Transcription

Next-GenSIMULATION& TRAINING

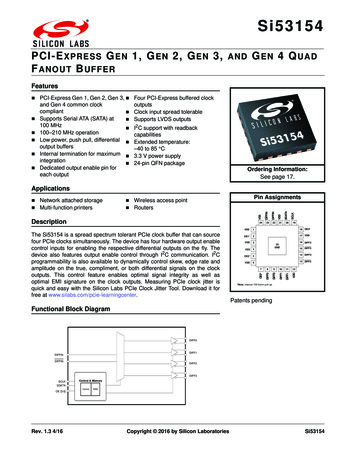

IMPROVE PRODUCTION EFFICIENCYSimuPACTis an Advanced Simulation Platform to hostFull-Scope Operator Training Simulators.Seamless integration with 3D PACT toenable comprehensive Crew Training.SimuPACT is a Powerful, Scalable and Flexible Software Platform builtfor all leading industries and systems with three main components:MODELLING TOOLS DCS EMULATION VIRTUAL INSTRUCTORMODELLINGTOOLSSimuPACT is an extremely powerful, integrated software platformwhich enables engineers to develop high fidelity, full-scope powerand process plant simulators quicker than ever before.It sports a modern, intuitive graphical user-interface which makesit exciting to develop, analyse and train on.The power of SimuPACT comes from embracing the latestsoftware technologies and engineering strategies, enablingquicker development of full-scope plant simulators, and deliveringhigher accuracy, which allows engineering analysis and operatortraining on the same simulation platform, at no extra cost.Page 2 of 7

Default Libraries in SimuPACT:FLOW SOLVERMulti-phase flow solver with incondensable gases and traceelements. The flow solver contains all components required tobuild a full-scope, high-fidelity flow model, e.g. pipes, valves, tanks,heaters, pumps, compressors, etc.CONTROL SYSTEMLIBRARYControl System (DCS) Library containing all control fundamentalslike links, ports and generic control system building blocks. It canbe used to develop and test a full-scope DCS system for any plant.SCRIPTING LIBRARYIntegrated C# Scripting Engine enables almost limitlesscustomizability and flexibility for power users.ELECTRICAL NETWORKSElectrical network solver and components to fully simulate thecomplete electrical reticulation for a power plant, including buses,motors, transformers, breakers, generators, etc.MILL/PULVERIZERMill models for the milling of coal into pulverized fuel, including balland vertical spindle mills.TRANSMITTERMATERIALS HANDLINGSHAFT LIBRARYAll instruments between the process model and the control system.This includes all standard transmitters and switches for measuringflow, temperature, pressure etc.Component models to simulate a materials handling system, e.g.conveyor belts, feeders, splitters, bins, gate valves, etc.Contains all components needed to simulate mechanical shafts,such as motor and turbine shafts, including models for standardbearing types and vibration monitoring.NUCLEAR POWERNuclear power plant library that contains a 3D neutron diffusionmodel for a pressurized water reactor (PWR).ACTUATORContains all interface objects between actuator models and thecontrol system to operate process equipment such as valvesand motors. This includes numerous types of valve actuatorcomponents and motor drives.FURNACEContains components such as a detailed combustion modelto simulate a furnace, including advanced burner and flamesimulation, as required to simulate coal, oil and gas boilers oftype drum, Benson, supercritical, ultrasupercritical and CirculatingFluidized Bed (CFB) type, as well as Combustion Turbines.OPC SERVER/CLIENTOPC Server and Client for Integration to 3rd party systems, such asvendor-supplied DCS and/or HMI emulators.LADDER LOGIC LIBRARYLadder logic emulator based on the GE Machine edition ladderlogic system. The ladder logic library features the same engineeringfunctions as the DCS library, but the main difference is theexecution order that is based on rows.VISUALISATION LIBRARYFull-featured to emulate computer-based HMI systems, localcontrol panels and soft panels. Contains a comprehensivetrending system, alarm and event processing/handling, aswell as all fundamental graphic objects such as rectangles,polygons, buttons, gauges etc. The system can be extended andcustomized, and all objects have animation capabilities based onsimulator property values. Styles are used to define the appearanceof an object, for example to assign an image as a background or tospecify border widths etc.Page 3 of 7

