Transcription

NNOVATIONEFFICIENCYQUALITYCPOOpen Impeller ASME (ANSI) B73.1 Pump forcontinuous use in Chemical Process ServicesTel: 866-777-6060Fax: 866-777-6383Springer Pumps, LLCWebsite: http://www.springerpumps.comInt'l: 001 267 404 2910

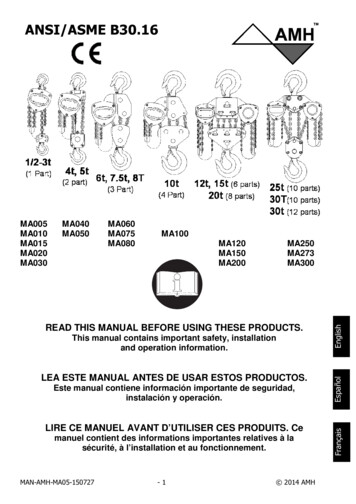

Horizontal Split CaseFor more than 60 years the name RuhrpumpenTM has been synonymous worldwidewith innovation and reliability for pumping technologyRuhrpumpen is an innovative and efficient centrifugal pump technologycompany that offers a wide range of quality products to our clients.Ruhrpumpen is committed to global excellence with a complete range ofPumps, Fire Pump Packages and related products, such as DecokingSystems and Tools to support the core markets, namely Oil & Gas,Petrochemical, Power, Heavy Industry Applications, Mining and WaterServices.The broad product line complies with the most demanding qualityspecifications and goes beyond stringent industry standards such as API,ANSI, Hydraulic Institute, Underwriter’s Laboratories, Factory Mutual andISO 9001.Ruhrpumpen is a vertically integrated company with its own foundry,machine shop, pump manufacturing plants and service centers. Withstrategically located manufacturing plants, operating offices and servicecenters in many parts of the world, Ruhrpumpen is truly a global pumpcompany which also has the strength to focus on the local necessities ofeach client.CPO PumpThis rugged process pump is ASME (ANSI) B73.1 compliant and operates even in the toughest industrial applications. ANSI 150#,300#, FF and RF Flanges are available depending on material selection and pump operating pressure.With 31 hydraulics this open impeller design covers a wide range of service conditions (including low-flow region) while providingindustry-leading low NPSHR performance and high efficiencies.CPO is designed around a modular concept which allows provision of multiple hydraulics with a small number of power frames. Inaddition these power frames are interchangeable with models of other common pump manufacturers.COUPLINGGUARDTelescopic design means that the same coupling guard sizecan be used for multiple pump and motor combinations.Designed to mount directly to the pump and motor andtherefore does not need to be mounted to the baseplate.2Tel: 866-777-6060Fax: 866-777-6383Springer Pumps, LLCWebsite: http://www.springerpumps.comInt'l: 001 267 404 2910

CPOOpen Impeller ASME (ANSI) B73.1 Pump forcontinuous use in Chemical Process ServicesSelection ChartCPOSelectionCharts2 POLES50 Hz / 2850 RPM60 Hz / 3500 RPM20040200504060608070100150100140200200250 m³/hm³/h250ftftm800m500220TOTAL 0200300400500110090060070080001400 gpm1100FLOW0gpm4 POLES50 Hz / 1420 RPM60 Hz / 1750 RPM0200ftTOTAL HEAD2400180300220 3005005006007008001000 1200 m³/h10001400 0x7304x3x10H4x3x8G10106x4x10G3x1.5x6000100100300 400 1.5x840201406x4x171004080 100200m1601406060140 1609523080402010031027010060ft35020012040700500 600900 1000 1400 1800 22003000700 800 1000 1400 1800 2200 2600005000 5800 6600 7400 gpm3400 4200 5000 gpmFLOW3Tel: 866-777-6060Fax: 866-777-6383Springer Pumps, LLCWebsite: http://www.springerpumps.comInt'l: 001 267 404 2910

Horizontal Split CaseAll Pumps are tested before shipto ensure they meet flowCharacteristics1The CPO is designed to meet your mostdifficult applications with a state-of-theart open impeller, CD4MCu wetted partsas standard and a Heavy Duty PowerFrame.2Open impeller design allows handling ofsolids in suspension. The impellers arelocked onto the shaft by threads andsealed with an O-ring. Hydraulic profilespecially designed for industry-leadingNPSH performance and high efficiencies.3Pre-loaded, double row, angular contactthrust bearings minimize axial shaftend-play thus maximizing mechanicalseal life.4Single piece casted power frameprovides easier assembly and increasedmechanical seal life.5A robust solid shaft with outstanding L3/D4 for low vibration and increasedmechanical seal life (shaft sleeves areavailable as an option).62759Machined flat surface suitable for usewith magnetic mount vibration probe.17Standard seal chambers designed toaccommodate all seal arrangementsand flush plans per ASME (ANSI) B73.1with plan 11 as standard.8Labyrinth type Bearing Isolator, to ensurebearings free from contaminants.9Lubrication6-- Oil bath lubrication as standard,with option for grease and oil mistlubrication.-- Large capacity oil sump and finnedhousing provide superior coolingand environment for bearings.10Axial impeller adjustment without theneed for special tools.Images for general arrangement use only, not certified for construction.4Tel: 866-777-6060Fax: 866-777-6383Springer Pumps, LLCWebsite: http://www.springerpumps.comInt'l: 001 267 404 2910

