 timesH4Compressor exhaust high temperature protectionFlash 7 timesE4Compressor overload protectionFlash 8 timesH3Power protectionFlash 9 timesL9EEPROM reads and write protectionFlash 11 timesLow PN voltage protectionFlash 12 timesPLOver voltage protection for PNFlash 13 timesPHPFC protectionFlash 14 timesHCPFC module temperature protectionFlash 15 timesoELow pressure protectionFlash 17 timesE3High pressure protectionFlash 18 timesE1Limit/decline frequency(electric current)Flash 1 timesFrequency limit(exhaust)Flash 2 timesFrequency limit(Over-burden)Flash 3 timesOutdoor ambient sensor malfunctionFlash 6 timesF3Outdoor tube sensor malfunctionFlash 5 timesF4Exhaust sensor malfunctionFlash 7 timesF5Attain the temperature of switch onFlash 8 timesFrequency limit(power)Flash 13 timesOutdoor fan malfunctionFlash 14 timesFrequency limit(PFC module temperature)Flash 15 timesPFC module sensor malfunctionFlash 16 timesLiquid pipe temperature sensor malfunction of AFlash 17 timesInstallation and MaintenanceoE23

4343444445454646474848Communication failurefailure withwith UnitUnit ication failure with Unit BCommunication failurefailure withwith UnitUnit CCCommunicationCommunication failurefailure withwith UnitUnit DDCommunicationUnit A freeze protectionUnit BB freezefreeze protectionprotectionUnitGas47pipe Unittemperaturesensor malfunction of AA freeze protectionLiquid pipe temperature sensor malfunction of B49 UnitUnit CC freezefreeze protectionprotection4950 Unit D freeze protection51 pipeUnitA ionof C52UnitBoverheatingpreventionprotection52 Unit B overheating prevention protectionGas50pipe Unittemperaturesensor malfunction of BD freeze protectionGas53pipe Unittemperaturesensormalfunctionof CC overheatingoverheatingpreventionprotection53 UnitCpreventionprotection54 pipeUnitD ionof D ƼƼ Flash 18 timesƼƼ Flash 19 times Flash 20 timesƼƼ Flash 21 times Flash 22 timesƼƼ Flash 23 times Unit AA communicationcommunication wirewire misconnectionmisconnection oror expansionexpansion valvevalve malfunctionmalfunction Unit555556 Unit B communication wire misconnection or expansion valve orexpansionvalvemalfunction 57 pipeUnitC communicationwiremisconnection Liquidtemperaturesensormalfunctionof Eor expansion valve malfunctionFlash 25 ionvalvemalfunction 58 Unit D communication wire misconnection or expansion valve malfunction Gas56pipe Unittemperaturesensorwiremalfunctionof D or expansion valve malfunctionFlash 24 timesB communicationmisconnectionƼGas pipe temperature sensor malfunction of EFlash 26 timesExit of the condenser tube sensor malfunctionFlash 27 timesƼƼƼƼ ƼƼƼƼƼƼ ƼƼƼƼƼƼƼƼƼƼƼƼƼƼƼƼƼƼ Service ManualƼƼƼƼƼƼƼƼƼƼFlash 7times(n indoorNote: dischargedischarge thethe positionposition inin belowbelow picturespictures withwith dischargedischarge resistanceresistance afterafter openopen thethe toptop covercover andandNote:unit number)check ifif thethe voltagevoltage isis belowbelow 20V20V withwith universaluniversal meter,meter, thenthen beginbegin toto check.check.checkOften oorunit ationfailure)Correspondence is normalIndoor ambient sensor malfunctionF1Indoor evaporate sensor malfunctionF2Mode conflictE7Accept fluorine modeFoJumper cap malfunction protectionC5Anti-freezing protectionFH9.2 Malfunction Checking and Elimination1 IPMIPM protectionprotection malfunction:malfunction:1Main checkingchecking point:point:Main If thethe inputinput voltagevoltage ofof thethe unitunit isis withinwithin normalnormal range?range?IfIf thethe connectionconnection wirewire ofof compressorcompressor isis connectedconnected well?well? IsIs itit loose?loose? IfIf thethe connectionconnection sequencesequence isis correct?correct?If If thethe resistanceresistance ofof compressorcompressor coilcoil isis normal?normal? IfIf thethe isolationisolation ofof compressorcompressor coilcoil withwith coppercopper pipepipe isis good?good?IfIf thethe unitunit isis overloaded?overloaded? IfIf thethe heatheat radiationradiation ofof thethe unitunit isis good?good?If If thethe refrigerantrefrigerant chargecharge isis suitable?suitable?IfFlow chart:chart:Flow24Installation and Maintenance

