Transcription

Bulletin C 1.2.34.5Dean Pump ANSI/ASME B73.1Horizontal Process PumpspH2140TelescopingGuardpH2140C-FaceAdapter

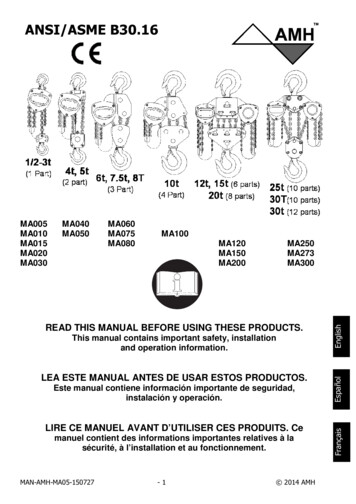

Dean Pump Series pHCentrifugal Process Pumps Capacities to 3200 GPM (726 m3/hr) Heads to 800 feet (245 m) Pumping temperatures to 500 F (260 C) Working presures to 375 PSIG (2585 kPa)ExperienceDean Pump is recognized as an industry leader in the design and manufactureof horizontal centrifugal process pumps used extensively in the chemical andpetrochemical industries, power plants, pulp and paper, mining, pharmaceutical andfood processing industries.When Dean Pump introduced the pH centrifugal process pump in 1958, the chemicalprocessing industry recognized it as the model for the proposed ASA StandardChemical Pump. Shortly thereafter, the Manufacturing Chemist Association (MCA)adopted, with minor changes, the service proven Dean pH pump as the AmericanVoluntary Standard (AVS). Subsequently, the American National Standards Instituteapproved the AVS Specifications as national standard B123.1-1971. This standardwas later revised and approved as ANSI/ASME B73.1M-1984. Dean Series pHpumps continue to meet or exceed the latest revised B73.1 standard.Dean Series pH centrifugal process pumps are designed to insure long, continuousservice life at low cost. Each phase in the production of these pumps is meticulouslymonitored by an independent quality control department.Pump SizesThe Dean Series pH pump is an end-suction back pull out design regularly availablein 22 sizes and divided into four size classifications: the pH2110 Series in 5 sizes the pH2140 Series in 11 sizes the pH2170/pH3170 Series in 4 sizes the pH2180 Series in 2 sizesMaterialsStandard materials of construction include ductile iron, 316SS, CD4MCu, and Alloy20. Additional higher metal alloys (Hastelloy B and C, Titanium, etc.) are availableupon request. (Standard Materials of Construction chart is available on Page 3).Parts InterchangeabilityThe Series pH provides the ultimate in standardization of process pumps. With wideparts interchangeability among pump sizes, fewer parts are required for inventory. Acomplete stock of spare parts is readily available from Dean Pump or its network ofstocking distributors, thereby reducing shipping time to a minimum.All Series pH parts, with the exception of the casing (and in some sizes, the impeller),are interchangeable with the Series pHP Self-Priming Pump.Shaft SealingDean Pump offers a broad line of mechanical seals and standard packing sets to solvethe most difficult sealing problems. This feature gives Series pH pumps the versatility tohandle a wide range of chemical services. A variety of seal chambers such as standardbore, jacketed, large taper bore, and large cylindrical bore are available for specificapplications.2

