Transcription

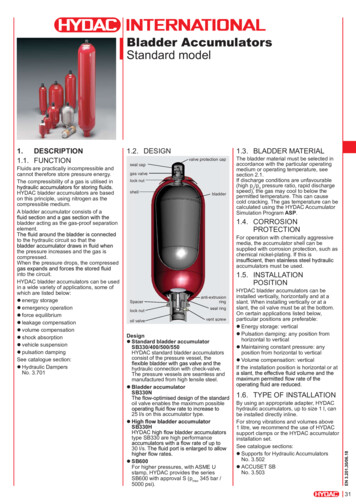

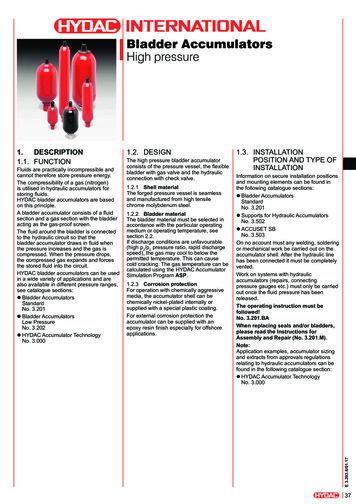

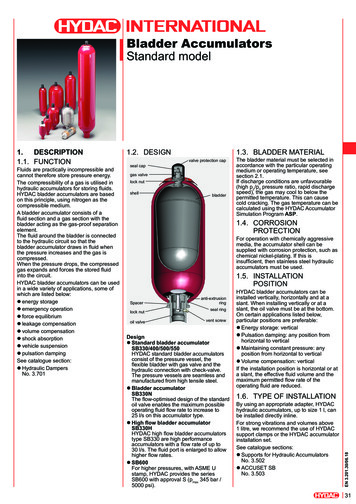

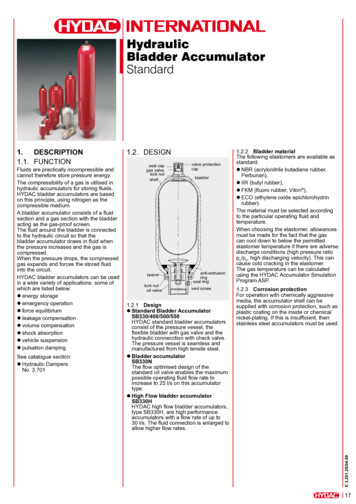

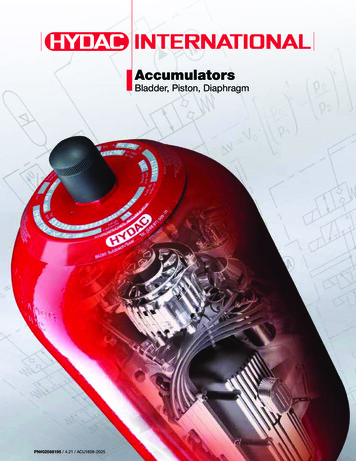

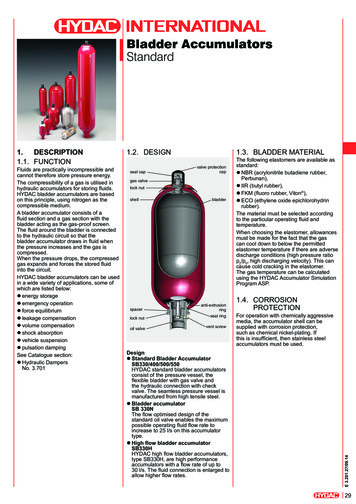

Bladder AccumulatorsStandardFluids are practically incompressible andcannot therefore store pressure energy.The compressibility of a gas is utilised inhydraulic accumulators for storing fluids.HYDAC bladder accumulators are basedon this principle, using nitrogen as thecompressible medium.A bladder accumulator consists of afluid section and a gas section with thebladder acting as the gas-proof screen.The fluid around the bladder is connectedto the hydraulic circuit so that thebladder accumulator draws in fluid whenthe pressure increases and the gas iscompressed.When the pressure drops, the compressedgas expands and forces the stored fluidinto the circuit.HYDAC bladder accumulators can be usedin a wide variety of applications, some ofwhich are listed below:zzenergy storagezzemergency operationzzforce equilibriumzzleakage compensationzzvolume compensationzzshock absorptionzzvehicle suspensionzzpulsation dampingSee Catalogue section:zzHydraulic DampersNo. 3.7011.2. DESIGNseal cap1.3. BLADDER MATERIALvalve protectioncapgas valvelock nutshellspacerlock nutoil valvebladderanti-extrusionringseal ringvent screwDesignzzStandard Bladder AccumulatorSB330/400/500/550HYDAC standard bladder accumulatorsconsist of the pressure vessel, theflexible bladder with gas valve andthe hydraulic connection with checkvalve. The seamless pressure vessel ismanufactured from high tensile steel.zzBladder accumulatorSB 330NThe flow optimised design of thestandard oil valve enables the maximumpossible operating fluid flow rate toincrease to 25 l/s on this accumulatortype.zzHigh flow bladder accumulatorSB330HHYDAC high flow bladder accumulators,type SB330H, are high performanceaccumulators with a flow rate of up to30 l/s. The fluid connection is enlarged toallow higher flow rates.The following elastomers are available asstandard:zzNBR (acrylonitrile butadiene rubber,Perbunan),zzIIR (butyl rubber),zzFKM (fluoro rubber, Viton ),zzECO (ethylene oxide epichlorohydrinrubber).The material must be selected accordingto the particular operating fluid andtemperature.When choosing the elastomer, allowancesmust be made for the fact that the gascan cool down to below the permittedelastomer temperature if there are adversedischarge conditions (high pressure ratiop2/p0, high discharging velocity). This cancause cold cracking in the elastomer.The gas temperature can be calculatedusing the HYDAC Accumulator SimulationProgram ASP.1.4. CORROSIONPROTECTIONFor operation with chemically aggressivemedia, the accumulator shell can besupplied with corrosion protection,such as chemical nickel-plating. Ifthis is insufficient, then stainless steelaccumulators must be used.E 3.201.27/09.141.DESCRIPTION1.1. FUNCTION29

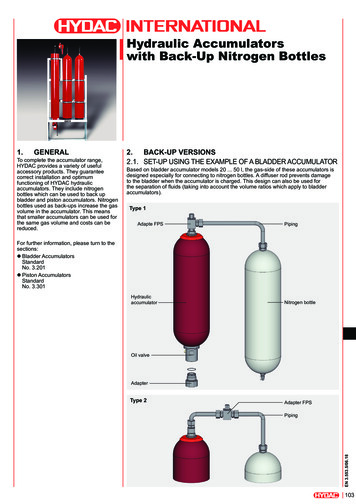

