Transcription

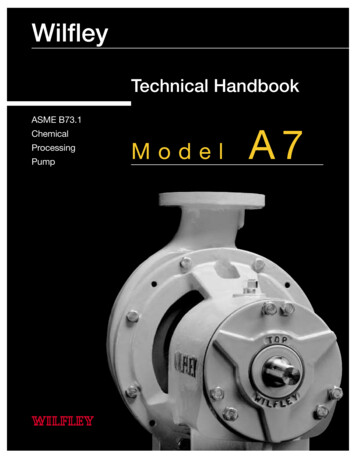

WilfleyTechnical HandbookASME B73.1ChemicalProcessingPumpModelA7

Wilfley Model A7 Chemical Processing PumpsWilfley hydraulic seal in actual operation.ASME B73.1 M-91Wilfley’s Model A7 pump seriesoffers maximum efficiency coupledwith ultimate seal flexibility. It isdesigned to be sealless, but canalso be used with virtually anytraditional seal—packing ormechanical.The Model A7 is an end-suction,single-stage centrifugal pump thatmeets ASME B73.1 M-91requirements. It handles liquids thatare highly corrosive and abrasive.Discharge sizes range from 1" to 8"in diameter. Flow rates range to4,500 gallons per minute.Original Sealless OperationTo prevent leakage while running,Model A7 pumps have the originalWilfley expeller. The impeller andexpeller rotate together duringoperation creating a hydraulic sealthat keeps liquids away from theshaft while the pump is operating.Static seal faces prevent leakagewhen the pump is shut down. Thepump remains leak free whilerunning and while shut down.Wilfley seals can be run dry withoutdamaging internal parts becausewetted parts operate freely with norubbing contact. Constant downtime to repair and replaceconventional contact seals iseliminated.Ultimate FlexibilityWilfley Model A7 pumps aredesigned to handle a wide range ofcorrosive applications—no matterwhat the requirements. Wilfleyengineers each pump to perform toexact specifications.

A.R. Wilfley & Sons is proud of theindividual engineering servicetraditionally provided to customers.Wilfley engineers have developednew sealing flexibility in answer tocustomers’ requests.The DryLock and Lube Seal arenow exclusively available throughWilfley for the Model A7. TheModel A7 can also use most otheravailable seals. This flexibilityextends to vapor seals. The A7series frame can use conventionallip seals, labyrinth or magnet seals.DischargeImpeller pumps liquidfrom suction todischarge.Pump Running/Seal OpenTradition of Innovation and QualityPump Off/Seal ClosedExpellerToday, Wilfley’s applications andengineering staff continue toprovide the most up-to-dateinformation and innovativetechnology on pumps and pumpprocesses to customers around theworld.SuctionImpellerArthur Redman Wilfley was aninventor and entrepreneur. Hebegan working on centrifugalpumps in 1902. Wilfley’s firstcommercially-available pump wassold in 1919 and was built aroundhis unique concept of the expellerfor hydraulic sealing. He continuedto perfect the expeller design andreceived a patent in 1920. Theexpeller is now the hallmark of allWilfley pumps.Expeller createspressure keepingliquid from shaft.Wilfley’s pump lines include a widerange of centrifugal pumps that aredesigned to handle highly-abrasiveslurries and corrosive materials.To locate the Wilfley office or agentnearest you, please contactA.R. Wilfley & Sons, Inc. directly at1-800-525-9930 orwww.wilfley.com.2

Wilfley Model A7 Features and BenefitsCentrifugally actuated seal provides smoothand efficient seal opening and closing.Close-fitting lipexcludescontaminants fromprimary seal.Wide range ofmaterials available.Guards isolate allmoving parts.Extra case wall thickness extendswear life.Rotary andstationary seal facesare open duringoperation and closedto prevent leakagewhen the pump isshutdown.Large impeller vanesprovide highlyefficient pumpingwith long wear life.Baseplate and frameare heavy cast ironwith heavy ribreinforcements madeto withstand severeoperating loads.Non-metallic andfabricated baseplatesare available.3The Wilfley expelleris a non-contacting,hydrodynamic sealthat provides long,trouble-free life andminimal operatingcosts and downtime.Shaft is isolated fromliquid. Sleeves available inwide variety of alloys.Frame support to ease assembly

