Transcription

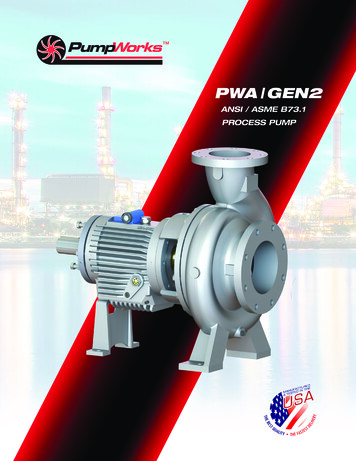

PWA GEN2ANSI / ASME B73.1PROCESS PUMP

PWA GEN2 ANSI/ASME B73.1 PROCESS PUMPPWA GEN2Innovative Power Frame FeaturesAll new patent pending frame design for enhanced reliability.25% more cooling surface than PWA GEN 1.Sealed lubrication chamber.ISOMAG magnetic seals IP65 rated Power Framesealing.n Sloped and segregated drain for contaminant isolation.n Predict Plus GEN2 proactive pump monitor.n Zero oil maintenance required for up to 3 years.*nnnnCarbon Steel vs. Ductile Ironn High strength, impact resistant Carbon Steel liquid endsfor improved durability and pressure containment.n Replaces non-repairable, ductile iron casing and impellers,with repairable carbon steel, for extended component life.n 30% Higher Thermalconductivity than Cast Iron forimproved heat dissipation, lower oil temperature andlonger bearing life.Shaft and Bearing Assemblyn Upgraded 316L SS vs. 4140 steel pump shaft is standard atno additional cost.n Proven flinger disk lubrication device to ensure effectivebearing lubrication. Provides 30% increased bearingL-10 life and minimun 15ºF lower bearing operatingtemperatures compared to flood oil design.25 Year UnconditionalPower FrameWarranty is Standard.

PWA GEN2 ANSI/ASME B73.1 PROCESS PUMPDESIGN FEATURES AND BENEFITSCasing Gasket Fully confined tomaximize liquid sealing Protects casing fits fromcorrosion, thereforeincrease maintenanceease and properalignment duringreassemblySeal Chamber / Sealing Options Multiple seal chambers for maximum sealing flexibilityfor all process applications Accommodates all mechanical seal manufacturer’scomponent and ANSI cartridge seal configurations Supports the full array of CPI seal support system options Ensures superior leak protection with maximum heatdissipation, maximizing seal life and pump reliabilityCasing Carbon Steel ASTM A216 material standard forimproved durability and pressure containment Precision serrated flange face finish for optimum gasketretention and sealing Class 150# standard and 300# option Self venting, centerline mounted discharge flange Casing thickness exceeds ASME B73.1specificationfor increased casing life Back pull out design for easy maintenance Full line of corrosive resistant materialsQuality Manufactured and tested in the USAImpeller Fully open for increased corrosion,abrasion and solids wear resistance Back pump out vanes forreduced thrust loading and sealchamber operating pressureDelivery Pump components strategicallyinventoried for rapid shipmentin a variety of material optionsCasing Drain Optional casing drain anddrain pipingFoot Mounted Casing Maximum casing stability andsupport for back pull outmaintenance feature Reduced vibration3Predict Plus GEN2Proactive Pump Monitor Temperature and 3 axisvibration monitoring IP66 and Class 1, Div. 2compliant

ePOD Pump Selector Access to end users and specifiersto select your pump application online atwww.pumpworks.comBearing Housing 25% additional cooling surface area than PWA GEN 1 Sealed lubrication chamber Sloped and segregated drain for isolation of contaminants Standard flinger disk design with optional purge or pure oil mist lubrication Optional finned tube cooler for process temperatures above 450º F Internal surfaces cleaned, rust preventative applied, and enamel coatedassuring internal casting cleanlinessISOMAG Magnetic Seals IP 66 rated Power Frame sealing (patent pending)Thrust Bearing Heavy duty double row standard Optional duplex angular contact thrust bearingExternally Adjustable Shaftand Impeller System Easily adjust impeller to front casing clearancewithout removal of pump from piping Restoration to factory efficienciesTwo Oil Level Sight Glasses 1” sight glass located on each side of bearing housing for flexible viewingOil Sump Drain Plug (Opposite Side) Magnetic plug to maintain bearing housing cleanliness and increased protection All PWA drain plugs located on side of frames for easy accessPWA GEN2 ANSI/ASME B73.1 PROCESS PUMPSealed Fill/Filter Cap Oversized for easier oil changes Internal filter, protecting against foreign object contamination when fillingShaft and Bearing System Rigid, heavy duty design for minimal shaft deflection at seal area and increased reliability Exceeds ASME B73.1 bearing life specification requirements 316L SS Shaft material is standard with optional material upgrades available4