DCSEMULATIONA DCS/HMI emulation for a Plant-Specific Engineering orTraining Simulator can be deployed in 3 ways:» Automatic Translation - SimuPACT» Manual Replication - SimuPACT» Virtual System - Supplied by DCS/HMI VendorAll DCS/HMI files from the actual plant are passed to anapplication which automatically builds an emulation insideSimuPACT.DCS SystemsSupportedABB 800xAABB 800xA/AC800MABB 800xA/MelodyABB Advant Controller 450ABB Harmony/Infi 90ABB Operate IT PPBABB POS30ABB Procontrol P14ABB Symphony Plus (S )Alstom ALSPA P320Emerson Delta VEmerson OvationFoxboro I/AGE Machine EditionGE Mark VIGE Mark VI CimplicityGE Mark VleGE Mark Vle CimplicityHoneywell ExperionHard PanelsMauellSiemens PCS7Siemens SPPA-T2000Siemens SPPA-T3000Siemens WinCCToshiba TOSMAPTriconexAUTOMATICTRANSLATION- SimuPACTThis includes automated setup of control and visual blocks’layout, faceplates, I/O signals and control signals for integrationwith a SimuPACT or 3rd party Process Model.This way is quick and efficient, and accommodates easyupdating of a Simulator in case the plant DCS/HMI changes.Manual drawing of all DCS/HMI screens, and creating all controland visual blocks, faceplates, I/O and control signals manuallyinside SimuPACT.MANUALREPLICATION- SimuPACTThis is to give an accurate representation of the actual plantDCS and/or look-and-feel of the actual plant HMI for integrationwith a SimuPACT or 3rd party Process Model.Even though updates on the Simulator do take more time thanthe other options in case the plant DCS/HMI changes, it is verycost-effective.Any DCS/HMI system can be emulated manually inSimuPACT (if we don’t already have an automatic translator)VIRTUALSYSTEM- Supplied byDCS/HMI VendorAll DCS/HMI files from the actual plant are passed to anapplication developed by the DCS/HMI vendor whichautomatically builds an emulation to run on a PC application,also developed by the vendor.This method also includes automated setup of control andvisual blocks’ layout, faceplates, I/O signals and control signalsfor integration with a SimuPACT or 3rd party Process Model.This way generally produces the most accurate emulationof the plant’s DCS/HMI system, but is also significantly moreexpensive than the other 2 options. Similar to the SimuPACTautomated translation option, it is quick and efficient, andaccommodates easy updating of a Simulator in case the plantDCS/HMI changes.We support all Systems from Major DCS VendorsPage 4 of 7

VIRTUALINSTRUCTOREasily create interactive training modules that guide the traineethrough an operating procedure, and optimize knowledge capturefrom experienced staff.» Instructor can compile elaborate performance requirements fortrainee to comply with while executing procedures/scenarios» Out Of Bounds (OOB) Monitor to ensure trainee never receivesnegative training» Tutorial (TUT) messages to assist trainee during trainingsessions, with flexible scoring penalties if assistance is requiredduring test situationsInstructorless 24/7 training possible using the VI’s powerfulscenario/procedure builder.SCENARIO SETUP:The Instructor can initiate an event recording system which willrecord all actions. The recording can be used for reporting, orsaved as a scenario for future use or it can be edited and onlycertain of the actions used to create a custom scenario.Actions that are recorded, include the following:» Initial Condition initiation» Actuation of student evaluation system» Actuation of pre-programmed and custom malfunctions» Initiation of pre-programmed monitor trending» Instructors can therefore set up their own scenarios, and/orhave some set up (by SimGenics) during commissioning of thesimulator.TRAINEE PERFORMANCEREVIEW (TPR):Using the virtual instructor, the instructor can set up customized,time-based limits for variables to be monitored during trainingsessions. The instructor can add any process variable from thesimulator. For each second the variable is not within the specifiedlimits the score for the variable will reduce. The weight for eachvariable is also considered in the total score calculation. When thescore for a variable reaches the aborting score value the simulationwill stop and the trainee needs to restart the scenario.Page 5 of 7

.VIRTUAL INSTRUCTORREPORTING:All the data above are stored and the instructor can look at theresults from the training session in their own time. The instructorcan also view the history of the same trainee over a time and seewhere the trainee has improved or if the trainee keeps making thesame mistakes.All trends from the training session is also stored for later viewingand analysis by the instructor.TUTOR SYSTEM (TUT):This feature allows the Instructor to define rules or hints that willhelp and steer the trainee during a training session. The rule/hintwill typically monitor a few process variables concurrently andbased on their combined values recommend one or more actionsto the trainee. Each time the trainee gets a TUT message he/shewill lose 1% of their total score.(Changeable according to user requirements)OUT OF BOUNDS MONITOR(OOB):This feature allows the instructor to define ranges for criticalparameters that will cause the simulator to stop/freeze if the traineeallows any of those variables to go out of the defined range duringa training session. There is also a messaging system that warns thetrainee if a parameter is nearing an out-ofbounds condition.Each time the trainee gets an OOB message he/she will lose 2% oftheir total score.(Changeable according to user requirements)Page 6 of 7

United States Head OfficeSimGenics Simulation Solutions LLC744 Horizon Ct, Suite 100Grand Junction, Colorado81506United States of AmericaTel: 1 (970) 639-2498Fax: 1 (817) 736-0427South AfricaSimGenics (Pty) Ltd.Corobay Corner Unit A-3003152 Dallas AvenueWaterkloof GlenPretoriaSouth AfricaTel: 27 (0) 12 345 5702/3Fax: 27 (0) 12 345 5704AustraliaSimGenics Pty Ltd.Level 1, 16 McDougall StreetMiltonQLD, 4064AustraliaPhone: 61 (0) 400 123 033Fax: 61 (0) 7 3198 2401simgenics.comPartnersSouth AfricaM-Tech Industrial (Pty) Ltd.Block E & F, 24 Totius StrPotchefstroomSouth AfricaTel: 27 (0) 18 297 0326/7Fax: 27 (0) 18 297 0318e-mail: iaDHIO Research & Engineering Pvt. Ltd.No 277, 1st Floor, Above CentralBank, 8th main, 4th Block, 3rd StageBasaveshwaranagarBangalore, 560 079IndiaTel: 91 080 42151310http://dhio.in/

Siemens PCS7 Siemens SPPA-T2000 Siemens SPPA-T3000 Siemens WinCC Toshiba TOSMAP Triconex AUTOMATIC TRANSLATION - SimuPACT All DCS/HMI files from the actual plant are passed to an application which automatically builds an emulation inside SimuPACT. This includes automated setup of control and visual blocks'