CPOOpen Impeller ASME (ANSI) B73.1 Pump forcontinuous use in Chemical Process Servicese shipment in our testing laboratoryflow and head requirements.DescriptionPRODUCT DESCRIPTION-- Single stage, horizontal centrifugal pump.-- Radially split casing with flanged connections.-- Horizontal end suction and vertical dischargeon the center line.-- Open impeller, clockwise rotation (viewedfrom coupling end).-- Foot mounted.-- ASME (ANSI) B73.1 compliant.4-- ”Back pull-out” design allows All ANSI flush plans are offered, as needed, ina variety of configurations.-- Power frame interchangeability with modelsof other common pump manufacturers.-- High pump efficiencies.105-- Standard baseplaterequirements.38accordingtoANSIBROAD APPLICATION RANGEThis rugged process pump is designed to operatein the toughest industrial applications such as:CPO PERFORMANCE DATA-- Petrochemical-- Power Generation-- Oil & Gas-- Pharmaceuticals-- Steel Industry-- Water Treatment-- Automotive-- Paper Stock-- Agriculture-- Pipeline-- Chemical-- Textile-- MiningCapacityup to 7,000 U.S. gpmup to 1,590 m3/hHeadup to 650 ftup to 198 m-- SemiconductorPressureup to 375 psiup to 26 bar-- Food ProcessingTemperature-20 to 572 F-30 to 300 CDischarge Flange 1 to 8 inNote: For pump operation outside this range, please contact a Ruhrpumpen representative.5Tel: 866-777-6060Fax: 866-777-6383Springer Pumps, LLCWebsite: http://www.springerpumps.comInt'l: 001 267 404 2910

Horizontal Split CaseOptional Features CPO BASEPLATE SEALING PIPAPI 610PolymerSpecial designs to meet customerspecifications.Packing with Sleeved Shaft.Cooling/Heating Jacket Designed tocontrol mechanical seal temperature.Cooling JacketHeavy Duty PIP BaseplatePIP baseplate can be offered in applications where moreheavy-duty and rigid support is required.Materials of Construction COOLING COILTo maintain proper oil temperature in hot applications.The Ruhrpumpen CPO pump is available in a variety ofmaterials such as: Duplex Stainless Steel (as standard)Ductile Iron / CD4MCuAlloy20Hastelloy CHastelloy BCooling CoilWe cover a large range of material options to satisfy everyneed, please contact us for more information.C-FRAMEC - Frame assures easieralignment and longer seal life.6Tel: 866-777-6060Fax: 866-777-6383Springer Pumps, LLCWebsite: http://www.springerpumps.comInt'l: 001 267 404 2910

CPOOpen Impeller ASME (ANSI) B73.1 Pump forcontinuous use in Chemical Process ServicesOther Ruhrpumpen ProductsEnd Suction Fire PumpsSump PumpOur End Suction Fire Pumps aredesigned according to ANSIstandards and certified by:-NFPA-20-UL-448-FM-1319Fire Pumps units and packagesavailable. Jockey Pumps alsoavailable.Single Stage single suction verticalcentrifugal pump, volute type case,flanged and threaded discharge,cast iron casing, flexible coupling.Sump Drainage, Flood Control,Air Wash Systems, Power Plants,Chemical Industry, MunicipalSystems, Water Treatment, ProcessPlants, and Sewage Lift Stations.Volute Casing CentrifugalPumpAxially split, horizontal single ortwo stage, double volute casing,double suction, closed impeller.Heavy duty process designaccording to API 610 latest edition.Pipeline Service-Mainline andBooster, Oil Extraction, Refinery,Chemical, Petrochemical,Metallurgical Industry, and PowerStations.Vertical Turbine PumpMultistage vertical centrifugalpump with diffuser type bowl,semi-open / enclosed impellers,cast iron bowls, counterclockwiserotation viewed from couplingend.Deep Well, Irrigation,Cooling Tower, Sump,and Condensate Pumps.7Tel: 866-777-6060Fax: 866-777-6383Springer Pumps, LLCWebsite: http://www.springerpumps.comInt'l: 001 267 404 2910

USA, Tulsa & OrlandMEXICO, MonterreyBRAZIL, Rio De JaneiroARGENTINA, Buenos AiresGERMANY, WittenEGYPT, SuezINDIA, ChennaiCHINA, ChangzhouUK, LancingMore Information:March.16Tel: 866-777-6060Fax: 866-777-6383Springer Pumps, LLCWebsite: http://www.springerpumps.comInt'l: 001 267 404 2910

This rugged process pump is ASME (ANSI) B73.1 compliant and operates even in the toughest industrial applications. ANSI 150#, 300#, FF and RF Flanges are available depending on material selection and pump operating pressure. With 31 hydraulics this open impeller design covers a wide range of service conditions (including low-flow region) while providing industry-leading low NPSHR performance .