PWA GEN2 ANSI/ASME B73.1 PROCESS PUMPYOUR PUMP WANTS TO TALK TO YOU Predict Plus is the Only Wireless and Cloud Connected Machinery HealthYOUR PUMP WANTS TO TALK TO YOU Monitor Designed Specifically for Proactive Pump MonitoringPredict-Plus is the Only Wireless and CloudConnected Machinery Health Monitor Designedfor Proactive Pump Monitoring.andSpecificallytemperaturen 24/7 online vibrationmonitoring device.n Automatic device registrationonvibrationthe cloudvia cellular24/7 onlineand temperaturemonitoring deviceinterface.device registration on the cloud vian Proactive alerts from vealertsfrom the Predict-Cloudn Long term storage of trenddataincludingFast FourierLong term storage of trend data includingTransform (FFT).Fast Fourier Transform (FFT)n Affordable and availableAffordableas as standardoptiononoptionall& available asa standardPumpWorks products. on all PumpWorks Industrial productsExternal or battery poweredn External or battery powered.Always OnALWAYS ONPredict-Plus is CONTINUOUSLYmonitoring and logging your pump’s health.Predict Plus is CONTINUOUSLYmonitoring and logging your pump’s health.VIBRATIONVibrationSelf-Calibrating Tri-Axial Accelerometerto captureFFT and RMS vibrationdata.Self-Calibrating Tri-AxialAccelerometerto captureFFT and RMS vibration data.BEARING TEMPERATUREIntegrated thrust bearing temperatureBearing Temperaturemonitoring.Integrated thrust bearingtemperature monitoring.ALERTSAlertsYOUR PUMP WANTS TO TALK TProactivevia emailSMS fromProactive alerts via emailandAlertsSMSfromandthethe Predict-Cloud.Predict-Cloud.Predict-Cloud is a powerful tool in attaining the gospending and increasing MTBR (Mean Time Betweidentifying detrimental system conditions prior to catasYOUR PUMP WANTS TO TALK TO YOU Predict-Cloudis aTALKpowerfultool in attaining the goal of reducing maintenanceYOUR PUMPWANTS TOTO YOU spending and increasing MTBR (Mean Time Between Repairs). By proactivelyidentifying detrimental system conditions prior to catastrophic machine failure.oud is a powerful tool in attaining the goal of reducing maintenancePredict-Cloudis a Repairs).powerfultool inand increasing MTBR (Mean Time BetweenBy proactivelyattainingtheto goalofmachinereducingg detrimental systemconditions priorcatastrophicfailure. maintenanceNTS TO TALKTO YOU and increasing MTBR (Mean TimespendingBetween Repairs). By proactively identifyingattaining thedetrimentalgoal of reducing maintenancesystem conditions prior toFFT Vibration failure.ean TimeBetweenRepairs). By proactivelyDashboardcatastrophicmachineGo to www.predict-cloud.comons prior to catastrophic machine failure.DashboardFFT VibrationGeneral DataRMS VibrationGoOrFFT VibrationGo to www.predict-cloud.comOrRMS VibrationGeneral DataRMS VibrationeasurementsGo to www.predict-cloud.comFootprint: 4.2” x 4.0” x 1.7”OrBattery (Low Power): 3 AA; Up to 4 samples per hourand 2 cloud upload times per dayBattery Voltage (3 AA): 4.5VDCWired Voltage: 9-24VDC/30mA Operation ModesMounting Screw: ¼-20 x 0.75” Button HeadOperation ModesoBattery Life: 1 year in temperatures -40 F to 140 FoBatteries must be changed in an area free ofBattery (Low Power): 3 AA; Up to 4 samples per hourignitable concentrations5MeasurementsOperation Modes

