Transcription

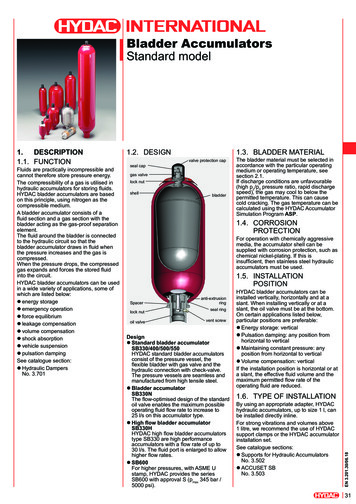

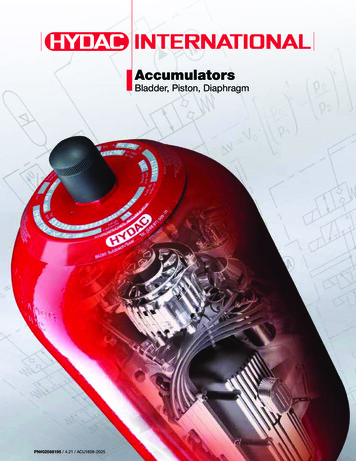

AccumulatorsBladder, Piston, DiaphragmPN#02068195 / 4.21 / ACU1808-2025

Components, Systems and Service.All from one Company.Our fluid engineering solutions are defined by the scope and complexity of our customers’ requirements.Our products range from individually designed components in the fields of fluid engineering, hydraulics andelectronics right up to complete systems for specific functions.All components and systems are conceived and designed in-house. Experienced industrial and product specialistsdevelop innovative products and efficient solutions for high-quality, cost-effective production. Throughout the globe,our production facilities share one common goal: quality. We take great pride in both our products and solutions.Industries and ApplicationsAgricultureSteel IndustryWind PowerPaper IndustryAutomotiveOil & Gas OffshoreConstruction MachineryPlastics IndustryPower IndustryPN#02068195 / 4.21 / ACU1808-2025

TABLE OF CONTENTSSection:OverviewAGeneral Introduction - A2; Certification - A3; Overview - A4; Industries and Applications - A8; Safety Requirements - A9;Protection on the Fluid Side - A9; Protection on the Gas Side - A10Bladder AccumulatorsSB Series - B2; Quad Certified Bladders - B4; Water Service - B7; Stainless Steel - B8; Oil, Gas / Offshore - B10; Spare Parts - B13;Seal Kits & Tools - B14; Competitive Crossover - B15BDiaphragm AccumulatorsCSBO Series - C2; Water Service - C6Piston AccumulatorsDSK Series Overview - D2; Advantages - D4; Model Code - D6; Connections - D7; Dimensions - D8; Spare Parts - D12Nitrogen BottlesESN Series - E2Pulsation DampenersFSB P and SBO P - F2Metal BellowsGSM50 & SM50P - G2AccessoriesThermal Fuse Caps - H2; Thermal Fuse Plug - H3; SAF Series - Safety & Shut-off Blocks - H4; Safety & Shut-off Blocks Spare Parts - H10;FPK & FPS Series Charging & Gaughing Units - H11; FPO Series - H13; Charging & Gauging Adapters - H14;Charging & Gauging Spare Parts - H17; Permanent Gauging Block - H19; Mounting Components - H21ApplicationsTypical Applications - I2; Shock Absorbers - I4Sizing AccumulatorsOperational Sequence Steps - J2; Behavior & Formulas - J3; Pulsation Dampeners - J5; Bladder, Diaphragm & Piston Form - J6;Shock Applications Form - J7; Pulsation Dampening Form - J8Accumulator Division90 Southland DriveBethlehem, PA 18017 1.610.266.0100Internet: www.hydac-na.comEmail: HYD.catalog@hydac-na.comPN#02068195 / 4.21 / ACU1808-2025NOTEInformation and related materials are subject to change without notice. This catalog, and all informationand related materials it contains, are provided “as is.” HYDAC makes no representation or warrantywhatsoever regarding the completeness, accuracy, “up-to-dateness”, or adequacy of, the HYDAC-NAdomain and this catalog.HIJ