1.5. INSTALLATIONPOSITIONHYDAC bladder accumulators can beinstalled vertically, horizontally and at aslant. When installing vertically or at aslant, the oil valve must be at the bottom.On certain applications listed below,particular positions are preferable:zzEnergy storage:vertical,zzPulsation damping:any position from horizontal to vertical,zzMaintaining constant pressure:any position from horizontal to vertical,zzVolume compensation:vertical.If the installation position is horizontalor at a slant, the effective volume andthe maximum permitted flow rate of theoperating fluid are reduced.1.6. TYPE OF INSTALLATIONBy using an appropriate adapter, HYDACaccumulators, up to size 1 l, can beinstalled directly inline.For strong vibrations and volumes above1 litre, we recommend the use of HYDACaccumulator supports or the HYDACaccumulator installation set.See catalogue sections:zzSupports for Hydraulic AccumulatorsNo. 3.502zzACCUSET SBNo. 3.5032.TECHNICALSPECIFICATIONS2.1. EXPLANATORYNOTES2.1.1 Operating pressuresee tables (may differ from nominalpressure for foreign test certificates)2.1.2 Nominal volumesee tables2.1.3 Effective gas volumesee tablesBased on nominal dimensions, this differsslightly from the nominal volume and mustbe used when calculating the effective fluidvolume.2.1.4 Effective fluid volumeVolume of fluid which is available betweenthe operating pressures p2 and p1.2.1.8 Gas chargingHydraulic accumulators must only becharged with nitrogen.Never use other gases.Risk of explosion!In principle, the accumulator may only becharged with nitrogen class 4.0, filtered to 3 µm.If other gases are to be used, pleasecontact HYDAC for advice.2.1.9 Limits for gas pre-chargepressurep0 0.9 p1with a permitted pressure ratio of:p2 : p0 4 : 1p2 max. operating pressurep0 pre-charge pressure2.1.10 Certificate codesCountry2.1.5 Max. flow rate of the operatingfluidIn order to achieve the max. flow rategiven in the tables, the accumulator mustbe installed vertically. It must be noted thata residual fluid volume of approx. 10% ofthe effective gas volume remains in theaccumulator. The maximum fluid flow ratewas determined under specific conditionsand is not applicable in all operatingconditions.2.1.6 FluidsThe following sealing and bladdermaterials are suitable for the fluids listedbelow.MaterialNBRECOIIRFKMFluidsMineral oils (HL, HLP,HFA, HFB, HFC), waterMineral oilPhosphate ester, waterChlorinated hydrocarbons, petrolOther fluids on request2.1.7 Permitted operating temperaturesThe permitted operating temperature of abladder accumulator is dependent on theapplication limits of the metal materials andthe bladder.Outside these temperatures, specialmaterial combinations must be used.The following table shows the correlationbetween bladder material and applicationtemperature.E mperature ranges-15 C . 80 C-50 C . 80 C-30 C . 80 C-30 C . 120 C-55 C . 100 C-10 C . 150 CCertificate code(AKZ)EU member statesUAUAustraliaF 1)BYBelarusA12CECanadaS1 1)CHSwitzerlandUCNChinaA9HKHong KongA9ISIcelandUJPJapanPKRKorea (Republic)A11NONorwayUNZNew th AfricaS2 Registration required in the individual territories orprovinces.others on request1)On no account must any welding, solderingor mechanical work be carried out on theaccumulator shell. After the hydraulic linehas been connected it must be completelyvented.Work on systems with hydraulicaccumulators (repairs, connectingpressure gauges etc) must only be carriedout once the pressure and the fluid havebeen released.Please read the Operating Manual!No. 3.201.CENote:Application examples, accumulator sizing,instructions and extracts from approvalsand transport regulations relating tohydraulic accumulators can be found in thefollowing catalogue section:zzHYDAC Accumulator TechnologyNo. 3.0002.1.11 Gas side connectionStandardSeriesVolume Gas valve type[l]SB330 / 15/8-18UNF 507/8-14UNFSB400 50M50x1.5 / 7/8-14UNFother pressure ranges on request