Service ManualEnergize the unitPlease check:1. if the indoor and outdoor heat exchanges aredirty, if there is obstacle to affect the radiation;2. if the indoor and outdoor fans are runningnormally;3. if the pressure of the system is too high;4. if the refrigerant is too much which causesthe high level of pressure;If the above cases are existed?YesNoCorrect according to the servicemanual and then energize theunit to operateNoIf the wire of compressor is connectedwell and correctly?YesReconnect the wire of thecompressor according to thecorrect wiring methodTest the resistance betweenthe three phasesNoIf the resistance is normal?YesTest the isolation impedancebetween the three phases of thecompressor and thecopper pipeYesIf the resistance is above 500M?NoReplace thecompressorMalfunction is eliminatedYesNoReplace the outdoormainboardEndInstallation and Maintenance25

Service Manual2. PFC protection malfunction, capacity charging malfunctionMain checking points:If the wiring of the induction is connected well and if the induction is broken;If the mainboard is broken;Flow chart:StartStartCheck if power supply is normalCheck If the power supply is normalPower supply is abnormal?Power supply is abnormalYesTurn on the unitafter power supplyresumes normalTurn on the unit after thepower supply resumes toYesnormal situationNoNoCheck if the outdoor induction is brokenReplace the outdoormainboardThe induction is broEndkenReplace the inductionYesNoReplace the outdoormainboardNoMalfunction is eliminatedYesEnd26Installation and Maintenance

Service Manual3. Compressor desynchronizing malfunctionMain checking points:If the pressure of the system is too high;If the eletric expansion valve is working normally or it is broken;If the radiation of the unit is good;Flow chart:The unit appears desynchronizingas soon as energizing and startingThe stop duration of the compressor is longerNothan 3min?YesThe wiring of the compressor isconnected properly?YesNoReconnect the wire properlyNoEliminate the malfunctionThe eletric expansion valve is broken?YesNoNoYesReplace the eletricexpansion valveEliminate the malfunctionYesReplace the outdoor mainboardEliminate the malfunctionYesNoReplace the compressorEndInstallation and Maintenance27

Service ManualDesynchronizing happensduring operationOutdoor unit is working?NoCheck if fanterminal isconnected wellReplace the fan capacitorNoImprove radiationsituation of the unit(such as cleaningthe heat exchanger,improve ventilationReplace the outdoor unitYesUnit radiation is good?YesInput voltage is normal?NoTurn on the unitafter the powersupply voltageresumes normalYesCharge refrigerantRefrigerant amount is too much?Yesaccording to theservice manualNoReplace the outdoormainboardEliminate the malfunctionYesNoReplace the compressorEnd28Installation and Maintenance

Service Manual4. Compressor overload, diacharge protectionmalfunctionMain checking points:If the eletric expansion valve is connected well or it is broken;If there is refrigerant leakage;If the overload protector is broken;Flow chart:StartIf the overload protector is connected well?NoYesNoCheck the resistance between the twoends of the overload protector in ambient temperature,if the resistance is below 1kYesIf the wiring of the eletric expansion valveis coonected well?NoReconnect accordingto the wiring diagramYesReplace theoverloadprotectorCheck the coil of the eletricexpansion valve, replaceit if it is brokenEliminate the malfunctionYesNoCheck the refrigerant status, if there isrefrigerant leakage, recharge it accordingto the service manualEliminate the malfunctionYesNoReplace outdoormainboardEndNote: the detection method of the coil of the eletric expansion valve: there is five pieces of coil of the eletric expansion valve,the resistance of one of them (the leftmost or the rightmost one) is almost the same as the resistance of other terminal (within100). Judge the condition of the electronic expansion valve through detecting these resistance.Installation and Maintenance29

Service Manual5. Start failuremalfunctionMain checking points:If the connection wire of the compressor is connected properly;If the stop duration of the compressor is sufficient;If the compressor is broken;If the; refrigerant charging amount is too much;Flow chart:Energize andstart the unitIf the stop duration of the compressoris longer than 3minNoYesIf the connection wire of the compressoris connected well and correctlyNoYesNoNoIf the refrigerant chargingamount is too muchReconnect the connection wireof the compressor accordingto the wiring diagramEliminate the malfunctionYesYesCharge the refrigerantaccording to theservice manualEliminate the malfunctionYesNoThe stop duration of the unit isnot enough, the high and lowpressure of the system is notbalanced, restart it after 3minReplace the outdoormainboardEliminate the malfunctionYesNoReplace the compressorEnd30Installation and Maintenance