øD 0.04M28 x 1.5OVERVIEWHYDAC has been a name synonymous with advanced technology,design, manufacturing and application engineering for more than50 years. HYDAC is the only manufacturer of all three types ofaccumulators – Bladder, Piston, & Diaphragm.Functions 0.91As an essential element in modern hydraulics,accumulators perform many useful functions, such as: reducing pump capacity and electrical energy providing auxiliary hydraulic power in case of an emergency limiting pressure fluctuations during temperature changesin a closed hydraulic loop compensation for leakage minimizing pump pulsations absorbing shocksBenefits increasing system performance and efficiencylowering operating and maintenance costsproviding fail-safe conditionsavoiding pump, pipe and system failures toachieve longer life expectancyAAccessoriesAll accessories required for installation andmaintenance of accumulators are available, including: safety and shut off blocksmounting componentsaccumulator setscharging and gauging unitsFJMDevelopment and EngineeringBased on research and development in our laboratories for testingof physical, chemical and mechanical properties, HYDAC achievesthe highest quality of accumulators and related parts.LFinite Element Analysis is implemented in the Computer AidedDesign package supporting development and engineering tooptimize the performance and safety of the components.Size 0.075 and 0.16Application assistance is available utilizing HYDAC computersoftware to simulate your system and optimize the sizing for energysavings, shock absorption or pulsation dampening.Manufacturing and AssemblyManufacturing and assembly at HYDAC are subject to strict qualitycontrol. HYDAC utilizes state-of-the-art manufacturing and qualityassurance techniques.F0.591)1.611)CAD and Finite Element Analysis (FEA)A2Electron-beam welding ofdiaphragm accumulatorsPrecharging of a Diaphragm AccumulatorPN#02068195 / 4.21 / ACU1808-2025

OVERVIEWCertificationUnited StatesHYDAC Technology GmbH in D-66280 Sulzbach/Saar is authorized (effective August 21, 1985) by the “National Board of Boiler and PressureVessel Inspectors”, in conformity with the appropriate specification of the American Society of Mechanical Engineers (ASME), to use the CodeSymbol as a stamp and for registration purposes.European Union Member States (listed in bold below)On June 1, 2015 the directive 2014/68/EU (Pressure Equipment Directive) replaced directive97/23/EC.This new directive applies to the design, manufacture, conformity assessment andcirculation of pressure equipment and assemblies with a maximum permissible pressure ofover 0.5 bar. It guarantees the free movement of goods within the European Community. EUmember states must not prohibit, restrict or obstruct the circulation and commissioning ofpressure equipment on account of pressure-related hazards, if the equipment complies withthe requirements of the pressure equipment directive, has the CE mark, and is subject to aconformity assessment.China (Self quality for China)HYDAC Technology GmbH is recognized as an importer of bladder, diaphragm and pistonaccumulators since March 30, 1998.Japan (KHK certificate)For the Japanese market, HYDAC Technology GmbH is approved as a “self inspectingmanufacturer”. Therefore HYDAC is authorized to manufacture, test and import accumulatorsfrom outside Japan.For details on other country certifications, please contact HYDAC.Bladder Accumulator Assembly AreaComplete Country Code Listing(European Union Member States listed in bold below)Assembly of Piston naCosta RicaCzech ong iaMexicoNew dPortugalPuerto RicoRomaniaRussia (CIS)Saudi ArabiaSingaporeSlovakiaSouth isiaTurkeyUnited )UUYSS3)1) approval required in the individual territories2) approval required in the individual provinces3) alternative certificates possibleInformation and related materials are subject to change withoutnotice. This catalog, and all information and related materials itcontains, are provided “as is.” HYDAC makes no representationor warranty whatsoever regarding the completeness, accuracy,“up-to-dateness”, or adequacy of the HYDAC-NA domain andthis catalog.PN#02068195 / 4.21 / ACU1808-2025A3