2.2. MODEL CODESeriesType codeno details standardH high flowN increased flow, standard oil valve dimensionsA shock absorberP pulsation dampfer 3)B bladder top-repairableE bladder with foam fillingD bladder integrity systemL lightweightCombinations must be agreed with HYDAC.Nominal volume [l]Fluid connectionA standard connection, thread with internal seal faceF flange connectionC valve mounting with screws on undersideE sealing surfaces on front interface (e.g. on thread M50x1.5 - valve)G male threadS special connection, to customer specificationGas side1 standard model (see point 2.1.11)2 back-up model 4)3 gas valve 7/8-14UNF with M8 female thread4 gas valve 7/8-14UNF with gas valve connection 5/8-18UNF5 gas valve M50x1.5 in accumulators smaller than 50 l6 7/8-14UNF gas valve7 M28x1.5 gas valve8 M16x1.5 gas valve (with M14x1.5 bore in gas valve)9 special gas valve, to customer specificationMaterial codedependent on operating mediumstandard model 112 for mineral oilsothers on requestFluid connection1 carbon steel2 high tensile steel3 stainless steel 2)6 low temperature steelAccumulator shell0 plastic coated (internally)1 carbon steel2 chemically nickel-plated (internal coating)4 stainless steel 2)6 low temperature steelAccumulator bladder 1)2 NBR203 ECO4 IIR (butyl)5 NBR21 (low temperature)6 FKM7 Others9 NBR22Certificate codeU PED 97/23/ECPermitted operating pressure [bar]Connection, fluid sideThread, codes for fluid connections: A, C, E, GA thread to ISO 228 (BSP)B thread to DIN 13 or ISO 965/1 (metric)C thread to ANSI B1.1 (UN.-2B seal SAE J 514)D thread to ANSI B1.20.1 (NPT)S special thread, to customer specificationFlange, codes for fluid connection: FA DIN flangeB flange ANSI B16.5C SAE flange 3000 psiD SAE flange 6000 psiS special flange, to customer specificationPre-charge pressure p0 [bar] at 20 C, must be stated clearly, if required!When ordering a spare bladder, please state diameter of the smaller shell portDependent on type and pressure rangeSee catalogue section Hydraulic Dampers, No. 3.7014)See catalogue section Hydraulic accumulators with back-up nitrogen bottles, No. 3.5531)2)3)SB330 (H) – 32 A 1 / 112 U – 330 A 050E 3.201.27/09.14Not all combinations are possible.Order example. For further information, please contact HYDAC.31