DEAN PUMP SERIES pH HORIZONTAL PROCESS PUMPSSTANDARD MATERIALSMECHANICAL DESIGN SPECIFICATIONSpH2110 pH2140pHP2110 pHP2140PUMP TYPEDirection of Rotation(Viewed from Coupling End)Horsepower Rating@ 3500 rpm@ 1750 rpm@ 1150 rpmHydrostatic Test PressureCorrosion AllowanceImpeller BalanceFlanges ANSI ClassFacing – standard– optionalFinishStuffing box jacket pressure maximumBearing housing cooler pressure maximumMaximum Suction PressureBearings:Thrust BearingRadial BearingLubricationApproximate oil capacity of bearing housingSeal Chamber Dimensions:Tapered Seal ChamberLength (Depth)Inside Diameter (Bore)Shaft Sleeve DiameterCylindrical Seal ChamberLength (Depth)Inside Diameter (Bore)Shaft Sleeve DiameterStuffing Box Dimensions:Length (Depth)Inside Diameter (Bore)Shaft Sleeve DiameterLantern Gland WidthPacking Size – SquareNumber of Rings with Lantern RingNumber of Rings without Lantern RingSpacing with Lantern RingPump Shaft Dimensions:Span Between BearingsSpan Between Radial Bearing and ImpellerDiameter Under the SleeveDiameter with No SleeveDiameter at CouplingDiameter Between BearingsDiameter at ImpellerL3/D4 RatioSleeved ShaftSolid Shaft (No Sleeve)CWCW35 HP100 HP15 HP40 HP10 HP30 HP430 psig 430 psig1/8"1/8"Single150150F.F.F.F.R.F.R.F.125 Ra125 Ra125 psig 125 psig125 psig 125 psig275 psig 275 psigPart No.pH2170pH3170CWCWpH2180CW—200 HP—100 HP100 HP 125 HP60 HP—75 HP430 psig 565 psig 450 psig1/8"1/8"1/8"Plane Dynamic Balance150300300F.F.F.F.F.F.R.F.R.F.R.F.125 Ra125 Ra125 Ra125 psig 125 psig 125 psig125 psig 125 psig 125 psig275 psig 375 psig 300 psig53066207Oil26 oz53096309Oil42 oz7311 BG 7311 BG63116311OilOil36 oz36 oz53126312Oil64 /4"123559652pH/pHP1 x 11/2 x 6 pH211011/2 x 3 x 62x3x61 x 11/2 x 811/2 x 3 x 8/ 11/2 x 11/2 x 81 x 2 x 81/2 pH214011/2 x 3 x 81/22 x 3 x 81/23 x 4 x 81/2 #13 x 4 x 81/2 #21 x 2 x 1011/2 x 3 x 10/ 2 x 2 102 x 3 x 10/ 3 x 3 x 103 x 4 x 10 #1/ 4 x 4 x 103 x 4 x 10 #211/2 x 3 x 111/22 x 3 x 111/23 x 4 x 111/24 x 6 x 111/211/2 x 3 x 131/22 x 3 x 131/23 x 4 131/2/ 4 x 4 131/24 x 6 x 131/2 pH217011/2 x 3 x 131/2 pH31702 x 3 x 131/23 x 4 x 131/24 x 6 x 131/2 pH21806 x 8 x 131/2WithBalance Holes3500 1750 1150RPMRPM mpellerC.I. (1)316 (12) Alloy20 (2) CD4MCuHast.Titanium5CasingD.I. (10) 316 (12) Alloy20 (2) CD4MCuHast.Titanium5ACasing Drain PlugHast.TitaniumHast.Titanium1020 Steel 316 S/SAlloy20316 S/S5CCasing Stud Nut⑥Steel (4)5DCasing CapscrewCasing Stud② ‡⑥Steel (11)Steel (6)7Cradle Spacer① ‡D.I. (13)7GSpacer to Brg. Hsg. Capscr.① ‡1020 Steel9Bearing Housing Foot①10Shaft Sleeve ‡10KSleeve Key ‡13Seal Chamber Gland316 S/SAlloy 20316 S/SHast.Titanium14Gland Stud304 S/SAlloy 20304 S/SHast.Titanium1517Alloy 20 304 S/STeflon C.I. (1) 316 S/S Alloy 20D.I. (10) 316 (12) Alloy 20 (2) CD4MCuHast.TitaniumHast.Titanium22Gland NutLantern RingLantern RingCasing Back Cover22ABack Cover to Cradle Capscrew ‡C.I. (1)316 S/SAlloy 20316 S/S304 S/S304 S/S⑦ ④ ‡ ‡1020 Steel ‡——————Thrust Bearing ‡——————35/16"41/4"21/4"26Bearing Housing ‡27Seal Ring① ‡28Bearing End Cover ‡C.I. 4"1/2"673-G-328ABearing End Cover Capscrew ‡1020 Steel28BEnd Cover Adjusting Screw ‡1020 Steel28CAdjusting Screw Locking Nut ‡1020 Steel29Pump Shaft ‡Steel (5)31Thrust Bearing Lock Nut① ‡1020 Steel1020 5210205200200200205200200200260Values of Fn3500 1750 1150RPMRPM .022.015.010.06.725.225.225.2275275Hast.3Radial Bearing300300285225225CONSTRUCTION25WithoutBalance Holes3500 1750 1150RPM RPM RPMmaximum allowablesuction pressure maximum allowabledischarge pressureless developed 00210200180180200180195195195260OFClass 22 Class 50 Class 60 CD4MCu25AMAX. ALLOWABLE PUMP SUCTION PRESSURE (psi)WITH 2 YR. MIN. THRUST BEARING LIFEPUMP SIZEPart Name275275Seal Chamber Pressure:With Balance Holes: Seal chamber pressure suction pressureWithout Balance Holes: Pumps are normally furnished without balance holes. Seal chamber pressure (suction pressure) (Fn x sp. gr.)*Seal pressure developed by impeller with a 1.0 specific gravity (water at ambient temp 60 F/16 C)3①②③④⑤⑥⑦ ‡ D.I. (13) for pH2110 & pHP2110, C.I. (1) for all othersC.I. (1)31AThrust Bearing Lock Washer① ‡56Casing Foot⑤C.I. (1)56ACasing Foot Capscrew⑤ 1020 Steel56BCasing Foot Dowel⑤ 1020 Steel75ATapered Retaining Ring③ Steel75BLarge Retaining Ring⑦ Steel76Labyrinth Seal – Front ‡Bronze & Viton Bronze & Viton 76ALabyrinth Seal – Rear ‡77Casing Gasket ‡Teflon 77AImpeller Gasket ‡Teflon 77BEnd Cover Gasket ‡Buna (7)80Vent ‡—83Motor Support (C Face)⑦ C.I. (1)95AMechanical Seal Stationary ‡95BMechanical Seal Rotary ‡109Oil Cooler ‡S/S Tubing with Steel Fins and Steel Fittings231Bearing Lock Ring④ ‡1020 Steel231ABearing Lock Ring Screw④ ‡1020 Steel231BBearing Lock Ring Washer④ ‡1020 SteelpH2140, pH2170, pH3170, pH2180 and pHP2140 onlypH2110, pH2140, pH2170, pH2180, pHP2110 and pHP2140 onlypH2110, and pHP2110 onlypH2170, pH3170, and pH2180 onlypH2140 and pHP2140 onlypH3170 onlypH2110, pH2140, pHP2110, and pHP2140 onlyDenoted parts are interchangeable in all pH2110 and pHP2110 pumpsDenoted parts are interchangeable in all pH2140 and pHP2140 pumpsDenoted parts are interchangeable in all pH2170 and pH3170 pumpsDenoted parts are interchangeable in all pH2180 pumpsRegistered Trademark of the E.I. DuPont CompanyMATERIAL SPECIFICATIONS (REFER TO NUMBERS IN PARENTHESES)(1) Cast Iron(8) Fibre Sheet — Non-Asbestos Fibre(2) Alloy 20 S/S: ASTM #A744, Grade CN-7M(9) Manila Paper(3) Cast Steel: ASTM #A216, Grade WCB(10) Ductile Iron: ASTM A395(4) Steel: ASTM #A194, Grade 2(11) Steel: ASTM #A449(5) Alloy Steel: 125,000 TS, 100,000 YP(12) 316 S/S: ASTM #A744 Grade CF-8M(6) Steel: ASTM #A193, Grade B7(13) Ductile Iron: ASTM A536(7) Buna “N” Rubber