Extreme Duty bearingsexpand the operatingrange to include severeduty applications.Standard labyrinth sealOptional vapor seal meetsEPA requirements.Cartridge-type Wilfley hydrodynamicseal to simplify maintenance.Optimum shaft size to transmit loadsand maximize sealing flexibility.Extreme Duty BearingsNon-metallic labyrinth seals isolate bearingsfrom contamination to improve durability.Other seals available.Bearings designed for long life. Bearingseats are ground to provide a precise fit.Large oil sump capacity to provide maximumcooling and increase bearing life.4

Wilfley DryLock Seal DryLock Features The DryLock uses the action ofcentrifugal force combined with thesmooth actuation of ball bearings toopen and close the seal. As thepump starts up, the expellerevacuates the liquid in the sealarea. The balls of the DryLock areforced outward and slide up a rampcreated by the ball housing. Theramp forces the balls into theactuator plate and opens the sealfaces. Upon shut-down, the ballslose their centrifugal force allowingthe spring-loaded actuator plate tomove back into its closed position.The seal is then closed.Seal activation can easily bechanged to open and closeat different speeds simply byadding or subtracting balls.Multiple sealface materialsavailable.Isolated spring forreliable seal action.Pump Running/Seal OpenHook sleeve designfor maximum shaftprotection.Actuator AssemblyPositive seal atshutdowntightens withpressure.Simple replaceableparts.5Pump Off/Seal ClosedSymmetricalactivationmechanism.No rubbing components.

Wilfley Options SealExtreme Temperature SealCarbon Drylock/Vapor BarrierExpeller/PackingDrylock/Labyrinth BackupFor Light Slurry ServicesDiaphram SealMechanical Seal6

Model A7 Pump Capacities60 cycle performance3550 RPM700A30-13 3x2-13600A20-133x1.5-13HEAD OW (GPM)1750 RPMA110-16 8x6-16S210A30-133x2-13HEAD -136x4-13A60-103x2-10110A110-158x6-15A06-10 8 1x1.5-8AA-6 1.5x1-6AB-6 3x1.5-610A80-106x4-10A120-1510x8-15A70-8A60-8 3x2-8 4x3-8100010010000FLOW (GPM)1150 RPM100A110-16 8x6-16SA30-133x2-13HEAD x8-16SA80-136x4-1310A60-103x2-10100FLOW (GPM)A120-1510x8-15A70-104x3-10100010000

50 cycle performance2950 RPM170150A40-134x3-13130A20-133x1.5-13HEAD 102x1-107050A50-83x1.5-8AA-8 1x1.5-830AA-6 1.5x1-6AB-63x1.5-6101A80-106x4-10A70-104x3-10A60-8 3x2-810A70-84x3-81000100FLOW (M3/HR)1450 RPM50A110-16 8x6-16SA30-13 A40-133x2-13 4x3-13HEAD (M)40A20-133x1.5-133020A06-102x1-1010AA-8 5-8 A60-8 3x2-8AA-6 8-15100010000FLOW (M3/HR)8