PWA GEN2 ANSI/ASME B73.1 PROCESS PUMPHYDRAULICPERFORMANCECOVERAGE50300200100400 5001,0001,500 2,0003003x4x10PWA 10" 1780 RPM2001501x2x10 PWA608x10x17PWA40301.5x3x10 PWA4x6x10HPWA1x1.5x8 PWA1x2x10 PWA-LF1x1.5x8 PWA-LF208x10x15 PWA3x4x8 PWA1x2x10 PWA-LF101x1.5x6 PWA51x1.5x4 PWA-LF10Visit our web site atwww.pumpworks.com andspecify flow and performanceneeds and obtain pump selectionand performance curve.6x8x15 NPWATOTAL HEAD (METERS)6x8x15PWA1.5x3x13 PWA1x2x10PWA-LF100100804x6x17 PWA3x4x17 PWA1.5x3x13 PWA-LFTOTAL HEAD (FT.)60 HzPerformanceCoverageFLOW (m3/h)1011,0001,00011780 RPM1200 RPM11101001,00010,000FLOW (GPM)FLOW (m3/h)1013,00050300200100400 5001,0001,500 2,0009001.5x3x13PWA 13" 3560 RPM5004001,0003001.5x3x13 PWA-LFnnnn1.5x3x6PWA1x1.5x6 PWA8060403x4x13 HSPWA3020TOTAL HEAD (METERS)1001004x6x10GPWA3x4x10 PWA2x3x10PWA1x1.5x8 PWA1x1.5x8 PWA-LFCapacities to 1,364 m³/h 7,000 GPMHeads to 223 m 730 ftTemperatures to 371 C 700 FPressures to 26 bar 375 PSIG103560 RPM510110100110,0001,000FLOW (GPM)50 HzPerformanceCoverage11,0001,000FLOW (m3/h)10501003002001000400 5001,500 2,0003002001508x10x17 13.5" 1475 RPM1x2x10PWA 5" 1475 RPM1x2x10PWA 10" 1475 RPM1x2x10PWA-LF 9.75" 1475 RPM100803x4x17 PWA1.5x3x13 PWA-LF1001x2x10PWA-LFTOTAL HEAD (FT.)Visit our web site atwww.pumpworks.com andspecify flow and performanceneeds and obtain pump selectionand performance curve.1501x2x10 PWA6x8x15 NPWA408x10x17PWA1.5x3x13 PWA1x2x10 PWA1x1.5x8 PWA-LF604x6x17 PWA6x8x15 PWA30201.5x3x10 PWA4x6x10HPWA1x1.5x8 PWA8x10x15 PWA103x4x8 PWA1x1.5x6 PWA510TOTAL HEAD (METERS)Capabilities2001.5x3x13 PWA1x2x10 PWA-LFTOTAL HEAD (FT.)Performances shown are nominaland are to be used for preliminaryselection only.1x1.5x4 PWA-LF11475 RPM1000 RPM11101001,00010,000FLOW (GPM)Performances shown are nominaland are to be used for preliminaryselection only.FLOW (m3/h)1011,00050100300200400 5001,0001,500 2,0003001x1.5x6PWA 6.063" 2950 RPM1x1.5x6PWA 3.5" 2950 RPM2001501x1.5x8 PWA-LF1x2x10 PWA402x3x10PWA1x1.5x8 PWA4x6x10GPWA3020101001.5x3x6PWA1x1.5x6 PWA3x4x13 HSPWA2950 RPM10110100FLOW (GPM)61,0005110,000TOTAL HEAD (METERS)Capacities to 1,364 m³/h 7,000 GPMHeads to 223 m 730 ftTemperatures to 371 C 700 FPressures to 26 bar 375 PSIG601.5x3x13 PWA1x2x10 PWA-LFTOTAL HEAD (FT.)nnnn100801.5x3x13 PWA-LFCapabilities