1. CASING COVERStandard bore, jacketed, large taper bore, largecylindrical bore. Designed to provide the bestenvironment for the specific application andservice conditions.12. INTEGRAL ONE-PIECE CASING FLANGESFlanges dimensioned according to ANSI/ASMEB16.5 Class 150 for the pH2110/pH2140/pH2170and Class 300 for the pH3170/pH2180. Flat faceflanges are standard with raised face flanges available as an option.33. SEALING FLEXIBILITYChoice of packed box or mechanical seal. Widerange of sealing arrangements (inside/outside,single/double, balanced/unbalanced, etc.)available to meet specific application and serviceconditions.24. FULLY OPEN IMPELLERThe fully open design provides smooth inlet passagesfor solids handling and stringy material, low NPSH,and minimum stuffing box pressure. The impellerdesign transmits low axial loads on the bearings.5. SHAFT SLEEVE“Hook” type shaft sleeves are standard. Alloy,hard-facing, hardened chrome 11/13, or ceramiccoatings are available as options. Solid shafts arealso available.6. ANSI/ASME B73.1 DIMENSIONAL CASINGPermits maximum interchangeability of pumps withexisting ANSI pumps eliminating any need forpiping or foundation changes. Back pull-out designfor ease of maintenance. Top centerline discharge forself-venting of casing. Casing drain/plug is astandard feature on Ductile Iron construction only.457. HEAVY DUTY SHAFT AND BEARINGSCarbon steel shaft (316SS optional) designed forminimum deflection of less than 0.002” (0.05 mm) atthe seal faces. Double row thrust bearings and singlerow radial bearings are sized for a 2 year minimumlife and a 10 year average life. With minimizedbearing spans and overhung lengths, Dean’s L3/D41346