MaterialsMaterialsWet EndAR Wilfley & Sons produces Model A7centrifugal pumps in a variety ofmaterials to meet a wide variety ofpumping conditions.ItemNumberModel A7 pumps have beenmanufactured in ductile iron, duplex,stainless steel, Hastelloys, hard irons,and a variety of austenitic stainlesssteels including; Alloy 20 (CN7M) 304L(CF3), 316L (CF3M).Wifley's Engineering Staff has theknowledge and experience to assistyou in material selection. Wilfleymaintains an extensive libraryof pumping services andcorrosion/abrasion data. Wilfleycontinually tests the effects ofabrasion and corrosion on a widevariety of materials.Wilfley's in-house metallurgicalresources have developed uniquematerials to survive in the most hostileenvironments. These proprietarymaterials were developed to extendthe erosion - corrosion performanceand reliability of the A7 pump underextreme conditions.WCD4 – Wilfley improved CD4MCuduplex stainless steel offering a 40%higher hardness, 42% increase intensile strength, 65% increase in yieldstrength, resulting in a lower wear rateand higher corrosion resistance thanthe industry standard CD4MCu.Maxalloy 5 – is a high chrome whiteiron providing a material hardnessup to 650 HBN and 4 to 9.5 pHoperating range.Maxalloy 8 – is a proprietary highchrome white iron providing 450-520HBN hardness, able to withstandchemical deterioration within a 1.3 to13.2 pH range.To assist with proper materialselection, Wilfley can provide materialcoupons for testing in your particularapplication followed by a materialdeterioration analysis report.911a34141517ItemNameAlloy 20316SSWCD4 Ductile IronCasingCap ScrewGasket, CasingLockwasherImpellerCasing PlateExpellerA2018-8Teflon 18-8A20A20A20316SS18-8Teflon 18-8316S316S316SWCD4 18-8Teflon 18-8WCD4 WCD4 WCD4 DI**18-8Teflon on DI**Viton 18-8Steel18-8Teflon 18-8DI**MSSteelWMS*SteelSteelSteelTeflon DI**Viton 18-8Steel18-8Teflon 18-8DI**MSSteelWMS*SteelSteelSteelTeflon DI**Viton 18-8Steel18-8Teflon 18-8DI**MSSteelWMS*SteelSteelSteelTeflon DI**Viton 18-8Steel18-8Teflon 18-8A20316SSWCD4 DI**MaterialPower herDrain PlugShaftBearing, InboardBearing, OutboardLocknutOil Seal, InboardBearing CarrierO-ring, Bearing CarrierJam NutRetaining RingCap ScrewOil Seal, OutboardSight GlassSealsDryLock * WMS – hardened steel** DI – ductile iron

910

Model A7 Options and Engineering SpecialsFeaturesOptionsBearings – single rowExtreme duty bearingsSingle row deep groove – inboard bearingDuplex angular contact – outboardOil lubricated bearingsGrease, oil mist, constant level oilerLabyrinth bearing sealMagnetic Bearing SealOil FilterFrame and bearing carrier material:Ductile iron316SSFrame with large sight glasson the right side when viewedfrom coupling end.Sight glass on the opposite side oron both sidesOil cooling provisionsO-Ring material: VitonKalrez Teflon encapsulatedWet end material: DI, 316SS, A20,WCD4 , High Nichol Alloy, Max5/Ma81/2" NPT connection for case drainSteam jackets150 lbs. raised faced flanges300 lbs raised faced flangesDryLock sealPackingMechanical sealLabyrinth sealLube sealFlush connections for sealsExpeller cavity drainMany applications require specialmotor and drive configurations,including baseplates and mountingbrackets. Non-metallic andfabricated baseplates are available.11Corrosion resistant alloys1/4" NPT connection for gaugeAlloys – special orderFlushing hardwareSpecial ModificationsA.R. Wilfley & Sons is dedicated tomanufacturing pumps that maximizetheir full potential. Wilfley routinelyaccommodates customer requestsfor steam jackets, special paint,flush ports, special drain plugs andother modifications required to fitspecific needs.Engineered SpecialsWilfley engineers assist in anyspecial configurations that the liquidand process require. Wilfley’sfamous high-quality workmanshipapplies to all special designs tocustomers’ needs.

Construction DetailsFrame 1Frame 2Frame 3Frame 4AA-6 AB-6 AA-8 A5O-8 A60-8 A70-8 A05-10 A50-10 A60-10 A70-10 A80-10 A20-13 A30-13 A40-13 A80-13 A110-15 A120-15GeneralPump weight137 lbs 16762 kg 4924947821749022252824057426010904941207547Max. working*temperature250 F120 C250120250120250120Max. workingpressure200 psi675 kPa200675200675200675Max. solids size 3/16 in. 1/4 5/165 mm 8103/8101/2131/213ShaftDiameter atImpeller.75 in.19 mm125.41.12528.62.12553.9Diameter atSleeve1.375 in.34.9 mm1.37534.91.87547.62.12353.9Diameter atCoupling.875 in.22.2 gs1.94 in.49.3 mm2.563.52.8472.14.41112Shaftoverhang6.413 in.162.9 mm6.85173.97.79197.910.21259.3Bearing span3.175 in.80.6 mm7.71195.86.63168.49.99253.7Standard radialbearing6308631163126319AStandard thrustbearing5208A5211A53127319BECBExtreme dutyradial bearing6308311M312MNU319ECExtreme dutythrust dified seal configurations are available for special pumping conditions up to 400º F.12