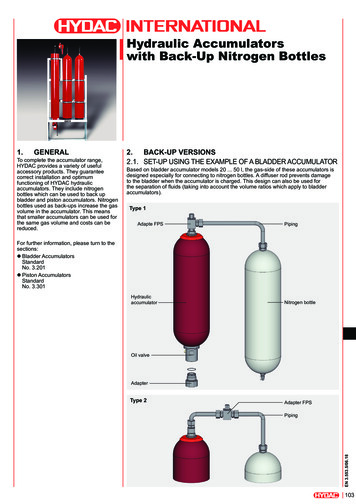

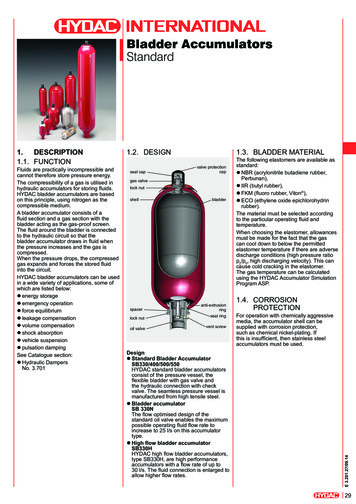

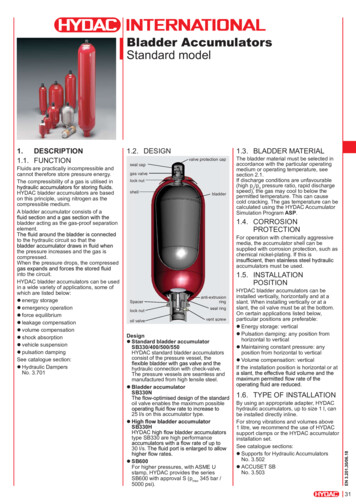

OVERVIEWBladder AccumulatorsThe standard bladder accumulator consists of a “closed” rubber bladder inside a forged steel shell. A mechanically actuated valve closes whenthe fluid has been expelled, blocking off the fluid port, thereby enclosing the bladder within the shell. Where high discharge rates are required, ahigh flow model is available.Applications with corrosive environments may require shells furnished with an internal and/or external coating or manufactured from stainlesssteel.The top repairable accumulator permits service and maintenance of the bladder without removing the accumulator from the hydraulic system.When the pressure level of a system permits, a low pressure accumulator may be used. It is similar to a standard bladder accumulator, exceptthat the poppet valve is replaced by a perforated plate covering the fluid port, and the shell may be of welded construction.For lightweight applications, a Kevlar wrapped accumulator shell is available. The wrapping supports the thinner metal shell to provide asubstantial weight reduction.Low PressureBottom RepairableTop RepairableHigh PressureHigh FlowKevlar WrappedPiston AccumulatorsA piston accumulator consists of a fluid section and a gas section with the piston acting as agas-proof screen. The gas section is precharged with dry nitrogen gas. Auxiliary gas bottles arefrequently used with piston accumulators to provide the required gas volume.StandardExtendingPiston RodElectricProximity SwitchesDiaphragm AccumulatorsA diaphragm accumulator performs the same function as a bladder accumulator, however, it operates like amembrane. A poppet is molded into the bottom of the diaphragm to prevent its extrusion through the fluid port.Diaphragm accumulators are frequently used where small volumes are required, weight is important, a higherpressure ratio is required (up to 10:1) or low cost is a prime factor.Applications with corrosive environments may require a coating or be manufactured from stainless SealedFactory PrechargeOEM - (non-repairable)PN#02068195 / 4.21 / ACU1808-2025