PWA GEN2 ANSI/ASME B73.1 PROCESS PUMP12/34182T98 (45)128 (58)197 (89)226 (103)375 (170)412 (187)495 (225)519 (235)700 (318)756 (343)948 (430)1009 (458)1330 (603)1820 (826)1893 (859)2343 (1073)3020 (1370)213T215T254T256T284T286T324TNEMA MOTORFRAME182T184TNot to be used for 213Tconstruction unless215T254Tcertified by manufacturer.256T284TPUMP DIMENSIONS AND ON SIZE1x1.5x6AA11.5x3x6AB1x1.5x6AA11.5 1.52x3x6AC21.5x3x6 GROUP 1.5x3x8AB1.51x1.5x8AA11.53x4x7A703ANSI1.5x3x8 FRAMEAB1.5 DISCHARGE SUCTION3SIZESIZESIZE2x3x8 DESIGNATION A6023x4x7A70343x4x8A7031x1.5x6AA 1GROUP 1 2x3x61x2x10AC233x4x8GA70341.5x3x10A5011x1.5x8AA1.5 1.51x2x10A052 3 22x3x10A601.5x3x8AB 11.51.5x3x10 GROUP 2 /3x4x7A503 4 3A70 1.53x4x10A703A60 23x4x10HA4022x3x10 GROUP 3 2x3x8A603 3 33x4x8A70344x6x10GA803x4x10A7034 4 43x4x8GA7034x6x10HA803x4x10HA404 2 41x2x10A05 311.5x3x13 & 13LA201.5x3x10A50 41.54x6x10GA806 3 1.52x3x10A603 22x3x13A3024x6x10HGROUP 2 /A80463x4x10A704 33x4x13A403GROUP 31.5x3x13A203 43x4x10HA40 1.54x6x13A80344x6x10GA80 242x3x13A303 66x8x13A9044x6x10HA806 63x4x13A40348x10x13A1001.5x3x13A201.53 84x6x13A80466x8x15A1102x3x13A3023 66x8x13A908 4 83x4x13A40 638x10x15A12048x10x13 GROUP 4 /4x6x13A10010 6 88x10x15G A80 8A1206x8x13A9066x8x15 GROUP 4–17A1108 8 88x10x16H A100 6A1208x10x138103x4x178x10x15A1208106x8x15A11068 34x6x17A1058x10x15G10 10 48x10x15A120 88A120GROUP 4 8x10x15G8A120 86x8x17A1108x10x16HA12010 10 68x10x16HA120810 EANSIANSI SIZE DISCHARGESUCTION SIZESIZEDESIGNATIONAXA6B365TB405TD444T1.5336.5 (165)1.513.5 (343)6.5 (165)3411 (280)XAB39.5 (242)11 (280)411 (280)9.5 (242)4211(165)(280) 13.5 (343) 8.5 (216)4.0 (102)6.539.5 (242)8.5 (216)311 (280)411 (280)9.512.5 (318)9.5(242)(242)41119.5 (496)11(280)(280) 613.5 (343)12.5 (318)68.5 (216)310.5 (267)13.5(343)39.5 (242)11.5 (292)4 (102)11 (280)4 19.5 (496) 12.5 (318)10.5(318)(267)12.5613.5 (343)11.5 (292)13.5 (343) 816 (406)12.5 (318)10.5 (267) 1018 (457)13.5 (343)11.5 (292) 816 (318)(406)1012.513.5 (343)19 (483)18(457)1016 (406)1018 (457)416 (406)27.875 (708)19 (483) 627.875(708)6 (152)19 (483)818 (457)19 (483)16 (406)10445T447T13.5 (343)4.0 (102)D449T4.0 (102)SPMAX SANSIBASEPLATENUMBERHA13912 (381)14815 (457)48 (1219)18 39(533)(991) 53 (1346)24515 (457)25218 (533)1248(381)(1219)45 (1143)25818 (533)58 (1473)(1143)64 (1626)2145(533)24 (660)52 (1321)68 (1727)26 (660)80 (2032)HA15312 (381)12 (381)264HBHBD 5.25 (133)39 (991)(229)D 5.259(133)8.25 (210)19.5 (496)4 (102)24 (660)26 (660)26 (660)68 (1727)80 (2032)98 (2489)WEIGHT BAREPUMP LBS ANDPUMP(Kg)lb (kg)88 (40)3.75 (95)WEIGHT BAREPUMPlb (kg)8.25 (210)3.75 (95)10 (254)210 (95)(95)270 210(122)125 (57)130 (59)135 (61)231 (109)3.75 (95)270 (122)265 (120)(95)280 (127)10285(254)(129)275 (125)290 (132)305 (138)27.875 (708)257 (116)347 (156)350 (159)425 (191)355 (161)588 (265)370 (168)704 (317)440641(200)(288)6 (152)14.5 (368)350 (159)355 (161)370 (168)440 (200)6 (152)14.5 (368)5.25 (133)D 8.25 (210)HD MaxD 10 (254)D 8.25 (210)D 14.5 (368)D 10 (254)4.5(368)(114)D 14.514.5620(368)(281)5.25 (133)740 (336)700 (318)5.25800 (363)775 (352)1030 (467)720 (327)815 (370)885 (401)12.38 (314)13 (330)12 (305)13.88(353)14.88 (378)12.38(314)15.88 (403)HFHE(133)HHHP TYPHF36.5 (927)0.75 (19)6 (152)7.5 (191)45.5 (1156)50.5(1283)4.5(114)0.75 (19)0.75 (19)36.513.75 (349)4.5 (114)42.56(1080)(152)0.75 (19)45.514.13 (359)14.75 (375)14.75 13.75(375)14.88 (378)14.1315.88 (403)6 (152)7.5 (191)7.5 (191)9.5 (241)9.5 (241)49.5(1257)7.5(191)55.5 (1410)4.5(114)61.5(1562)65.5 (1664)6 (152)77.5 (1969)10.5 (267)12 (305)HE14.7514.7514.8815.88(349)(359)(375)19.25 (489)(375)19.25 (489)(378)19.25 (489)(403)9.5 (241)9.5 (241)9.5 (241)7.5 (191)65.5 (1664)7.5 (191)77.5 (1969)9.5(241)95.5(2426)9.5 (241)19.25 (489)19.25 (489)19.25 (489)9.5 (241)9.5 (241)9.5 (241)280

PWA GEN2 ANSI/ASME B73.1 PROCESS PUMP Innovative Power Frame Features n All new patent pending frame design for enhanced reliability. n 25% more cooling surface than PWA GEN 1. n Sealed lubrication chamber. n ISOMAG magnetic seals IP65 rated Power Frame sealing. n Sloped and segregated drain for contaminant isolation.