DimensionsPump DimensionsMotor Frame RangePumpDimensionSize, Suction X Discharge XGroupDesignationNominal Impeller DiameterCPDXYNema1AA1.5 X 1 X 6 (40 X 25 X 150)17.5 (445)5.25 (133)6.5 (165)4 (102)AB3 X 1.5 X 6 (80 X 40 X 150)17.5 (445)5.25 (133)6.5 (165)4 (102)AA1.5 X 1 X 8 (40 X 25 X 200)17.5 (445)5.25 (133)6.5 (165)4 (102)A503 X 1.5 X 8 (80 X 40 X 200)23.5 (597)8.25 (210)8.5 (216)4 (102)A603 X 2 X 8 (80 X 50 X 200)23.5 (597)8.25 (210)9.5 (242)4 (102)A704 X 3 X 8 (100 X 80 X 200)23.5 (597)8.25 (210)11 (280)4 (102)A052 X 1 X 10 (50 X 25 X 250)23.5 (597)10 (254)8.5 (216)4 (102)A503 X 1.5 X 10 (80 X 40 X 250)23.5 (597)10 (254)8.5 (216)4 (102)A603 X 2 X 10 (80 X 50 X 250)23.5 (597)10 (254)9.5 (242)A704 X 3 X 10 (100 X 80 X 250)23.5 (597)10 (254)A806 X 4 X 10 (150 X 100 X 250)23.5 (597)10 (254)2A203Number143T - 184T80M - 90L139213T-256T132M - 160L148284TS - 326TS 180M - 180L153143T - 184T100L - 132M245213T - 215T160M 180L2524 (102)254T - 286T200L25811 (280)4 (102)324TS - 365T225S - 225M26413.5 (343)4 (102)404T - 405TS250M268405T - 447TS280S 280M2803 X 1.5 X 13 (80 X 40 X 330)23.5 (597)10 (254)10.5 (266)4 (102)A303 X 2 13 (80 X 50 X 330)23.5 (597)10 (254)11.5 (292)4 (102)A404 X 3 X 13 (100 X 80 X 330)23.5 (597)10 (254)12.5 (318)4 (102)A806 X 4 X 13 (150 X 100 X 330)23.5 (597)10 (254)13.5 (343)4 (102)A1108 X 6 X 15 (200 X 150 X 380)33.875 (860)14.5 (368)18 (457)6 (152)284T - 286T180L368A12010 X 8 X 15 (250 X 200 X 380)33.875 (860)14.5 (368)19 (483)6 (152)324T - 405T200L - 250M380444T - 449TS280S - 315L398The dimensions listed above conformto ASME B73.1 specifications andapply to fabricated and non-metallicbase plates only. dimensions aredifferent for iron bases.These dimensions are not forconstruction. Certified dimensionprints are available for your specificinstallation.13BaseplateIECAll dimensions printed in black are ininches and those in red are theapproximate equivalent in millimeters.Flanges are drilled to match ASMEB16.5 150lbs.

General Installation RecommendationsHAHBHEHDHFHGHHHLHP15 (381)39 (991)9 (229)4.5 (114)36.5 (927)3.75

ASME B73.1 M-91 Wilfley’s Model A7 pump series offers maximum efficiency coupled with ultimate seal flexibility. It is designed to be sealless, but can also be used with virtually any traditional seal—packing or mechanical. The Model A7 is an end-suction, single-stage centrifugal pump that meets ASME B73.1 M-91 requirements. It handles liquids that are highly corrosive and abrasive .