OVERVIEWComparison of Standard AccumulatorsTypeDesignDiaphragm small volume and flow low weight compact design good for shockapplications(good sureRatioFlowRateMountingPositionWeightCost5 in3 to1 gal3000, 5000(up to 10,000)8:1typically(up to 10:1)up to60 gpmanylowestlowest1 qt.to15 gal3000, 5000(up to 10,000)4:1up to480gpmpreferverticalmiddlemiddle1 qt.to100 gal3000, 5000(up to 10,000) :1up to2000gpmpreferverticalhighestmiddle tohighestBladder best general purpose wide range of standardsizes good for shockapplications(good responsecharacteristics)Piston best for large storedvolumes best for high flow rates not recommended forshock applications best for use withbackup nitrogenbottlesAccumulator Type Selection Considerations System Pressure System Temperature Volume / Usable Volume Flow Rate Pressure Ratio Installation Space and Position Chemical CompatibilityUse the comparison chart above as a quick reference guide.Stainless Steel AccumulatorsStainless steel piston and diaphragm accumulators are available in various sizes and pressureranges. They offer special corrosion resistance that is required for chemical and off-shore industries,petro-chemical and nuclear power plants and for food applications.PistonPN#02068195 / 4.21 / ACU1808-2025DiaphragmBladderA5

OVERVIEWAccessoriesA full range of accessories for the installation, service and maintenance of all accumulators completes the program. In addition to the itemsshown, special valve blocks and adapters are available for your particular requirements.Safety & Shut-off BlocksMountingCharging UnitsPermanent Gauge BlockNitrogen BottlesNitrogen ChargingServersFor more information on these accessories, see page 67Metal BellowsMetal Bellows Accumulators are a unique type of dampener that use a metal bellows separation element between the fluid and gas side of themetal bellows accumulator. This makes the accumulator virtually gas-tight and maintenance free. By replacing the traditional elastomer elementor seals, the metal bellows is fluid resistant in temperature ranges of -85 F to 320 F. These special features lend themselves to dampeningapplications in fuel injection systems in heavy diesel engines in the mobile, marine & industrial markets. The SM50P series has a fluid portdiverter feature to maximize its dampening capability. The SM50 series has a threaded fluid connection to allow for easy retrofit of standardaccumulators in existing systems.Threaded Connection for RetrofitFlange Connectionwith Flow DiverterAccumulator StationsHYDAC supplies fully assembled piston accumulator stations which are readyfor operation, complete with all the necessary valve controls, ball valves andsafety equipment as an individual accumulator unit or in a back-up model withnitrogen bottles to increase the effective volume.A6PN#02068195 / 4.21 / ACU1808-2025

OVERVIEWDampenersPulsations and shocks in hydraulic lines can result in costly damage to the piping and other system components. Reciprocating piston pumpsby design create pressure pulsations, vibrations, and noise in the system. HYDAC suction stabilizers, pulsation dampeners and silencers,when applied to piston pumps, will reduce pulsations and noise. Furthermore, pressure pulsations can make control in servo systems nearlyimpossible without installing a pulsation dampener. HYDAC shock absorbers can be applied to greatly reduce shock wave energy. These wavescan be harmful to all components in your hydraulic system. Shock waves can be created by closing a valve in a high flow line, such as one foundin a petroleum terminal.Diaphragm DampenerStandard & High PressureBladder DampenerSilencersSuction FlowStabilizerPTFE Dampeners - Aggressive MediaHYDAC has developed an all-PTFE cup diaphragm and has patentedits design and application. It is resistant to aggressive operating fluidsand can be installed in almost all standard diaphragm accumulatorswhich are available in both carbon steel and stainless steel.Pulsation DampenerPVDF with PTFE diaphragmPN#02068195 / 4.21 / ACU1808-2025A7

OVERVIEWIndustries and ApplicationsIndustrial HydraulicsMobile TechnologyMachine toolsAgricultural and forestry machines Support for the hydraulics for tool drive or tool change Energy storage in the compact hydraulics of machining centersPlastics technology Accumulator stations for energy storage during the in

Precharging of a Diaphragm Accumulator HYDAC has been a name synonymous with advanced technology, design, manufacturing and application engineering for more than 50 years. HYDAC is the only manufacturer of all three types of accumulators – Bladder, Piston, & Diaphragm. 0.591) 1.611) F Size 0.075 and 0.16 M28 x 1.5 øD 0.04 0.91 M F J A L. PN#02068195 / 4.21 / ACU1808-2025 A3