Service Manual6. Temperature sensor malfunctionMain checking points:If the temperature; sensor is damaged or brokenIf the terminal of the temperature sensor is loosended or not connected;If the mainboard is broken;Flow chart:StartCheck whether the wiring terminal betweentemperature sensor and controller is loosened or poorlycontacted?YesInsert the temperaturesensor tightlyNoEliminate themalfunctionNoCheck whether thetemperature senspr is normal according toNoReplace the temperature sensorwith the same modelNoEliminate the malfunction6.resistance tableYesYesYesReplace the controller withthe same modelEndInstallation and Maintenance31

Service Manual7. DC fan malfunctionMain checking points:If the outdoor fan is blocked by foreign objects;The connection wire of DC fan is connected reliably? If it is loose?Flow chart:StartCheck if theoutdoor fan is blocked byYesforeign objects?Turn on the unitafter removing theforeign objectsNoIf the connection wireof DC fan is loose?YesTurn on the unit afterthe connection wireis properly connectedNoReplace the outdoormainboardEnd32Installation and Maintenance

Service Manual8. Communication malfunctionMain checking points:If the connection wire between the indoor unit and outdoor unit is connected well, if the wires inside the unit is connected well;If the indoor mainboard or outdoor main board is broken;Flow chart:Communication malfunction of someindoor unitsDe-energize,check if the connectionwire of indoor and outdoor unit andthe wire of the eletric box isconnected correctlyConnected correctlyNoReconnect according tothe wiring diagramEliminate the malfunctionNoYesYesDe-energize, change the communication wire of the wellcommunicated indoor unit and malfunction indoor unit,then energize the unit and wait for 3minThe malfunction indoor unitresumes normalYesReplace outdoormainboardNoReplace the mainboard of themalfunction indoor unitEndInstallation and Maintenance33

Service ManualAll the indoor units appearcommunication malfunctionDe-energize,check if the connectionwire of indoor and outdoor unit andthe wire of the eletric box isconnected correctlyConnected correctly?Reconnect according toNothe wiring diagramEliminate the malfunctionYesYesDe-energize, check if the connection wire betweenthe outdoor mainboard and the filter boardaccording to the wiring diagramConnected correctly?NoReconnect according tothe wiring diagramEliminate the malfunctionYesNoYesYesThe connection wire is broken?Replace theconnection wireEliminate the malfunctionYesNoNoCheck if there is power inputbewtween the netrual wire and livewire of the outdoor mainboardThere is power input?NoReplace the filter board ofthe outdoor unitEliminate the malfunctionYesNoYesReplace the outdoormainboardResume communication?NoReplace indoormainboardYesEnd34Installation and Maintenance

Service Manual9. Anti-high temperatureand overload malfunctionMain checking points:If the outdoor ambient temperature is within the normal range;If the indoor fan and outdoor fan are running normally;If the indoor and outdoor radiation environment is good;Flow chart:StartIf the outdoor ambient temperatureis above 53YesIt is a normal protection, pleaseoperate the unit after the outdoorambient temperature has changedYesImprove the radiationenvironment of the unitNoIf the indoor and outdoor radiationis insufficientNoIf the outdoor fan is working normallyNoCheck if the terminal of the fan isconnected well, if the fan is brokenYesReplace fan capacitorReplace outdoormainboardReplace outdoor fanEndInstallation and Maintenance35