ratio is one of the best in the business.8. STANDARD LABYRINTH SEALSRugged bronze construction with Viton O-rings.These seals will ensure that the bearings are keptproperly lubricated and uncontaminated throughouttheir project design life.89. EXTERNAL IMPELLER ADJUSTMENTNo shimming required. Allows field setting ofimpeller-to-casing clearance. Impeller adjustment isaccomplished by adjusting screws in the bearing endcover.910. LUBRICATION OPTIONSOil bath lubrication is standard. Extra large oilreservoir designed for cooler bearing operation.Oil mist lubrication and grease lubrication areoptional features. A finned tube oil cooler is alsoavailable (as an option) to directly cool oil forlower bearing temperature.11. FILL PLUGEasy access to fill plugs supplied on both sides ofthe bearing housing. Designed to minimize thepossibility of overfilling.12. ONE INCH OIL SIGHT GLASSAllows for simple and easy monitoring of oil leveland condition. Oil sight glass can be installed oneither side of the bearing housing, in the field, forbest location and ease of viewing. Combinationautomatic (bottle) oiler/sight glass also available.1013. RIGID BEARING HOUSING AND CASING FEETDesigned to reduce the effect of pipe loads on pumpand shaft alignment.11712135

pH2110pH21406

pH2170/pH3170pH21807

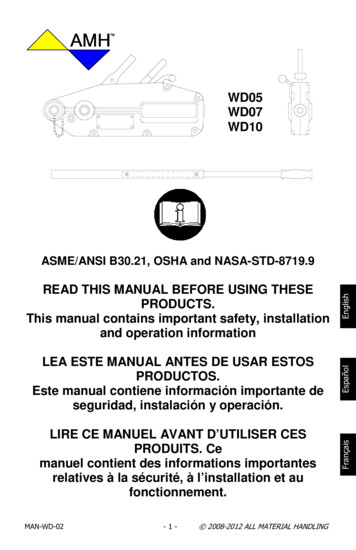

HEAD CAPACITY RANGE CHARTSpH2110, pH2140 & pH31703500 RPMCAPACITY – 02003X4X10#1A702X3X81/2ABA6013X4X8 /2#1AB010020050A701X11/2X6100AA11/2X3X6 2X3X603X4X131/22X3X10TOTAL HEAD – METERSTOTAL HEAD – 10012000CAPACITY – G.P.M.pH2110, pH2140 & pH21701750 RPM010203040 3X131/2A20140A30404X6X131/23X4X131/2120A80A40100 1X2X103011/2X3X10 2X3X10A05A5080A60 3X4X10#2120A70160 1X1 /2X811/2X3X8 2X3X8 /2AA3X4X81/2#2A60AB4010A701X11/2X6 11/2X3X62X3X620AAACAB0004080120 160 200 400 600 800 1000 1200 1400 1600 1800TOTAL HEAD – METERSTOTAL HEAD – FEETCAPACITY – M3/HRCAPACITY – G.P.M.pH21801750 RPMCAPACITY – M3/HR050100 150 200 250 300 350 400 450 500 550 600 650 700 75080020060180TOTAL HEAD – 400800120016002000CAPACITY – G.P.M.82400280032003600TOTAL HEAD – METERS50160

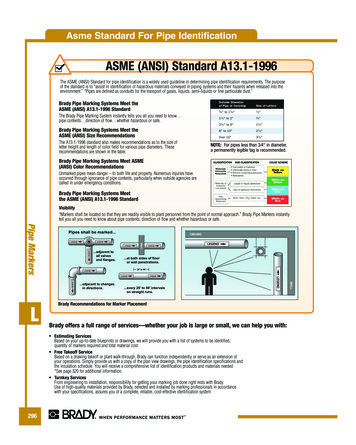

DEAN PUMP PARTS INTERCHANGEABILITY OF 22 PUMP SIZESpH2140Pump SizepH2110Casing ImpellerCasingCoverAdaptorCradleBearing HousingAssemblyPump SizeCasingImpellerCasingCoverBearing HousingAssembly1x1.5x62x3x8.51.5x3x63x4x8.5 #12x3x63x4x8.5 #21x1.5x81x2x101.5x3x8pH2170/pH31701.5x3x10Pump SizeImpellerCasingCoverAdaptorCradleBearing dleBearing HousingAssembly1.5x3x13.52x3x103x4x10 #1CasingBearingHousing Foot3x4x10 Pump Size4x6x13.53x4x13.5Casing covers with jackets, standard bore, large taper

Bulletin C 1.2.34.5 Dean Pump ANSI/ASME B73.1 Horizontal Process Pumps pH2140 Telescoping Guard pH2140 C-Face Adapter. Dean Pump Series pH Centrifugal Process Pumps Capacities to 3200 GPM (726 m3/hr) Heads to 800 feet (245 m) Pumping temperatures to 500 F (260 C) Working presures to 375 PSIG (2585 kPa) Experience Dean Pump is recognized as an industry leader in the