E dard3304400555063302)10,330StandardN33010 H400Standard500StandardN33013HStandard 400StandardN33020 H400Standard500Standard24 N330HStandardN33032 H400Standard500StandardN33050 H400Standard5006080100Standard 3301301602001)2)ABmax.[l]CDimensionsØD JØ E SWmax. threadQ 1)Weight approx.Eff. gas volumeMax. operating pressure(PED 97/23/EC)Type of valve, fluid sideNominal volume3.DIMENSIONS AND SPARE PARTS3.1. DIMENSIONS[kg][mm] [mm] [mm] [mm]0.52.8 27033.5 95.5574.5 30211818.5 343 681212.4 10531 631182.5550 681215813.53.7419 631734.95.79.32315258795318089.331.5583 10399.38.834.537.545618 138579 103595 10143696 1034649730 138681 10350.5896 1031218.4681216317317.518.41753.563.575.5931 138896 103904 10123.6691062 10324721097 13833.9871411 10332.5 90 1446 13833.9 104.5 1411 10333.5 127 1419 101586858120.514248.3 8233241582295868117.5 1931 10347.522922923324122968233241ISO228G 3/4[mm] [mm] [l/s]50G1G 1 1/4G1G 1 1/467G1G 1 1/4G 1 1/432445504561065010456501010070G 2 1/2 12590152530G21007015G210070G 2 1/2 125G21009070G210070G 2 1/2 125100G2110907075G210070G 2 1/2 12590G210070G 2 1/2 125100G2110907075G210070G 2 1/2 3015356138Q max. flow rate of operating fluid for optimal conditionsslimline version, for confined spaces68G 2 1/2 1254069030Adaptorforspecialthread

3.2. SPARE PARTSSB330/400/440/500/550SB330H / SB330NDesignationBladder assemblyconsisting of:BladderGas valve insert*Lock nutSeal capValve protection capO-ringSeal kitconsisting of:O-ringWasherO-ringVent screwBack-up ringO-ringRepair kit 1)consisting of:Bladder assembly (see bove)Seal kit (see above)Anti-extrusion ringOil valve assemblyconsisting of:Valve assembly (items 9-13)Anti-extrusion ringWasherO-ringSpacerLock nutBleed screwBack-up 0NBR, carbon steelStandard gas 336427433643123127313320138431847693461300Seal kit3536063536093536213102043 1)Repair kit2128169 3117515311751631175173117558* slimline version for confined spaces1)only for SB3302)only for SB400others on requestWhen replacing seals and/or bladder,please read the Instructions forassembly and repair (No. 3.201.M).* available separately1)When ordering, please state diameter of the smallershell portItem 1 not available as a spare partItem 19 for NBR/Carbon steel:seal ring (item 20) includedAdapter (item 25) must be ordered as an accessory,see Point 4Detail "X"SB330/400 – 0.5 . 6 lE 3.201.27/09.14SB330/400/500 – 10 . 200 l andSB330H – 10 . 200 lSB550 – 1 . 5 l33

ACCESSORIES FOR BLADDERACCUMULATORS4.1. ADAPTERS (GAS SIDE)To monitor the accumulator pre-charge pressure, HYDAC offers aselection of gas side adapters.The adapters shown below are available for standard connectionson bladder accumulators and must be specified separately in theorder.4.1.1 Pressure gauge modelGas side connection on the bladder accumulator for permanentmonitoring of the pre-charge pressurepressure gaugeØ63Gauge indicationrange–0 - 10 bar0 - 60 bar0 - 100 bar0 - 160 bar0 - 250 bar0 - 400 bar* pmax 400 barPressure gaugePart no.–614420606886606887606888606889606890Adapter* assemblyPart 74.1.2 Pressure gauge model with shut-off valveGas side connection on the bladder accumulator for permanentmonitoring of the pre-charge pressure with shut-off option.pressure gaugeØ100gauge shut-offvalveGauge indicationrange–0 - 25 bar0 - 60 bar0 - 100 bar0 - 160 bar0 - 250 bar0 - 400 barE 3.201.27/09.14* pmax 400 bar34approx.4.Pressure gaugePart no.–617928606771606772606773606774606775Adapter* assemblyPart 26

4.1.3 Remote monitoring of the pre-charge pressureTo monitor the pre-charge pressure in hydraulic accumulatorsremotely, gas side adapters with pressure gauge and mountingholes are available.In order to connect these adapters directly with the hydraulicaccumulator using appropriate lines, accumulator adapters arealso available for connection at the top (see diagram 1) or forside-connection (see diagram 2).4.2. ADAPTERS FOR STANDARD BLADDERACCUMULATORS (FLUID SIDE)To connect the bladder accumulator to pipe fittings. These areavailable separately.O-ring2 holespressure gaugeØ63approx.Gauge indicationrange–0 - 10 bar0 - 60 bar0 - 100 bar0 - 160 bar0 - 250 bar0 - 400 barPressure gaugePart no.–614420606886606887606888606889606890Adapter* assemblyPart no.3037666309581

Application examples, accumulator sizing, instructions and extracts from approvals and transport regulations relating to hydraulic accumulators can be found in the following catalogue section: z HYDAC Accumulator Technology No. 3.000 2.1.11 Gas side connection Standard Series Volume [l] Gas valve type SB330 / SB400 1 5/8-18UNF 50 7/8-14UNF