Service Manual9.3 Maintenance Method for Normal Malfunction1. Air Conditioner Can't be Started UpPossible CausesNo power supply, or poorconnection for power plugDiscriminating Method (Air conditioner Status)TroubleshootingConfirm whether it's due to power failure. If yes,After energization, operation indicator isn’t bright wait for power recovery. If not, check powerand the buzzer can't give out soundsupply circuit and make sure the power plug isconnected well.Wrong wire connection betweenindoor unit and outdoor unit,Under normal power supply circumstances,or poor connection for wiringoperation indicator isn't bright after energizationterminalsCheck the circuit according to circuit diagramand connect wires correctly. Make sure allwiring terminals are connected firmlyMake sure the air conditioner is groundedreliablyMake sure wires of air conditioner is connectedAfter energization, room circuit breaker trips off atElectric leakage for air conditionercorrectlyonceCheck the wiring inside air conditioner. Checkwhether the insulation layer of power cord isdamaged; if yes, place the power cord.Model selection for air switch isAfter energization, air switch trips offSelect proper air switchimproperAfter energization, operation indicator is bright,Replace batteries for remote controllerMalfunction of remote controller while no display on remote controller or buttonsRepair or replace remote controllerhave no action.2. Poor Cooling (Heating) for Air ConditionerPossible CausesSet temperature is improperRotation speed of the IDU fanmotor is set too lowFilter of indoor unit is blockedDiscriminating Method (Air conditioner Status)TroubleshootingObserve the set temperature on remote controller Adjust the set temperatureSmall wind blowSet the fan speed at high or mediumCheck the filter to see it's blockedClean the filterCheck whether the installation postion is properInstallation position for indoor unitAdjust the installation position, and install theaccording to installation requirement for airand outdoor unit is improperrainproof and sunproof for outdoor unitconditionerDischarged air temperature during cooling ishigher than normal discharged wind temperature;Discharged air temperature during heating isFind out the leakage causes and deal with it.Refrigerant is leakinglower than normal discharged wind temperature; Add refrigerant.Unit's pressure is much lower than regulatedrangeMalfunction of 4-way valveBlow cold wind during heatingReplace the 4-way valveDischarged air temperature during cooling ishigher than normal discharged wind temperature;Discharged air temperature during heating isMalfunction of capillarylower than normal discharged wind temperature; Replace the capillaryUnit't pressure is much lower than regulatedrange. If refrigerant isn’t leaking, part of capillaryis blockedFlow volume of valve isThe pressure of valves is much lower than thatOpen the valve completelyinsufficientstated in the specificationRefer to point 3 of maintenance method forMalfunction of horizontal louver Horizontal louver can’t swingdetailsRefer to troubleshooting for H6 for maintenanceMalfunction of the IDU fan motor The IDU fan motor can’t operatemethod in detailsRefer to point 4 of maintenance method forMalfunction of the ODU fan motor The ODU fan motor can't operatedetailsRefer to point 5 of maintenance method forMalfunction of compressorCompressor can't operatedetails3. Horizontal Louver Can't SwingPossible CausesWrong wire connection, or poorconnectionCheck the wiring status according to circuitdiagramStepping motor is damagedStepping motor can't operateOthers are all normal, while horizontal louvercan't operateMain board is damaged36Discriminating Method (Air conditioner Status)TroubleshootingConnect wires according to wiring diagram tomake sure all wiring terminals are connectedfirmlyRepair or replace stepping motorReplace the main board with the same modelInstallation and Maintenance

Service Manual4. ODU Fan Motor Can't OperatePossible causesWrong wire connection, or poorconnectionDiscriminating method (air conditioner status)Check the wiring status according to circuitdiagramTroubleshootingConnect wires according to wiring diagram tomake sure all wiring terminals are connectedfirmlyMeasure the capacity of fan capacitor with anCapacity of the ODU fan motor is universal meter and find that the capacity is out ofReplace the capacity of fandamagedthe deviation range indicated on the nameplate offan capacitor.Power voltage is a little low orUse universal meter to measure the power supplySuggest to equip with voltage regulatorhighvoltage. The voltage is a little high or lowWhen unit is on, cooling/heating performanceChange compressor oil and refrigerant. If noMotor of outdoor unit is damaged is bad and ODU compressor generates a lot ofbetter, replace the compressor with a new onenoise and heat.5. Compressor Can't OperatePossible causesWrong wire connection, or poorconnectionDiscriminating method (air conditioner status)Check the wiring status according to circuitdiagramTroubleshootingConnect wires according to wiring diagram tomake sure all wiring terminals are connectedfirmlyMeasure the capacity of fan capacitor with anuniversal meter and find that the capacity is out ofReplace the compressor capacitorthe deviation range indicated on the nameplate offan capacitor.Power voltage is a little low orUse universal meter to measure the power supplySuggest to equip with voltage regulatorhighvoltage. The voltage is a little high or lowUse universal meter to measure the resistanceCoil of compressor is burnt outRepair or replace compressorbetween compressor terminals and it's 0Cylinder of compressor is blocked Compressor can't operateRepair or replace compressorCapacity of compressor isdamaged6. Air Conditioner is LeakingPossible causesDiscriminating method (air conditioner status)TroubleshootingEliminate the foreign objects inside the drainpipeReplace drain pipeDrain pipe is blockedWater leaking from indoor unitDrain pipe is brokenWater leaking from drain pipeWater leaking from the pipe connection place ofWrap it again and bundle it tightlyindoor unitWrapping is not tight7. Abnormal Sound and VibrationPossible causesDiscriminating method (air conditioner status)When turn on or turn off the unit,the panel and other parts willThere's the sound of "PAPA"expand and there's abnormalsoundWhen turn on o

24 Installation and Maintenance Service Manual 14/18K: 24/28K: 43 Communication failure with Unit A ¼ 44 Communication failure with Unit B ¼ ¼ 45 Communication failure with Unit C ¼ 46 Communication failure with Unit D ¼ 47 U